Power generating lying energy recycling electric hydraulic pressure energy-saving balance beam type pumping machine

A beam pumping unit, electro-hydraulic technology, applied in the direction of mechanical equipment, mining fluid, wellbore/well components, etc., can solve the problems affecting the normal operation of the pumping unit, self-consumption of equipment, etc., to save electric energy, The effect of improving the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The invention is explained in more detail below with reference to preferred embodiments.

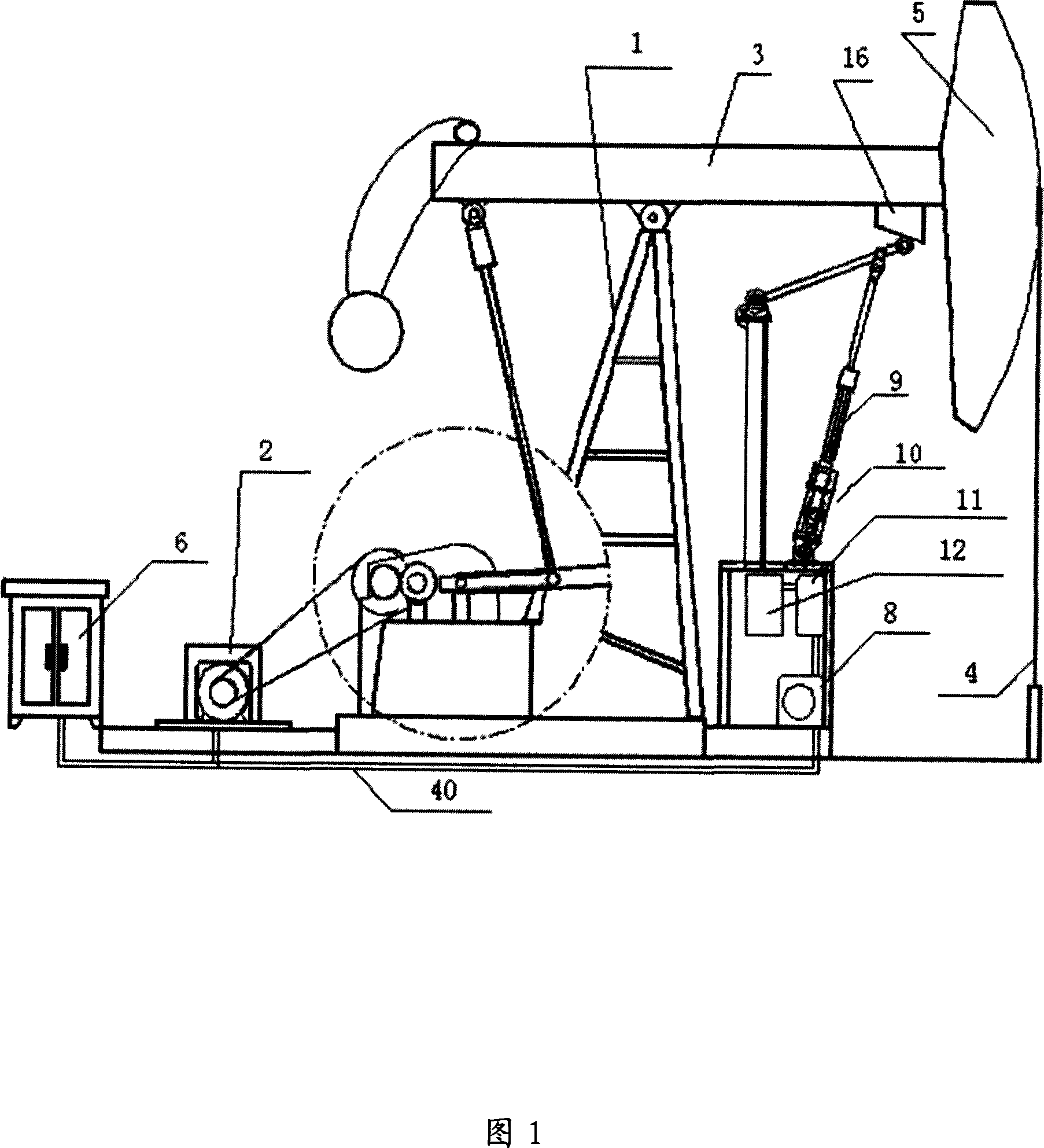

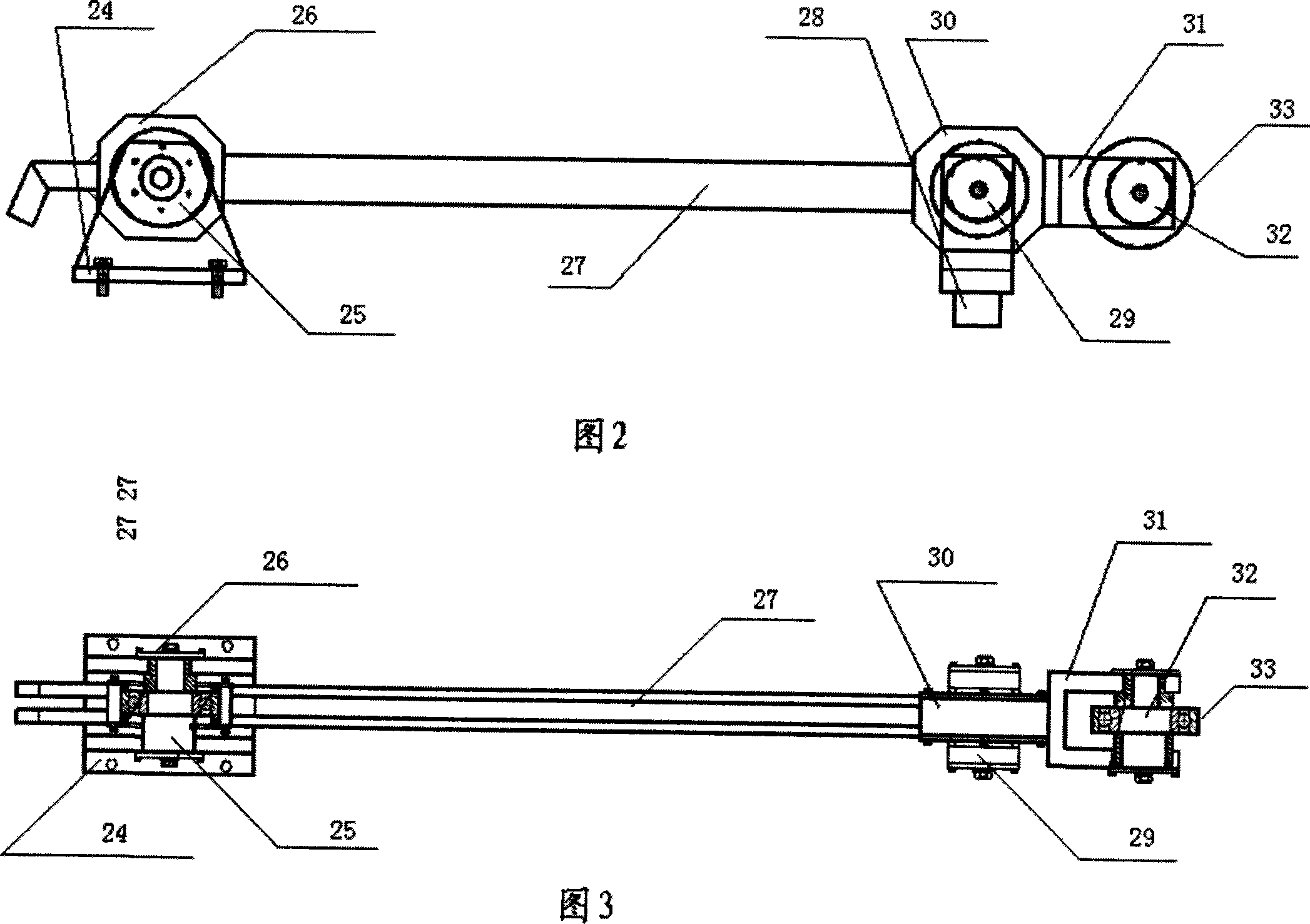

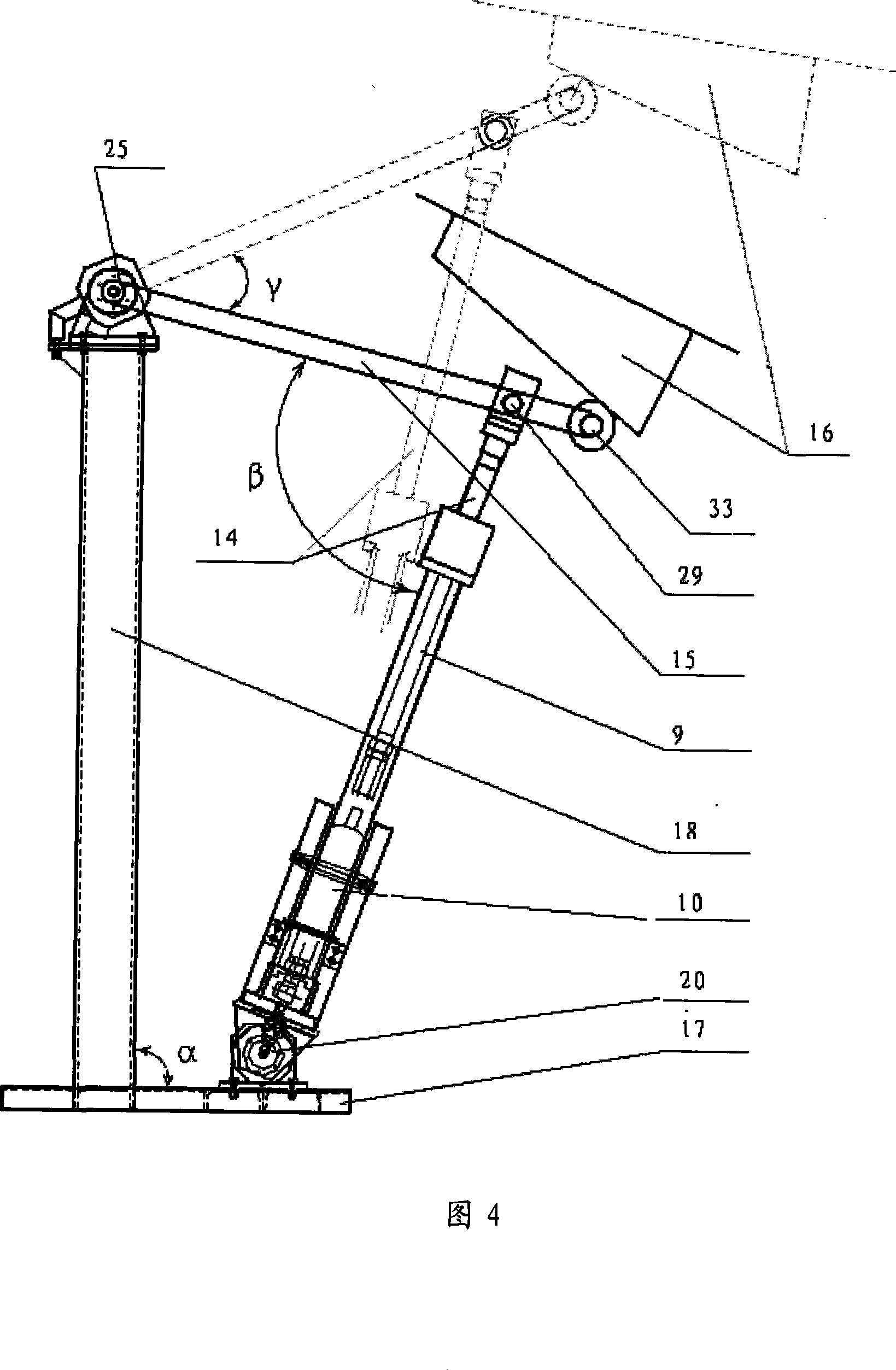

[0056] Please refer to Fig. 1 , the electrohydraulic energy-saving beam pumping unit of the present invention, which utilizes power state energy, includes a frame 1, a drive motor 2, a beam 3, a polished rod 4, a front donkey head 5, and an auxiliary hydraulic energy regeneration device. Wherein, a photoelectric position sensor (WZ) for detecting the position change of the beam is installed on the beam 3 . The auxiliary hydraulic energy regeneration device consists of two parts, the electronic control unit 6 and the hydraulic system. The hydraulic system mainly includes auxiliary support truss 7, movable contact mechanism, hydraulic pump 8, hydraulic cylinder 9, accumulator 10, hydraulic manifold 11, hydraulic auxiliary oil tank 12, hydraulic pipeline, accumulator bracket 13 and initialization motor 39 . The movable contact mechanism is arranged on the beam 3 close to the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com