Zinc metallurgy ore smelting electric arc furnace spherical top integral pouring and maintenance method

A submerged electric furnace and integral pouring technology, which is applied in furnace crown/roof, building material processing, ceramic molding machine, etc., can solve the problems of furnace gas rushing slope and other problems, and achieve the effect of low power consumption, short construction period and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

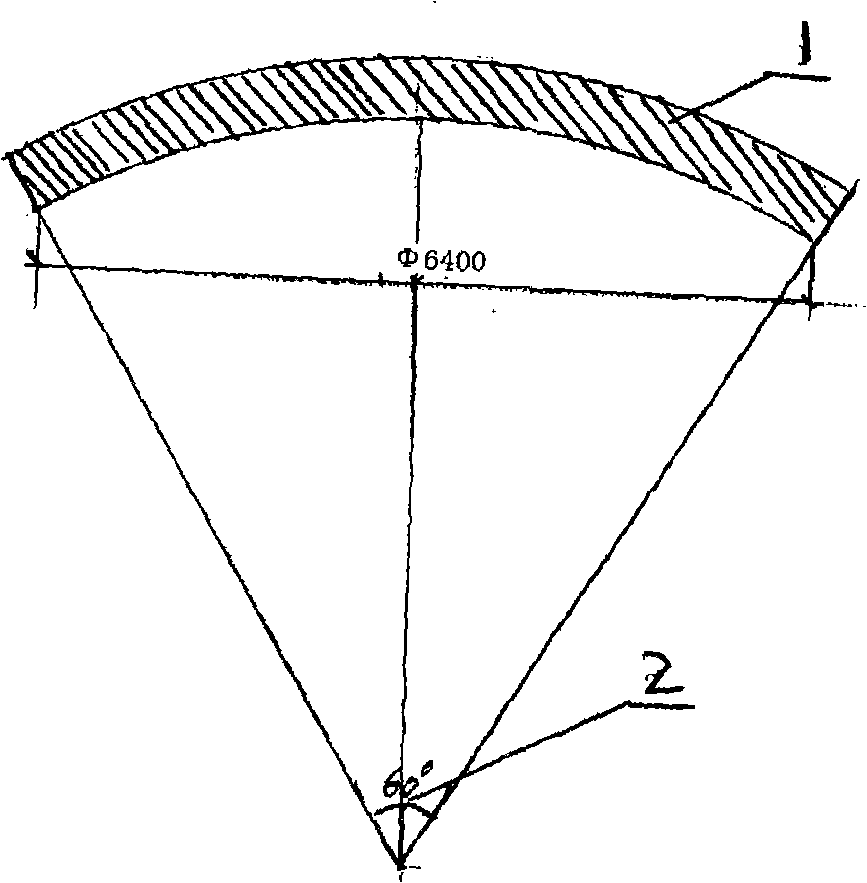

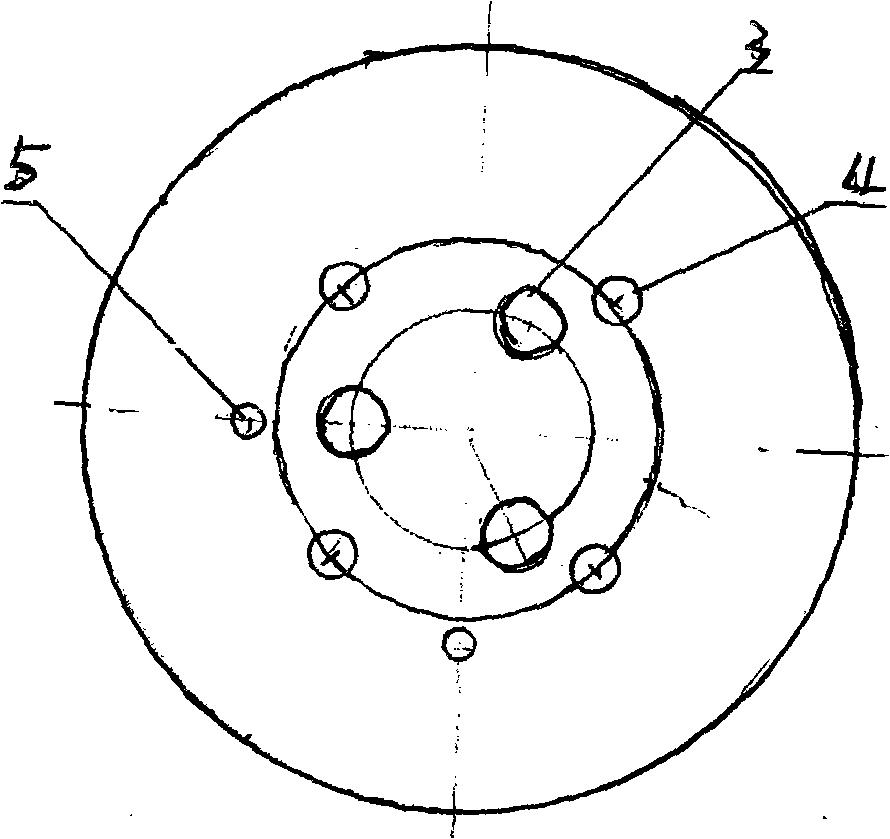

[0033] like figure 1 , figure 2 As shown, select a reasonable central angle 2 and locate the electrode hole 3 and the feeding hole 4 according to the type and power of the electric furnace.

