Vacuum coating device

A technology of vacuum coating and vacuum chamber, which is applied in the directions of vacuum evaporation coating, sputtering coating, ion implantation coating, etc., and can solve the problem of increasing the coating cycle, inconsistent characteristics of double-sided coating layers, and increasing the number of times of vacuuming, etc. problem, achieve the effect of reducing time cost, reducing the number of heating and vacuuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

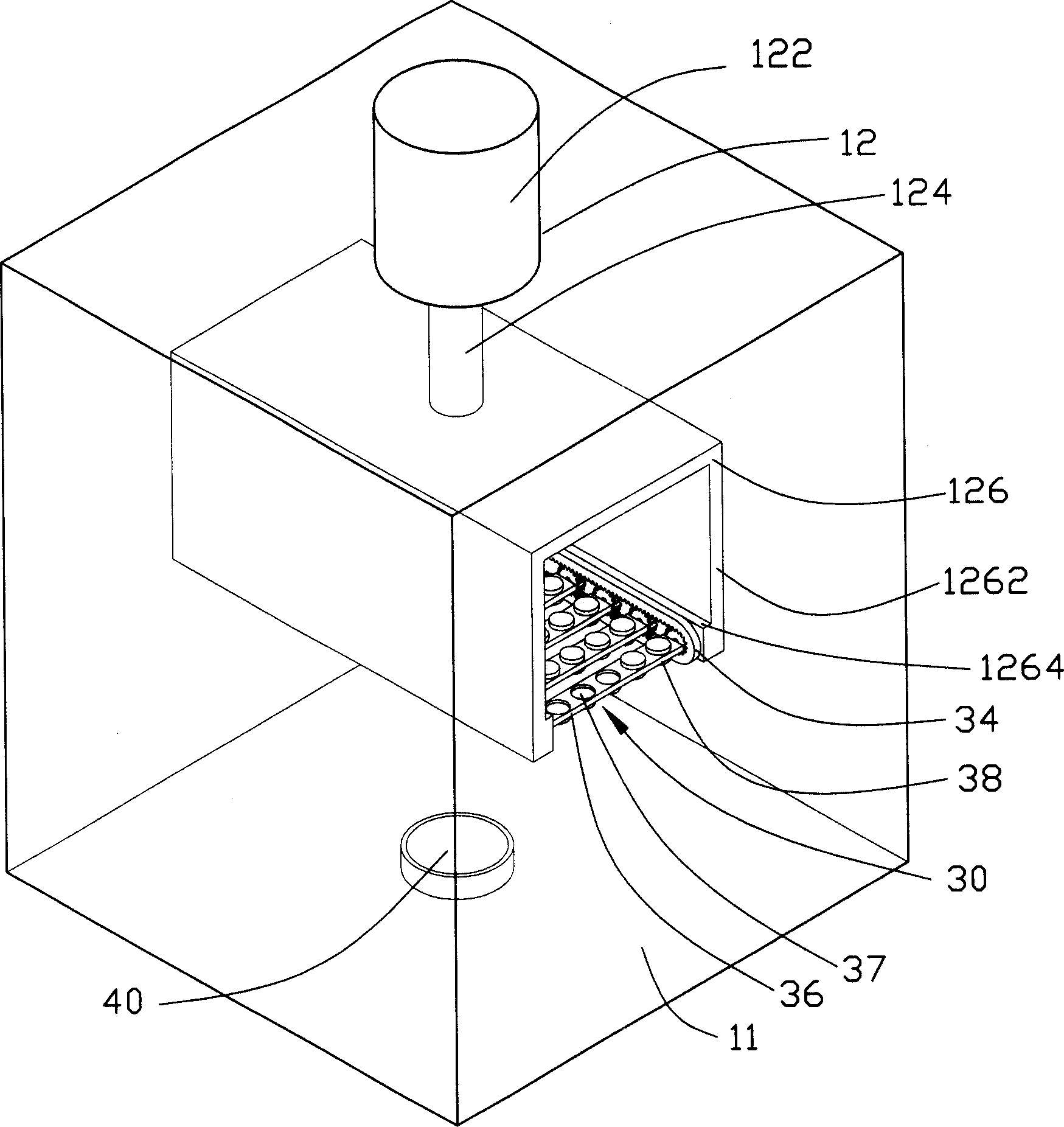

[0013] see figure 1 , The vacuum coating device 10 of the present invention comprises a vacuum chamber 11 , a rotating support assembly 12 , a substrate support frame 30 , a turning device 31 and at least one evaporation source 40 .

