Electric furnace device for component fire protection design and fire protection supervision and using method

A protection design, electric furnace technology, applied in furnace control devices, measuring devices, heat insulation devices, etc., can solve problems such as lack of reliability, increase in cost, and inability to quickly form supervision result reports, so as to reduce heating capacity and control System requirements, the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

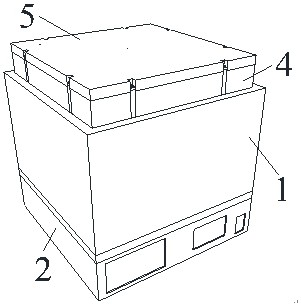

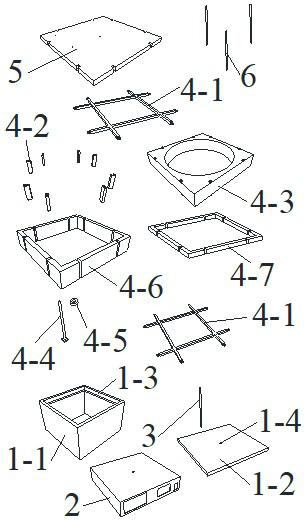

[0126] Such as Figure 1 to Figure 29 As shown, an electric furnace device for component fire protection design and fire supervision, including a furnace body 1 composed of a rectangular hollow furnace wall 1-1 and a square furnace cavity chassis 1-2, the rectangular hollow furnace wall 1-1 is equipped with a heating body To realize the heating in the furnace cavity, it also includes the control display transmission box 2, the furnace cavity thermocouple 3, the constrained heat insulation component 4, the heat insulation cover 5, and the additional thermocouple 6.

[0127] The upper end of the rectangular hollow furnace wall 1-1 is provided with a ring of L-shaped retracted cornices 1-3, and the center of the square furnace cavity chassis 1-2 is provided with a fixing hole 1-4.

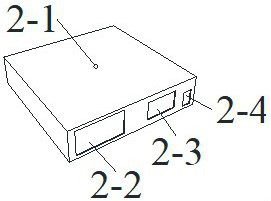

[0128] The control display transmission box 2 is a hollow rectangular box, and a through hole 2-1 is provided in the center of the upper surface of the control display transmission box 2, and a displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com