Ultrasonic high-precision linear displacement device

A linear displacement, high-precision technology, used in electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

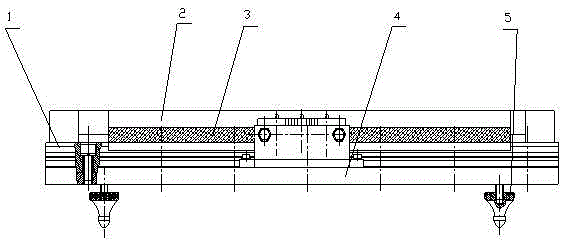

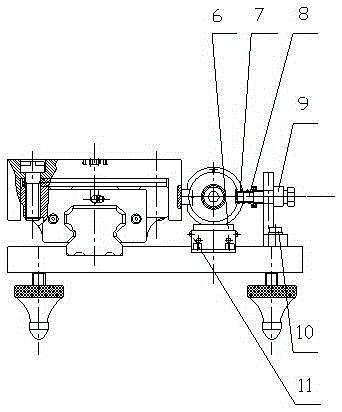

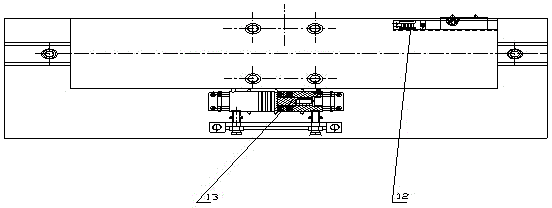

[0016] The ultrasonic high-precision linear workbench of the present invention includes 1. guide rail, 2. workbench, 3. ceramic wear-resistant coating, 4. base, 5. foot, 6. distance measuring instrument, 7. vibrator base, 8. bolt pre- Tightening mechanism, 9. Self-locking nut, 10. Pre-tightening mechanism base fixing nut, 11. Vibrator base fixing nut, 12. Linear micro-motion slide table, 13. Vibrator. The worktable is driven by a unilateral biped longitudinal bending vibrator, and a piezoelectric ceramic sheet is installed inside the vibrator. When a voltage with appropriate frequency and phase difference is applied to the piezoelectric ceramic sheet inside the vibrator, which is used to excite longitudinal vibration and bending vibration respectively, the superposition of these two vibrations will cause the surface particles of the vibrator to drive the foot to produce elliptical motion, and then drive the worktable Make a linear movement along the guide rail in one direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com