Manufacturing method of fan blade and special prestress applying device thereof

A manufacturing method and application device technology, applied in the field of fan blade manufacturing, can solve problems such as the reduction of mechanical properties of uniaxial composite materials, and achieve the effects of improving overall mechanical properties, lightweight and efficient design, and improving static strength and fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

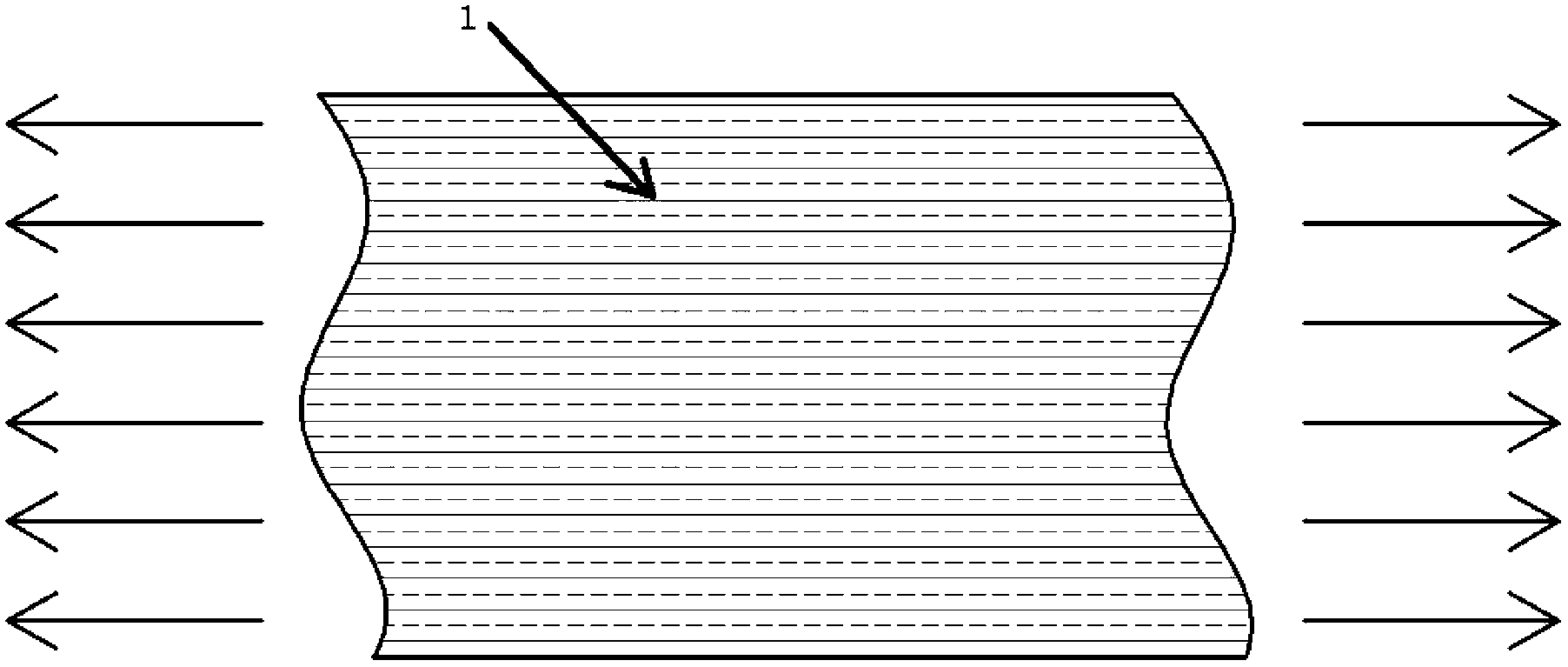

[0027] The main steps of the existing manufacturing method for fan blades include lamination and laying of uniaxial fiber fabrics on the blade mold, and then infusion of reinforcing resin. Using the above method, the uniaxial fiber fabrics will be slightly bent during laying, resulting in The mechanical properties of uniaxial composites are reduced.

