Piezoresistive pressure sensor of MEMS (Micro-Electro-Mechanical Systems) and preparation method thereof

A pressure sensor, piezoresistive technology, applied in the field of microelectromechanical system (MEMS) sensor design, can solve the problem of reducing device sensitivity, achieve high process reliability, reduce steps, and avoid the effect of strain film cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below through specific embodiments and accompanying drawings.

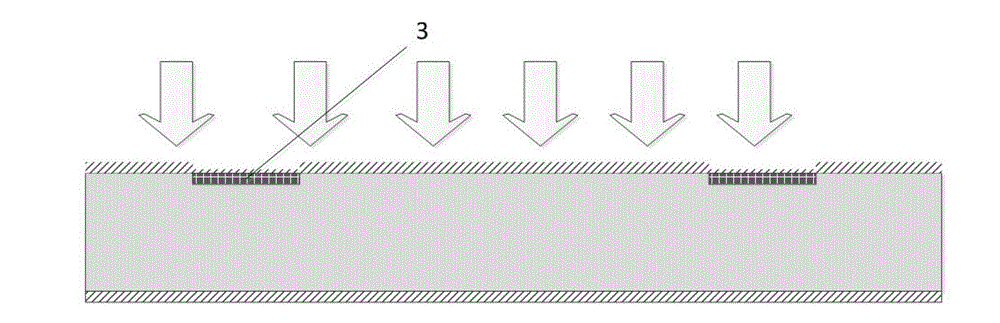

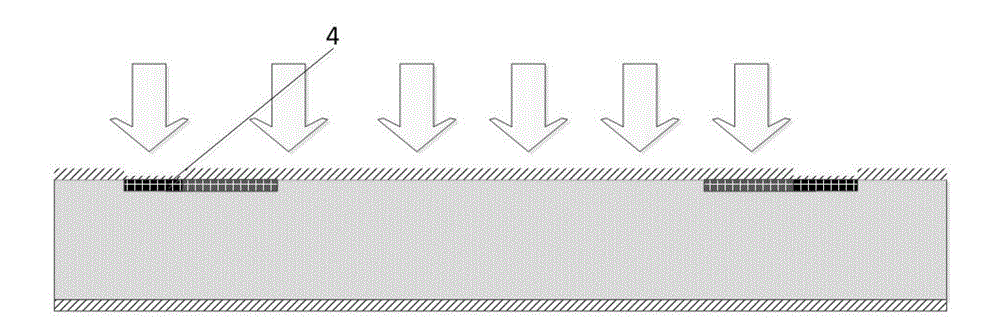

[0035] The preparation method of the MEMS piezoresistive pressure sensor in this embodiment is to manufacture four groups of along the substrate by ion implantation at the midpoint of the edge of the square substrate (other embodiments can also use a circular substrate). The varistors with symmetrical distribution of crystal orientation, the number of varistors in each group can be arbitrary (generally 1 to 5), and this embodiment is 4; before anisotropic etching on the back of the sensor, increase the number of varistors on the front A photolithography process etches stress-concentrated silicon islands around the front varistor, and after the etching is completed, the varistors are distributed on the stress-concentrated silicon islands. Specifically, the steps of the method include:

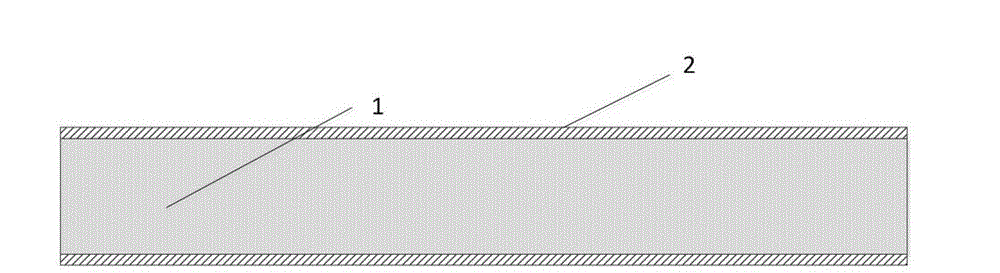

[0036] 1) Select (100) crystal plane single crystal silicon wafer or (100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com