A method for reforming the box girder of the base of the door-grabbing boom oil cylinder

The technology of box girder and oil cylinder is applied in the field of heavy engineering lifting equipment of gantry type steel grabber, which can solve the problems of structural fatigue of key parts of the car body, production maintenance operation and safety impact, and can not be completely dealt with, so as to realize the safe and stable operation of the equipment. , to achieve the effect of ensuring production and supply, and solving equipment hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

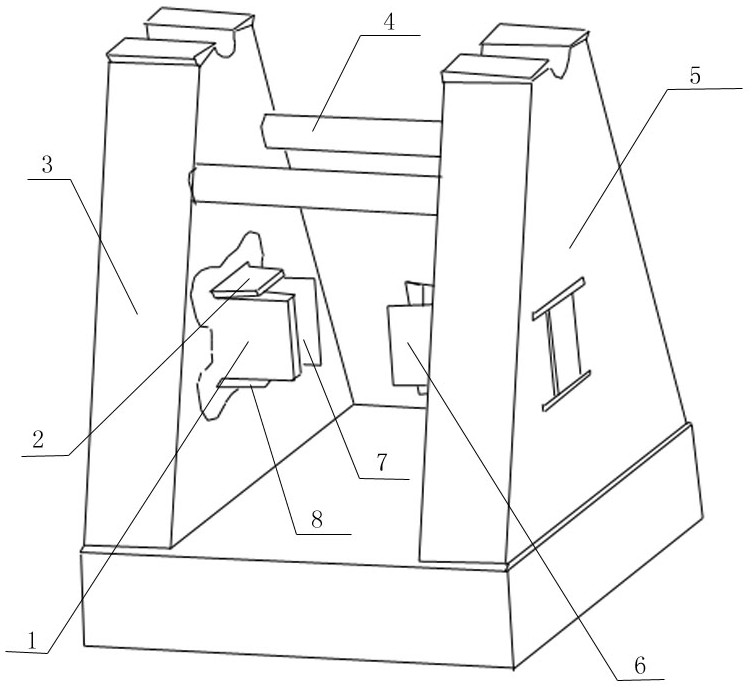

[0013] Such as figure 1 As shown, Shanxi Taigang Stainless Steel Co., Ltd. has 2 imported door-type steel grabbers in the scrap yard of the processing plant. Through this transformation method, the problem of frequent cracking of the boom cylinder base box is effectively solved, and the domestic structure and the imported structure are realized. Perfect replacement, the specific implementation is as follows:

[0014] Lay double layers of asbestos cloth on the lower part of the box girder for protection. Before dismantling the box girder, measure and record the distance between the two tripods, and then support the tripods to make two seamless seamless Steel pipe support; the support rods are welded in place and fixed side by side on the inside of the tripod.

[0015] Cut the cracks on the upper plate, lower plate, front plate, and rear plate of the box girder. The boom oil cylinder seat beam is fixed at both ends. The maximum bending moment is located at the midpoint and two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com