Cooling and support systems for furnace roofs

A furnace roof and furnace technology, applied in the direction of furnace cooling device, furnace cooling, furnace crown/roof, etc., can solve the problems that refractory bricks cannot be replaced from above, shorten the service life, and affect the removal of dust and debris, so as to shorten the time period and cost, the effect of simplifying the time period and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

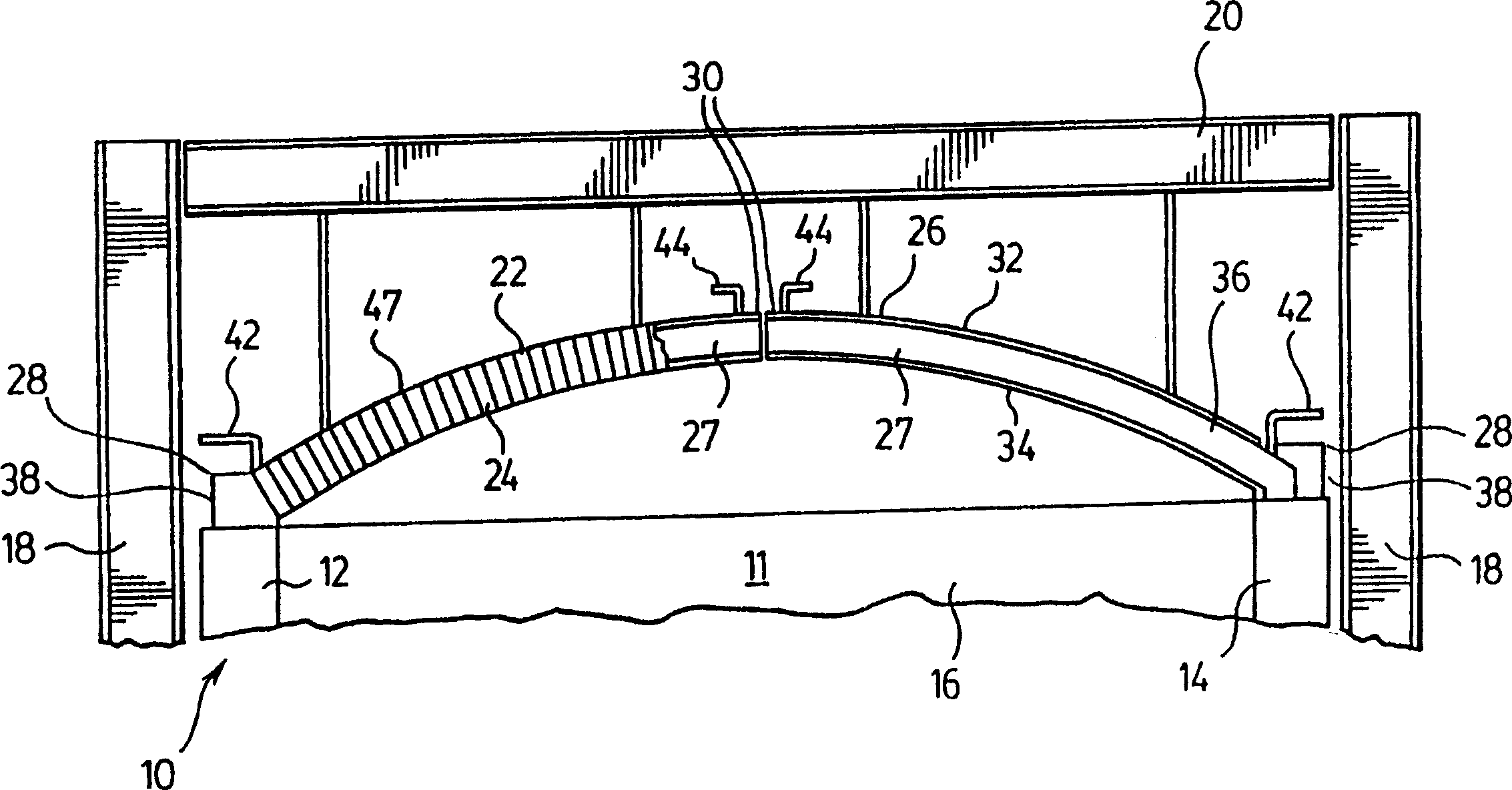

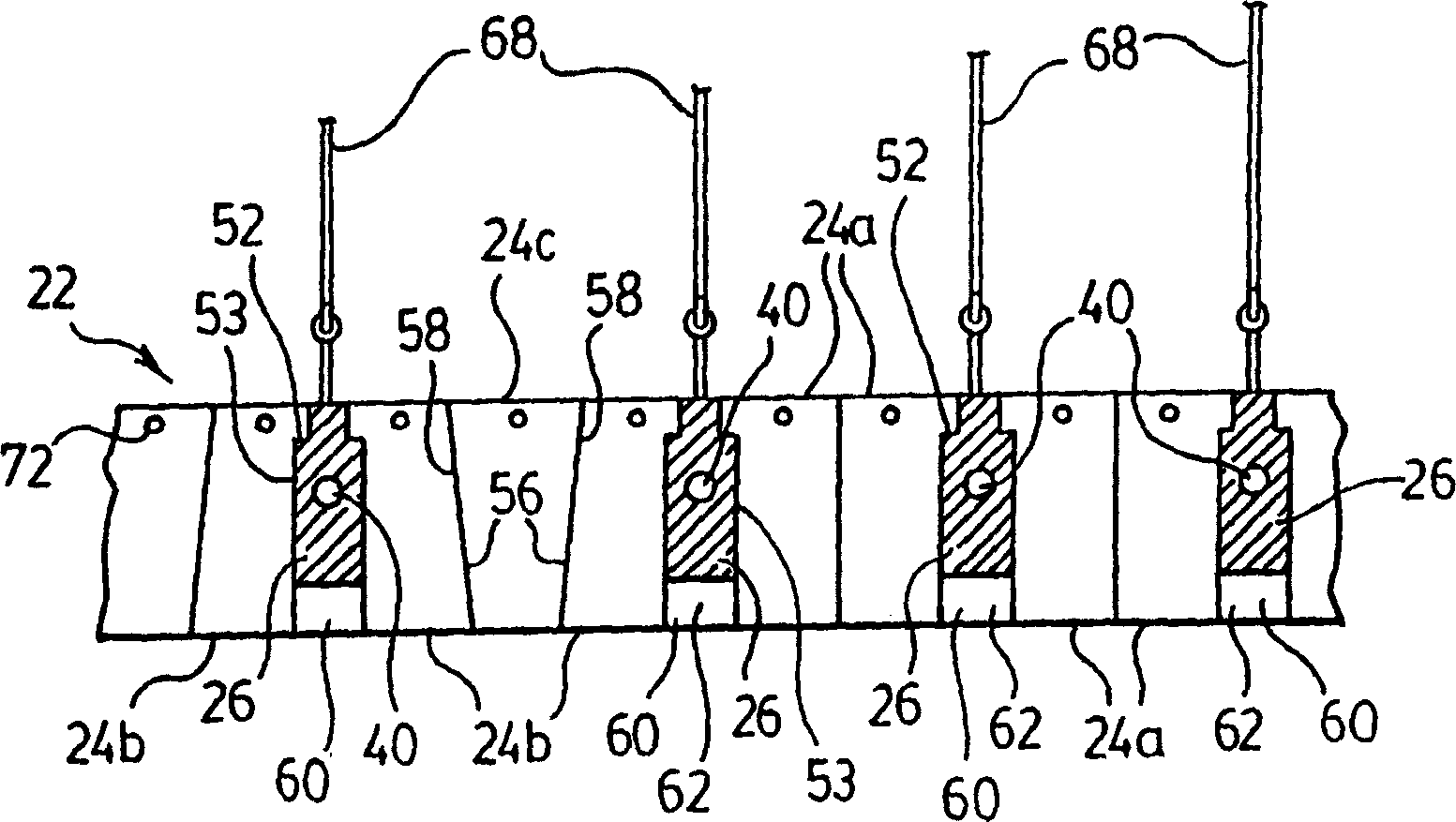

