Zero adjusting device for magnetic performance parameter test of torque motor

A torque motor and parameter testing technology, applied in the field of measurement, can solve the problem of lack of better methods and devices, and achieve the effect of ensuring precision and realizing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be clearly and completely described below in conjunction with the drawings and specific implementation methods of the present invention.

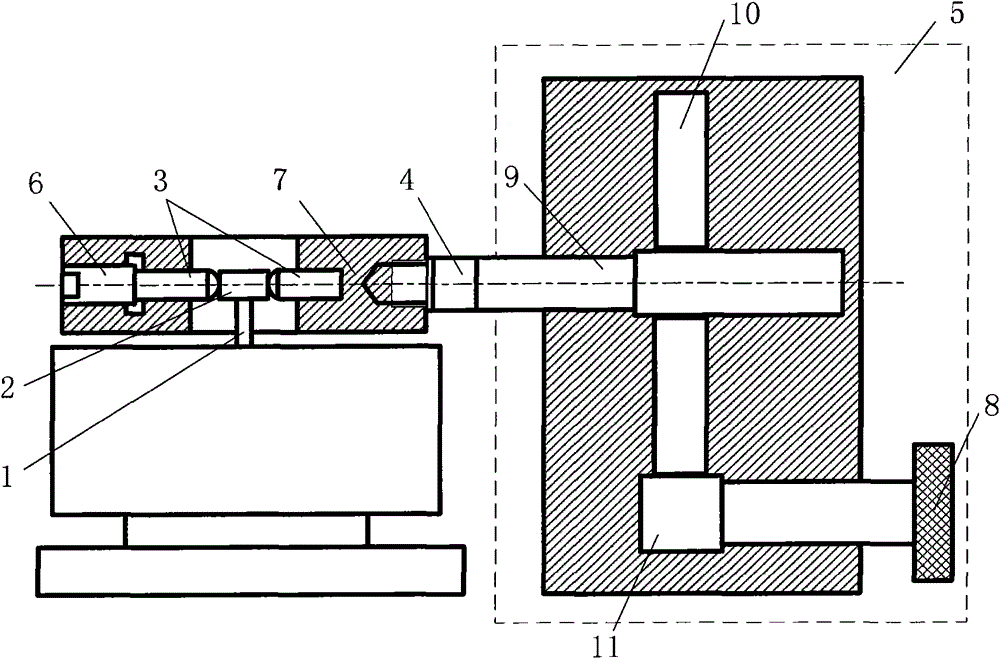

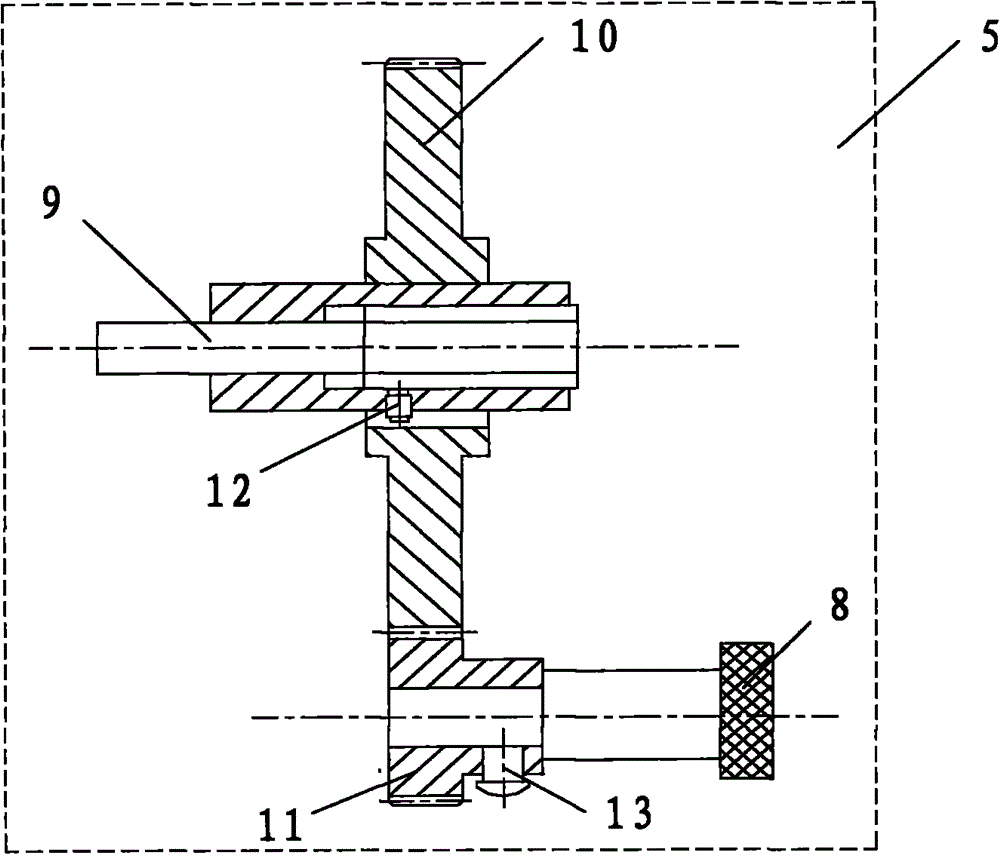

[0017] Such as figure 1 The schematic diagram of the overall structure of the zero position adjustment device for torque motor magnetic performance parameter testing in the present invention is shown, wherein the measuring rod 2 is rigidly connected with the components to be zeroed in the torque motor 1, and the top of the measuring rod 2 is inserted between the chucks 3 , The collet 3 is installed on the collet mounting seat 7, one end of the micro force sensor 4 is fixed on the collet mounting seat 7 through threads, and the other end is connected with the micro-motion mechanism 5 through threads. By adjusting the adjustment screw 6 on the left side of the collet 3, the collet 3 can clamp the measuring rod 2, and manually push the torque motor 1 to move it along the axial direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com