A work support used to contain especially a flat workpiece in a processing unit and having a supporting element capable of being attached to a bearing element

A technology for workpiece support and support components, which is applied to metal processing machinery parts, supports, auxiliary devices, etc., can solve problems such as high cleaning costs, pollution, and inoperability of workpiece supports, and achieve the effect of reducing backsplash or reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

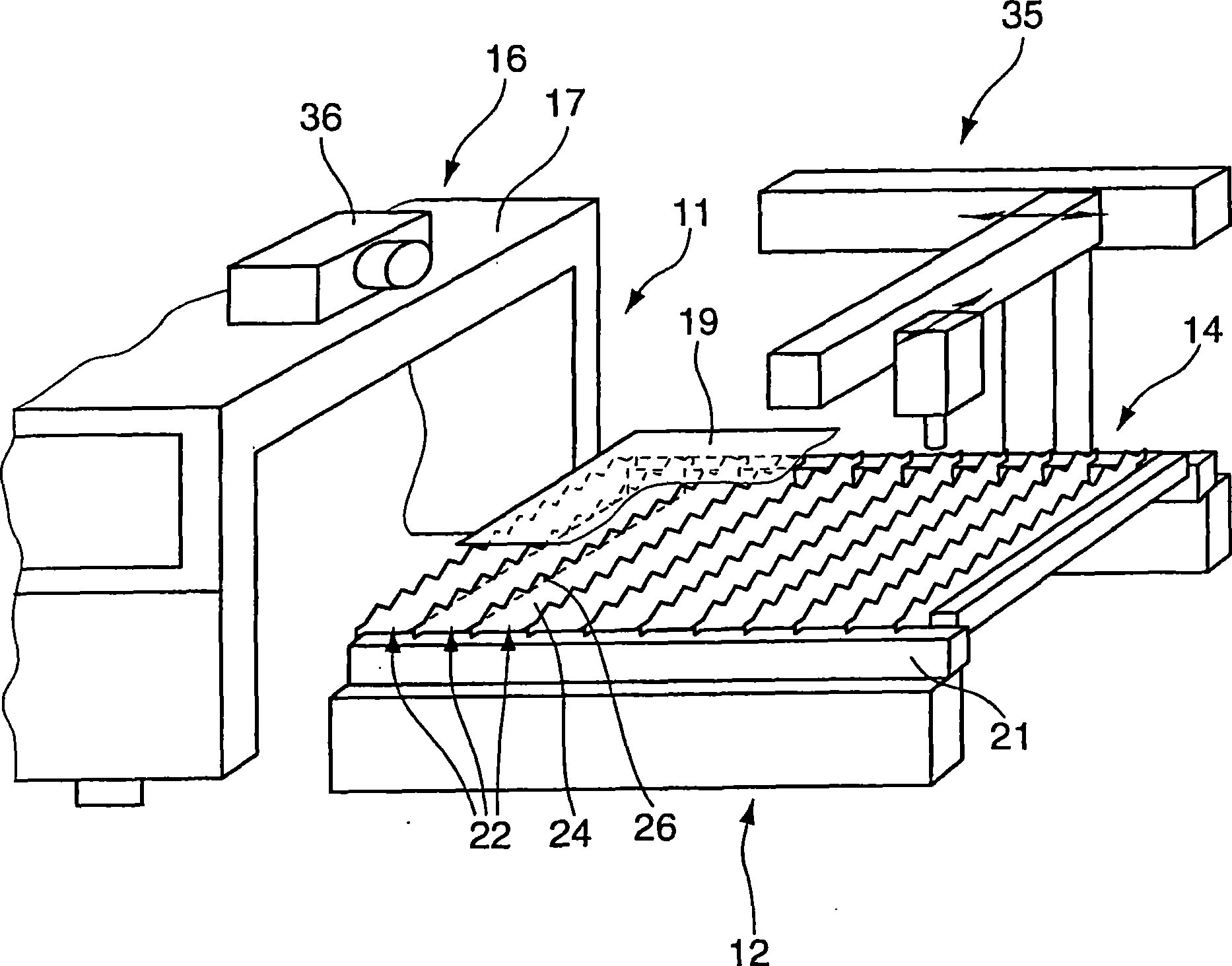

[0038] figure 1 A partial perspective view of a machining system 11 , in particular a laser machining system, is shown. A workpiece carrier 14 is arranged in the loading and unloading area 12 for movement into a processing machine, in particular a laser processing machine 16 , the housing 17 of which is partially shown. In said laser processing machine, the cutting head is moved by means of a linear system (not shown in more detail) over a workpiece 19 placed on a workpiece holder 14 in order to form the cutting contour.

[0039] The workpiece carrier 14 includes a frame 21 which holds a plurality of support elements 22 arranged adjacent to one another. In the first exemplary embodiment, the support element 22 comprises a support band 24 and a support peak 26 arranged above the latter, said support peak comprising a support peak tapering towards a point.

