A micro rotating mechanism based on shape memory alloy

A technology of memory alloy and rotating mechanism, which is applied to motors, generators/motors, and electrical components that apply thermal effects, and can solve problems such as troublesome installation, inability to complete control tasks, and difficulty in realizing motor drive methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

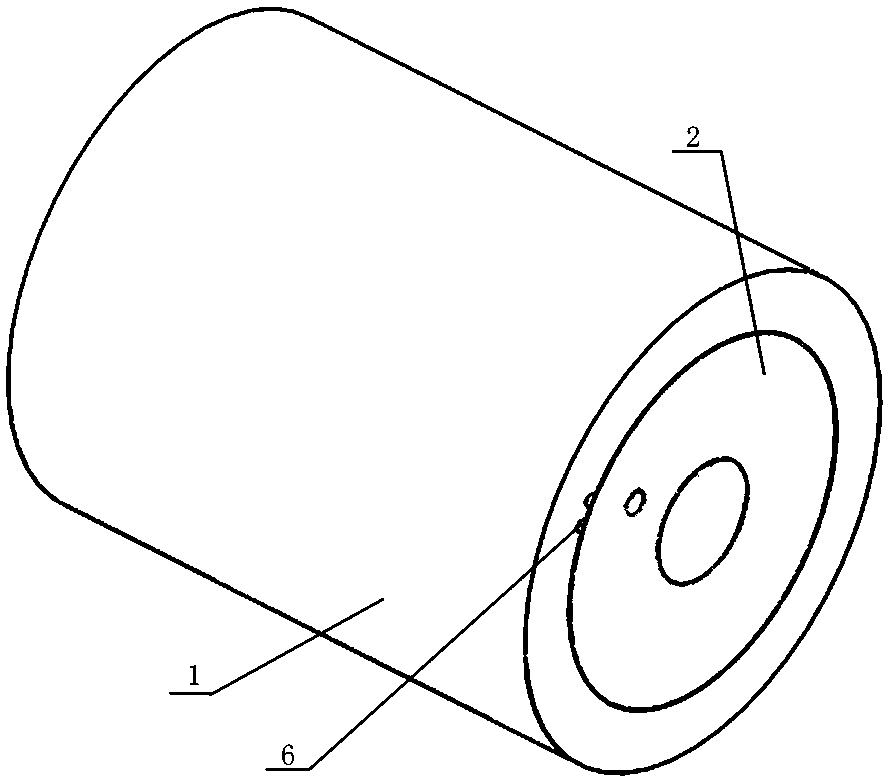

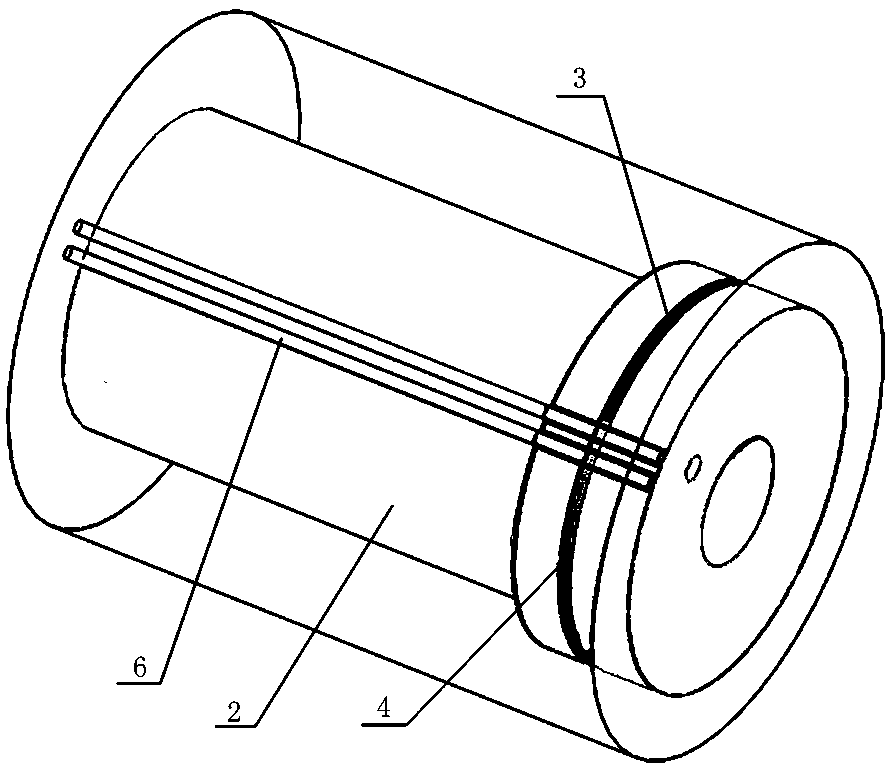

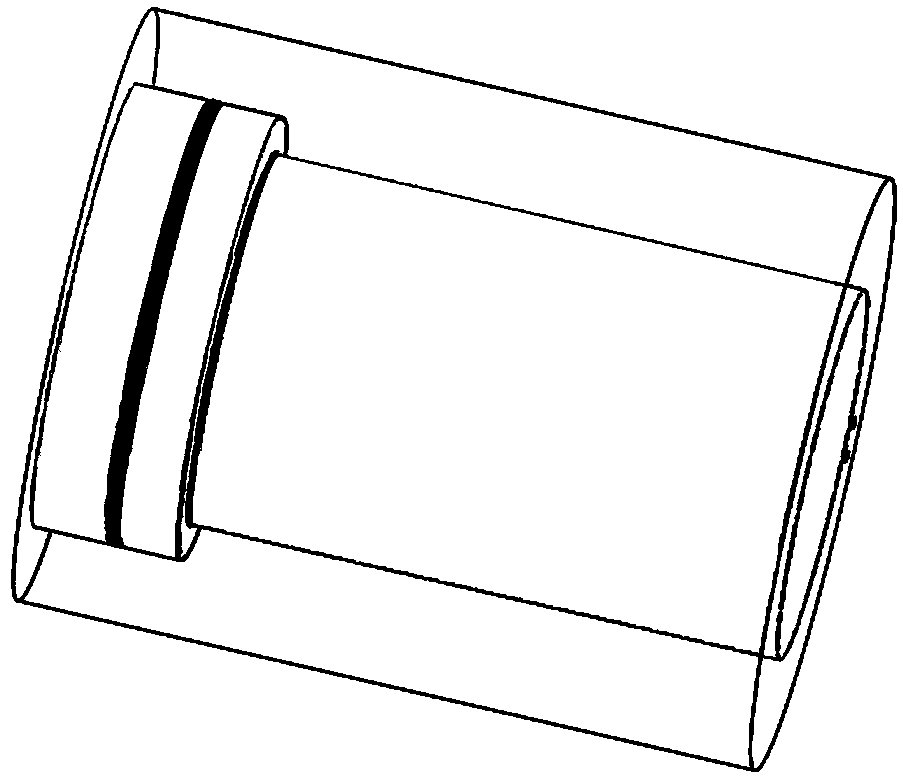

[0026] Embodiment one: see Figure 1 to Figure 3 As shown, a micro rotating mechanism based on a shape memory alloy is mainly composed of a fixed sleeve 1 and a rotating shaft 2. The surface of the rotating shaft 2 is provided with a circumferentially arranged installation groove, and the first wire 3 and the second wire are respectively arranged in the groove. Wire 4, the first end of the first wire 3 and the first end of the second wire 4 are respectively fixed on the rotating shaft and the distance between the two fixed points is less than 5% of the circumference of the rotating shaft, the first wire 3 and the second wire 4 are respectively facing away from the rotating shaft 2, and are respectively drawn out and fixed through the fixed sleeve 1, so that the first wire 3 and the second wire 4 are in a state of opposite pull; the first wire 3 is for working in A shape memory alloy wire in a shape memory state, the second wire material 4 is a shape memory alloy wire in a supe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com