Optical system image quality compensating apparatus

A technology of optical system and compensation device, which is applied in the direction of optics, photo-plate making process exposure device, optical components, etc., can solve the problems of difficult assembly, difficult adjustment, and high requirements for device sealing, and achieves convenient operation, low assembly difficulty, and excellent structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

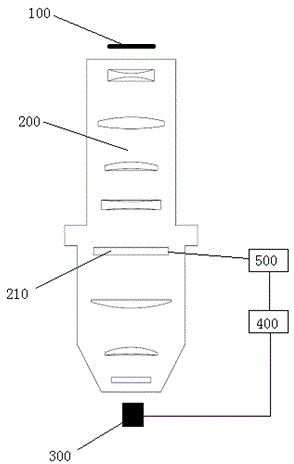

[0023] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the exposure device of the present invention. The exposure device mainly includes a reticle 100 , an optical system 200 , a fine mechanism control unit 500 , a main control system 400 and a wavefront sensor 300 . The micro-mechanical control unit 500 controls the deformable mirror 210 , and the micro-mechanical control unit 500 is connected with the main control system 400 . The wavefront sensor 300 detects the image quality of the incident light for imaging, and feeds back the obtained image quality to the main control system 400. The main control system 400 determines the compensation amount by analyzing the deviation between the image quality of the incident light for imaging and the expected image quality, The change of the surface shape of the deformable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com