Composite material laying profile structure and forming process thereof

A technology of composite materials and molding process, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of inability to obtain comprehensive mechanical properties, achieve the effect of improving the overall mechanical properties and avoiding the decline in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

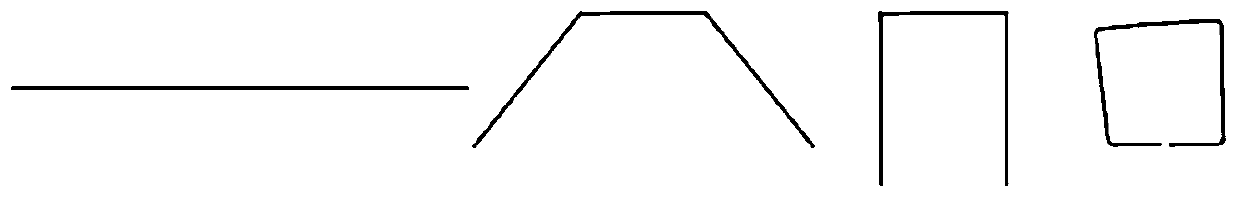

[0023] Without loss of generality, in this embodiment, the composite material lay-up profile with the cross-sectional shape shown in the figure is used as the main body of description, and the technical solution of the composite material lay-up structure is described in detail. It should be understood that the specific shape and number of internal cavities of the profile structure body do not constitute a substantial limitation on the technical solution claimed in this application.

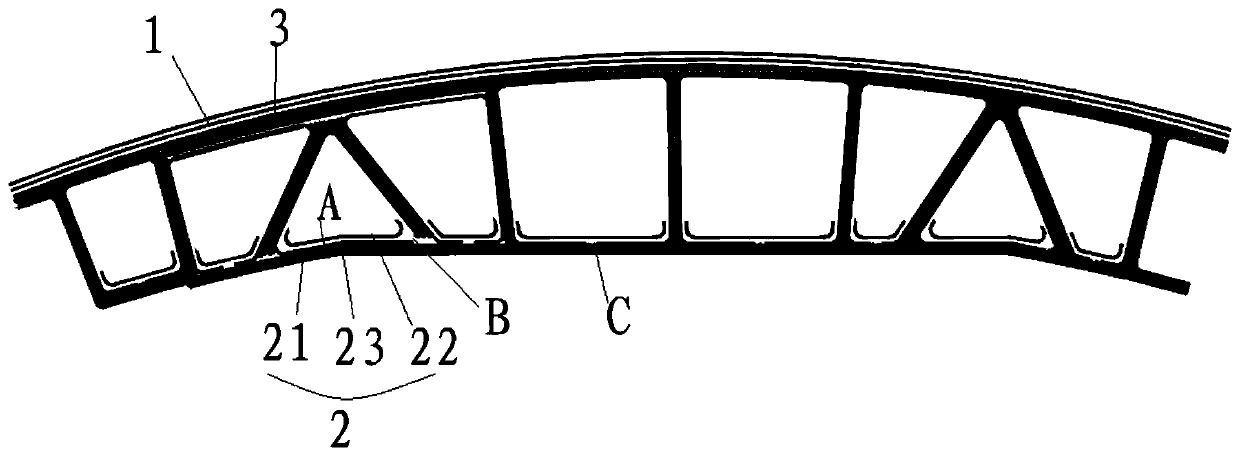

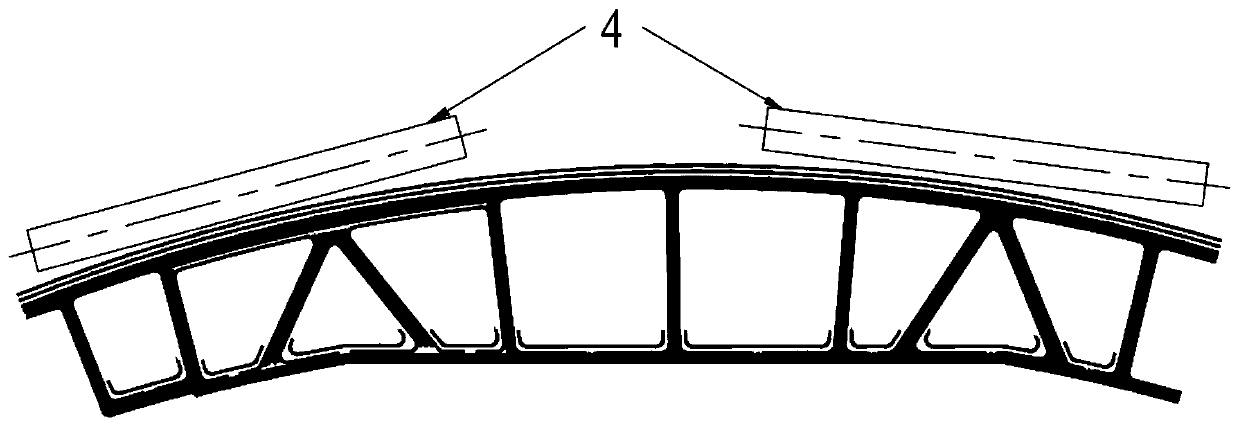

[0024] Please also see figure 1 , which is a schematic cross-sectional view of the composite material laminate profile structure.

[0025] As shown in the figure, the profile structure is formed by the combination of multi-axial cloth and un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com