Furnace top of preheating furnace

A technology for preheating furnace and furnace top, which is applied in the direction of preheating fee, furnace crown/roof, furnace, etc. It can solve the problems of furnace top fire, furnace roof masonry life not exceeding one year, and affecting the normal operation of the preheater, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

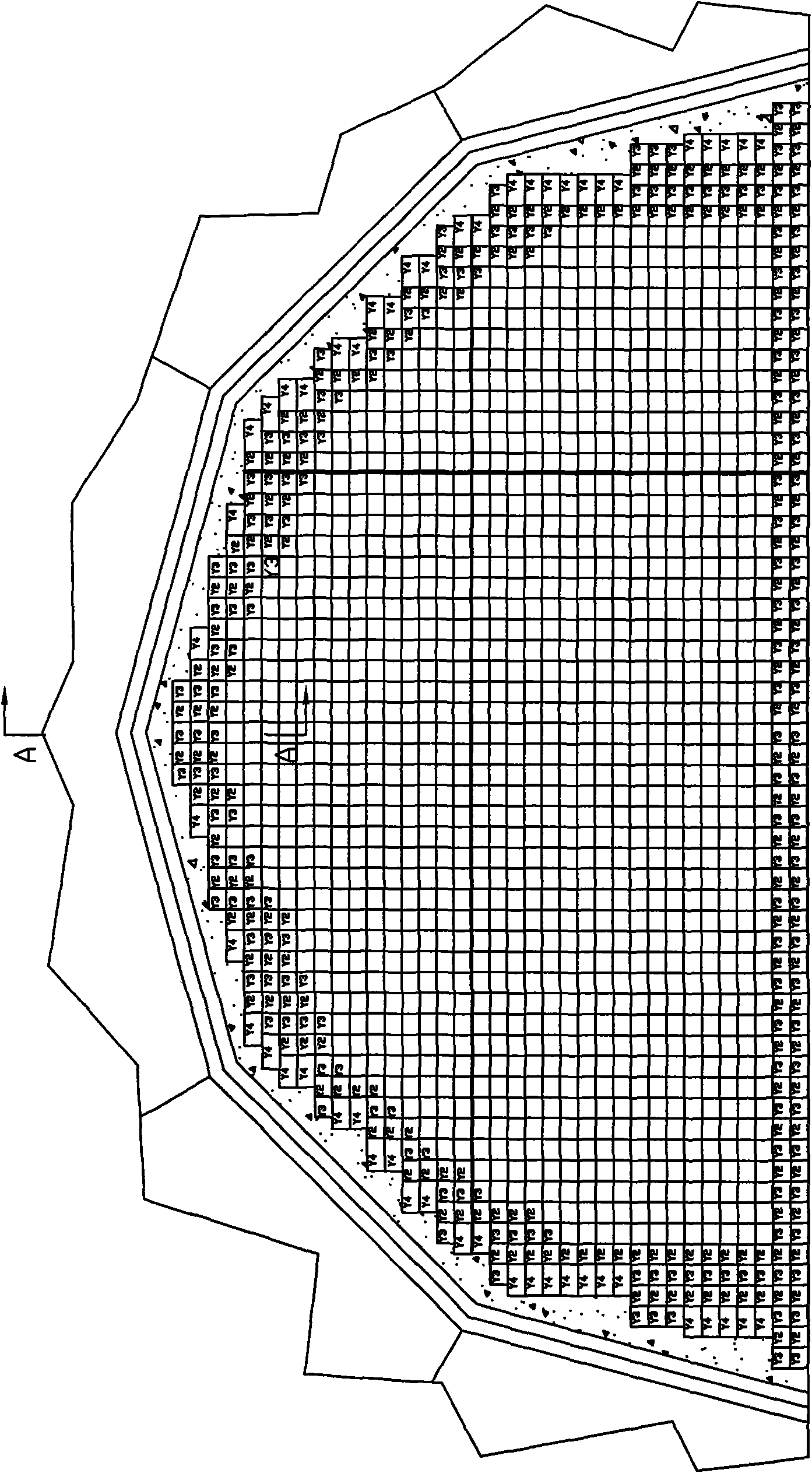

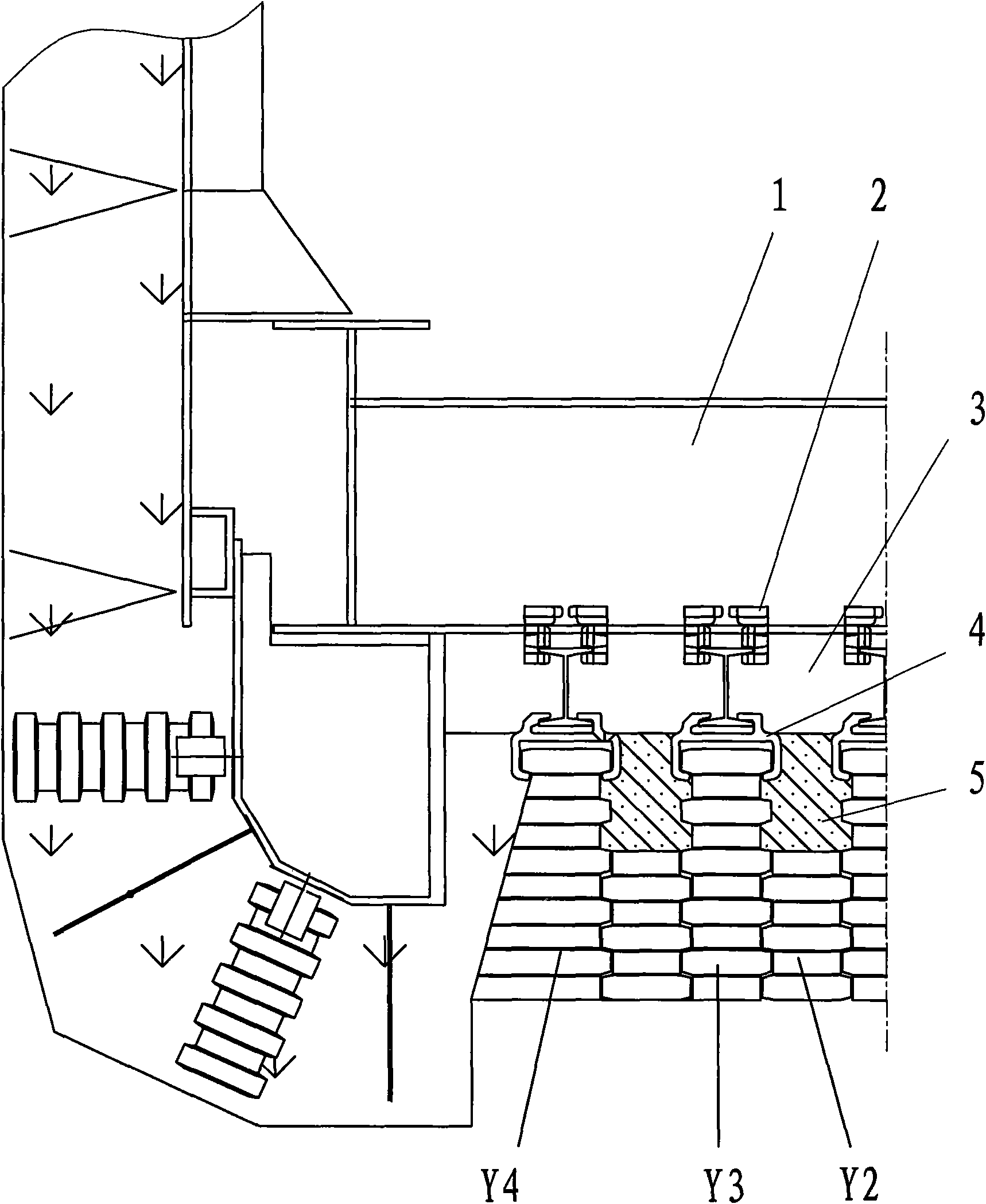

[0009] As shown in the drawings, the upper part of the furnace roof is built with a large I-beam 1, the lower end of the large I-beam 1 is fixed by the upper anchor 2 to the upper end of the small I-beam 3, and the lower end of the small I-beam 3 is fixed by the lower anchor 4 Wedge anchor brick Y4 and main anchor brick Y3. Anchor brick Y2 is inlaid between wedge-shaped anchor brick Y4, main anchor brick Y3 and two main anchor bricks Y3, and light is filled between wedge-shaped anchor brick Y4 above anchor brick Y2, main anchor brick Y3 and two main anchor bricks Y3. Quality castable 5. The wedge-shaped anchor brick Y4 is used to connect surrounding castables. The main anchor brick Y3 and the anchor brick Y2 are dumbbell-shaped, and one side of the wedge-shaped anchor brick Y4 is dumbbell-shaped. The main anchor brick Y3, anchor brick Y2 and wedge-shaped anchor brick Y4 can also be in zigzag shape, candied haws shape or other shapes capable of realizing convex-concave connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com