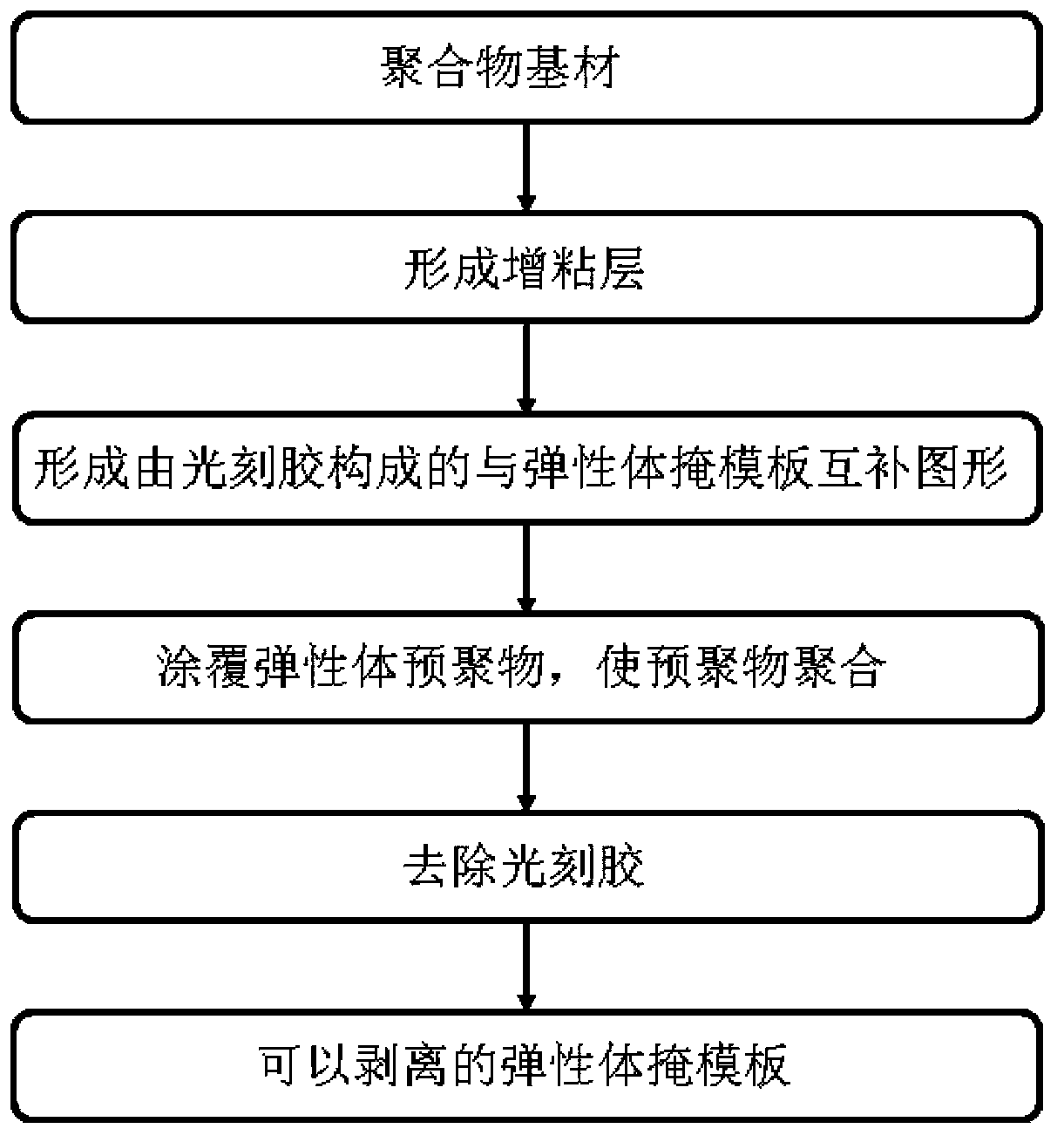

Method for forming peelable elastomer mask plate on surface of polymer base materials

A technology of substrate surface and elastic body, which is applied in the field of masks, can solve problems such as difficult fixing, inability to restore graphics well, large hole spacing of mask templates, etc., and achieve the effect of avoiding difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