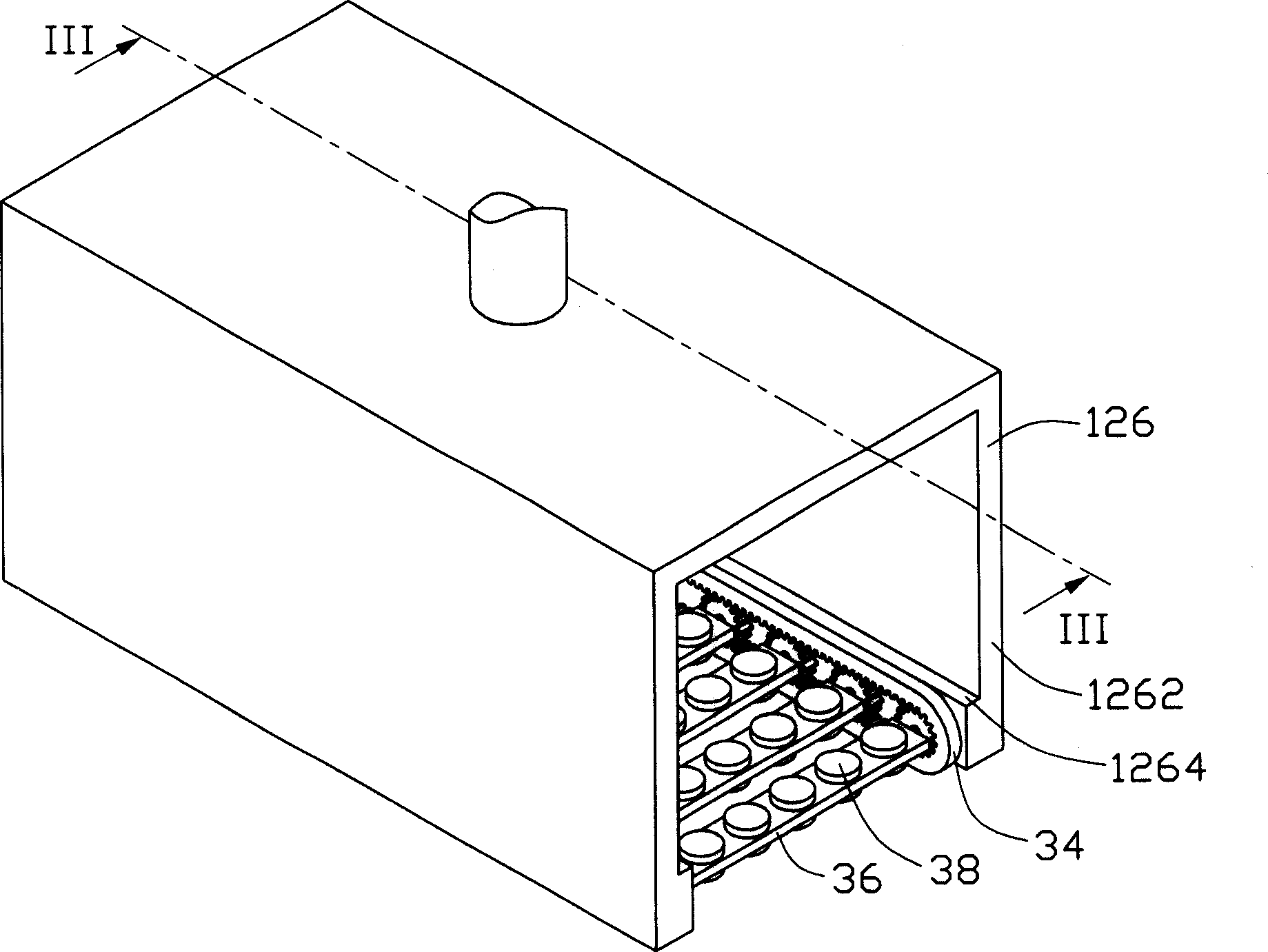

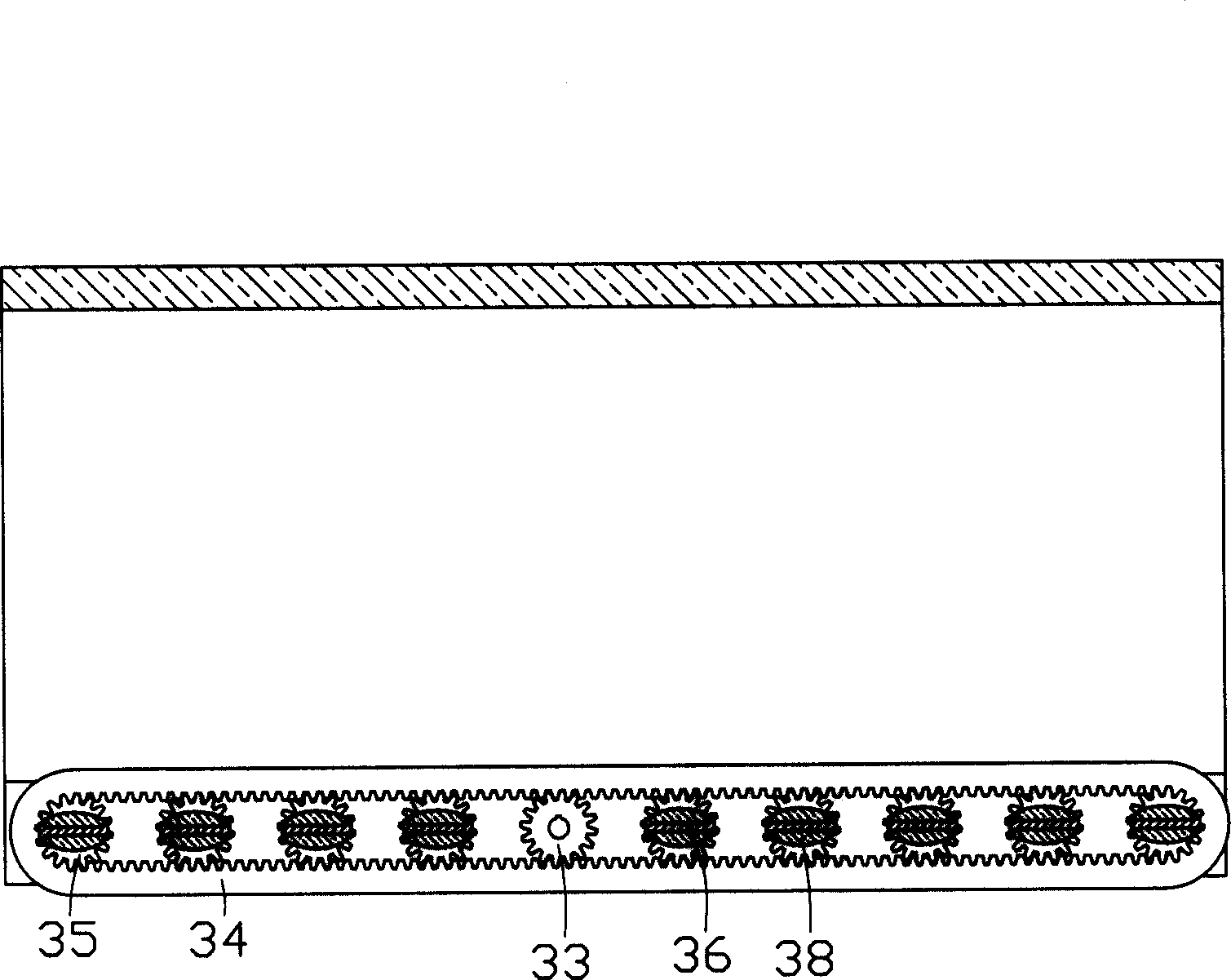

[0014] The rotating support assembly 12 includes a main motor 122, a central rotating shaft 124 and a main supporting frame 126, the main motor 122 is connected with the main supporting frame 126 through the central rotating shaft 124, and is used to drive the entire main supporting frame 126 to rotate, so that each base The film layer is uniform. In this embodiment, the main support frame 126 is square, and it includes two side walls 1262. The bottoms of the inner walls of the side walls 1262 respectively extend a longitudinal boss 1264, and a plurality of through holes ( not shown). In addition, a main motor control device is provided outside the vacuum chamber to control the rotation of the main support frame 126 .

[0015] Please also see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com