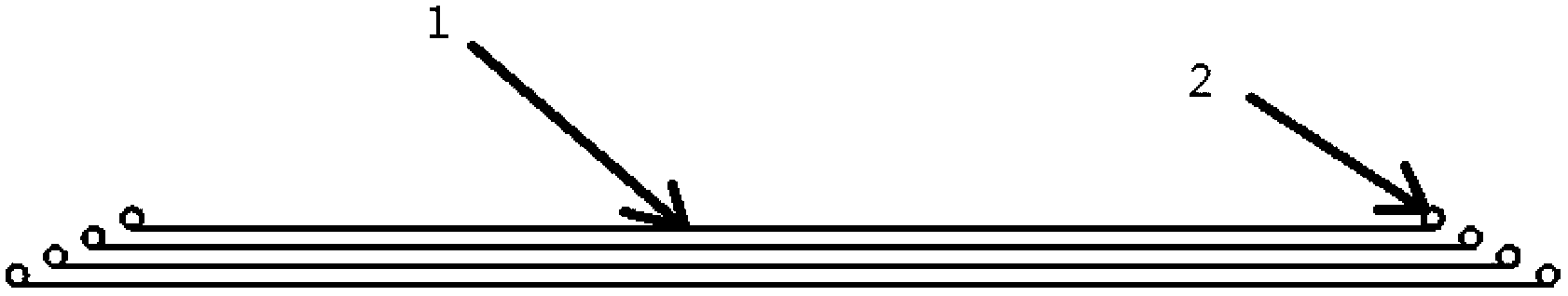

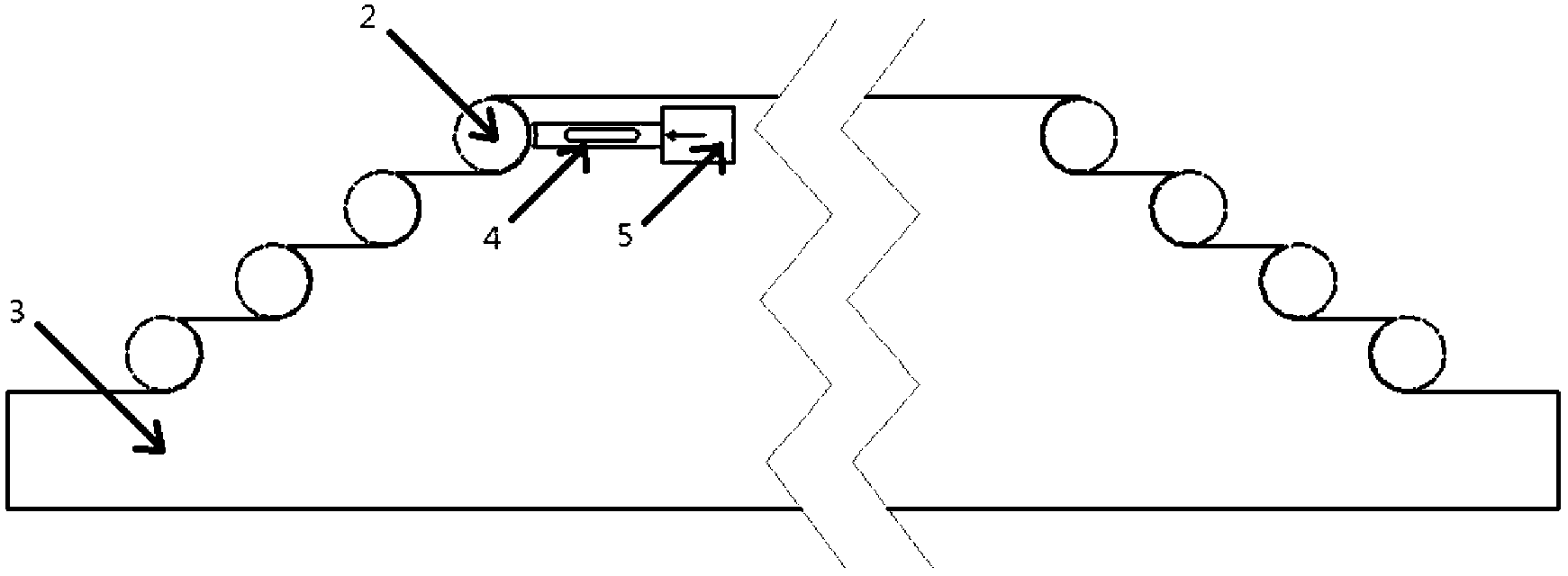

[0028] A method for manufacturing fan blades according to the present invention improves the above method, mainly in the process of laminating the uniaxial fiber fabric (glass fiber or carbon fiber fabric) by utilizing the prestressed force fixed on the blade mould. The applicator applies prestress to the uniaxial fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com