Leak-proof leak-stopping reinforcing agent

A reinforcing agent and leakage prevention technology, which is applied to the drilling composition, chemical instruments and methods, etc., can solve the problems of easy occurrence of new wellbore, high hardness of leakage plugging materials, and high density of leakage plugging slurry, so as to achieve easy and harmless treatment. Treatment, good coagulation and solidification, uniform particle size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

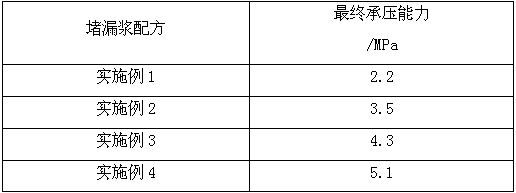

Examples

Embodiment 1

[0028] A leak-proof plugging reinforcing agent, which is composed of the following components and parts by weight: 3 parts of sodium silicate; 1 part of potassium silicate; 10 parts of calcium silicate; 0.1 part of polyacrylamide PAM; 10 parts of calcium hydroxide; low viscosity 0.1 part of polyanionic cellulose; 0.1 part of water-soluble polyamide resin powder; 2 parts of water-soluble urea-formaldehyde resin powder.

[0029] Preparation method: add the above-mentioned substances into the container one by one under normal temperature and pressure according to their components and contents, mix and stir evenly, wait for it to dry, crush or sieve into granular products with a particle size of 0.05mm-0.8mm. During use, add the anti-leakage plugging strengthening agent of the present invention of the total amount of 2% of the total amount of the plugging drilling fluid in the plugging drilling fluid.

Embodiment 2

[0031] A leak-proof plugging reinforcing agent, which is composed of the following components and parts by weight: 6 parts of sodium silicate; 3 parts of potassium silicate; 12 parts of calcium silicate; 0.2 part of polyacrylamide PAM; 15 parts of calcium hydroxide; low viscosity 0.5 parts of polyanionic cellulose; 0.5 parts of water-soluble polyamide resin powder; 3 parts of water-soluble urea-formaldehyde resin powder.

[0032] Preparation method: add the above-mentioned substances into the container one by one under normal temperature and pressure according to their components and contents, mix and stir evenly, wait for it to dry, crush or sieve into granular products with a particle size of 0.05mm-0.8mm. During use, add the anti-leakage plugging strengthening agent of the present invention of the total amount of 8% of the plugging drilling fluid in the plugging drilling fluid.

Embodiment 3

[0034] A leak-proof plugging reinforcing agent, which consists of the following components and parts by weight: 9 parts of sodium silicate; 4 parts of potassium silicate; 16 parts of calcium silicate; 0.4 parts of polyacrylamide PAM; 20 parts of calcium hydroxide; low viscosity 0.8 parts of polyanionic cellulose; 0.7 parts of water-soluble polyamide resin powder; 5 parts of water-soluble urea-formaldehyde resin powder.

[0035] Preparation method: add the above-mentioned substances into the container one by one under normal temperature and pressure according to their components and contents, mix and stir evenly, wait for it to dry, crush or sieve into granular products with a particle size of 0.05mm-0.8mm. During use, add the anti-leakage plugging strengthening agent of the present invention of the total amount of 15% of the total amount of the plugging drilling fluid in the plugging drilling fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com