Patents

Literature

46results about How to "Curb energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

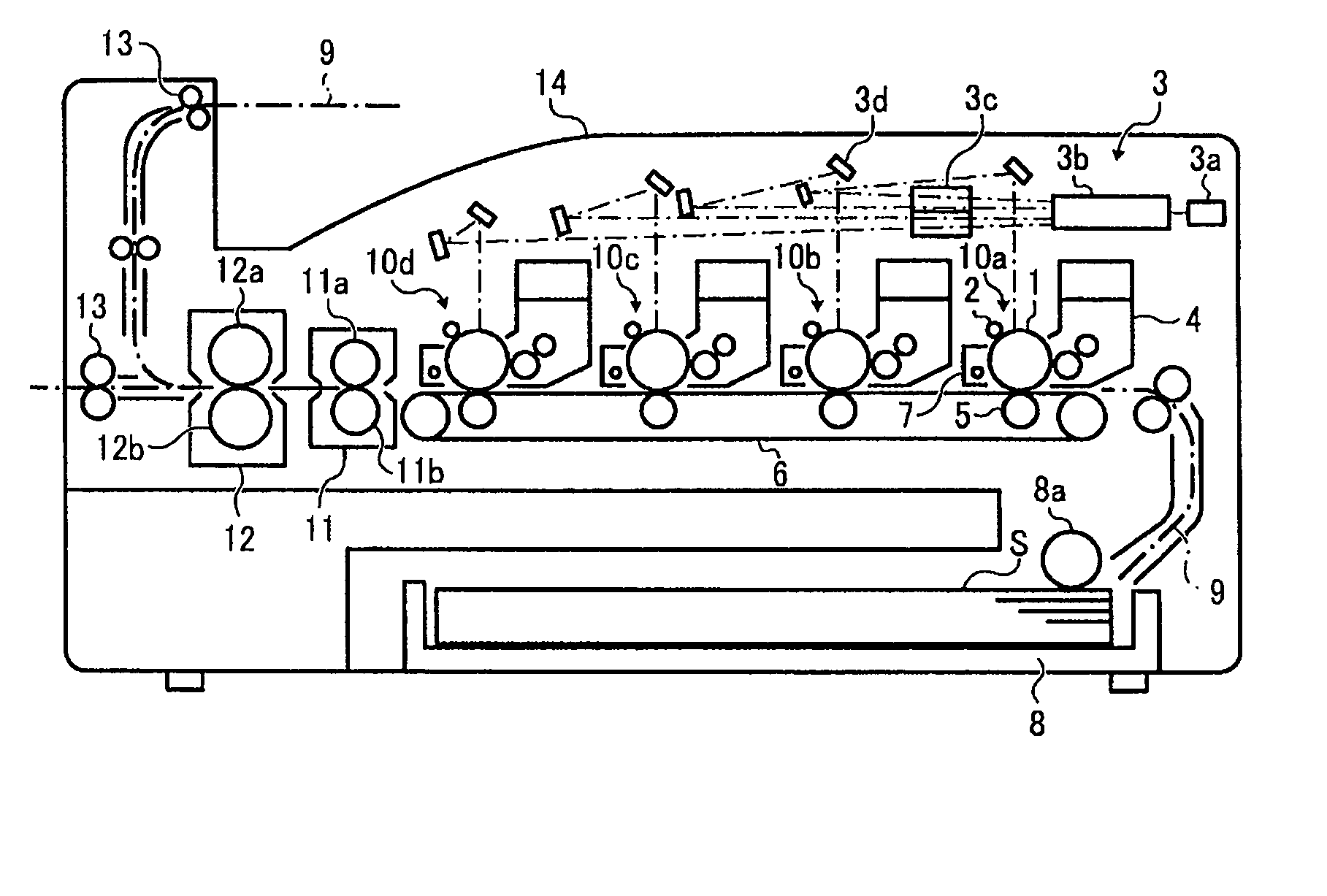

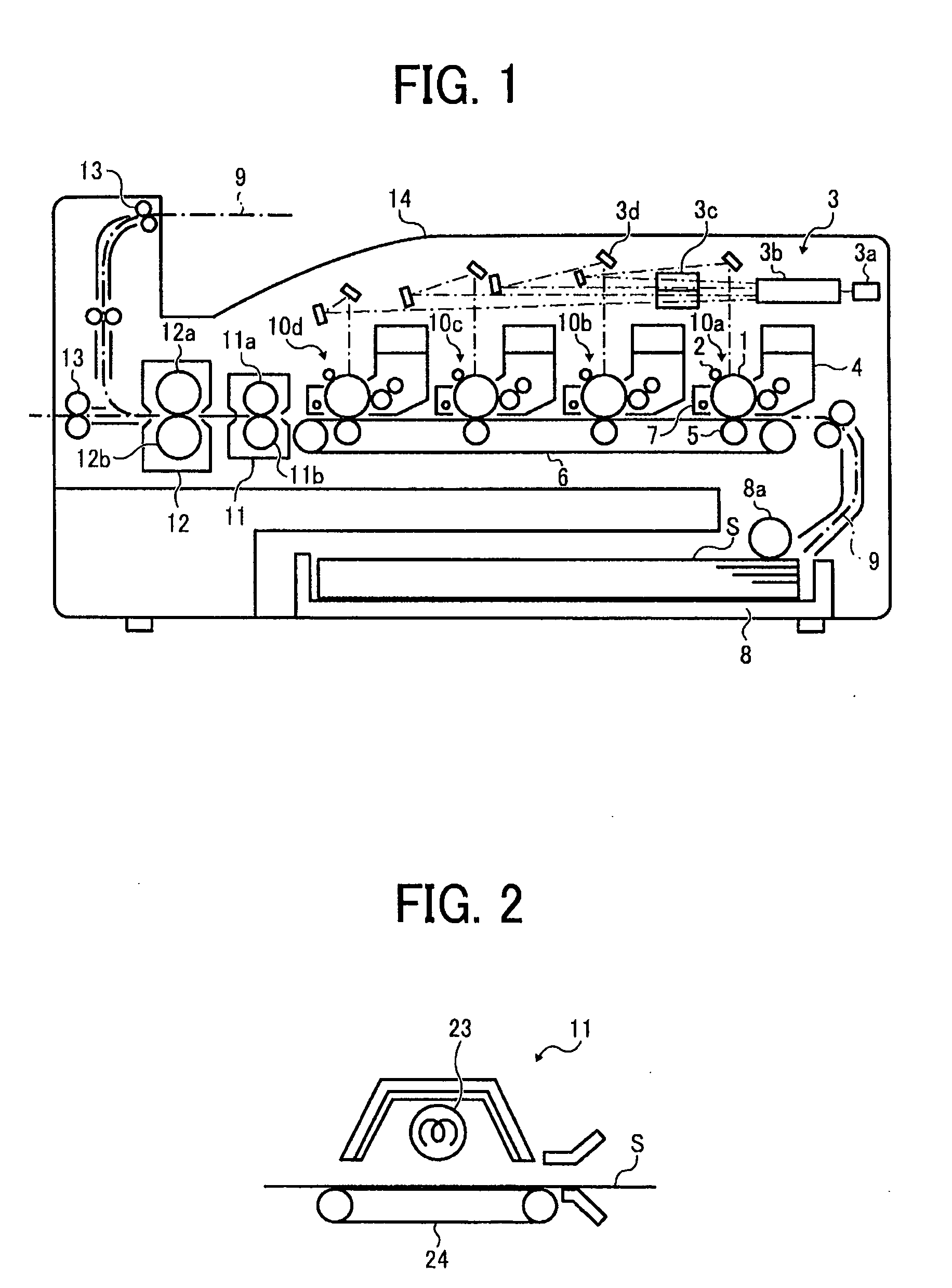

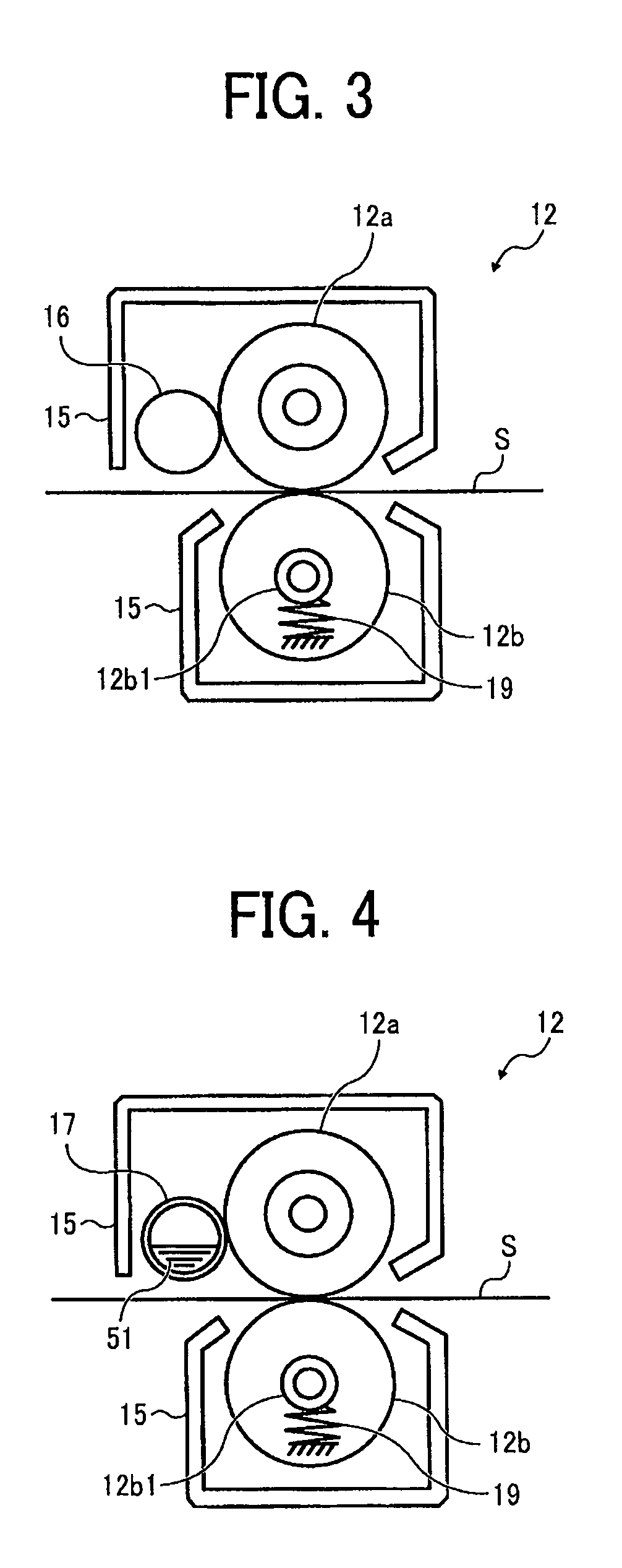

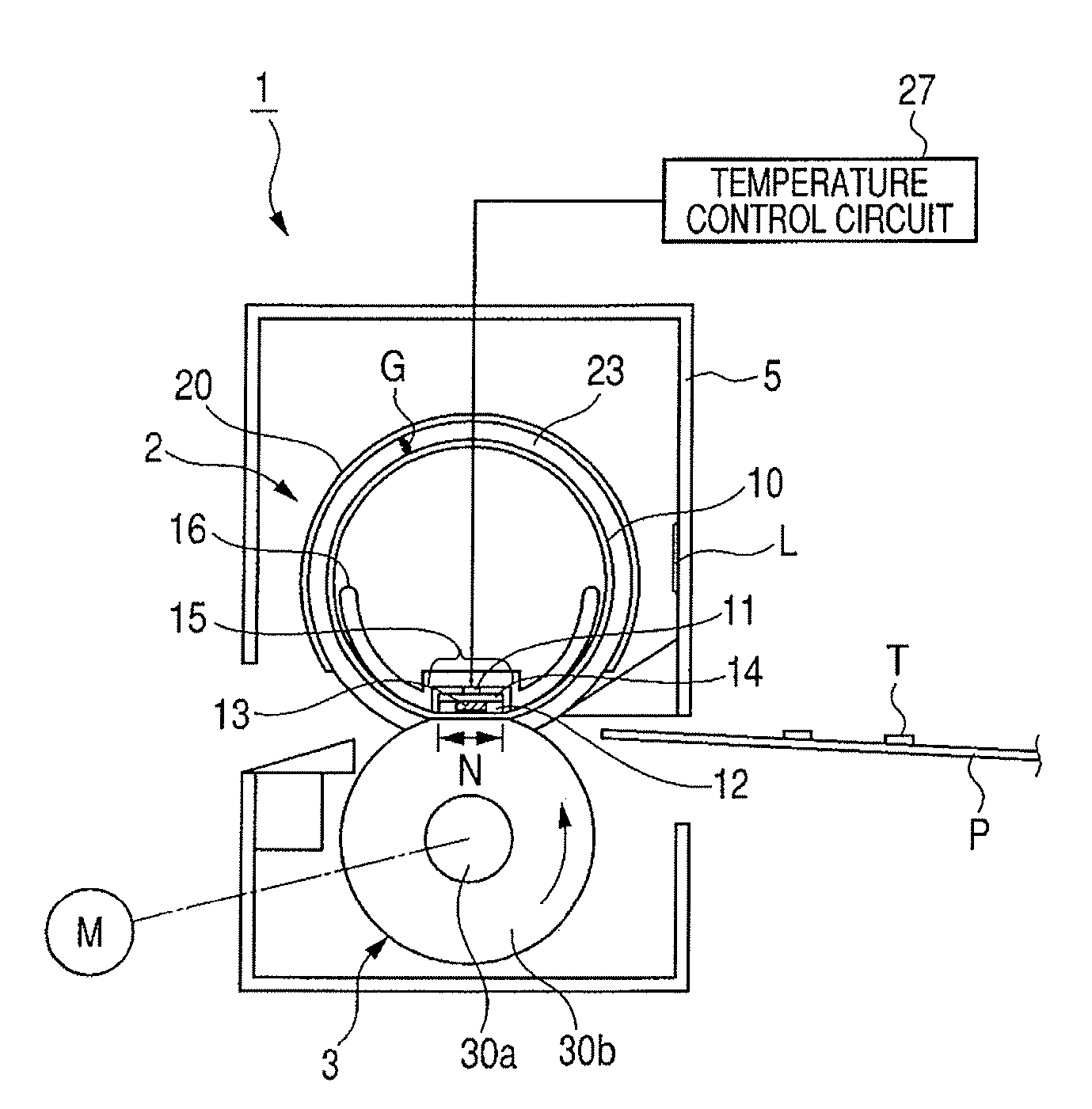

