Railway tunnel bottom defect treatment technology based on assembly type beam slab pile

A disease remediation and prefabricated technology, applied in infrastructure engineering, construction, etc., can solve the problems of slow construction speed, poor quality, large amount of engineering, etc., and achieve the effect of fewer construction procedures, faster construction speed, and less masonry work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

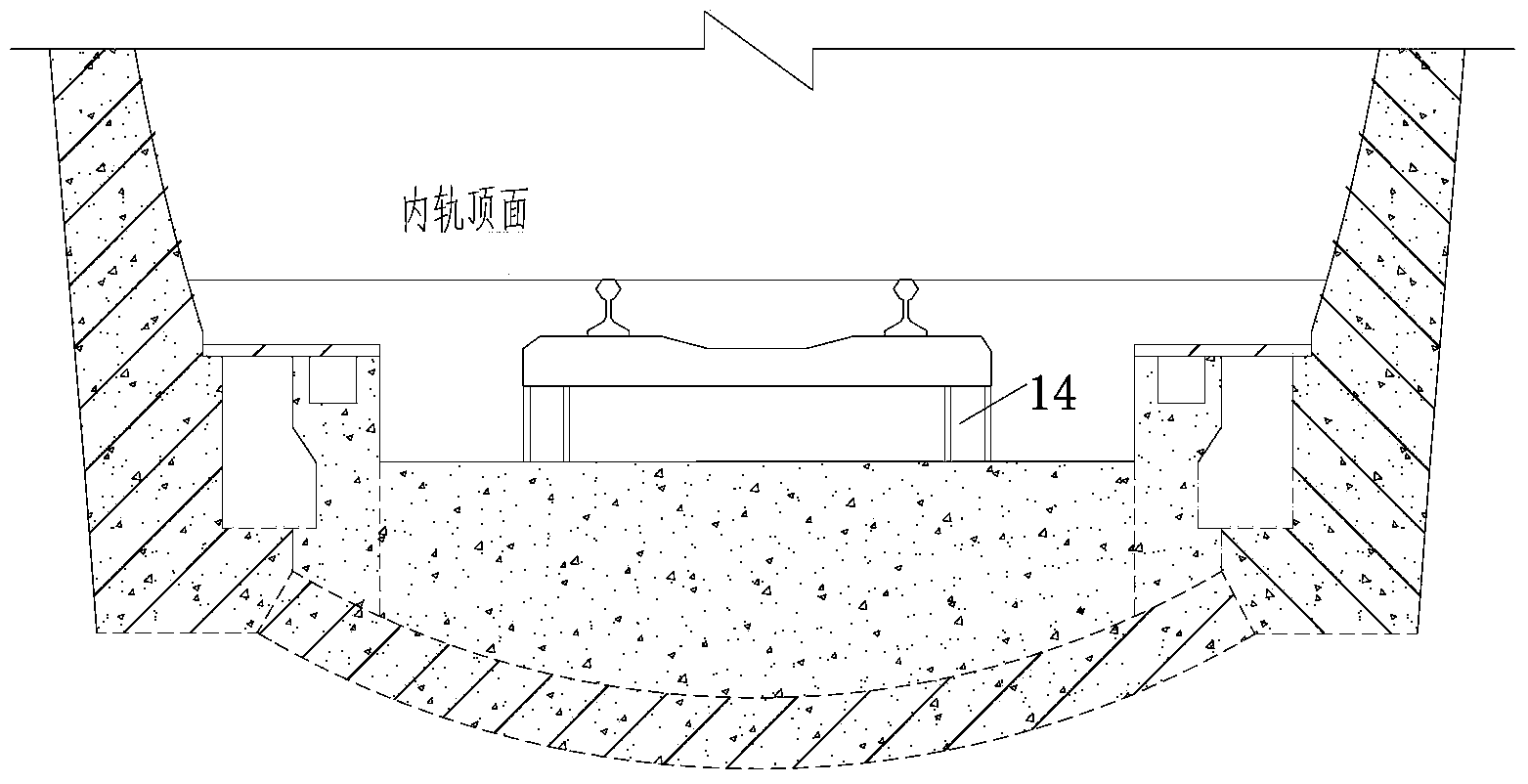

[0026] (1) if figure 2 and image 3 Ballast (12) is removed and rails and concrete ties (18) are supported with restraint beams (14) as shown.

