Unsaturated polyester resin composite material for furniture and preparation method thereof

A technology of polyester resin and composite materials, which is applied in the field of unsaturated polyester resin composite materials for furniture and its preparation, can solve the problems of unsatisfactory overall mechanical properties and flame retardancy, and meet modern environmental protection requirements and excellent overall mechanical properties. Performance and flame retardant performance, the effect of protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

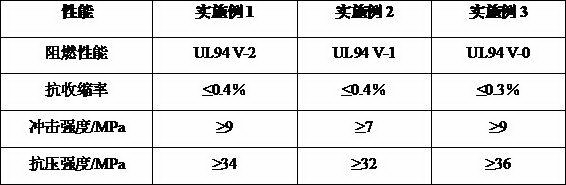

Embodiment 1

[0022] In this embodiment, the preparation method of the unsaturated polyester resin composite material for furniture comprises the following steps in sequence:

[0023] (1) Weigh the following raw materials: 100 kg of unsaturated polyester resin (both 191 # Unsaturated polyester resin), 30 kg of modified bamboo fiber, 40 kg of flame retardant (both are phosphorus-containing expandable graphite-ammonium polyphosphate compound flame retardant), 2 kg of accelerator (both are cobalt naphthenate) , 1.5 kg of initiator (including 0.8 kg of cyclohexanone peroxide and 0.7 kg of benzoyl peroxide), 1 kg of defoamer (both polydimethylsiloxane), 6 kg of coupling agent (both isocyanate Propyltriethoxysilane coupling agent);

[0024] (2) Mix the coupling agent, modified bamboo fiber and flame retardant evenly at 35°C to obtain the coupling agent pretreatment mixture;

[0025] (3) Mix the coupling agent pretreatment mixture obtained in step (2) with the unsaturated polyester resin, accele...

Embodiment 2

[0032] In this embodiment, the preparation method of the unsaturated polyester resin composite material for furniture comprises the following steps in sequence:

[0033] (1) Weigh the following raw materials: 100 kg of unsaturated polyester resin (both 191 # Unsaturated polyester resin), 40 kg of modified bamboo fiber, 50 kg of flame retardant (both are phosphorus-containing expandable graphite-ammonium polyphosphate compound flame retardant), 0.5 kg of accelerator (both are zinc naphthenate) , 0.8 kg of initiator (both methyl ethyl ketone), 2 kg of defoamer (both polyacrylamide), 1 kg of coupling agent (both isocyanate propyl triethoxysilane coupling agent);

[0034] (2) Mix the coupling agent, modified bamboo fiber and flame retardant evenly at 25°C to obtain the coupling agent pretreatment mixture;

[0035] (3) Mix the coupling agent pretreatment mixture obtained in step (2) with the unsaturated polyester resin, accelerator, initiator and defoamer prepared in step (1), and...

Embodiment 3

[0042] In this embodiment, the preparation method of the unsaturated polyester resin composite material for furniture comprises the following steps in sequence:

[0043] (1) Weigh the following raw materials: 100 kg of unsaturated polyester resin (both 191 # Unsaturated polyester resin), 20 kg of modified bamboo fiber, 20 kg of flame retardant (both are phosphorus-containing expandable graphite-ammonium polyphosphate compound flame retardant), 3 kg of accelerator (both are cobalt naphthenate) , initiator 2 kg (both methyl ethyl ketone peroxide), defoamer 0.5 kg (both polydimethylsiloxane), coupling agent 10 kg (both isocyanate propyl triethoxysilane coupling agent) ;

[0044] (2) Mix the coupling agent, modified bamboo fiber and flame retardant evenly at 45°C to obtain the coupling agent pretreatment mixture;

[0045] (3) Mix the coupling agent pretreatment mixture obtained in step (2) with the unsaturated polyester resin, accelerator, initiator and defoamer prepared in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com