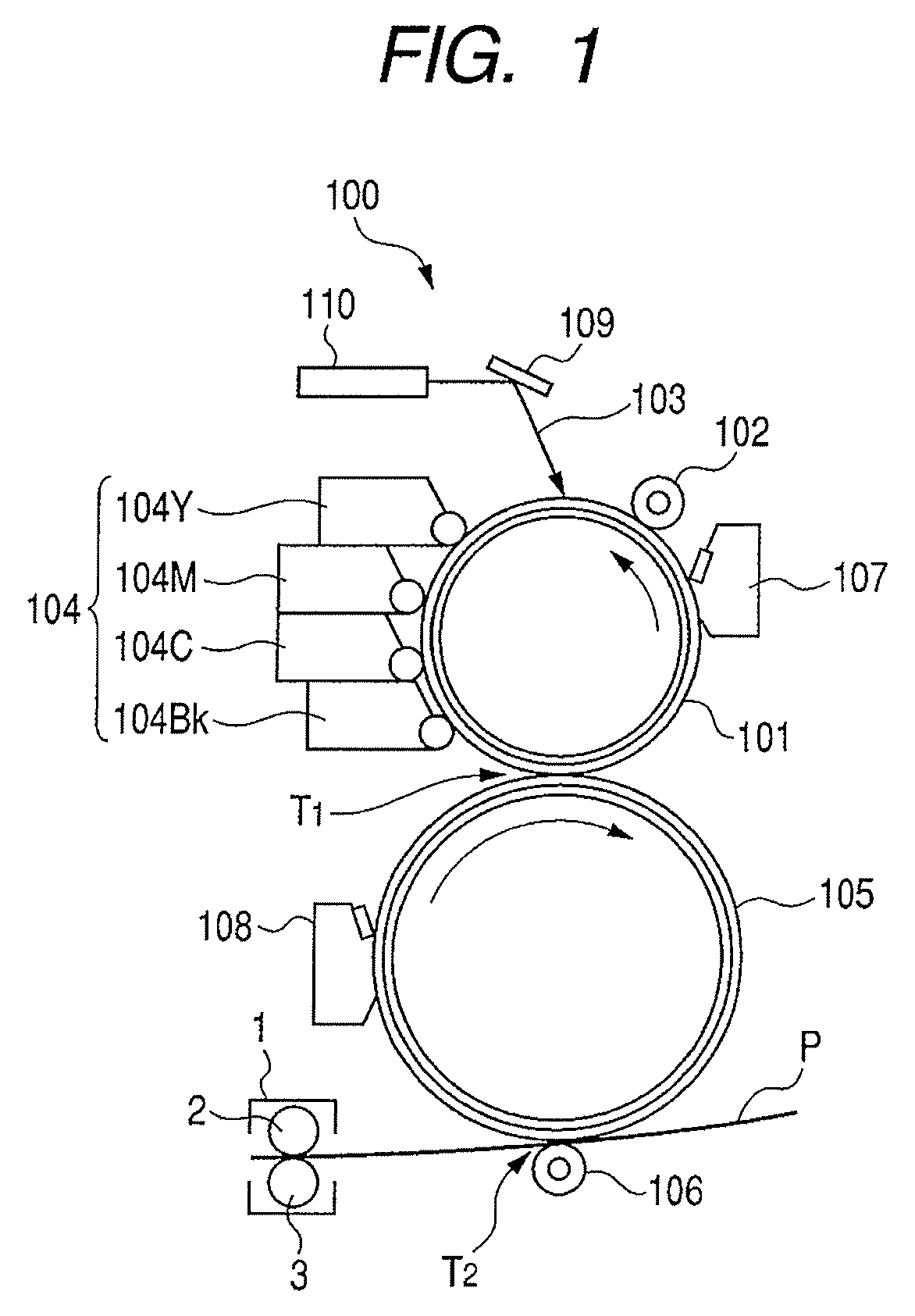

Image forming apparatus and method

InactiveUS20090245896A1Improve performanceCurb energy consumptionElectrographic process apparatusElectrographic processes using charge patternImage formationEngineering