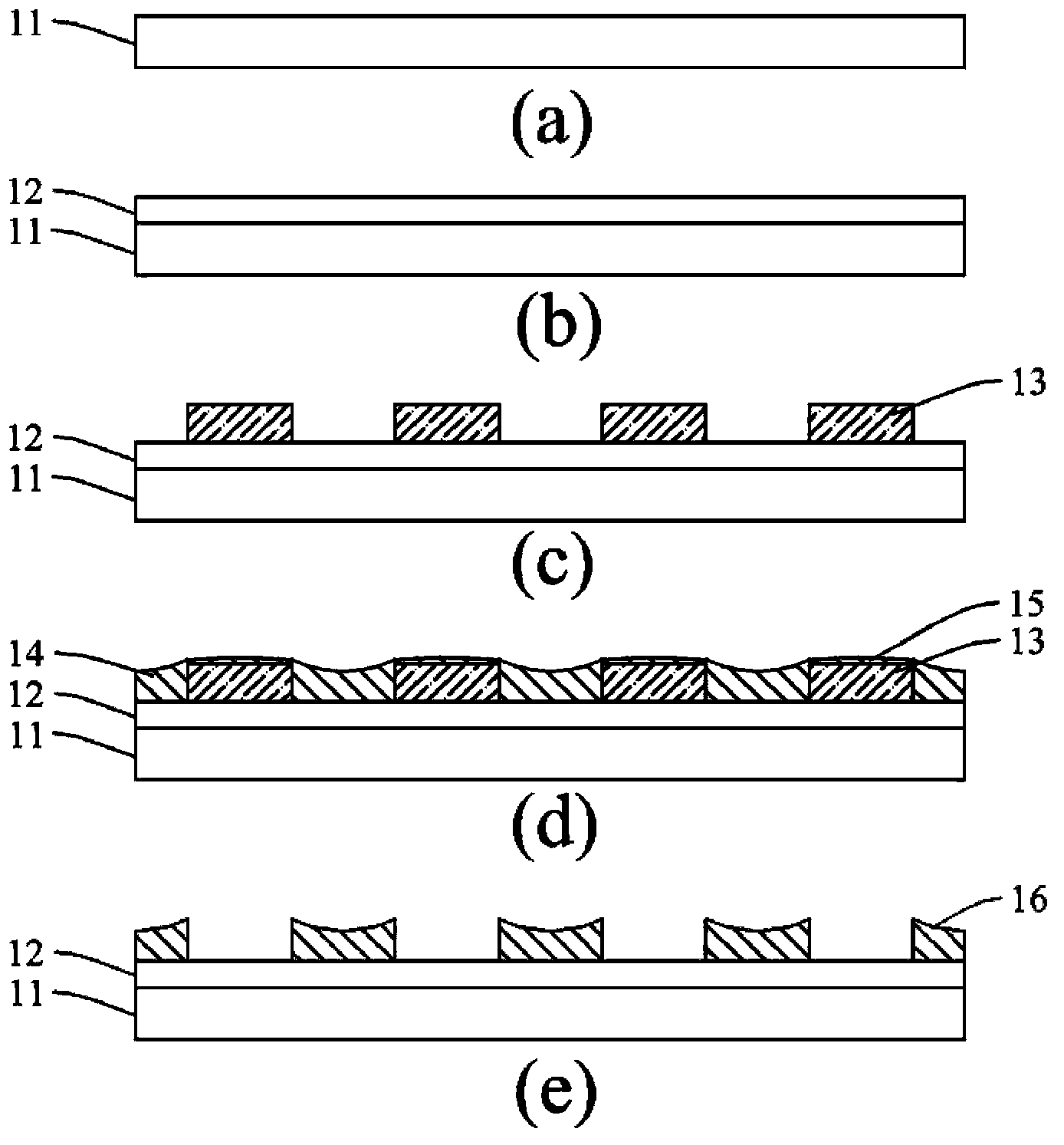

Embodiment 1

[0028] A 188-micron thick PET (polyethylene terephthalate) film is used as the substrate 11 (polymer substrate), and a layer of 50 micron ZrO is deposited on the surface of the substrate 11 by magnetron sputtering. 2 The film serves as the adhesion promoting layer 12 . deposited ZrO 2 The power used for the film is 100 watts, the background gas is Ar gas, and the pressure is 7.2×10 -1 Pa, the deposition time is 10 minutes. After that, the deposited ZrO 2 A negative photoresist is coated on the film with a coater. The coated photoresist was baked on a hot plate at 70 degrees for 2 hours, and the thickness of the photoresist was 90 microns. During exposure, the aperture width of the chrome mask used is 100 microns, and the aperture pitch is 100 microns. The light intensity of the exposure was 25 mW / cm2, and the exposure time was 120 seconds. Place the exposed plastic substrate in tetramethylammonium hydroxide for development to form the required photoresist pattern 13 . T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com