Step printed circuit board and manufacture method of the step printed circuit board

A printed circuit board and manufacturing method technology, applied in the directions of printed circuit manufacturing, printed circuit, multilayer circuit manufacturing, etc., can solve the problems of stepped groove deformation, pressing warpage, difficult stepped board processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

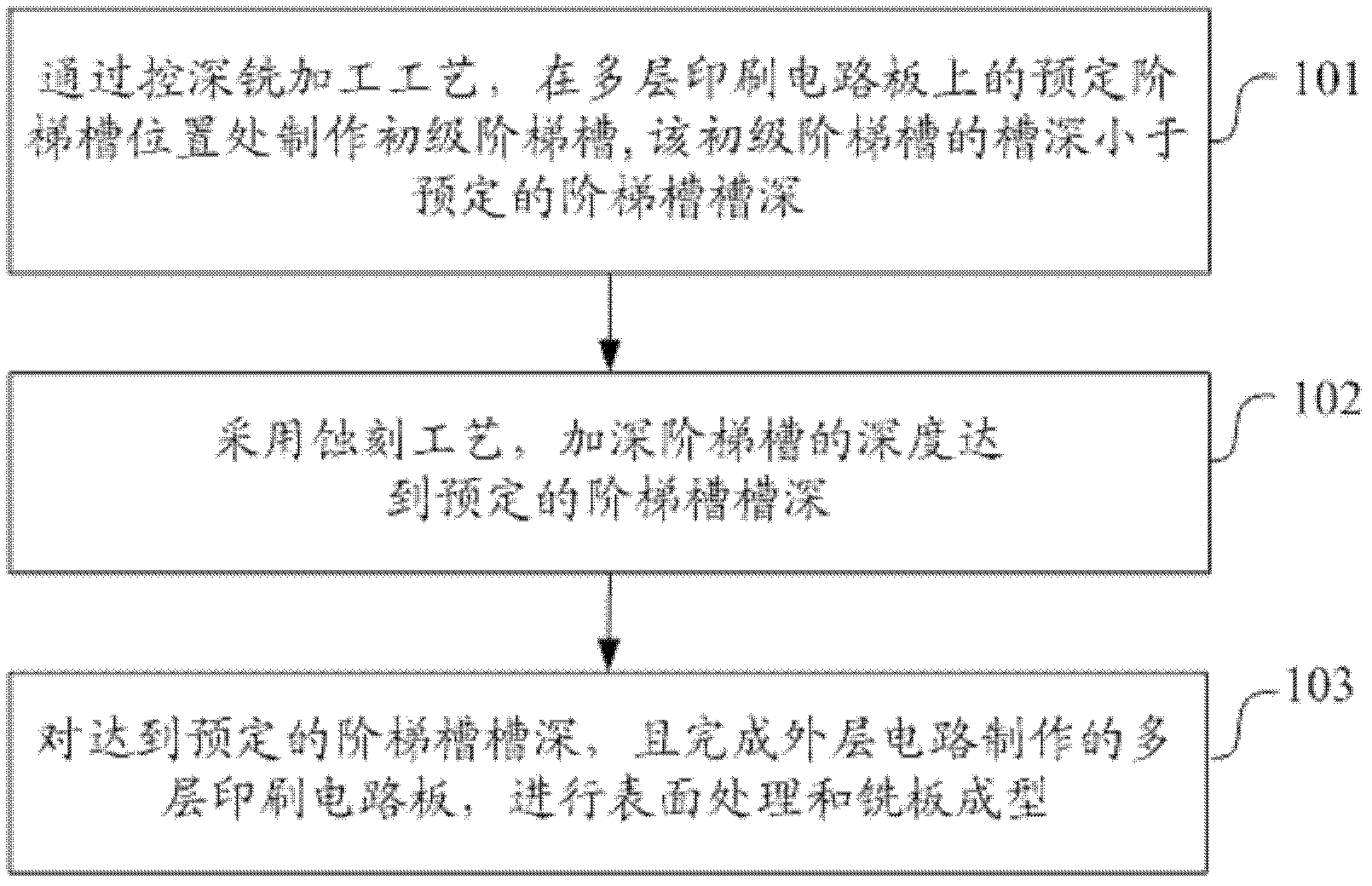

[0019] An embodiment of the present invention provides a method for manufacturing a stepped printed circuit board, such as figure 1 shown, including the following steps:

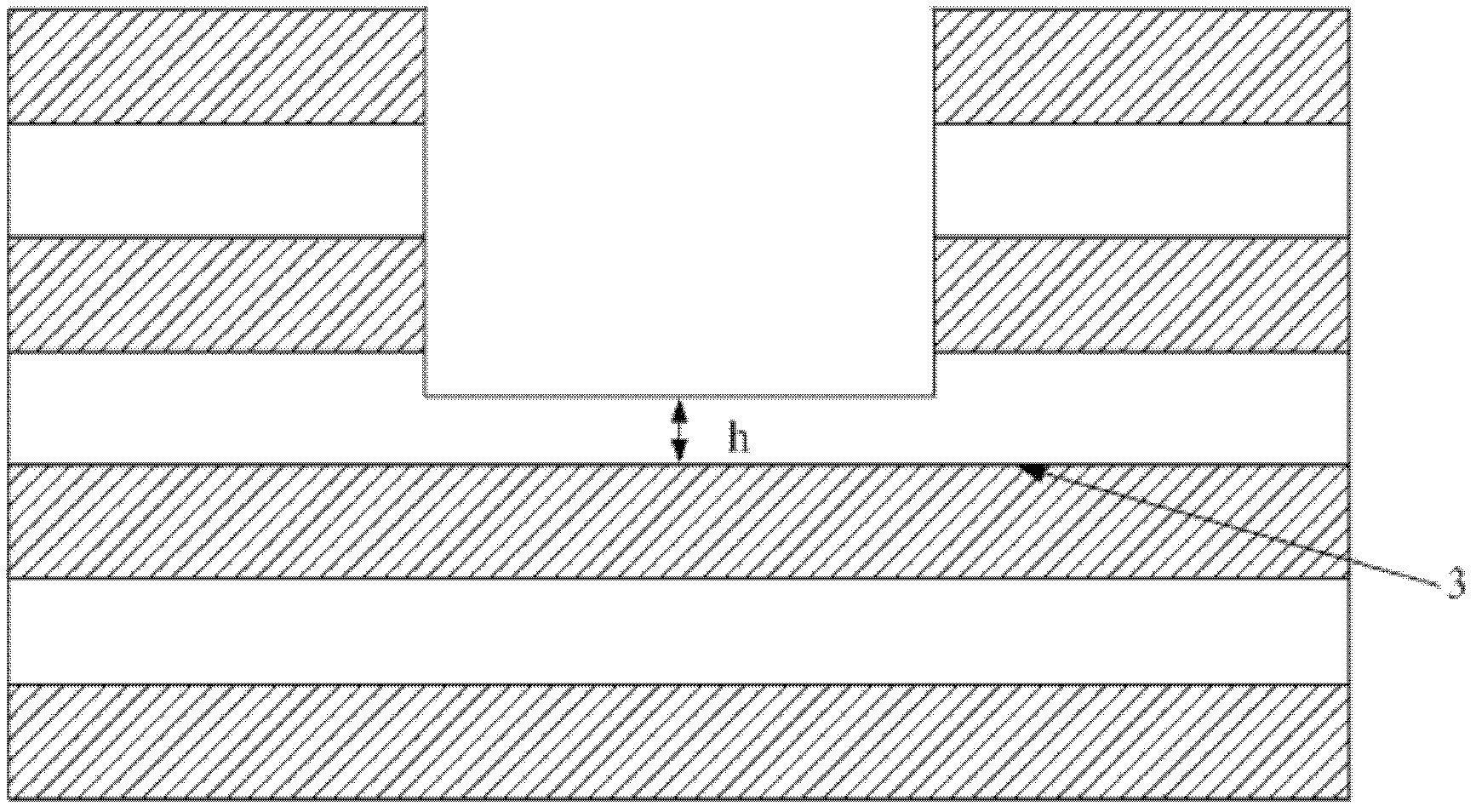

[0020] Step 101, through the depth-controlled milling process, make a primary stepped groove at the predetermined stepped groove position on the multilayer printed circuit board, and the groove depth of the primary stepped groove is smaller than the predetermined stepped groove depth;

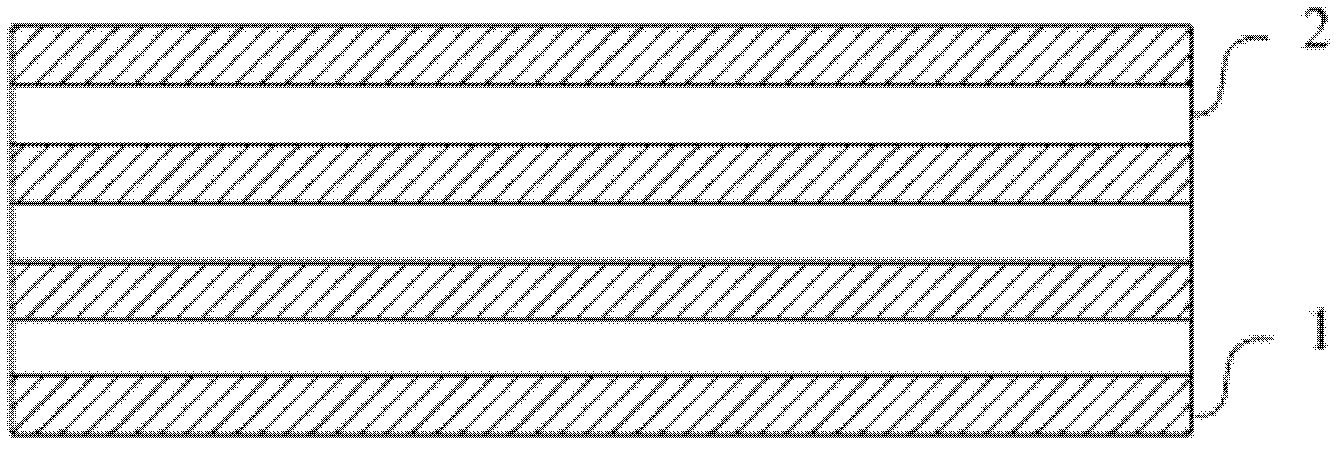

[0021] Specifically, when manufacturing a stepped printed circuit board, it is necessary to firstly manufacture a plurality of printed circuit boards to be laminated; to laminate a plurality of printed circuit boards to form a multilayer printed circuit board. Moreover, after copper plating is performed on the surface of the multilayer printed circuit board, the outer layer circuit is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com