Furnace top structure of heating furnace

A furnace top structure and heating furnace technology, applied in the direction of the furnace crown/roof, can solve the problems of easy falling of fiber folded blocks, shortening the service life of the furnace lining, and difficult repairs, so as to reduce costs, prolong service life and facilitate replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

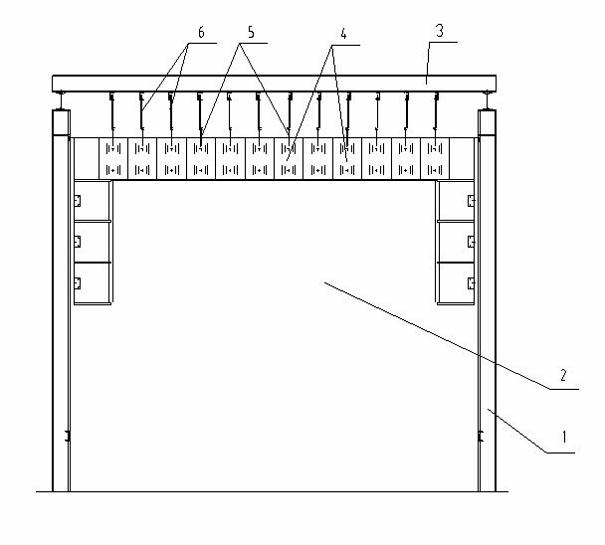

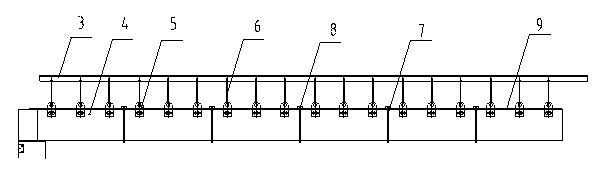

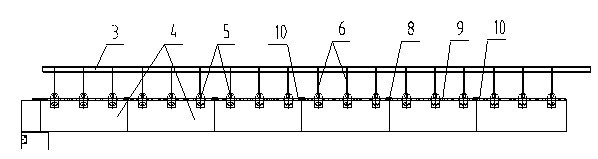

[0022] Such as figure 1 , 2 Among them, the roof structure of a heating furnace in the present invention includes a furnace body 1 of the heating furnace, the cavity in the furnace body 1 is a furnace 2, and several steel beams 3 are arranged above the furnace body 1, and the steel beams 3 The number of furnaces increases correspondingly according to the size of the furnace body 1, and the steel beams 3 with a certain interval between them, arranged in the same direction or arranged in a staggered manner, are used to set the furnace lining 4, and several furnace linings 4 are arranged (suspended) under the steel beams 3; the present invention The furnace lining 4 is an all-fiber furnace lining, which is a composite fiber containing zirconium fiber, chromium fiber, or zirconium fiber and chromium fiber. It belongs to the fiber module or fiber folding block of the prior art, has excellent high temperature resistance, and can adapt to To meet the needs of heating above ℃, the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com