Owner:RICOH KK

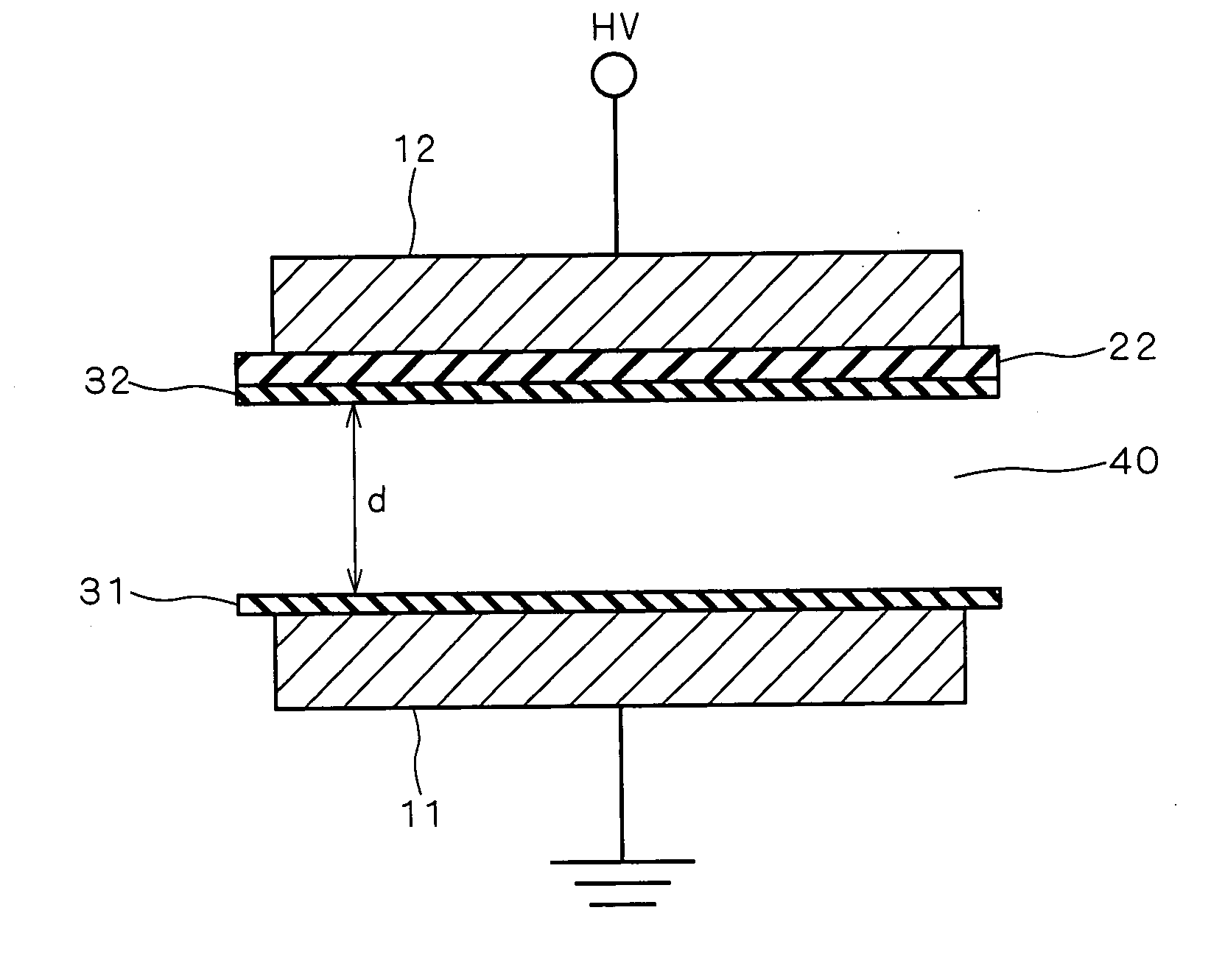

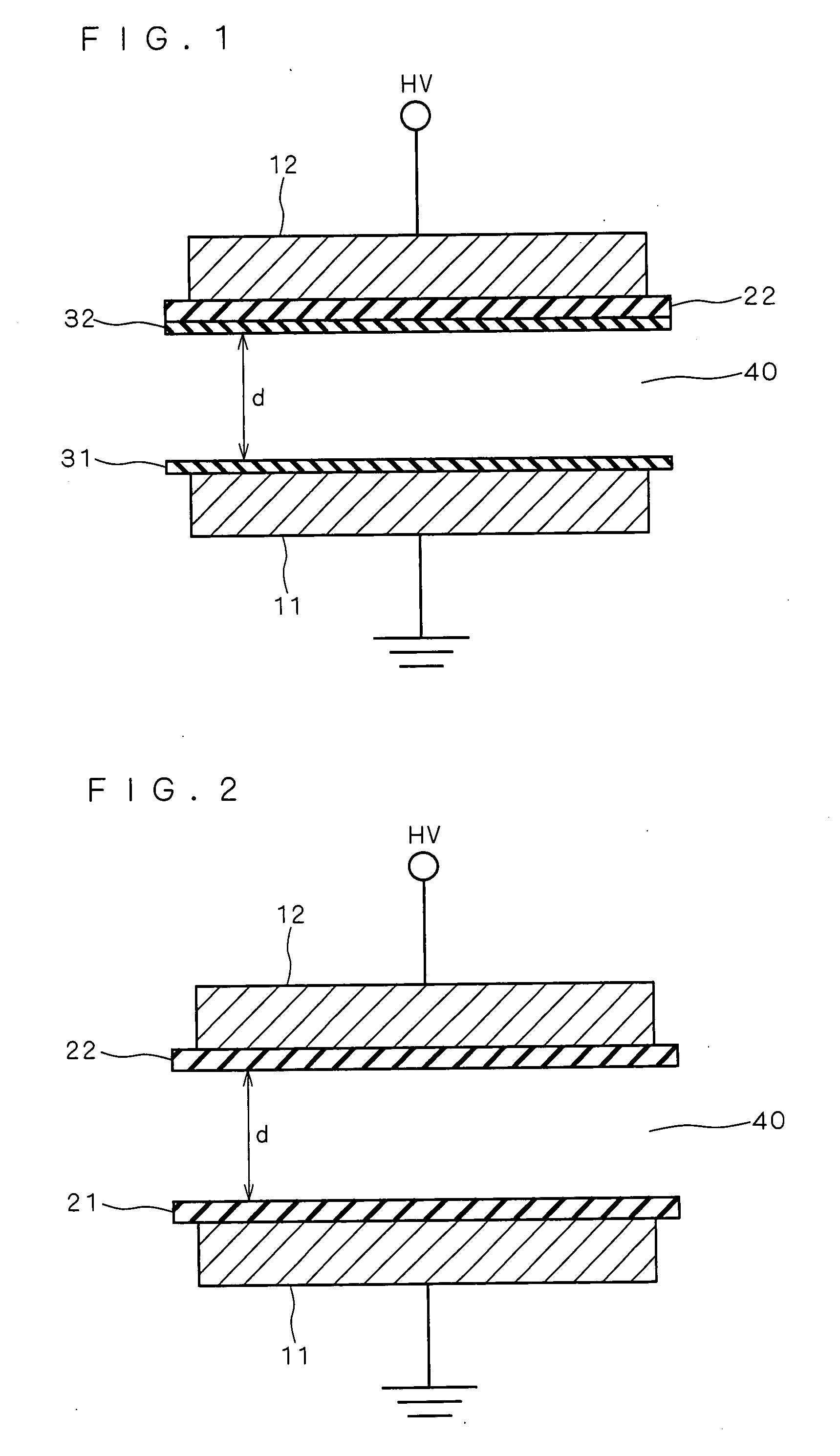

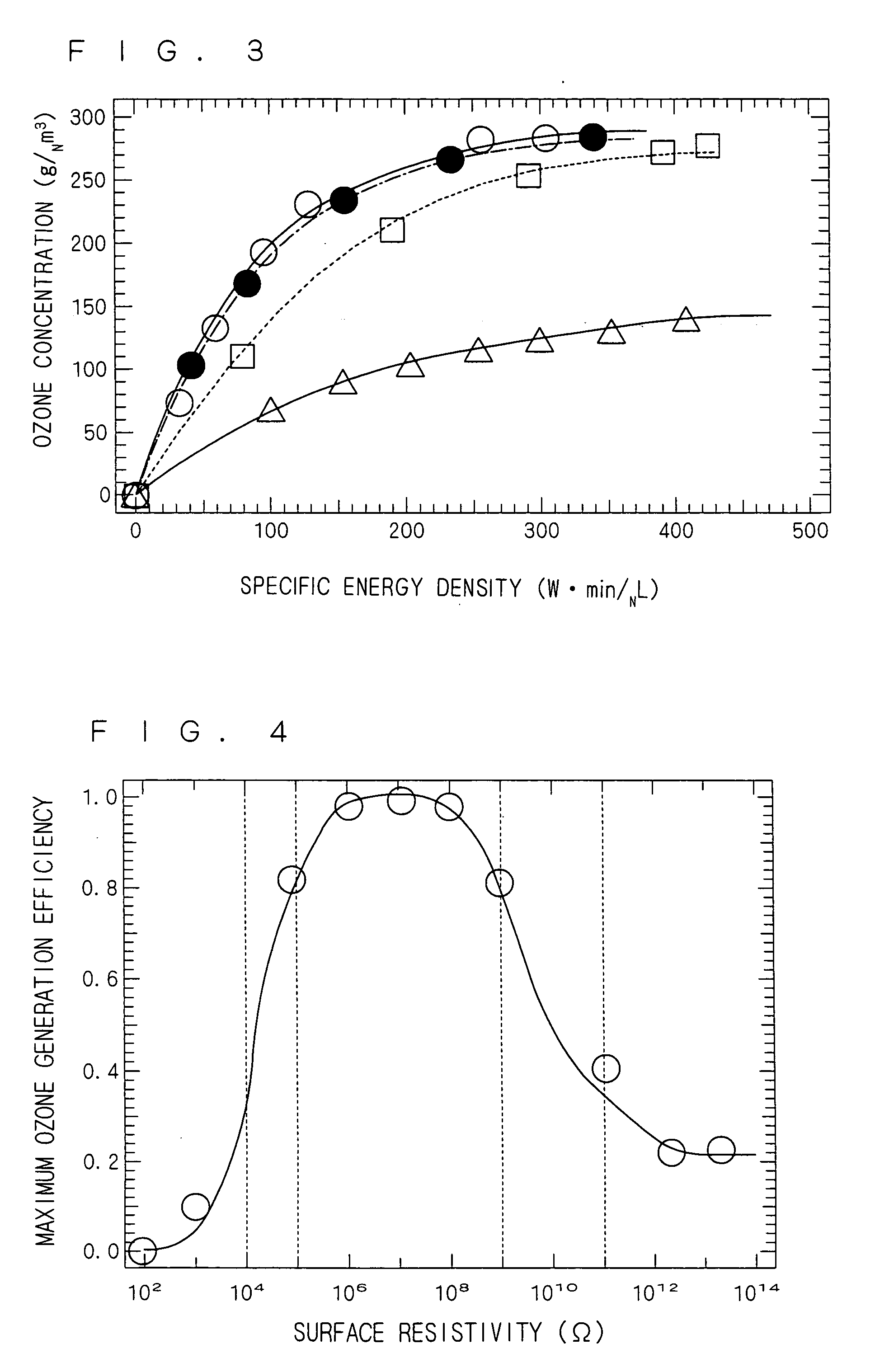