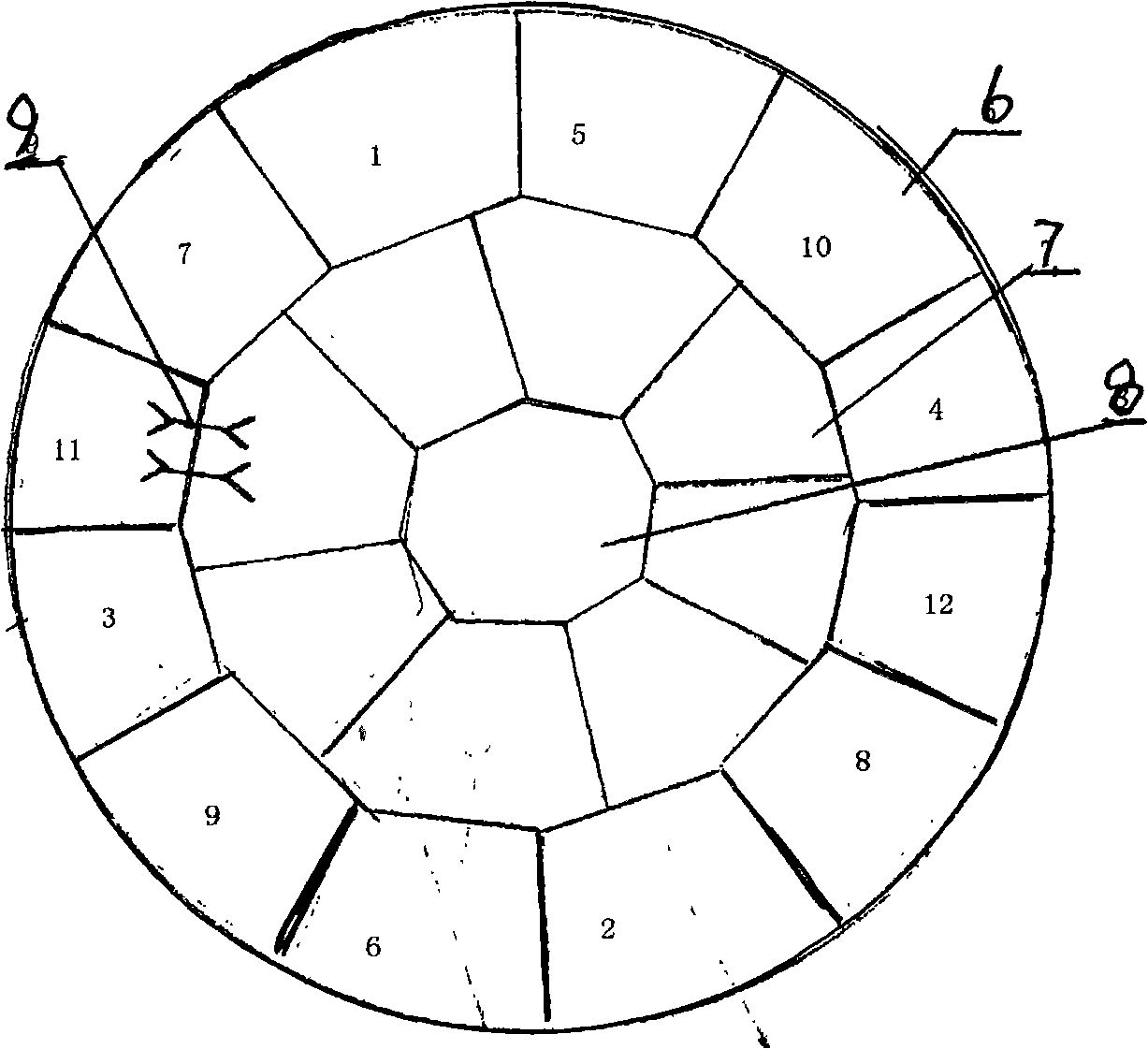

[0034] like image 3 , Figure 4 As shown, the vault is poured in separate rings and blocks, with a thickness of 350 mm and a thickness of 450 mm in the center of the electrode circle. The blocks are connected as a whole with anchors 9 .

[0035] The dome of the 3000KVA electric furnace is divided into 3 rings and 21 blocks for pouring, and the angle of the center of the circle must be accurately controlled.

[0036] The outer surface of the inner mold of the vault is required to be smooth and flat, and the line is drawn in advance according to the pouring block and the cut surface is vertical.

[0037] Heat loss semi-expansion joints are arranged longitudinally intermittently in the middle of each formwork. The material is plywood ≤ 3mm, and 3 pieces of 80×300mm are reserved for eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com