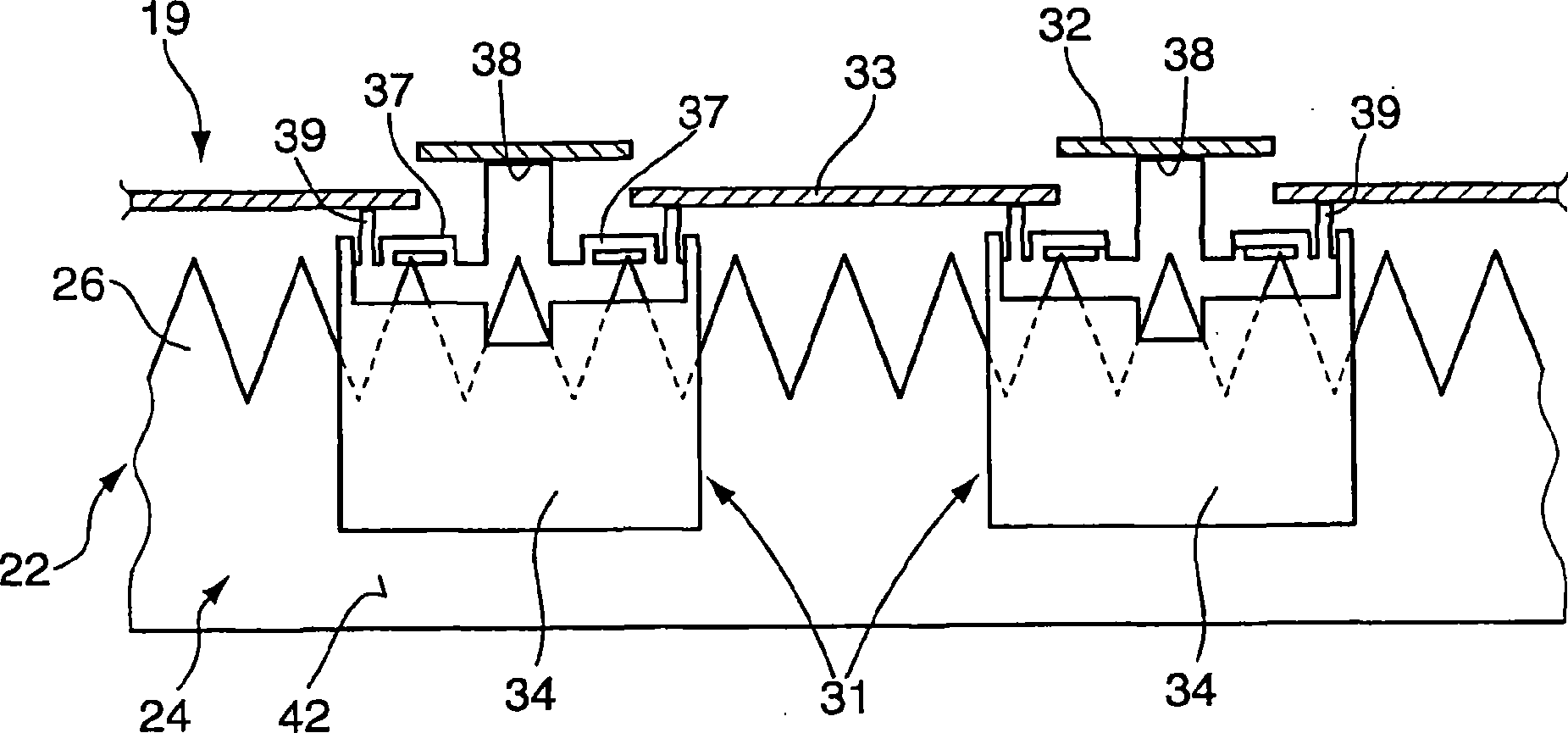

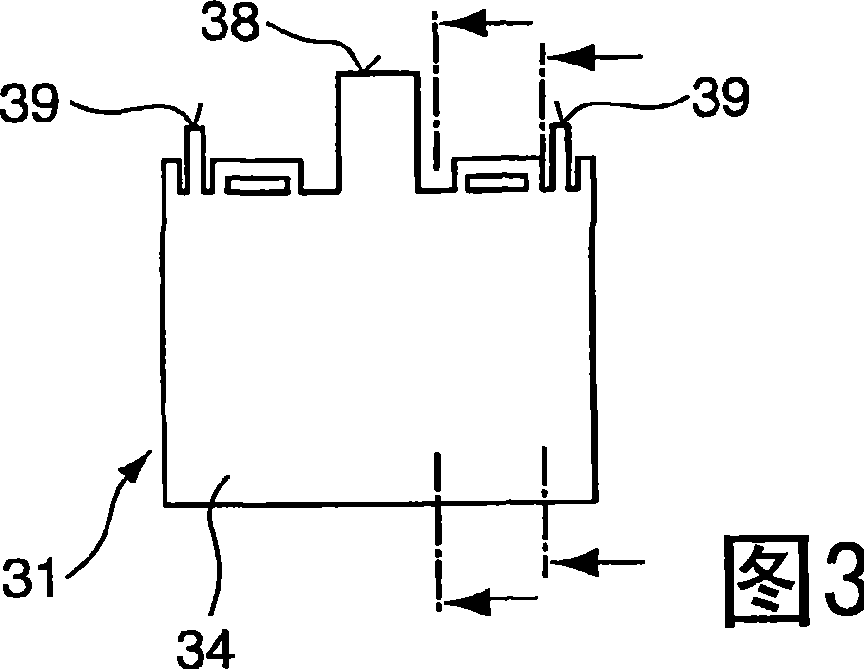

[0040] figure 2 A schematic side view of a first exemplary embodiment of a support element 22 is shown with a support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com