Manufacture of electromechanical element, microelectro mechanical and resonance element and air tightness test method

A resonant element and micro-electromechanical element technology, applied to electromechanical elements, can solve the problem of not easy to detect the damage phenomenon, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

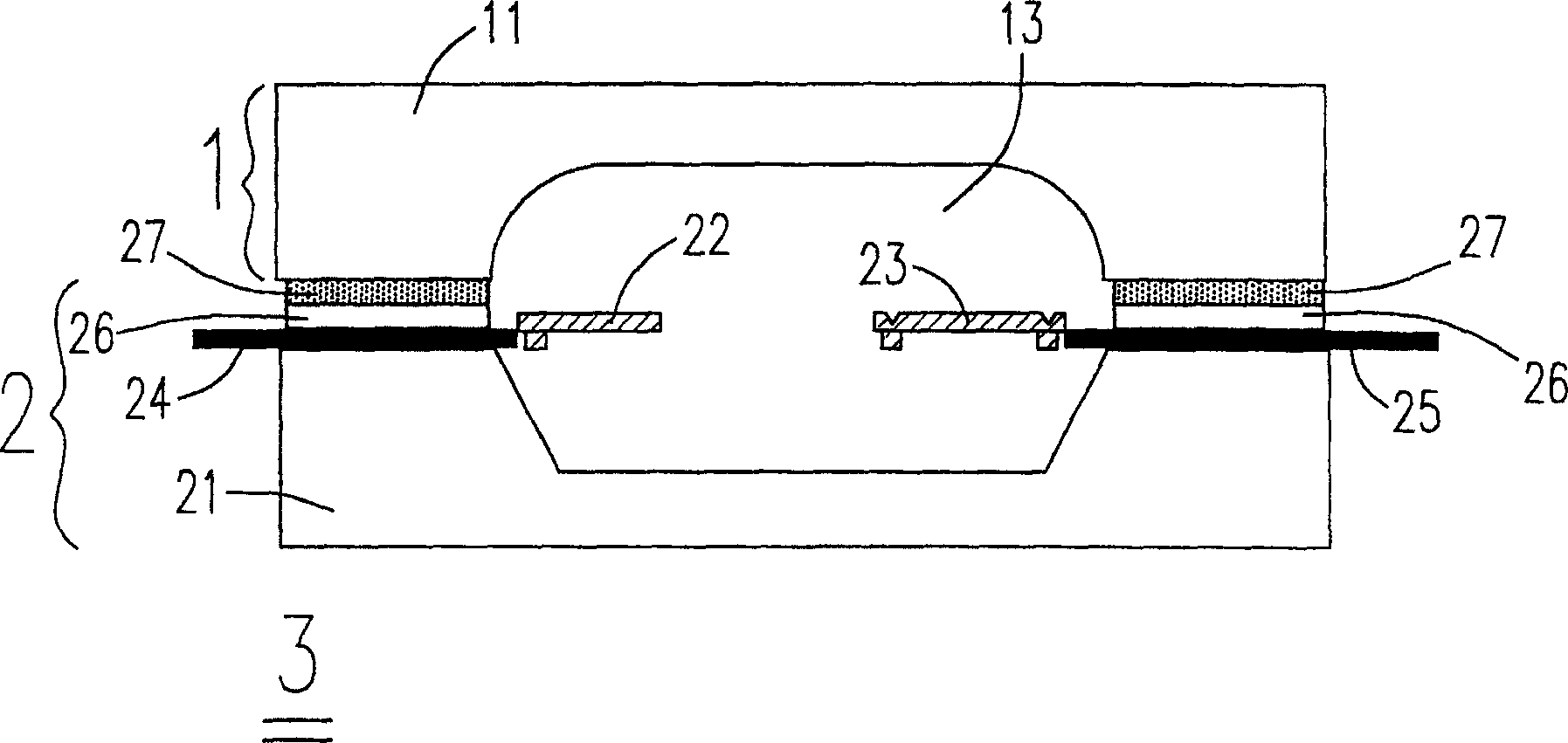

[0059] The integration technology of packaging, testing and fabrication of micro-electromechanical components proposed by the present invention can be fully understood from the following descriptions of the embodiments, and can be completed by those skilled in the art. In addition, although the present invention takes the manufacture of optical MEMS elements as an example, the implementation of the present invention is not limited to the field of manufacturing optical MEMS elements, and should also be applicable to the manufacture of other MEMS elements.

