A Three-dimensional Machining Method for Gantry Machining Center

A processing center and processing method technology, applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problem that the processing method is difficult to achieve multi-angle processing functions, etc., to ensure stability, good stability, and ensure processing The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

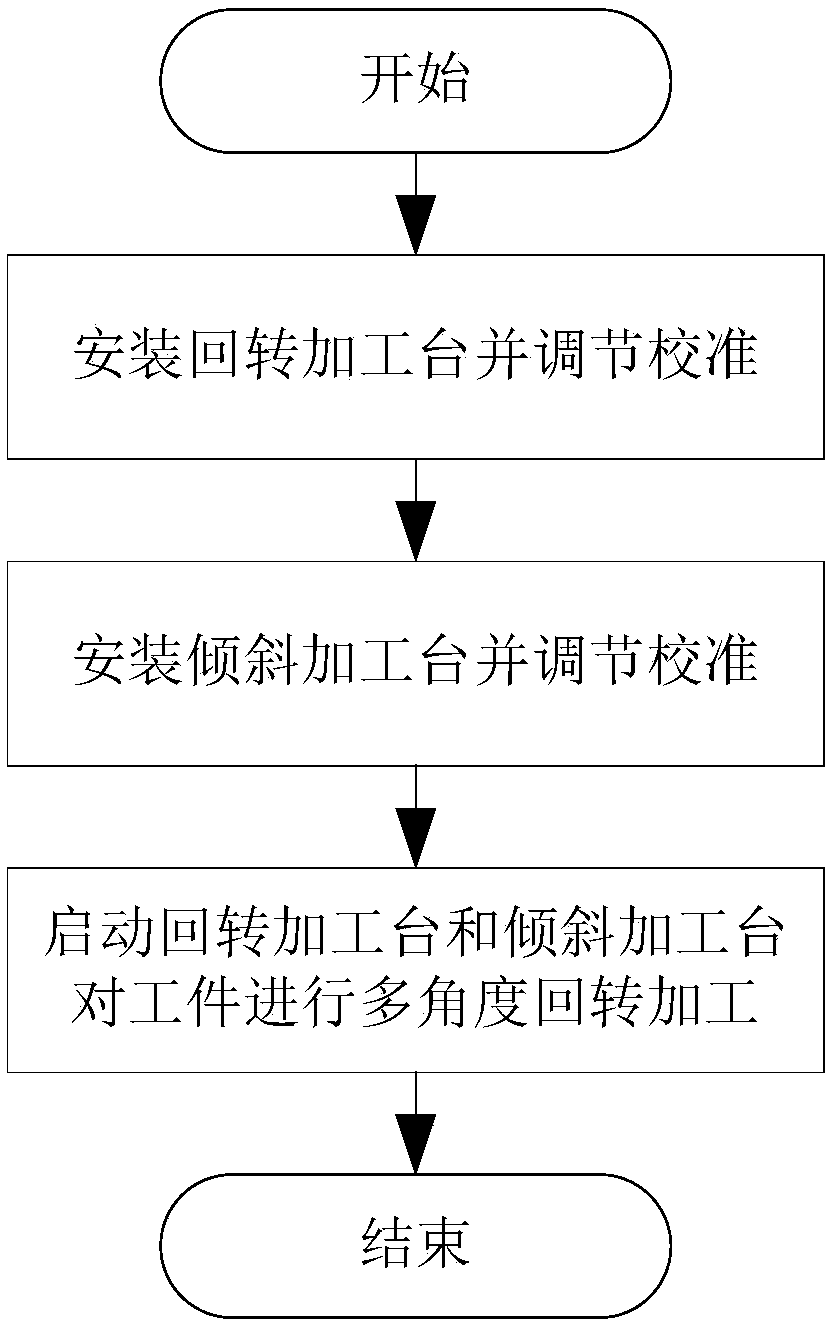

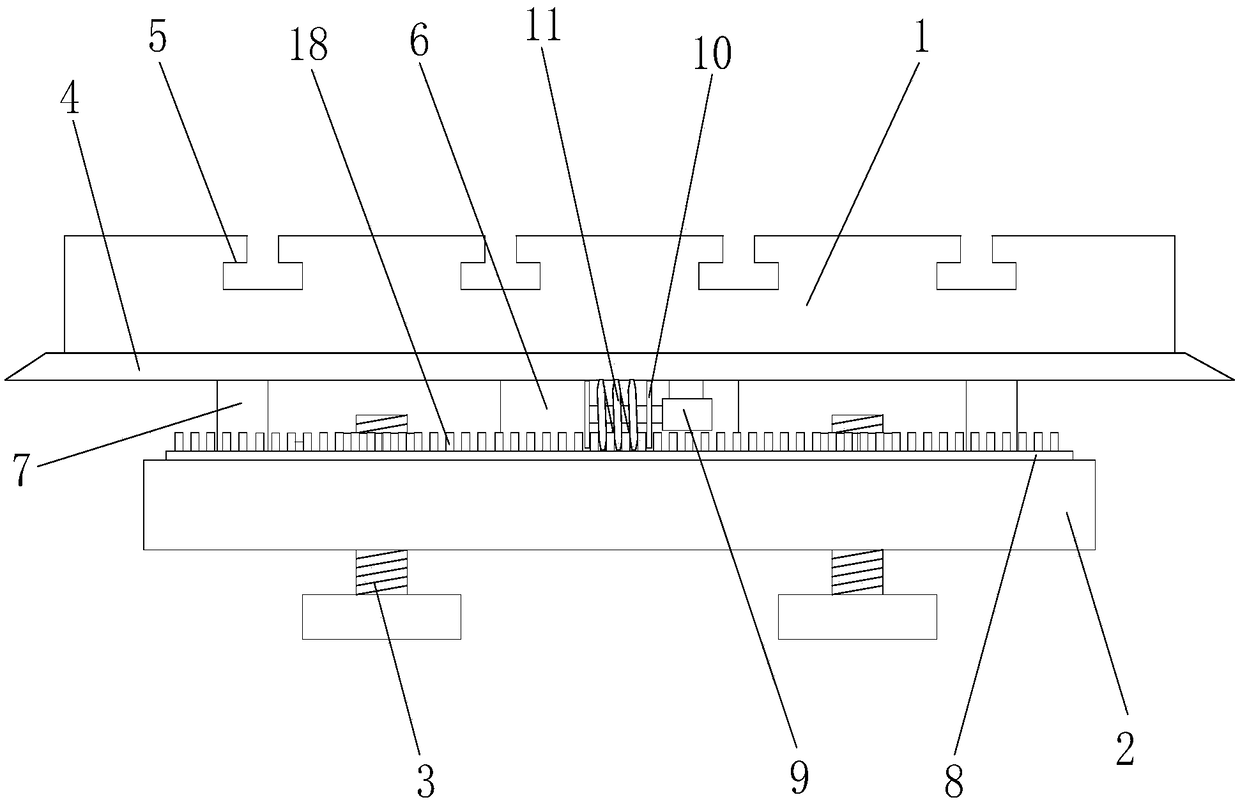

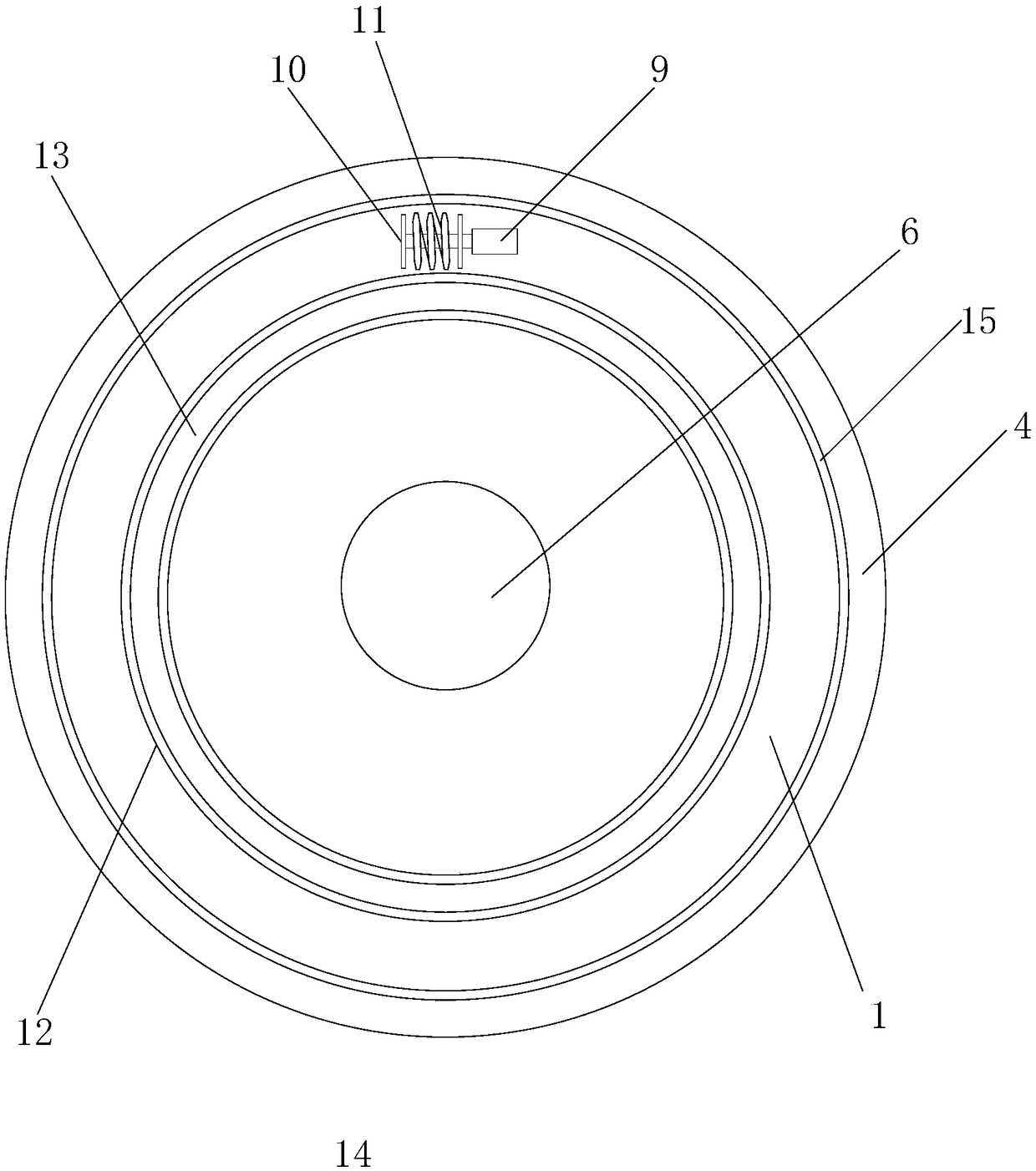

[0027] Such as Figure 1-7 As shown, a three-dimensional processing method for a gantry type machining center disclosed by the present invention includes the following steps:

[0028] Step 1, install the rotary processing table on the worktable of the gantry type machining center, and make the rotary axis of the rotary processing table coincide with the reference position of the worktable center;

[0029] Step 2, installing an inclined processing table on the rotary processing table, and making the table center of the inclined processing table consistent with the position of the rotary axis of the rotary processing table;

[0030] Step 3, install the workpiece to be processed on the table of the inclined processing table, start the rotary processing table and the inclined processing table, and realize the multi-angle rotary processing of the workpiece to be processed by using the rotation control of the rotary processing table and the tilting swing control of the inclined proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com