Synchronous switched reluctance motor

A reluctance motor and synchronous switch technology, which is applied to synchronous motors, electric components, electrical components, etc. for single-phase current, can solve the problems of complex rotor structure of synchronous reluctance motors, large torque pulsation of switched reluctance motors, convex problems such as extremely small, to achieve the effect of simple structure, small current pulsation, and avoidance of Lq increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

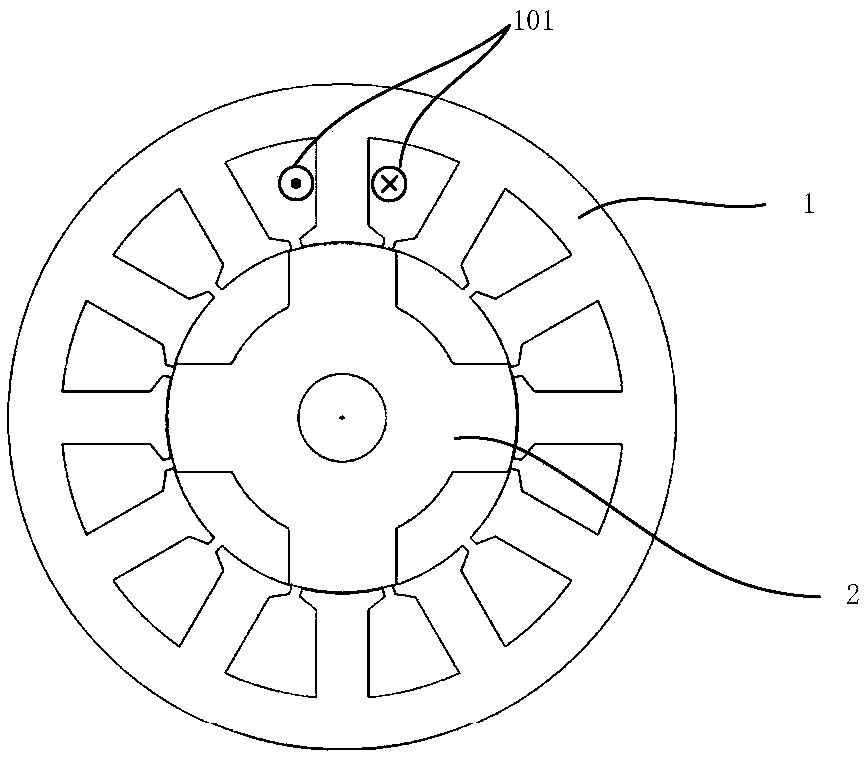

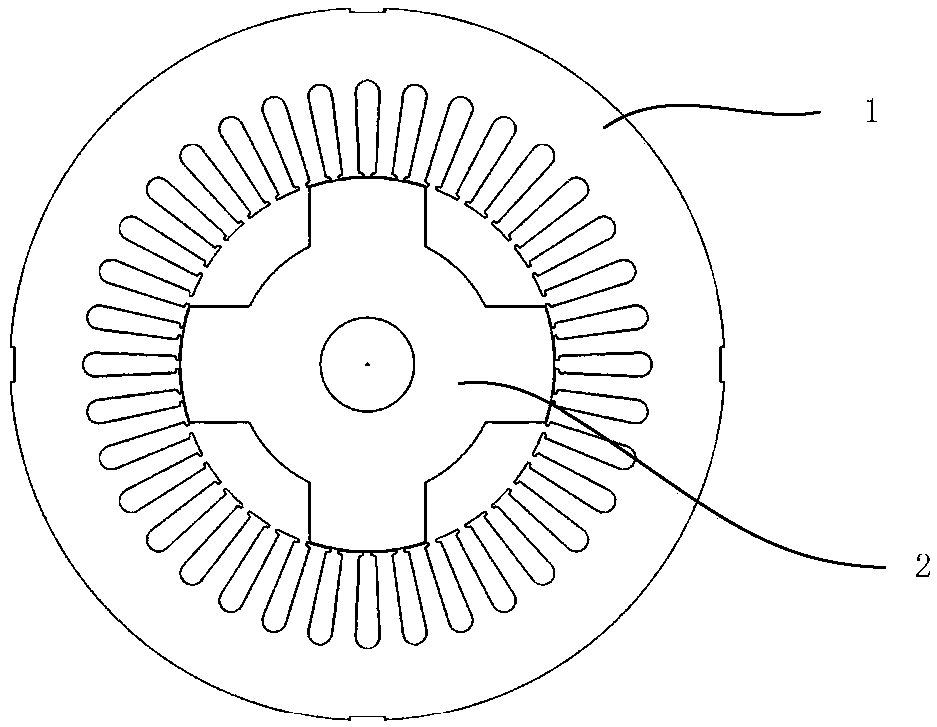

[0043] Synchronous switched reluctance motor with radial magnetic circuit, figure 1 Schematic diagram of centralized winding for synchronous switched reluctance motor; figure 2 Schematic diagram of cogging using distributed windings for a synchronous switched reluctance motor. from figure 1 It can be seen that the stator winding 101 is wound directly on the stator teeth. The number of slots of the three-phase stator 1 is s=3*n*2p, where n is the number of slots per pole and phase, n=0.5, 1, 2, 3, 4, 5...; p is the number of pole pairs, p = 1, 2, 3, 4, 5 . . .

[0044] The three-phase stator 1 is installed inside the casing 4, the salient pole rotor 2 is installed on the shaft 6, and is installed on the casing 4 through the shaft 6, and the rotor position sensor 3 is installed at one end of the shaft 6;

