Protecting mixed gas supplier for magnesium-alloy smelting furnace

A technology of shielding gas and magnesium alloy, which is applied in lighting and heating equipment, furnaces, crucible furnaces, etc., can solve problems such as hidden safety hazards, complex structure, and reduce the service life of mass flow sensors, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

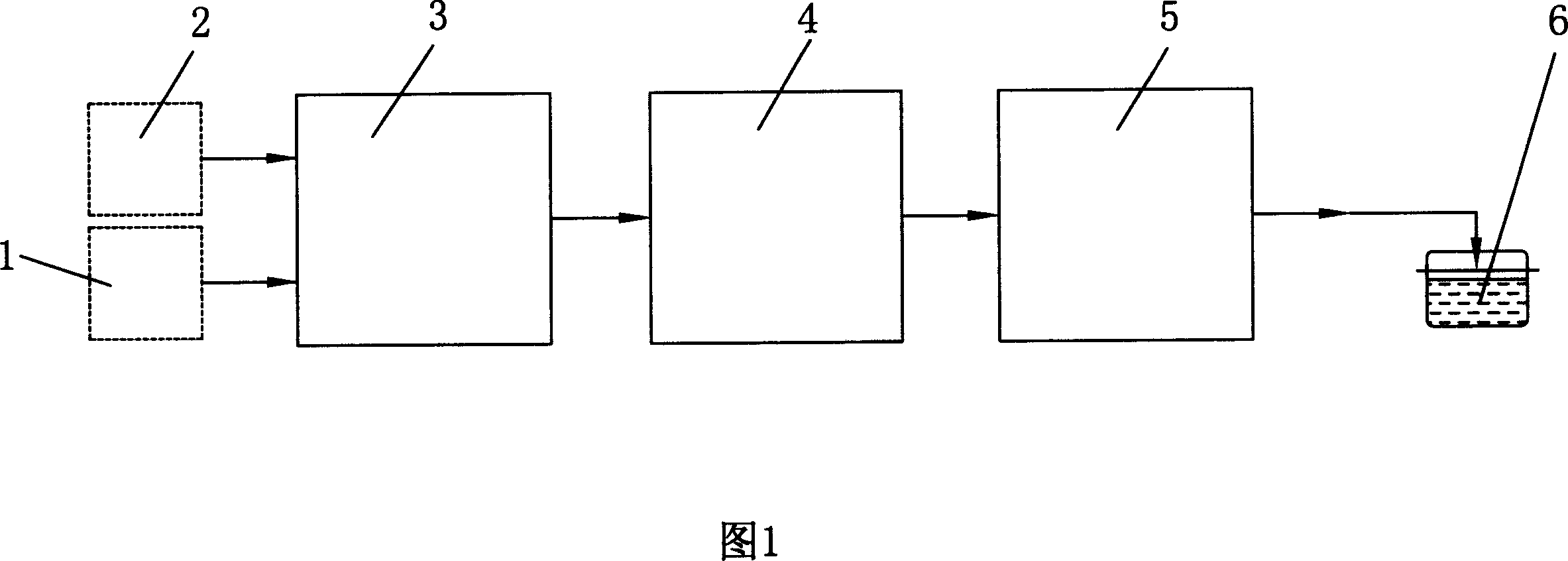

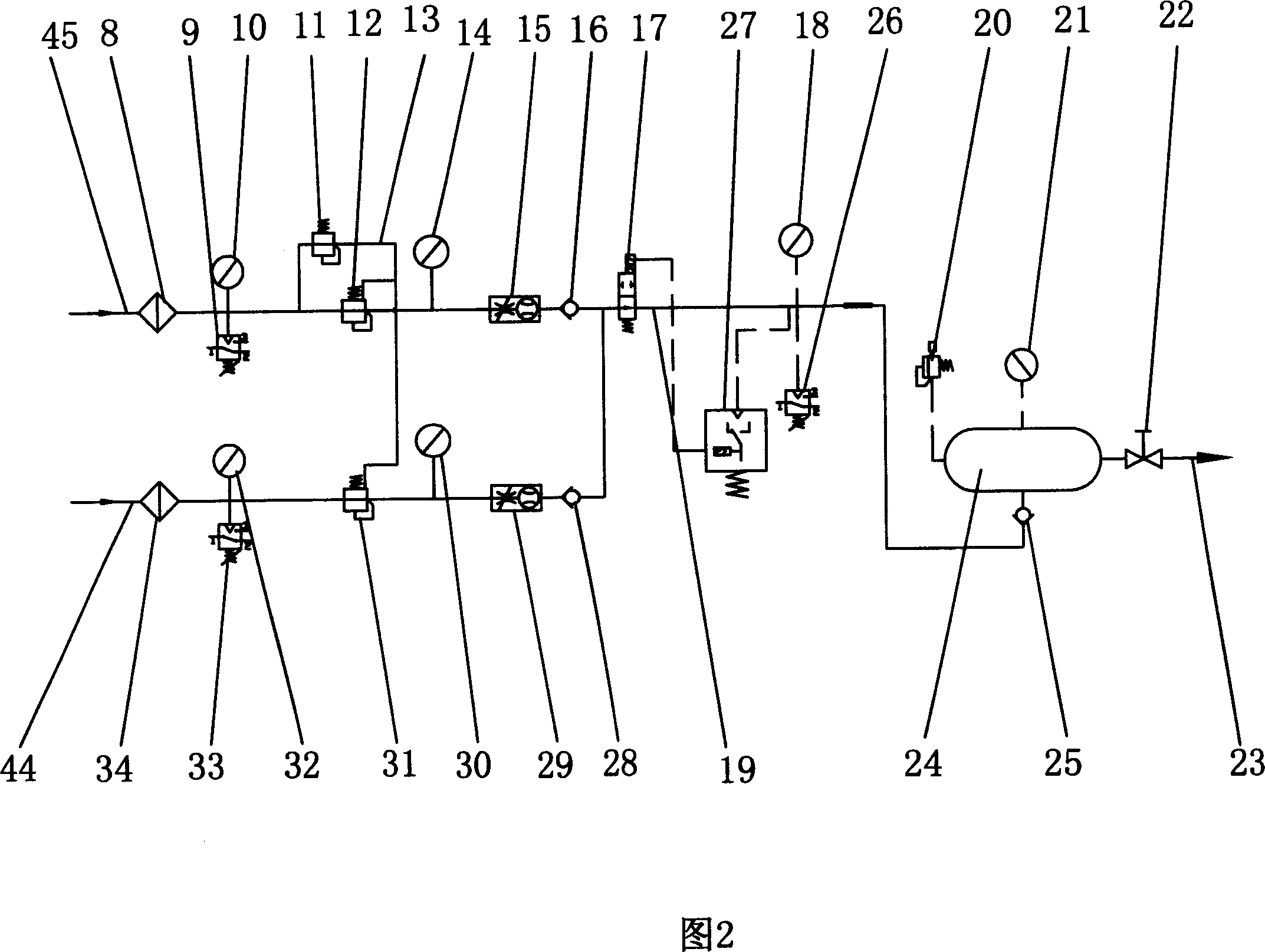

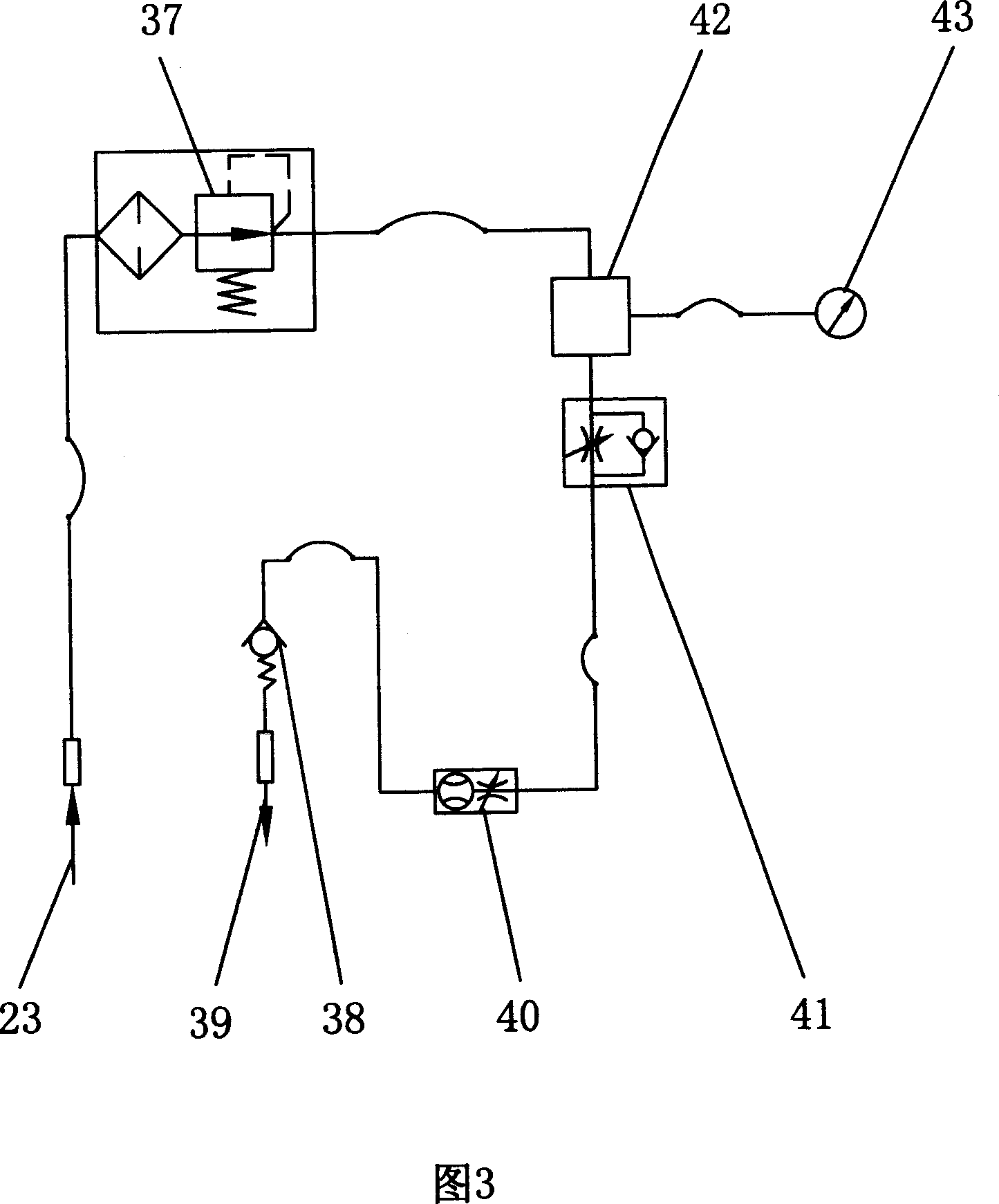

[0020] Please refer to Fig. 1 to Fig. 4, a protective gas mixed gas supply equipment for magnesium alloy melting furnace flame retardant in the present invention includes a gas mixing device 3 connected in sequence, a gas collecting device 4 and at least one for supplying gas to the melting furnace 6 Gas input device 5, the gas mixing device includes an SF6 gas input pipeline for SF6 gas input, a nitrogen gas input pipeline for nitrogen input and a mixed gas pipeline for SF6 gas and nitrogen mixing, SF6 gas input Both the pipeline and the nitrogen input pipeline are connected to the inlet of the mixed gas pipeline, the gas outlet of the mixed gas pipeline is connected to the gas collecting device, and the gas collecting device is connected to each gas input device through the mixed gas output pipeline. SF6 gas and nitrogen are input into the SF6 gas input pipeline and nitrogen input pipeline respectively from the gas source, and after filtration, decompression and metering, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com