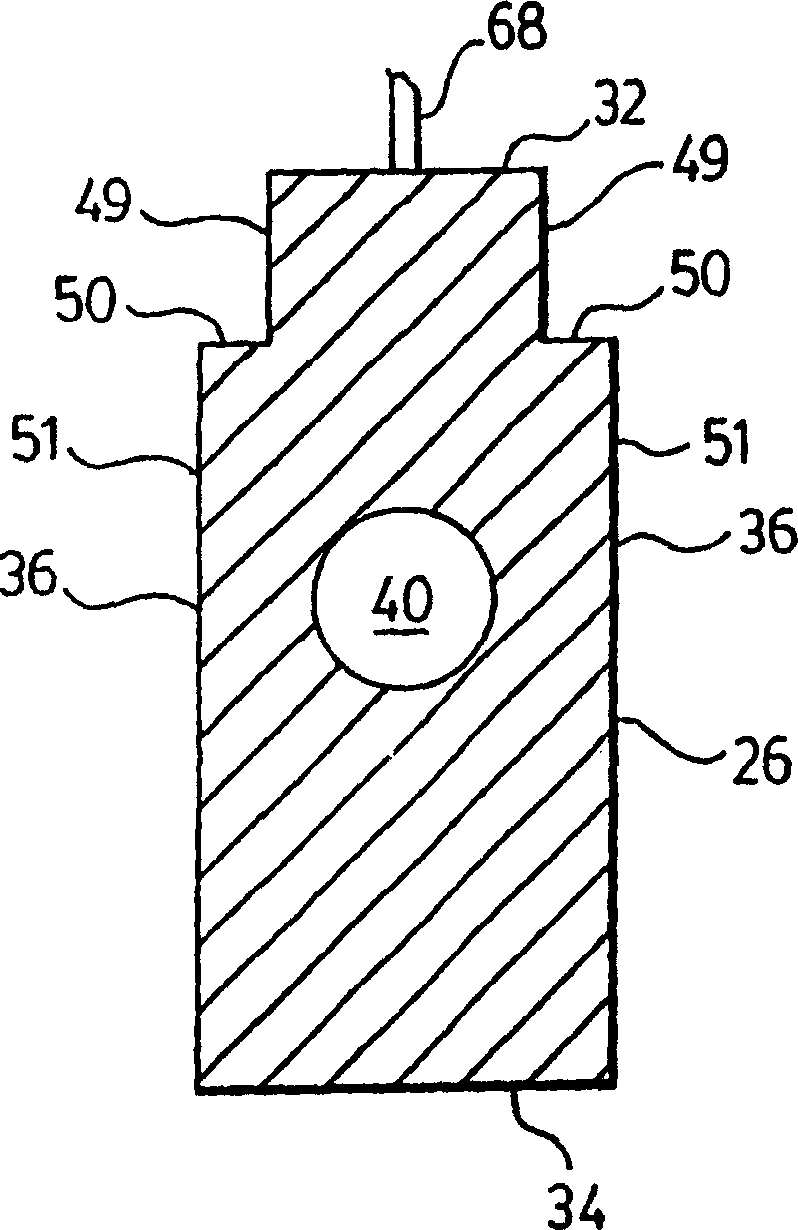

[0017] figure 1 A portion of a furnace 10 is schematically shown, which is rectangular in shape and has four vertically extending walls surrounding an interior space 11, preferably constructed of a refractory material. Parts of side walls 12, 14 and end wall 16 are shown in figure 1 middle. Although the preferred embodiment of the invention is described in connection with a rectangular furnace, it will be appreciated that the principles practiced in the invention can be applied to furnaces of various shapes, such as circular furnaces having generally cylindrical side walls.

[0018] Supporting the side walls 12 and 14 of the furnace 10 are vertical beams commonly referred to as "pillars". These columns are arranged in pairs along opposite sides of the furnace 10 . Although figure 1 Only one pair of struts 18 is shown in , but it will be appreciated that there are preferably a plurality of such pairs of struts spaced apart along the length of the side walls 12 and 14 . Ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com