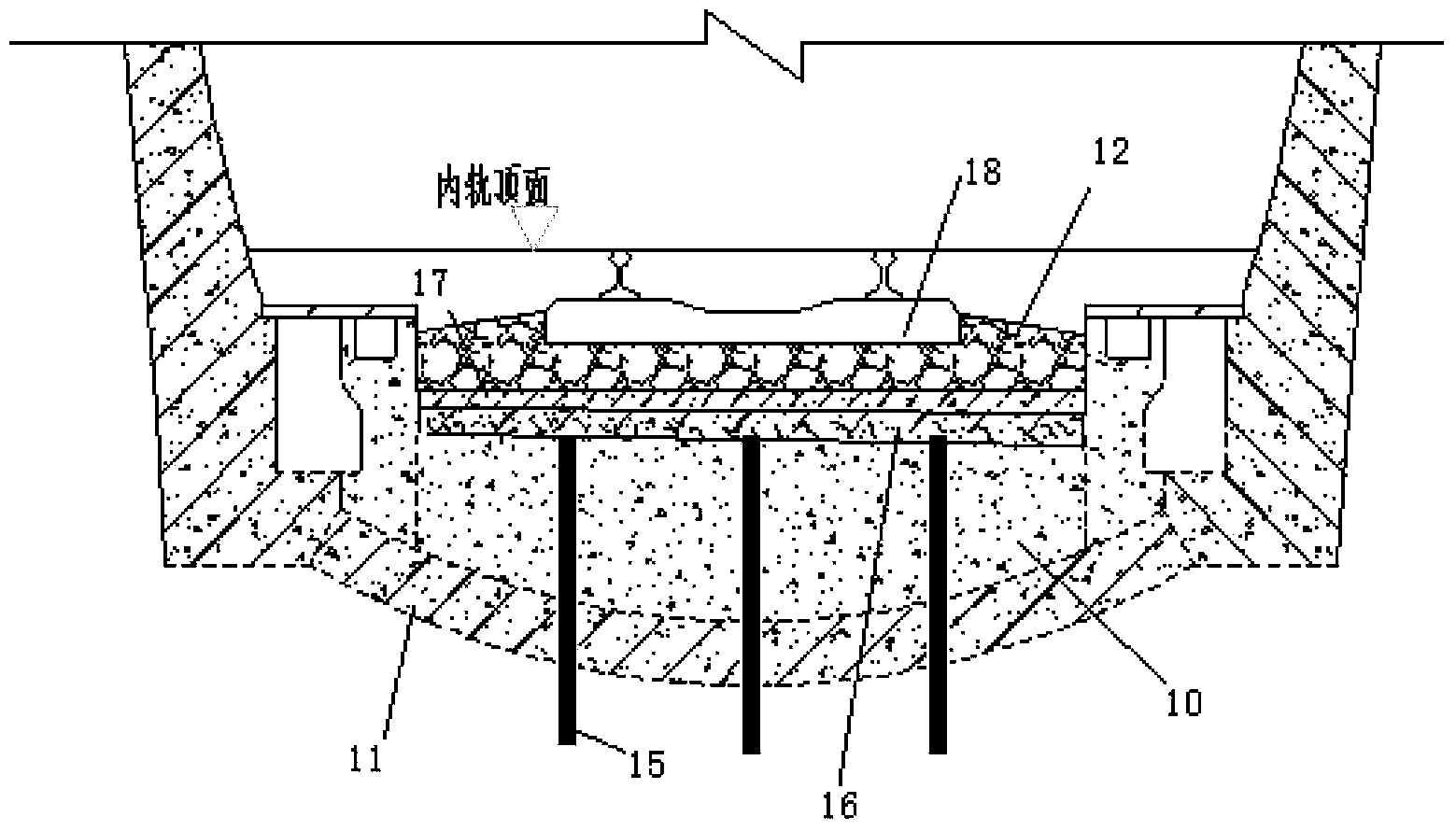

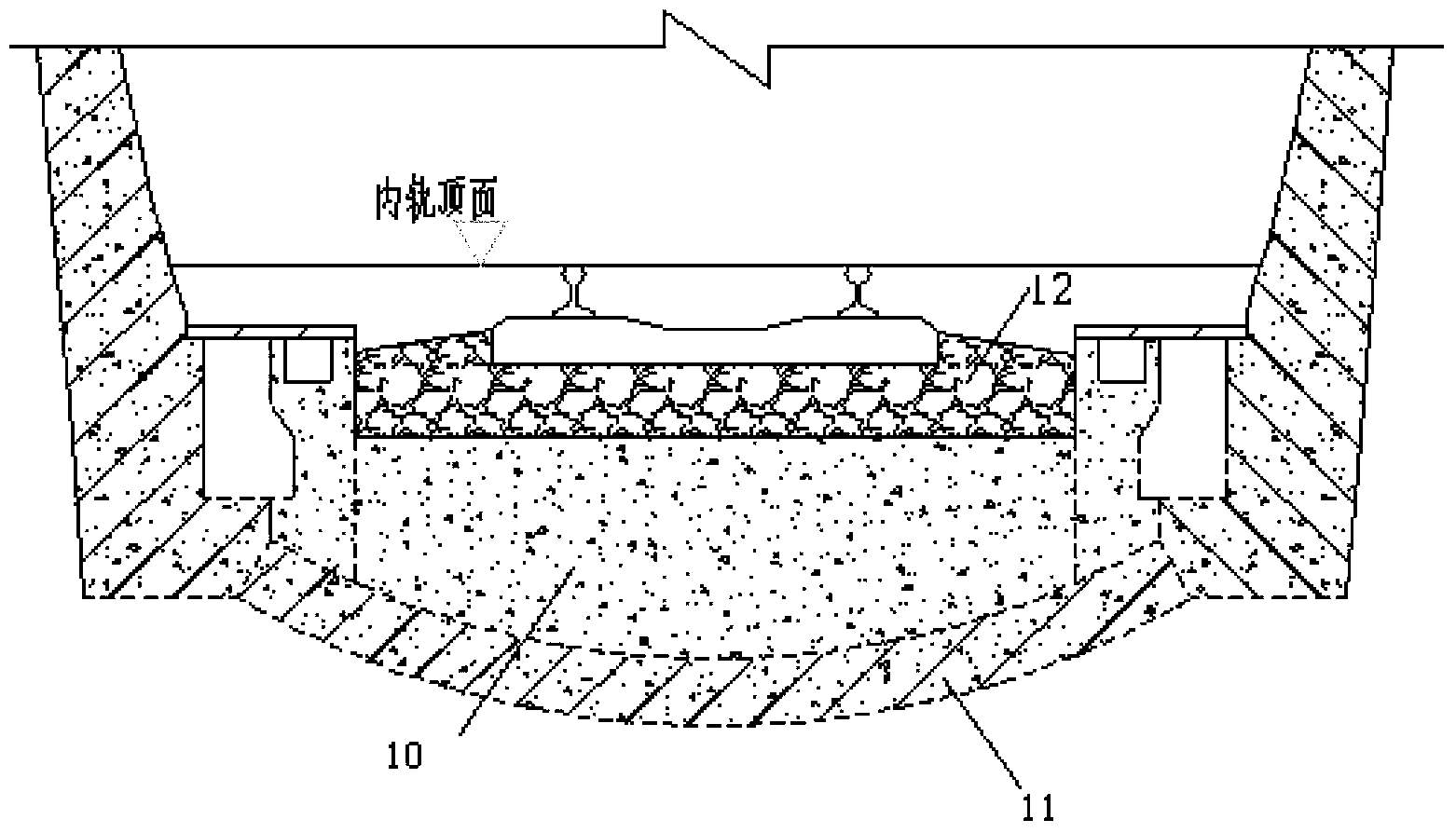

[0027] (2) Excavate slots for placing beams (16) and drill holes (15) for placing piles according to the predetermined positions in the design. The holes should pass through the concrete filling layer (10) and inverted arch (11) to reach more than 50cm of bedrock. Such as Figure 4 and Figure 6 shown.

[0028] (3) After the slotting and drilling process is completed, put the prefabricated steel pipe pile into the drilled hole, and fill the gap between the pile and the hole with grout. Such as Figure 5 and Figure 7 shown.

[0029] (4) After the grout is solidified, lay the prefabricated beams (16) and prefabricated slabs (17), and backfill the ballast, such as Figure 5 and Figure 8 shown. Start the construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com