[0045] The three-phase stator 1 and the salient pole rotor 2 form an axial radial magnetic circuit. The salient pole rotor 2 does not contain permanent magnets, does not ...

Embodiment 2

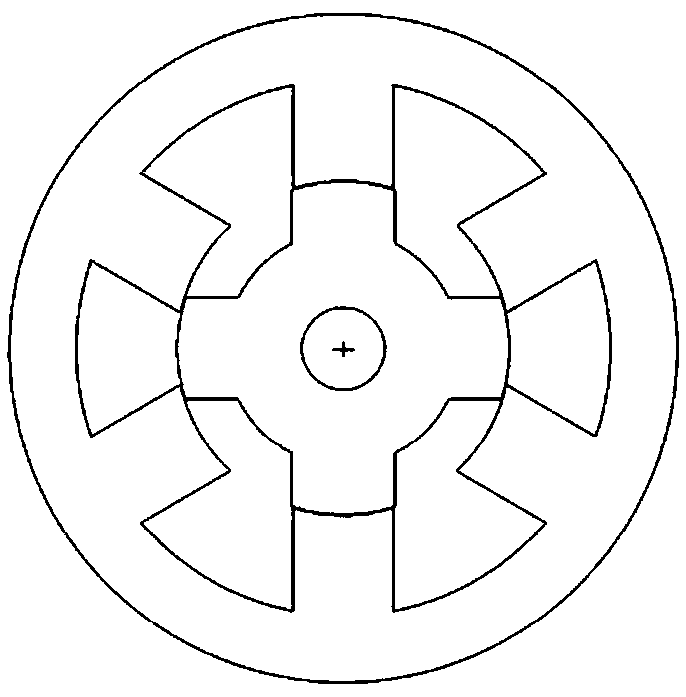

[0051] Another embodiment of the synchronous switched reluctance motor of the present invention is a synchronous switched reluctance motor with an axial magnetic circuit, see Figure 12 , the three-phase stator 1 and the salient pole rotor 2 are divided into two halves and installed opposite to each other, with a small air gap inserted in the middle, and the magnetic field generated by the three-phase stator 1 passes through the air gap parallel to the axis 6 to reach the salient pole through the motor controller 5 The rotor 2 forms a loop of magnetic lines of force. Its control effect is the same as that of the synchronous switched reluctance motor with radial magnetic circuit, see figure 1 , figure 2 .

[0052] When the synchronous switched reluctance motor forms an axial magnetic circuit, the diameters of the stator and the rotor are the same, the stator and the rotor are axially opposite, and the number of slots of the three-phase stator 1 is s=3*n*2p, where n is each p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com