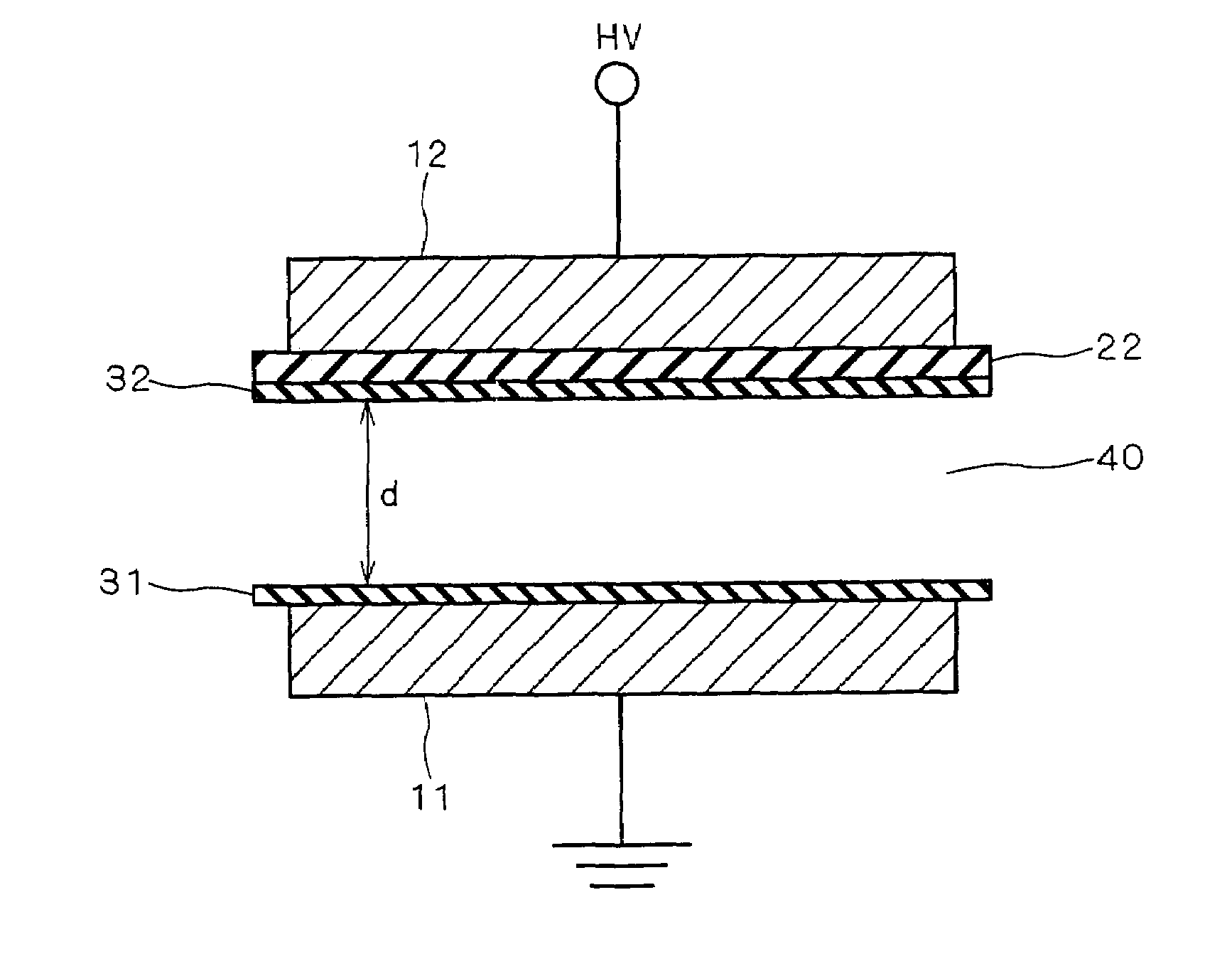

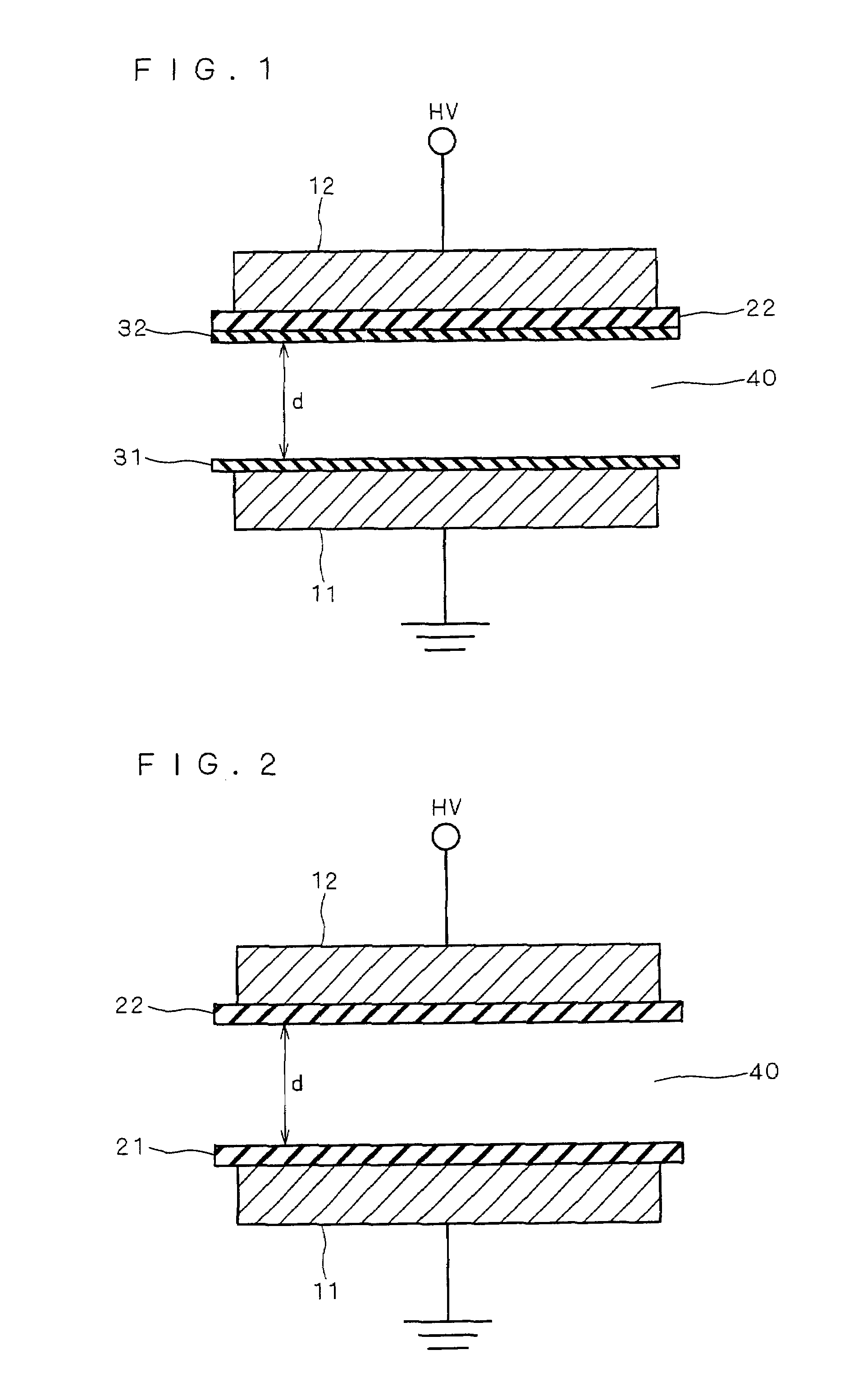

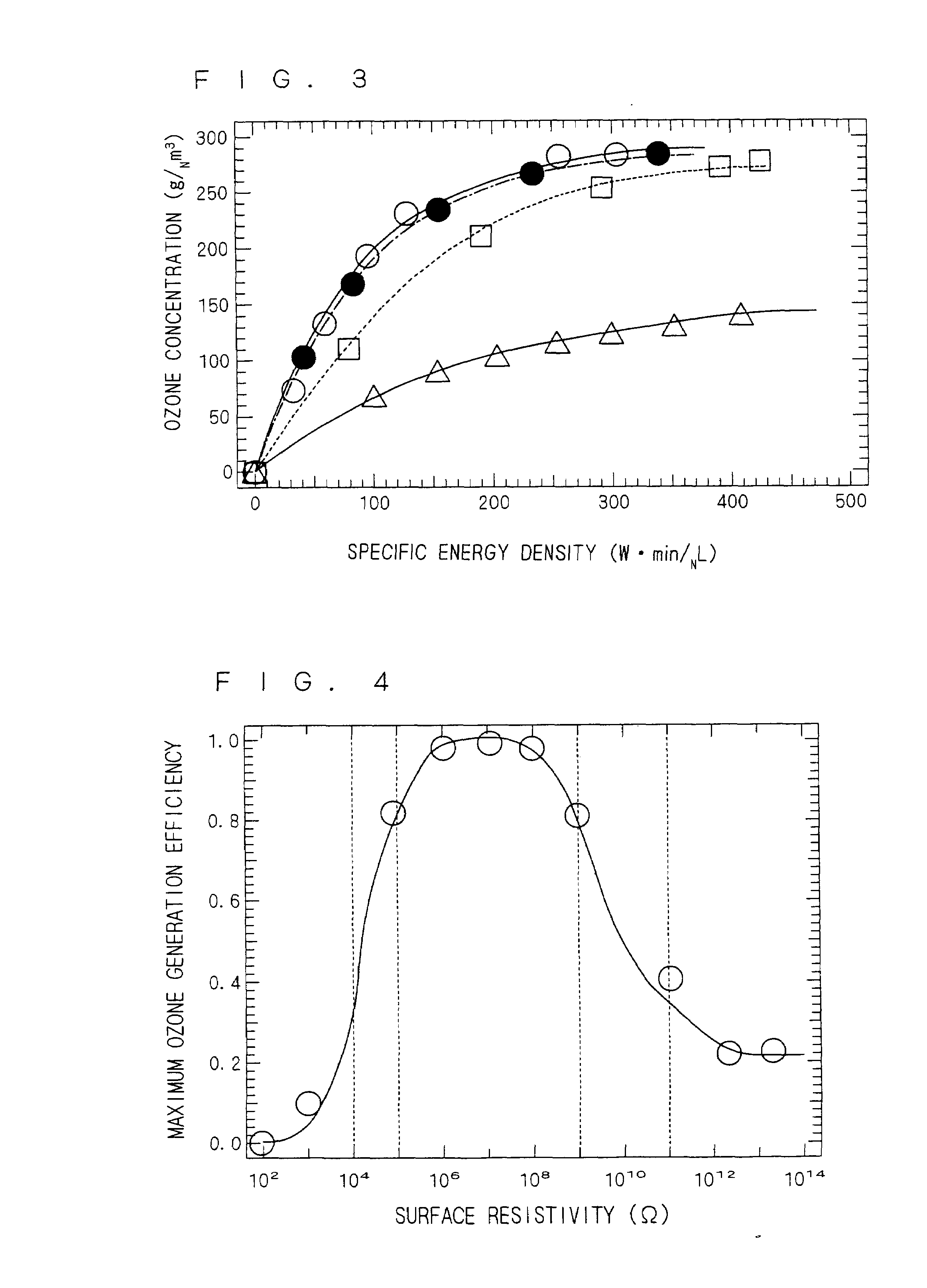

Ozone generating apparatus

ActiveUS20050226791A1Improve efficiencyHigh ozone concentrationElectrical apparatusElectrical discharge ozone preparationDielectricElectricity

