Robot dual-joint unit as well as foot robot applying robot dual-joint unit and cooperative mechanical arm

A robot, double-joint technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of demanding wire fatigue strength, increasing moment of inertia, load and power consumption, and easily interfering with the external environment, etc. To achieve the effect of reducing the difficulty of wiring, the scheme is feasible, and the structure is simple and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

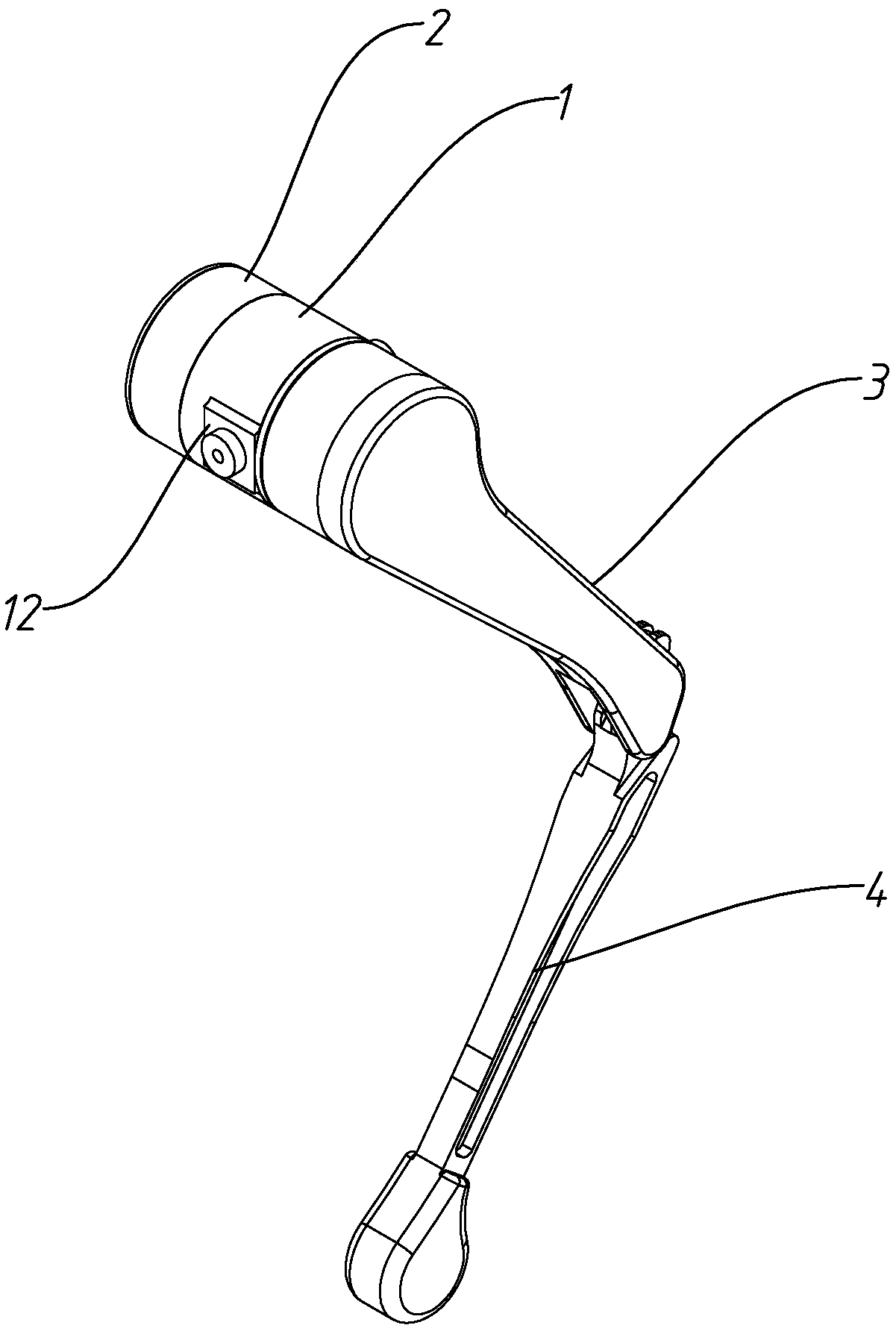

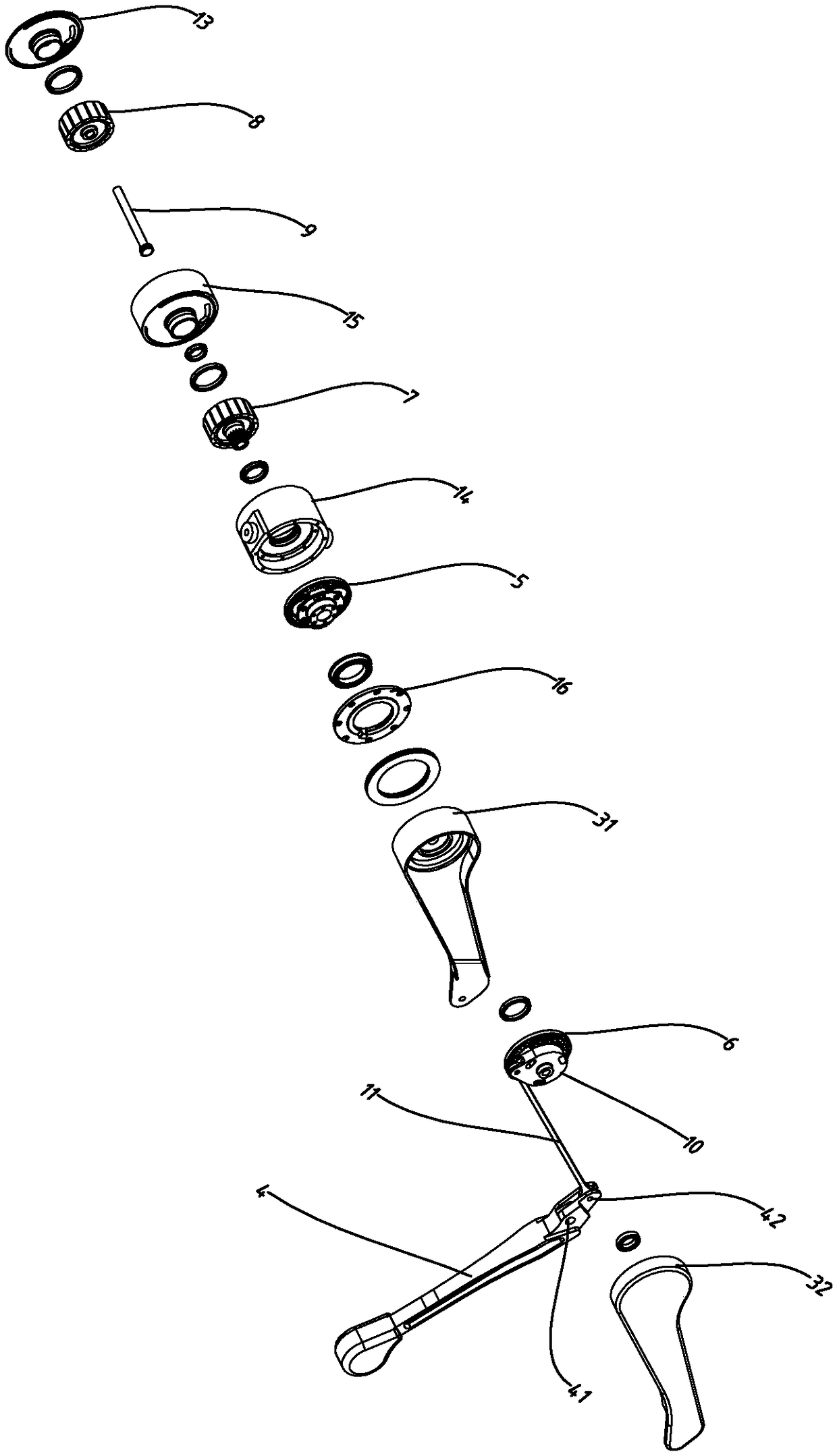

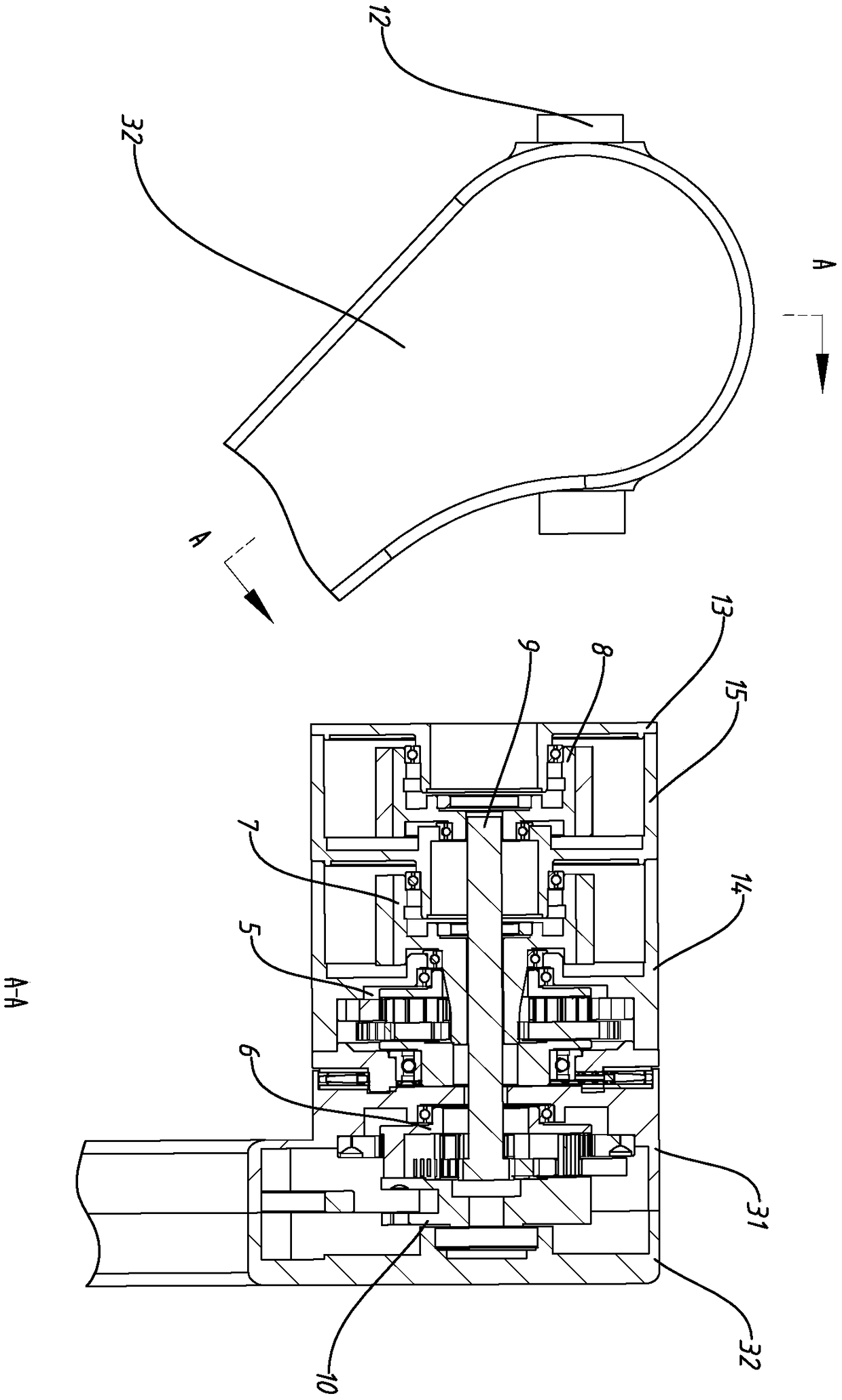

[0039] Such as figure 1 , figure 2 As shown, the highly integrated robot double-joint unit includes the first joint composed of the first motor and reducer assembly 1, the second joint composed of the second motor assembly 2 and the second reducer 6; the first motor and reducer A first output connecting rod 3 is fixed on the output shaft of the gear assembly 1 , and a second reducer 6 is arranged in the first output connecting rod 3 , and the second motor assembly 2 drives the second reducer 6 through a transmission rod 9 .

[0040] The first motor and reducer assembly 1 includes the first motor base 14, the first motor stator, the first motor rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com