Precise workstable structure for array IC photoetching system

A technology of integrated circuits and lithography systems, which is applied in the field of precision workbench structures and can solve problems such as difficulty in realizing workbench synchronization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

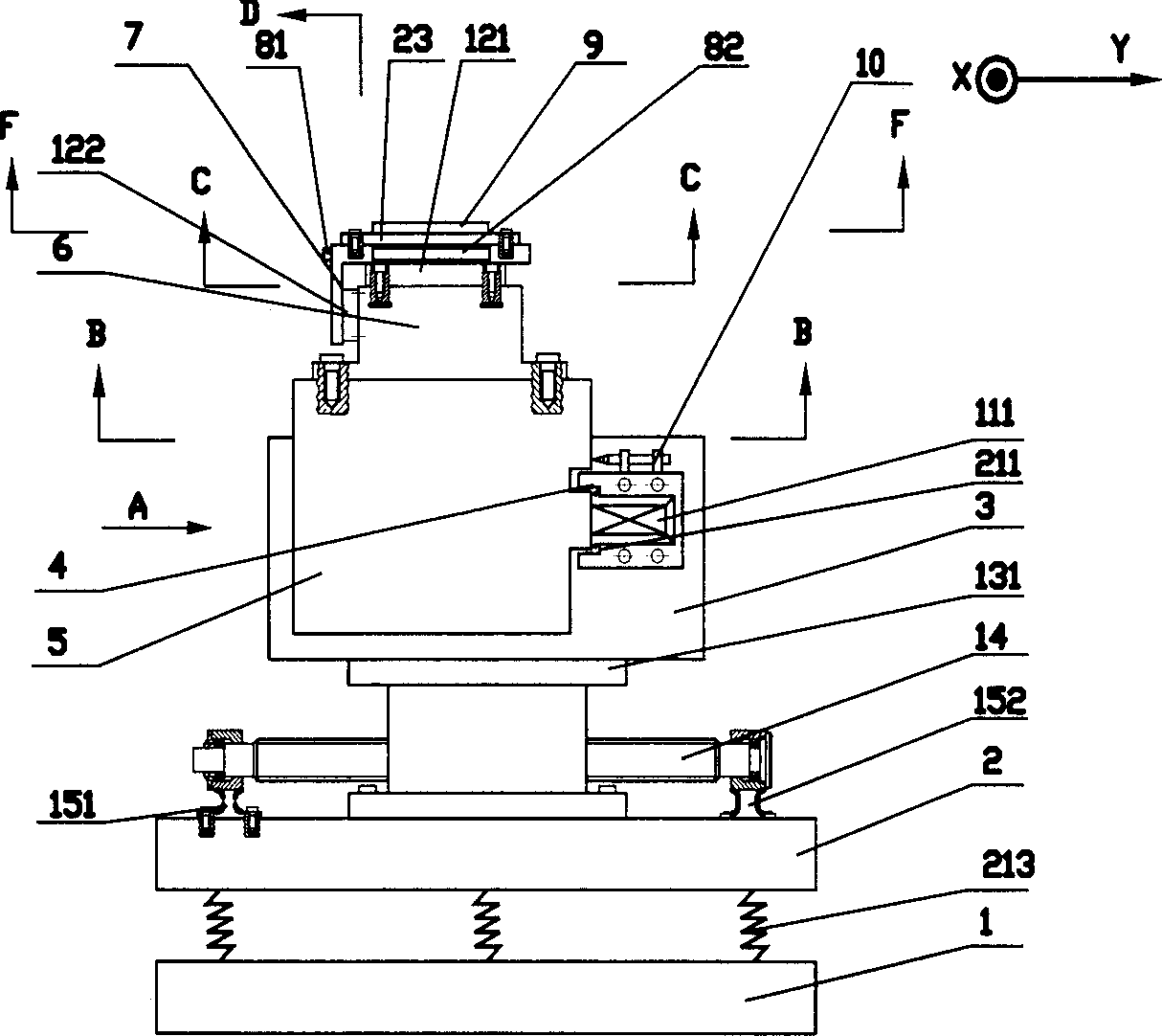

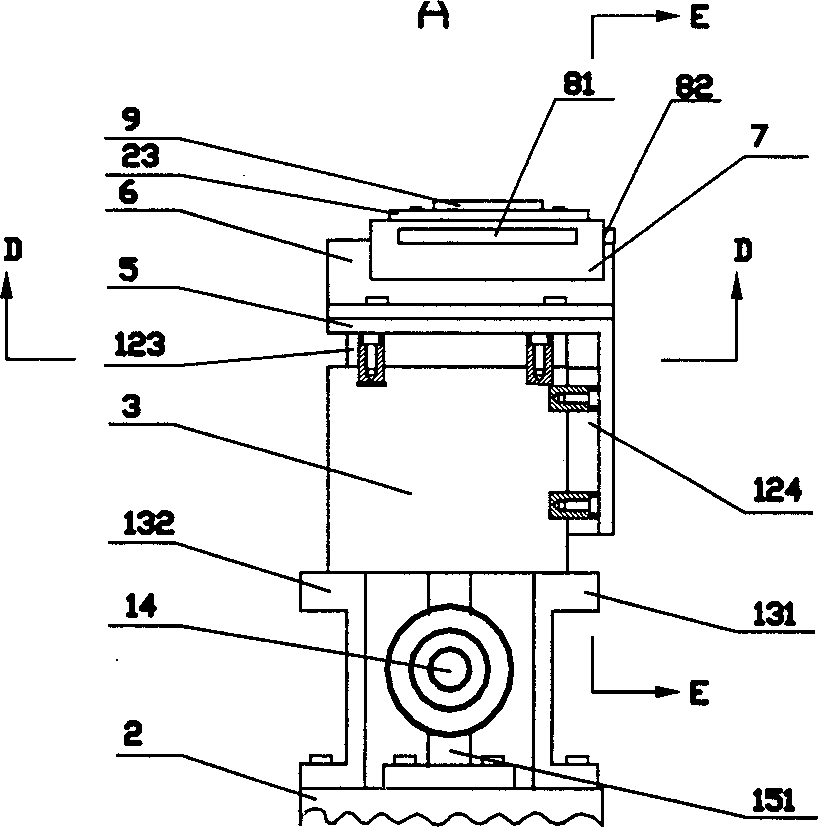

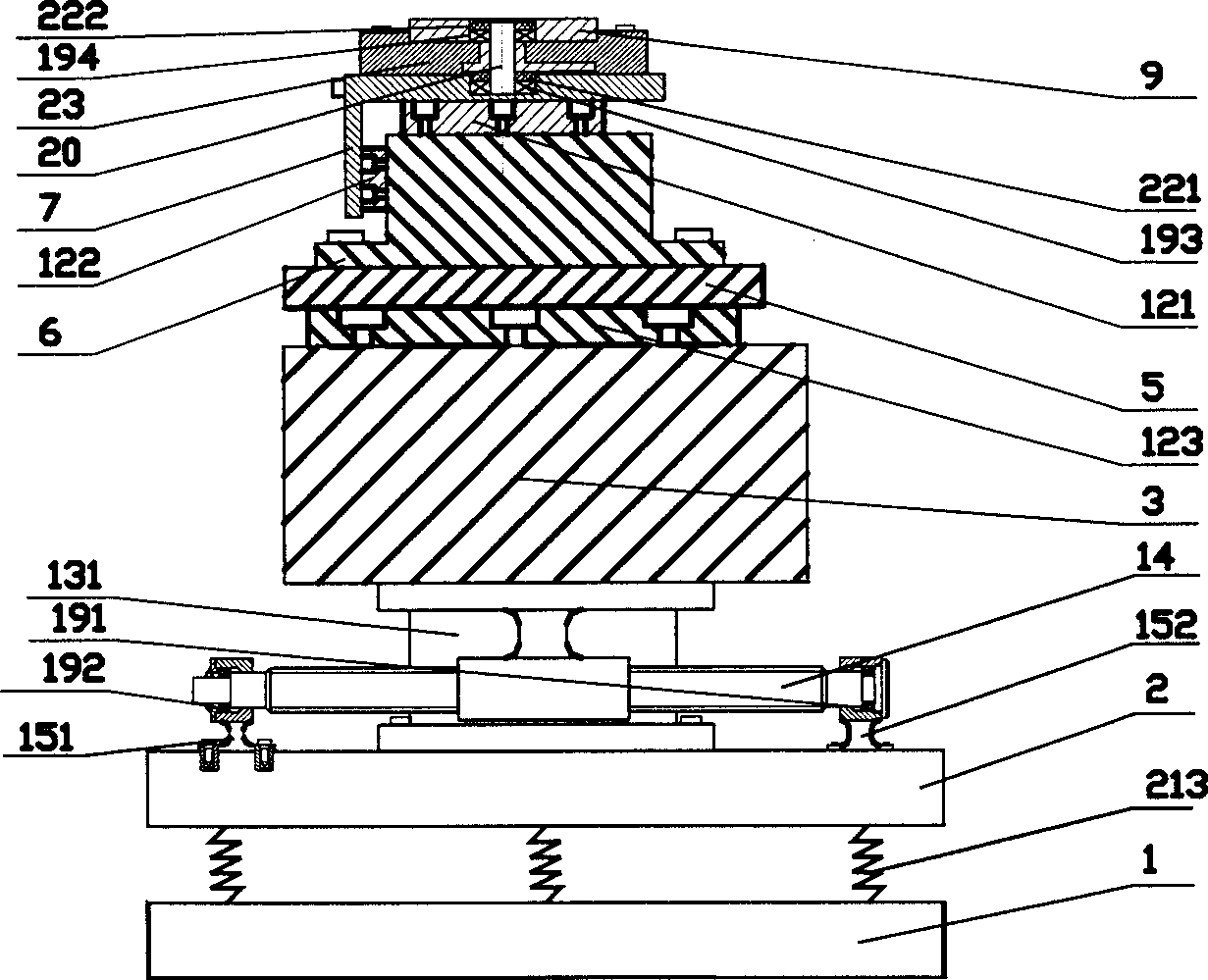

[0015] please see Figure 1 to Figure 9 . 1 is an anti-vibration table, and the 2nd is a workbench base, which links to each other with the anti-vibration table 1 with a spring 213. The 14th, ball screw, it is connected with workbench base 2 screws through support members 151,152. 131,132 are support rails connected with workbench base 2 screws. The Y-direction aerostatic guide rail 3 is connected with the support guide rails 131 and 132 . The Y-direction piezoelectric ceramic frame 4 is fixed on the Y-direction aerostatic guide rail 3 with screws. One end is fixed on its inner bottom surface to the Y-direction piezoelectric ceramic body 111 of T-shaped Y-direction motion workbench 5 in Y direction, and 161 is its electrode; To the inductance micrometer, the Y-direction motion table 5 is connected with the Y-direction piezoelectric ceramic frame 4 with a spring. The T-shaped Y-shaped motion table 5 is in contact with the T-shaped guide rail air cushions 123, 124 on the Y-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com