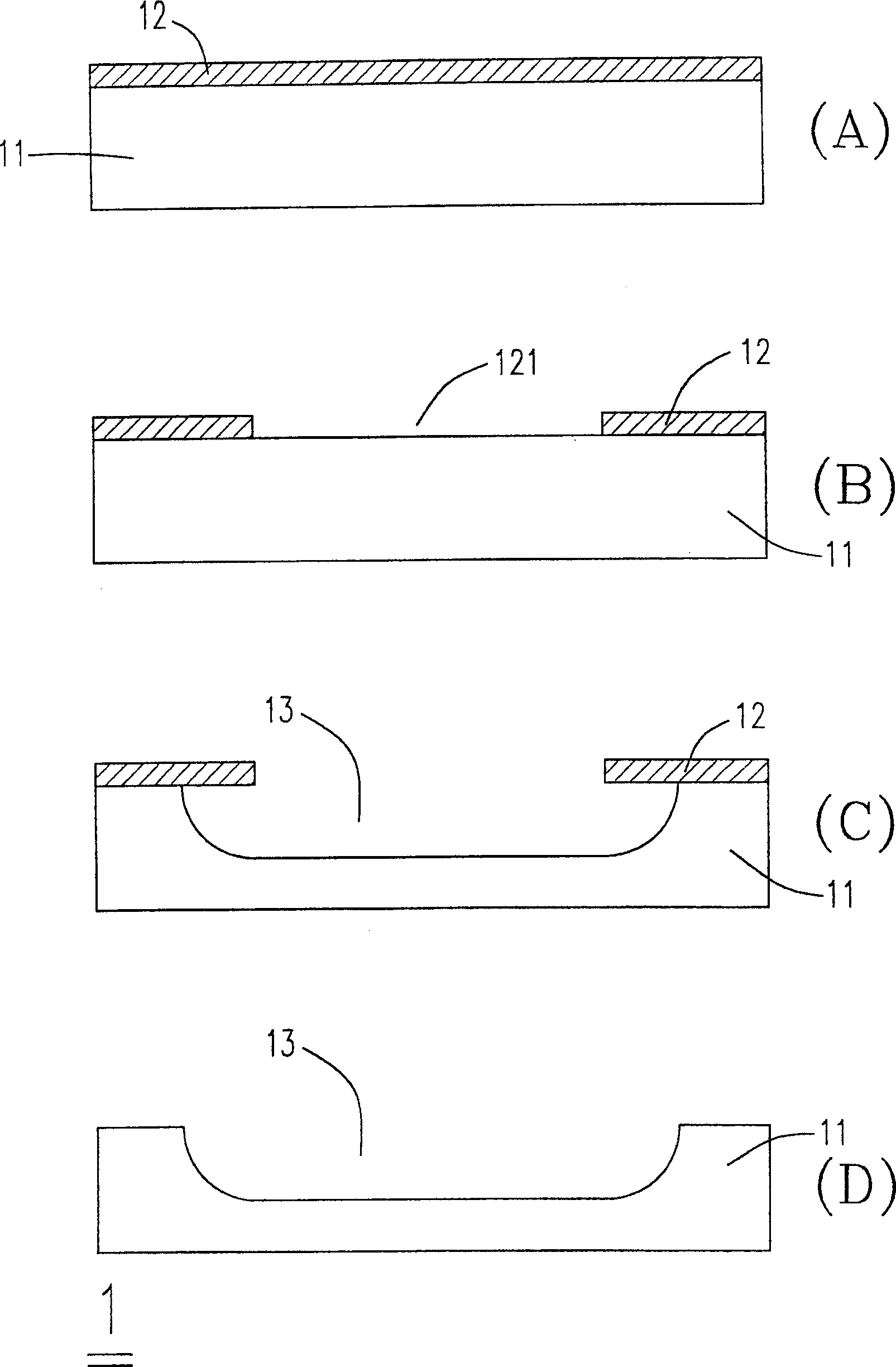

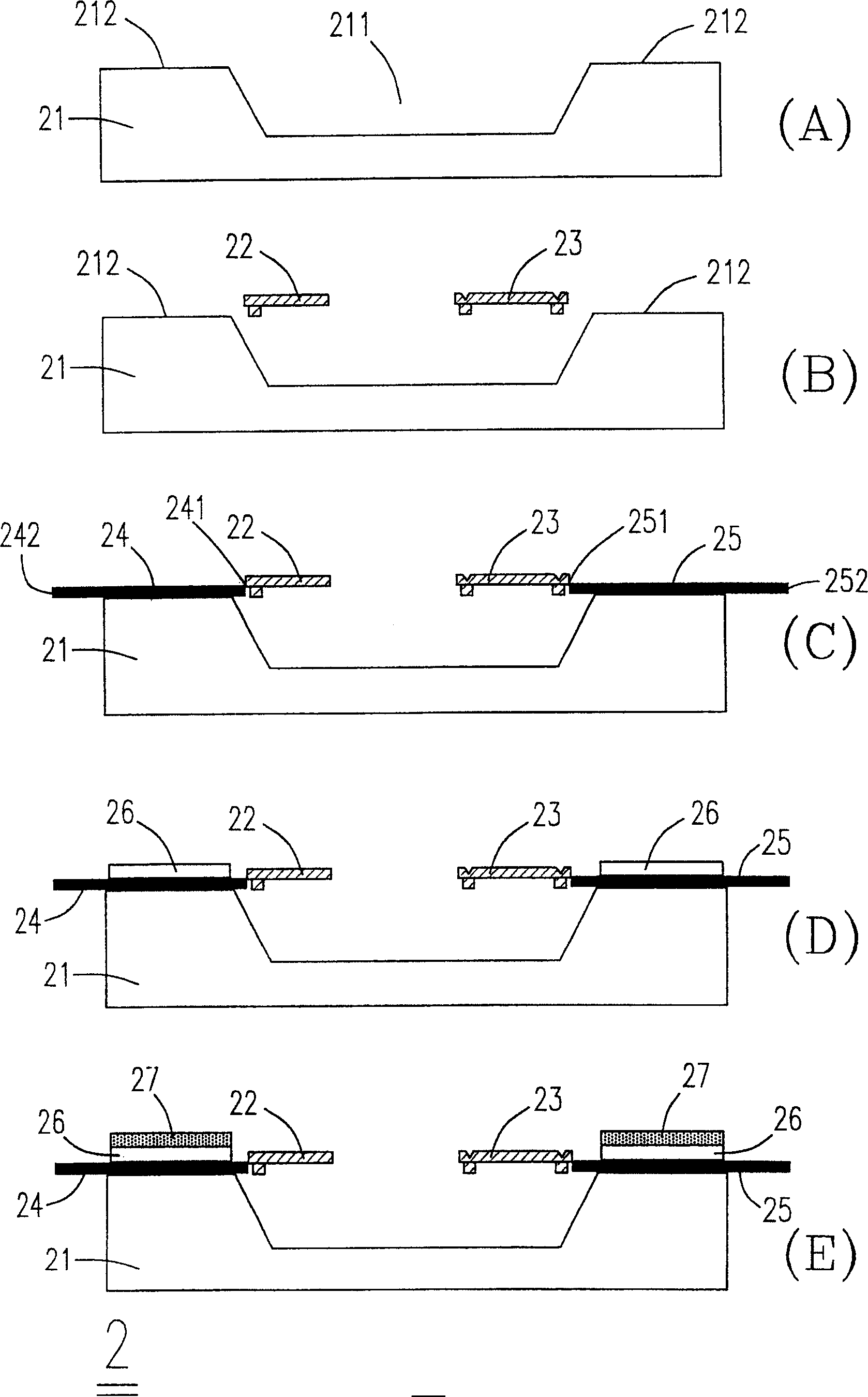

[0060] Please refer to figure 1 (A) to figure 1 (D), which is a fabrication flow chart of an exemplary protective cover of the present invention. like figure 1 (A) to figure 1 As shown in (D), in the process of making the protective cover 1, a substrate 11 with high light transmittance (such as a glass substrate or a quartz substrate) is firstly provided, and a low pressure chemical vapor deposition method (low pressure c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com