Double-step cutting structure bit

A cutting structure and drill bit technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problem of not being able to drill strata containing gravel layers in the middle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

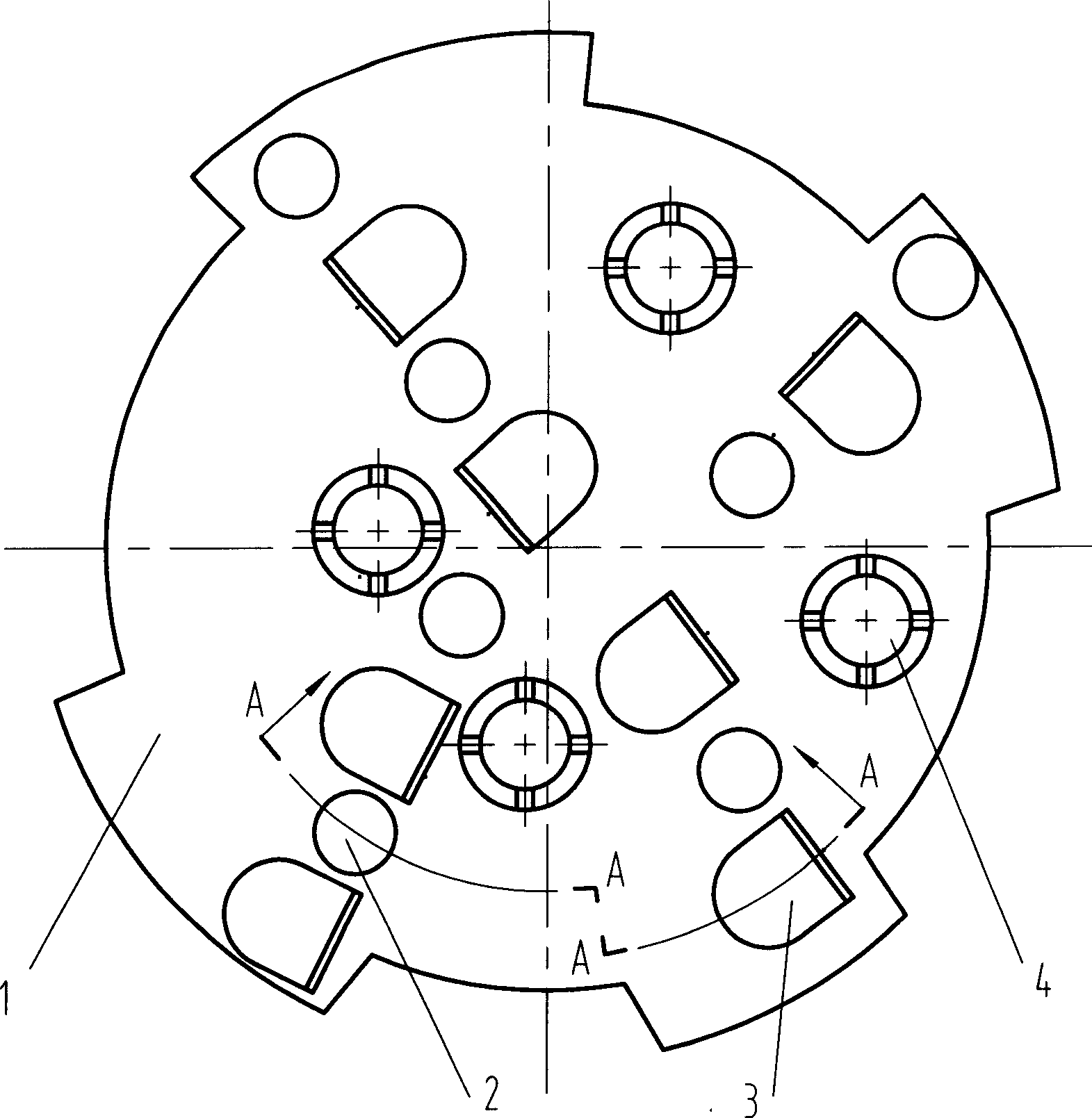

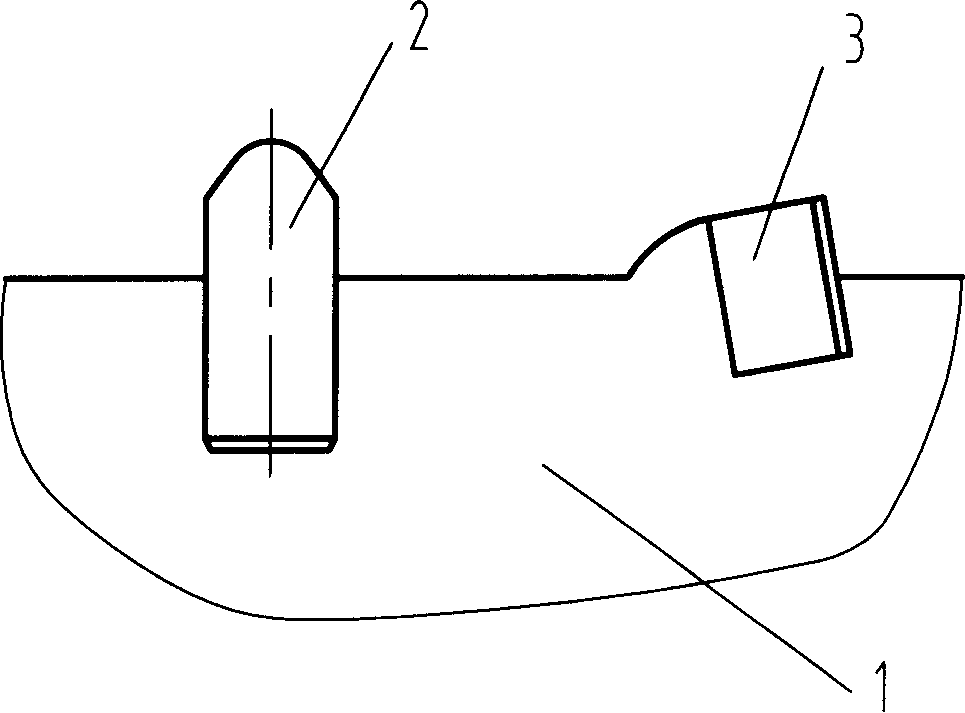

[0009] refer to figure 1 and figure 2 A dual-stage cutting structure drill bit for oil and gas drilling includes a drill body 1 and several cemented carbide cutting pieces 2 , several PDC cutting pieces 3 and several nozzles 4 installed on the end face of the drill body 1 . In the radial direction, the arrangement of the PDC cutting parts 3 adopts the same approximate equal cutting method as most conventional PDC drill bits, while the arrangement of the cemented carbide cutting parts 2 adopts an approximate equal power method. The exposed height of the cemented carbide cutting part 2 is 4.0-5.5mm greater than that of the PDC cutting part 3, the cemented carbide cutting part 2 forms the first-level cutting structure, and the PDC cutting part 3 forms the second-level cutting structure. The arrangement density of cemented carbide cutting parts 2 is relatively small, about 1.5, but it can completely cover the bottom of the well; while the arrangement density of PDC cutting parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com