Modified antistatic polypropylene material and preparation method thereof

A polypropylene material and antistatic technology, which is applied in the field of modified antistatic polypropylene material and its preparation, can solve the problems of mechanical properties such as the decrease of toughness, and achieve the effect of improving the overall mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

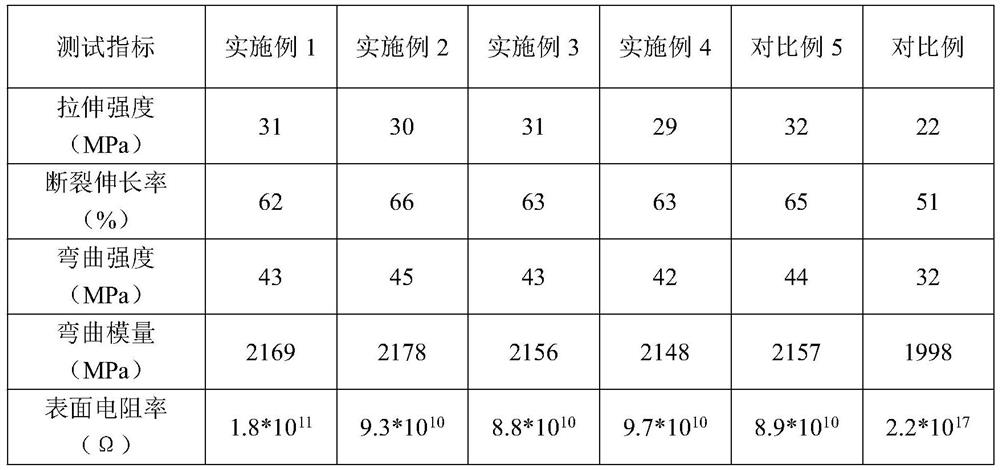

Examples

Embodiment 1

[0024] A modified antistatic polypropylene material, comprising the following components in parts by weight, 115 parts of homopolypropylene, 25 parts of glass fiber, 16.5 parts of ethylene-octene copolymer, 2-acrylamido-2-methyl - 6.5 parts of 1-propanesulfonic acid, 8.5 parts of CNT conductive masterbatch, 5.5 parts of glyceryl monostearate, 13 parts of graphene, 14.5 parts of dispersant P12, 1.5 parts of hindered phenolic antioxidant, calcium stearate 2.5 parts, of which the specific surface area of graphene is 210m 2 / g, particle size D50﹤10μmm.

[0025] Its preparation method is: S1) Weigh each component according to parts by weight, mix homopolypropylene, glass fiber, ethylene-octene copolymer, 2-acrylamido-2-methyl-1-propanesulfonic acid, CNT conductive masterbatch, glyceryl monostearate, graphene, dispersant P121, hindered phenolic antioxidant, calcium stearate and mix evenly; S2) Put the mixture obtained in S1 into the mixer and mix for 5 minutes; S3 ) The mixture ...

Embodiment 2

[0027] A modified antistatic polypropylene material, comprising the following components in parts by weight, 100 parts of homopolypropylene, 30 parts of glass fiber, 13.5 parts of ethylene propylene rubber, 2-acrylamido-2-methyl-1- 10 parts of propanesulfonic acid, 6 parts of CNT conductive masterbatch, 7.5 parts of glyceryl monostearate, 12.5 parts of graphene, 3.5 parts of dispersant P121, 1 part of hindered phenolic antioxidant, 2.5 parts of calcium stearate, Among them, the specific surface area of graphene is 240m 2 / g, particle size D50﹤10μmm.

[0028] The preparation method is as follows: S1) Weigh each component according to parts by weight, mix homopolypropylene, glass fiber, ethylene-propylene rubber, 2-acrylamido-2-methyl-1-propanesulfonic acid, CNT conductive mother granules, glyceryl monostearate, graphene, dispersant P121, hindered phenolic antioxidant, calcium stearate and mix evenly; S2) put the mixture obtained in S1 into a mixer and mix for 5 minutes; S3) ...

Embodiment 3

[0030] A modified antistatic polypropylene material, comprising the following components in parts by weight, 120 parts of homopolypropylene, 30 parts of glass fiber, 20 parts of ethylene-octene copolymer, 2-acrylamido-2-methyl -5 parts of 1-propanesulfonic acid, 10 parts of CNT conductive masterbatch, 8 parts of glyceryl monostearate, 10.5 parts of graphene, 4.5 parts of dispersant P121, 2.5 parts of hindered phenolic antioxidant, zinc stearate 1.5 parts, wherein the specific surface area of graphene is 280m 2 / g, particle size D50﹤10μmm.

[0031] Its preparation method is: S1) Weigh each component according to parts by weight, mix homopolypropylene, glass fiber, ethylene-octene copolymer, 2-acrylamido-2-methyl-1-propanesulfonic acid, CNT conductive masterbatch, glyceryl monostearate, graphene, dispersant P121, hindered phenolic antioxidant, zinc stearate and mix evenly; S2) Put the mixture obtained in S1 into the mixer and mix for 8 minutes; S3 ) The mixture obtained in S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com