High-temperature-resistant ablation carbon/ carborundum composite material fixing hinge and preparation method

A technology for fixing hinges and composite materials, which is applied in the field of high-temperature-resistant ablation carbon/silicon carbide composite material fixing hinges and its preparation, which can solve the problem of making fixed hinges without C/SiC composite materials, high-temperature alloy materials with high density, and difficult to meet the use requirements and other issues, to achieve the effect of improving the overall mechanical properties, improving fracture toughness, and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A method for preparing a high-temperature-resistant ablation carbon / silicon carbide composite fixed hinge, comprising the following steps:

[0064] (1) Design the structure and size of the fixed hinge

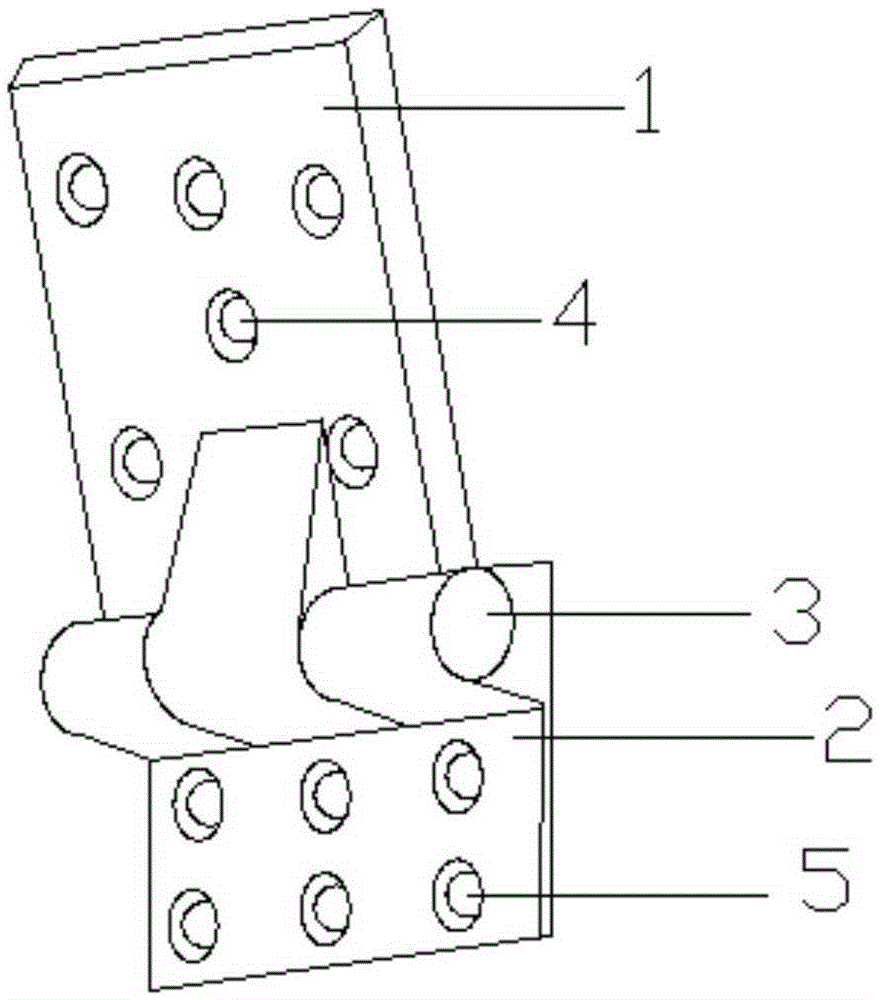

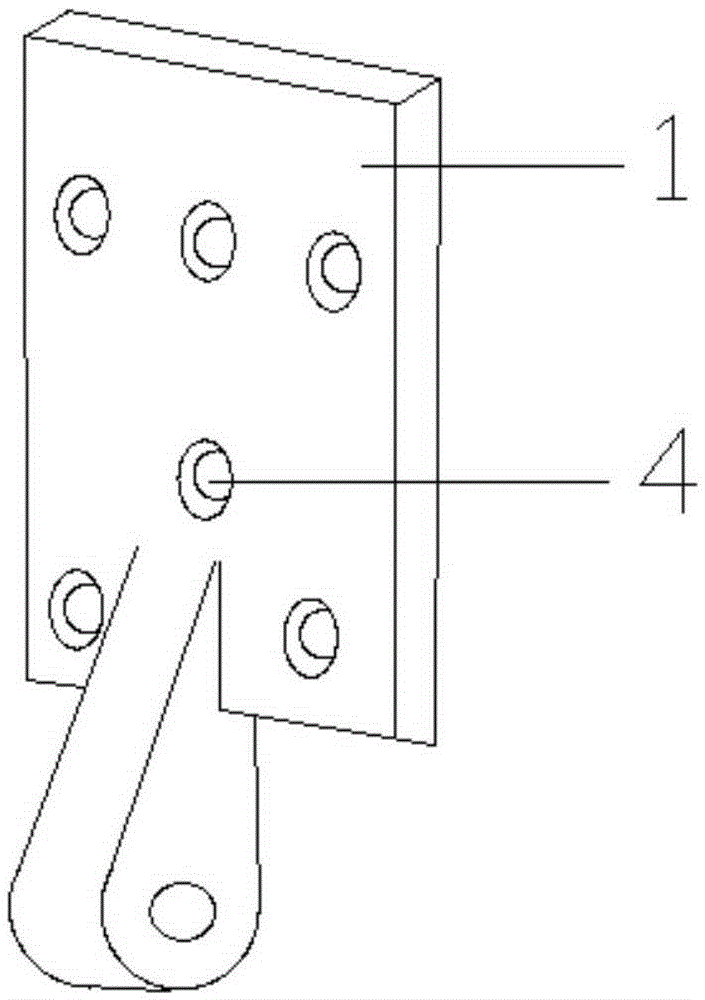

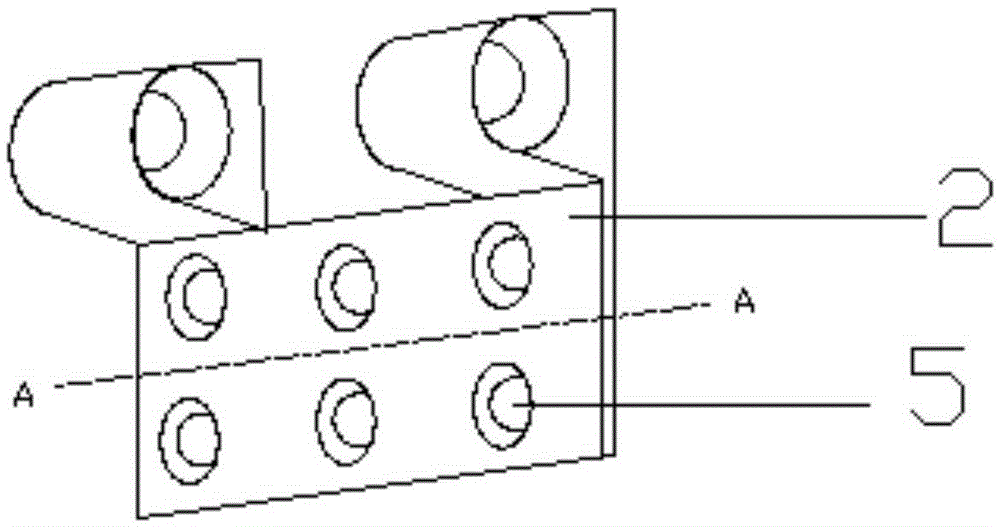

[0065] Such as Figure 1~4 As shown, according to the use of the fixed hinge in aerospace and specific extreme environments, the fixed hinge is designed as a hinged hinge structure, including the rotating shaft 3; the hinge upper support 1 has a first installation for connecting with the connected object Surface structure, the first installation surface structure is provided with 6 first through holes, through the first through holes 6, the fixing of the hinge upper support 1 and the connected object is realized; the hinge lower support 2 has a The second installation surface structure connected to the connected object, the second installation surface structure is provided with 6 second through holes 5, through the second through holes 6, the fixing of the hinge lower s...

Embodiment 2

[0089] A method for preparing a high-temperature-resistant ablation carbon / silicon carbide composite fixed hinge, comprising the following steps:

[0090] (1) Design the structure and size of the fixed hinge

[0091] Such as Figure 1~4 As shown, according to the use of the fixed hinge in aerospace and specific extreme environments, the fixed hinge is designed as a hinged hinge structure, including the rotating shaft 3; the hinge upper support 1 has a first installation for connecting with the connected object Surface structure, the first installation surface structure is provided with 6 first through holes, through the first through holes 6, the fixing of the hinge upper support 1 and the connected object is realized; the hinge lower support 2 has a The second installation surface structure connected to the connected object, the second installation surface structure is provided with 6 second through holes 5, through the second through holes 6, the fixing of the hinge lower s...

Embodiment 3

[0115] A method for preparing a high-temperature-resistant ablation carbon / silicon carbide composite fixed hinge, comprising the following steps:

[0116] (1) Design the structure and size of the fixed hinge

[0117] Such as Figure 1~4 As shown, according to the use of the fixed hinge in aerospace and specific extreme environments, the fixed hinge is designed as a hinged hinge structure, including the rotating shaft 3; the hinge upper support 1 has a first installation for connecting with the connected object Surface structure, the first installation surface structure is provided with 6 first through holes, through the first through holes 6, the fixing of the hinge upper support 1 and the connected object is realized; the hinge lower support 2 has a The second installation surface structure connected to the connected object, the second installation surface structure is provided with 6 second through holes 5, through the second through holes 6, the fixing of the hinge lower s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com