High-load micro-mechanism dynamic characteristic testing apparatus

A technology for dynamic characteristics and testing devices, which is applied in measurement devices, testing/calibration of speed/acceleration/shock measuring equipment, speed/acceleration/shock measurement, etc., and can solve problems such as high working environment requirements and dynamic performance of difficult-to-micro components , to achieve the effect of strong environmental adaptability and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

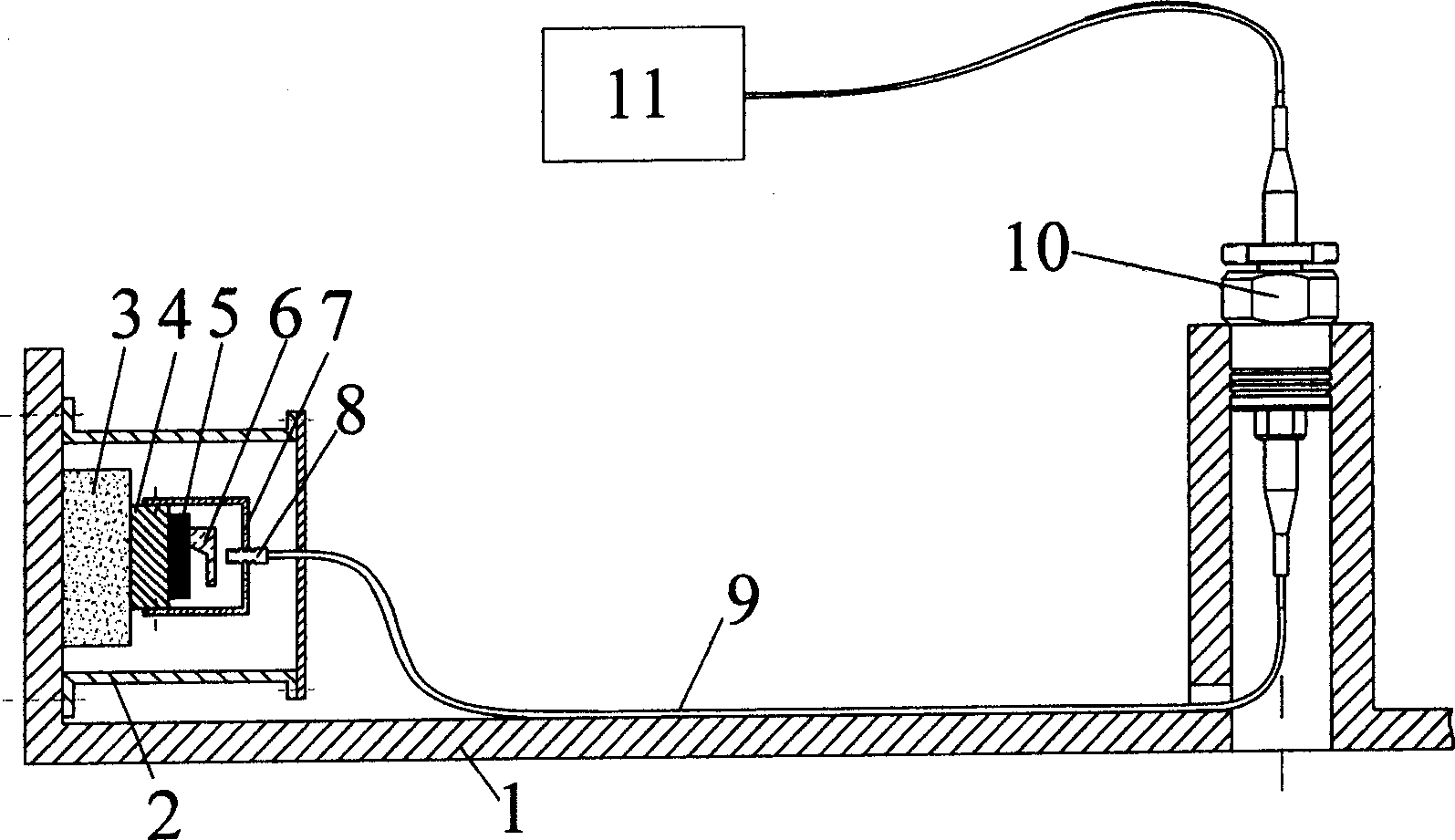

[0009] The specific implementation of the present invention is described in detail in conjunction with the accompanying drawings. The present invention is a high-load micro-component dynamic characteristic testing device. Under the action of external inertial load, the natural frequency of a typical micro-component—micro-cantilever beam changes, thereby affecting the micro-component. Dynamic properties of components. In order to test the change of the dynamic characteristics of the micro-components in the micro-mechanical accelerometer under high-load conditions, the high-speed turntable 1 is rotated, and the inertial centrifugal force is generated during the rotation to form a high-g acceleration environment. The micro-component 6 is installed on the rotating arm of the high-speed turntable In the above, different centripetal accelerations are generated by adjusting the rotation speed of the high-speed turntable 1 to simulate various acceleration environments with high g value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com