Housing of an electrical machine comprising cooling channels extending in a housing wall

A technology for cooling channels and shell walls, applied in cooling/ventilation devices, casings/covers/supports, electromechanical devices, etc., can solve problems such as high production costs and unsatisfactory results, and achieve sealing, Simple diversion function, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

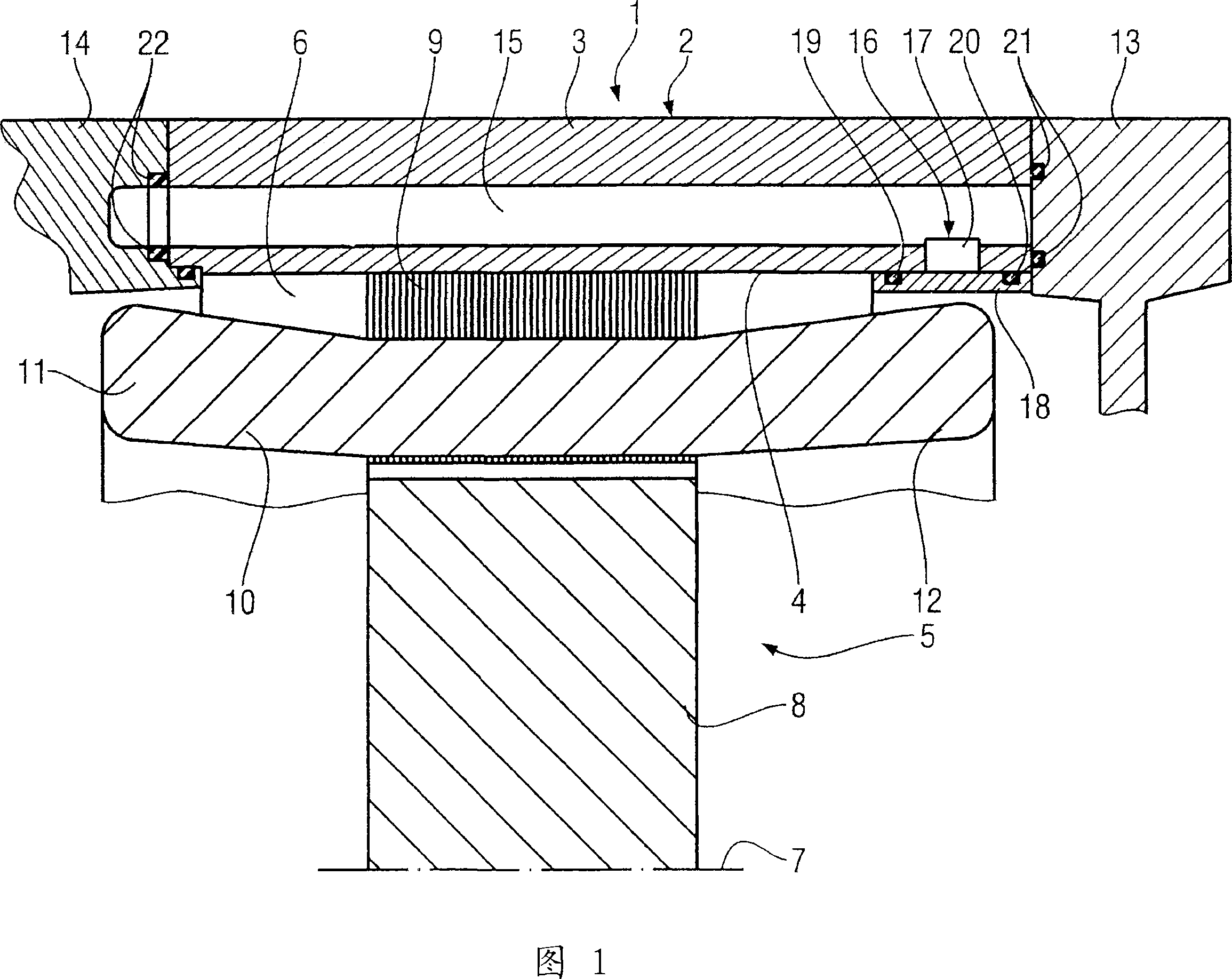

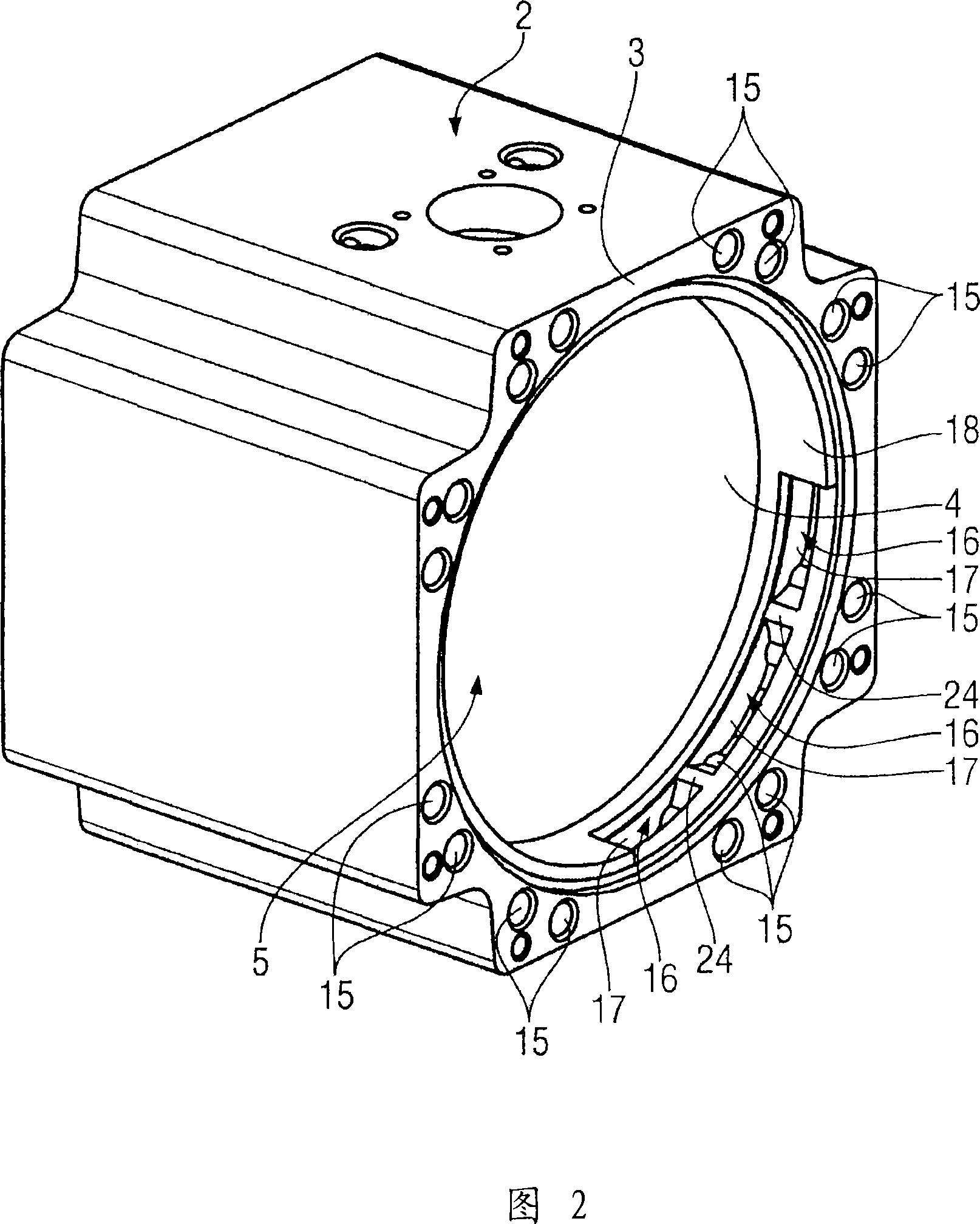

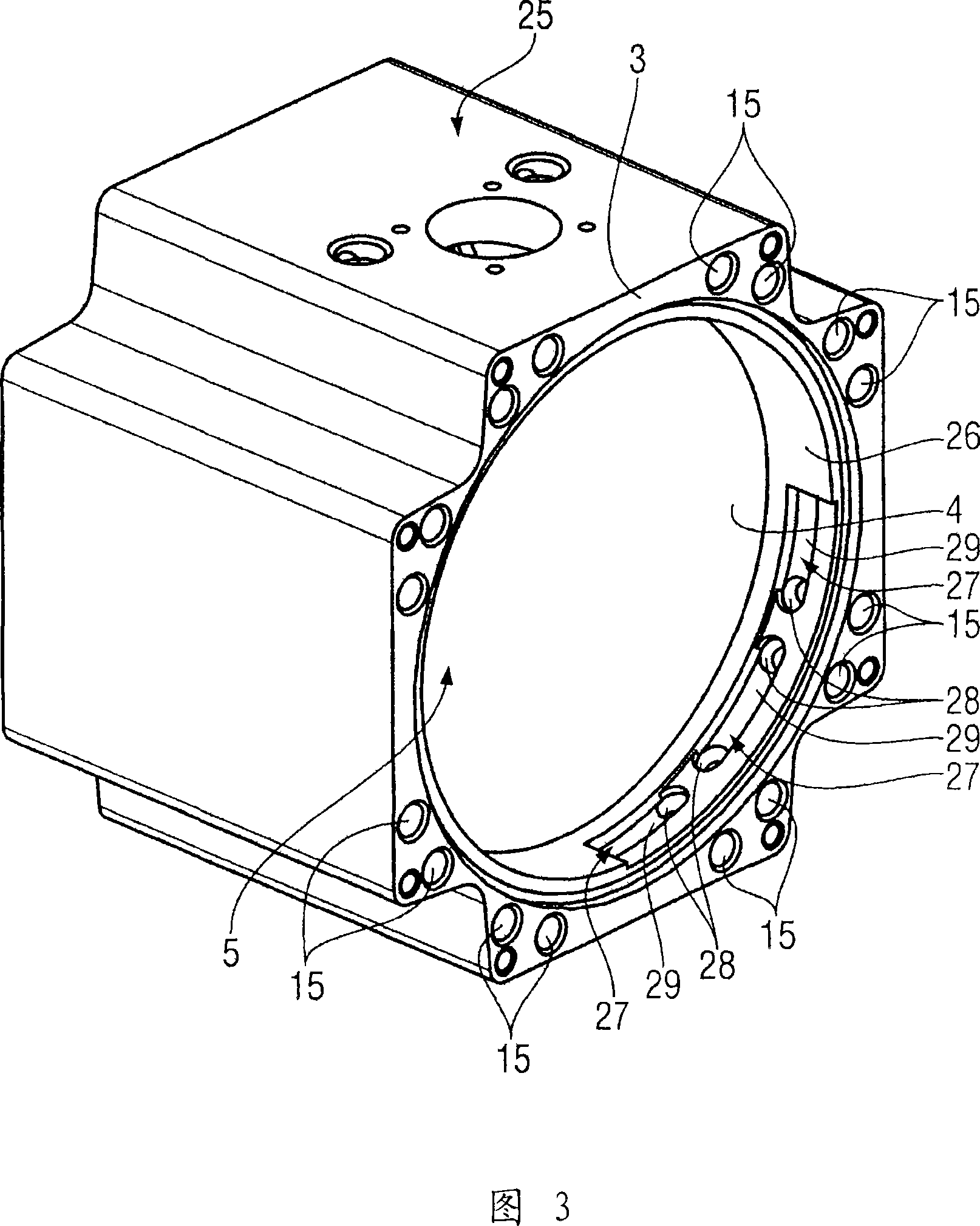

[0025] FIG. 1 shows a cross-section of an electric machine 1 in the form of an electric motor with a first embodiment of a housing 2 . The housing 2 , which is designed as an extruded part, has a housing 3 with an inner surface 4 surrounding a hollow cylindrical interior 5 . Inside the hollow interior 5 , a stator 6 , which is reliably fixed in the housing 2 , and a rotor 8 , which is rotatably supported around a rotation axis 7 , are arranged. The stator 6 comprises a stator lamination 9 , in which the electrical conductors of a winding system 10 run. In the axial direction, ie in the direction of the axis of rotation 7 , the winding system 10 has a winding tap 11 and 12 in each case facing the stator lamination 9 on both sides. The housing 2 is open on both sides in the axial direction. On this open side, a bearing cap 13 and 14 are respectively provided as connections.

[0026] The housing 2 comprises a plurality of cooling channels 15, only one of which is shown in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com