An ozone generating apparatus is provided which includes a pair of electrodes for producing a discharge by the application of an ac voltage therebetween, and at least one dielectric provided between the pair of electrodes. A source gas containing oxygen is provided into a discharge space in which the discharge is produced to generate ozone by the action of the discharge. A surface lying between at least one of the pair of electrodes and the discharge space and in contact with the discharge has a surface resistivity of 104 Ω to 1011 Ω. The source gas provided into the discharge space includes ultrapure oxygen having a purity of not less than 99.9%.

Owner:MITSUBISHI ELECTRIC CORP

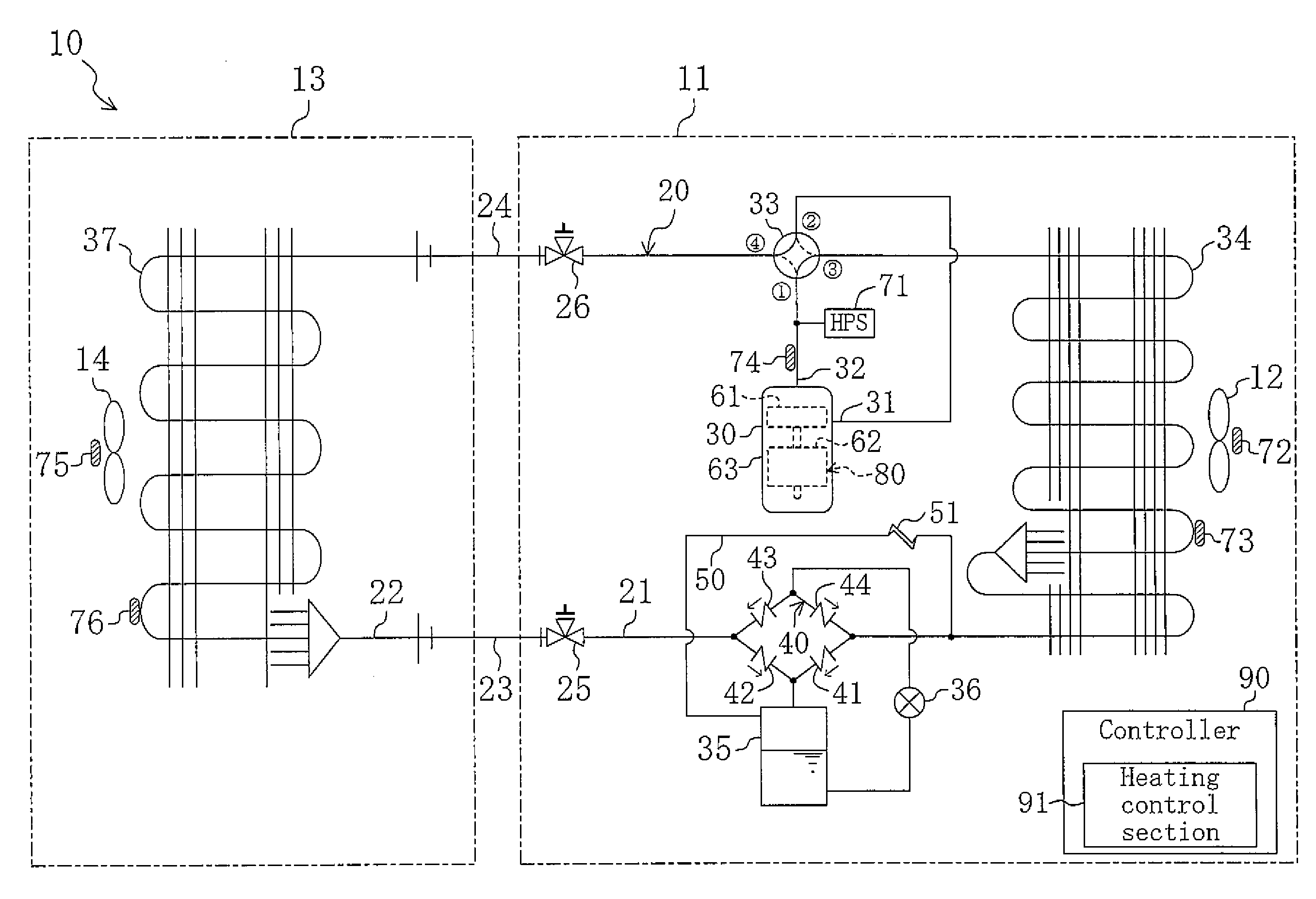

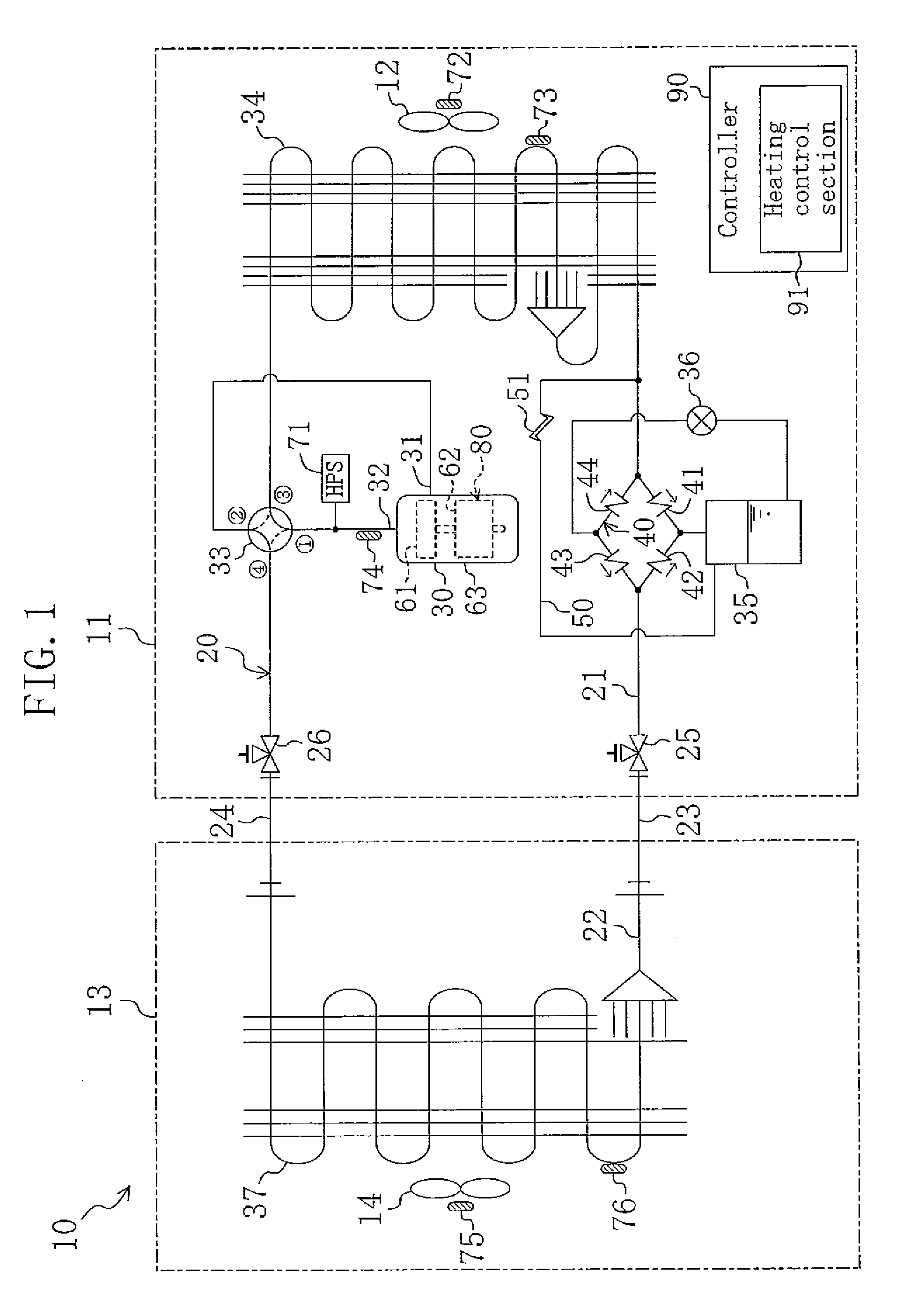

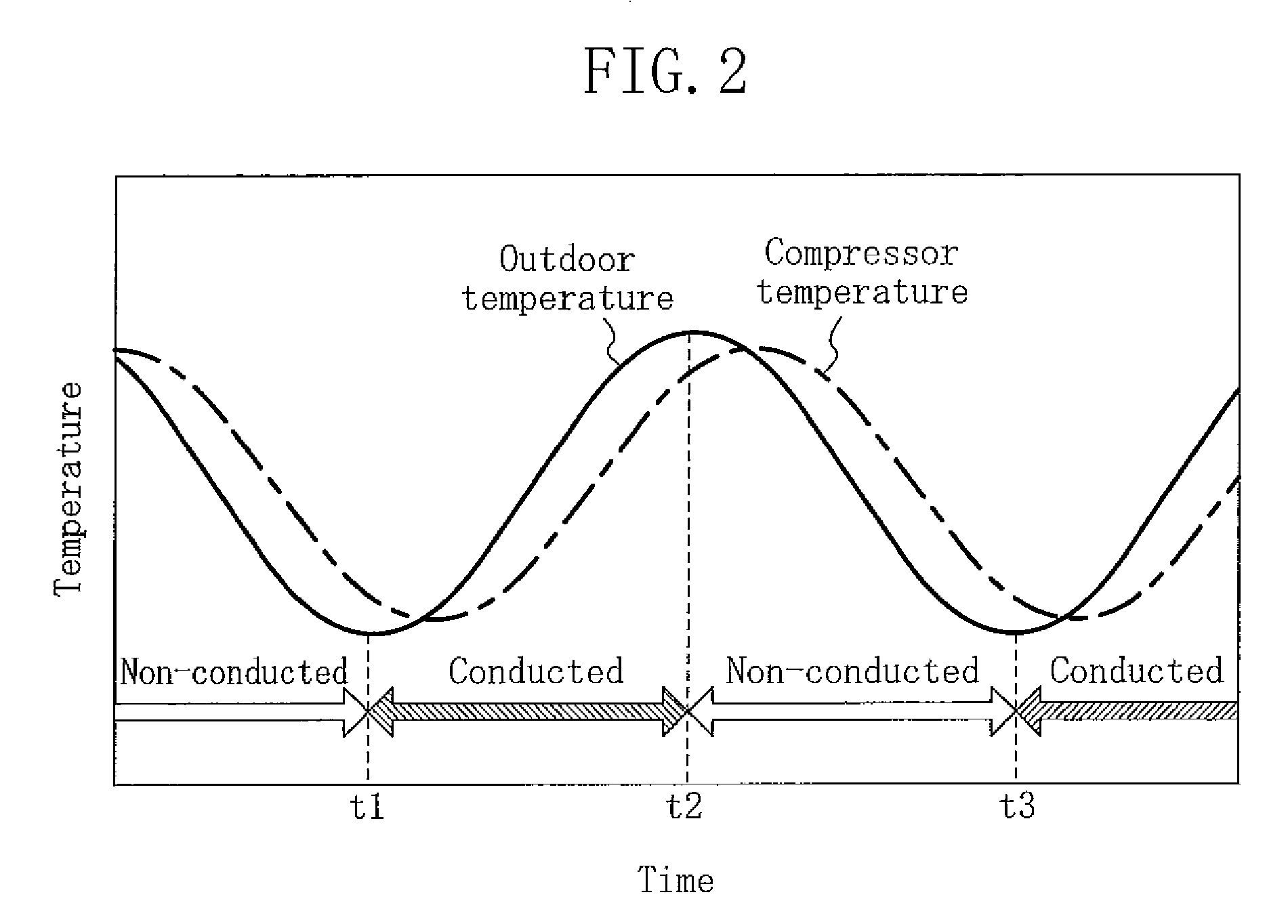

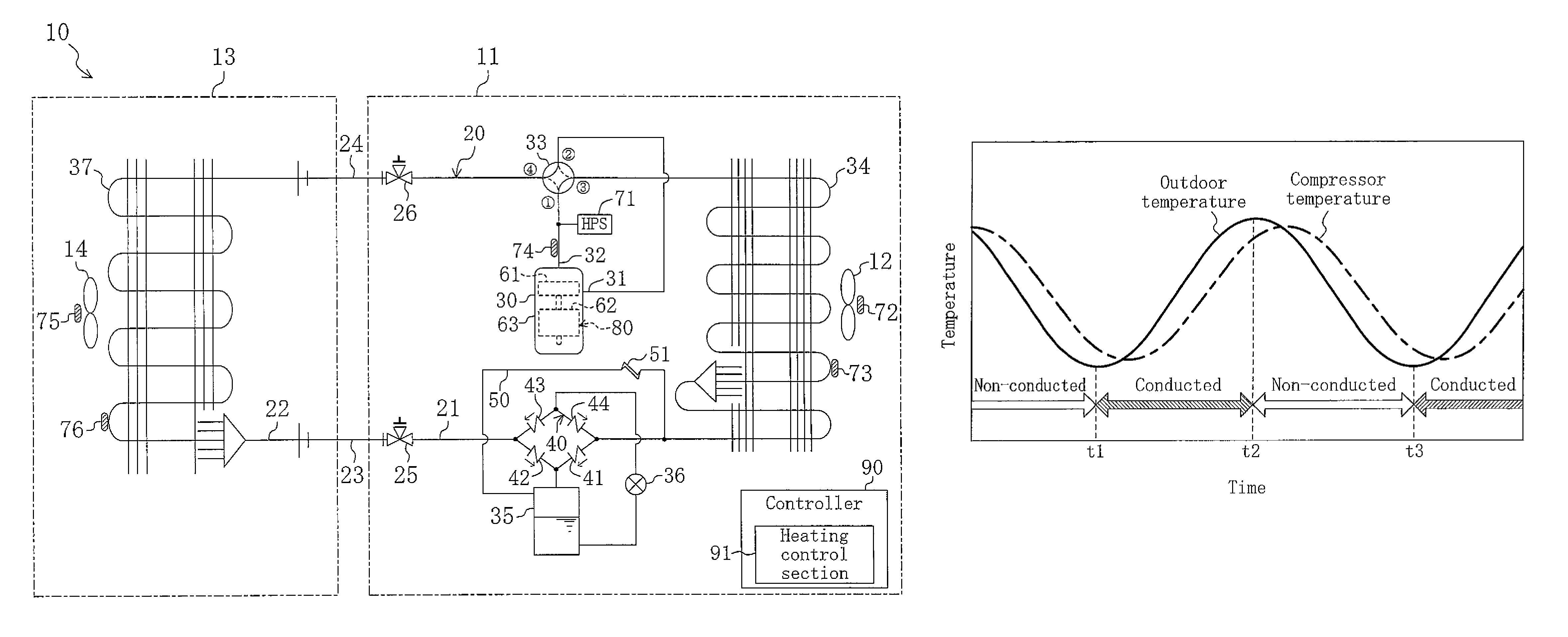

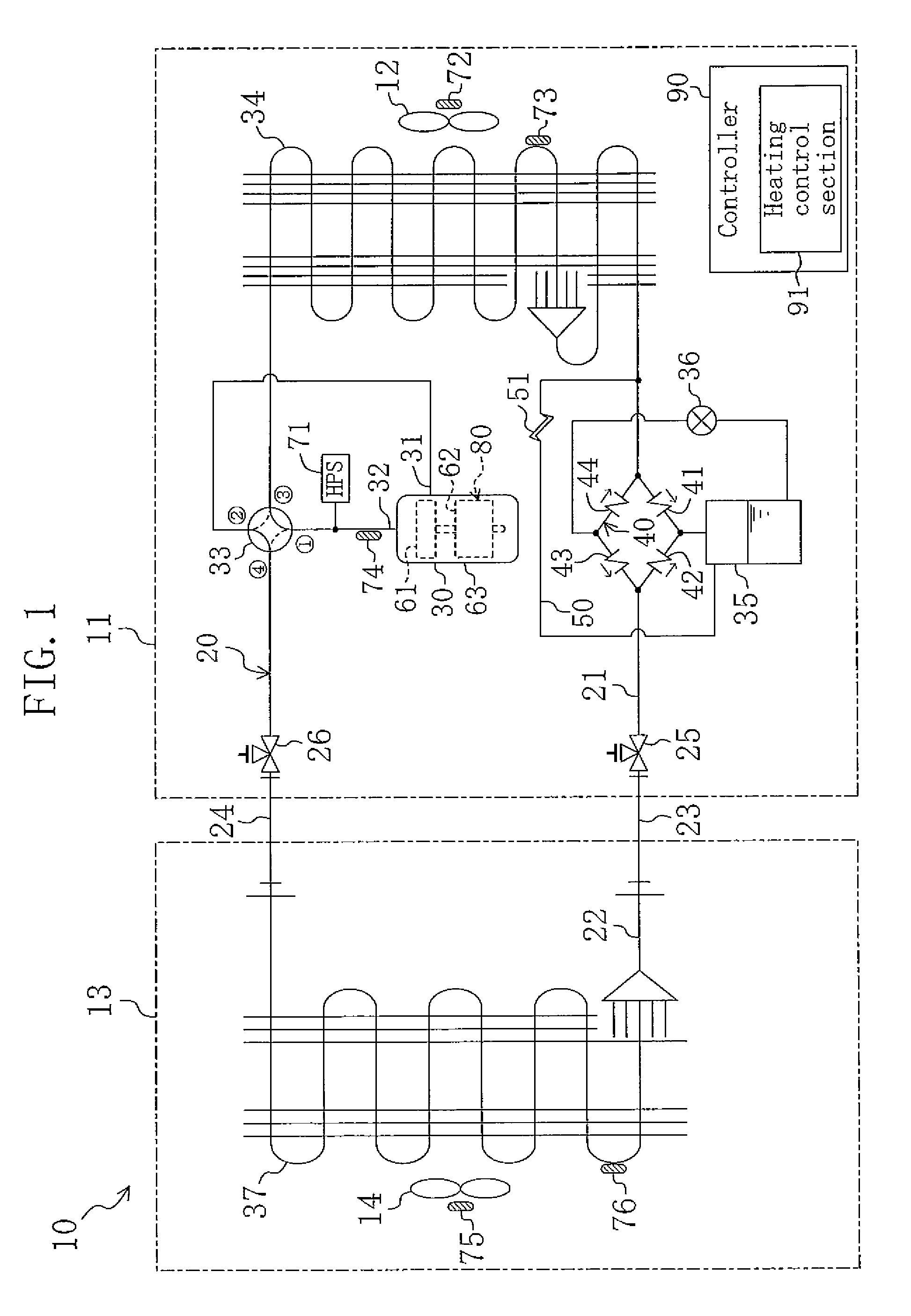

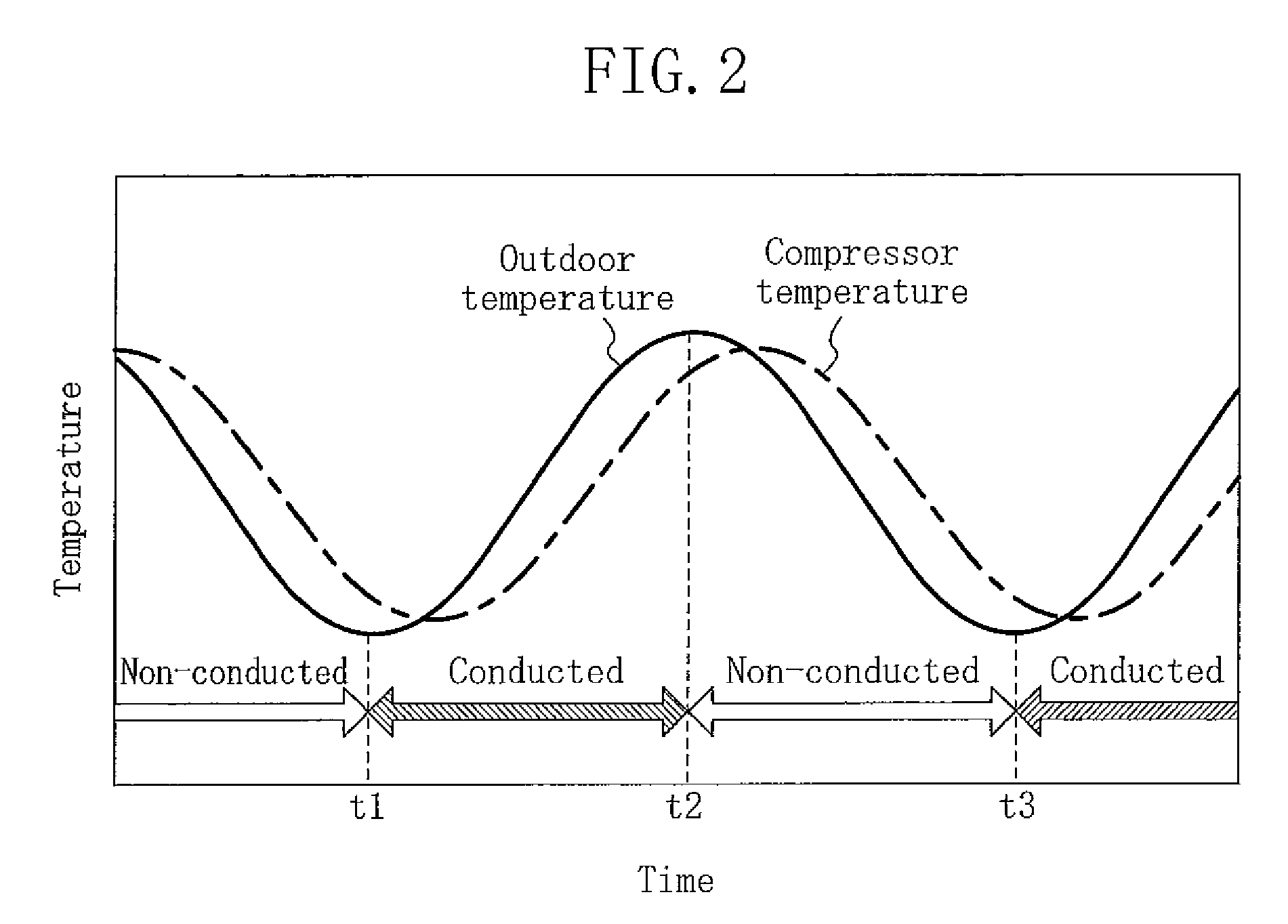

Refrigeration apparatus

ActiveUS20100162742A1Lower energy requirementsReduce energy consumptionTemperatue controlStatic/dynamic balance measurementPhase stateControl theory

An air conditioner (10) composed of a refrigerating apparatus includes a controller (90). A heating control section (91) of the controller (90) feeds electric current in an open phase state to an electric motor (62) of a compressor (30) to heat the compressor (30) in operation stop of the air conditioner (10). The heating control section (91) monitors the detection value of an outdoor air temperature sensor (72) during the operation stop of the air conditioner (10) and keeps on stopping feeding the electric current to the electric motor (62) during the time when the detection value decreases.

Owner:DAIKIN IND LTD

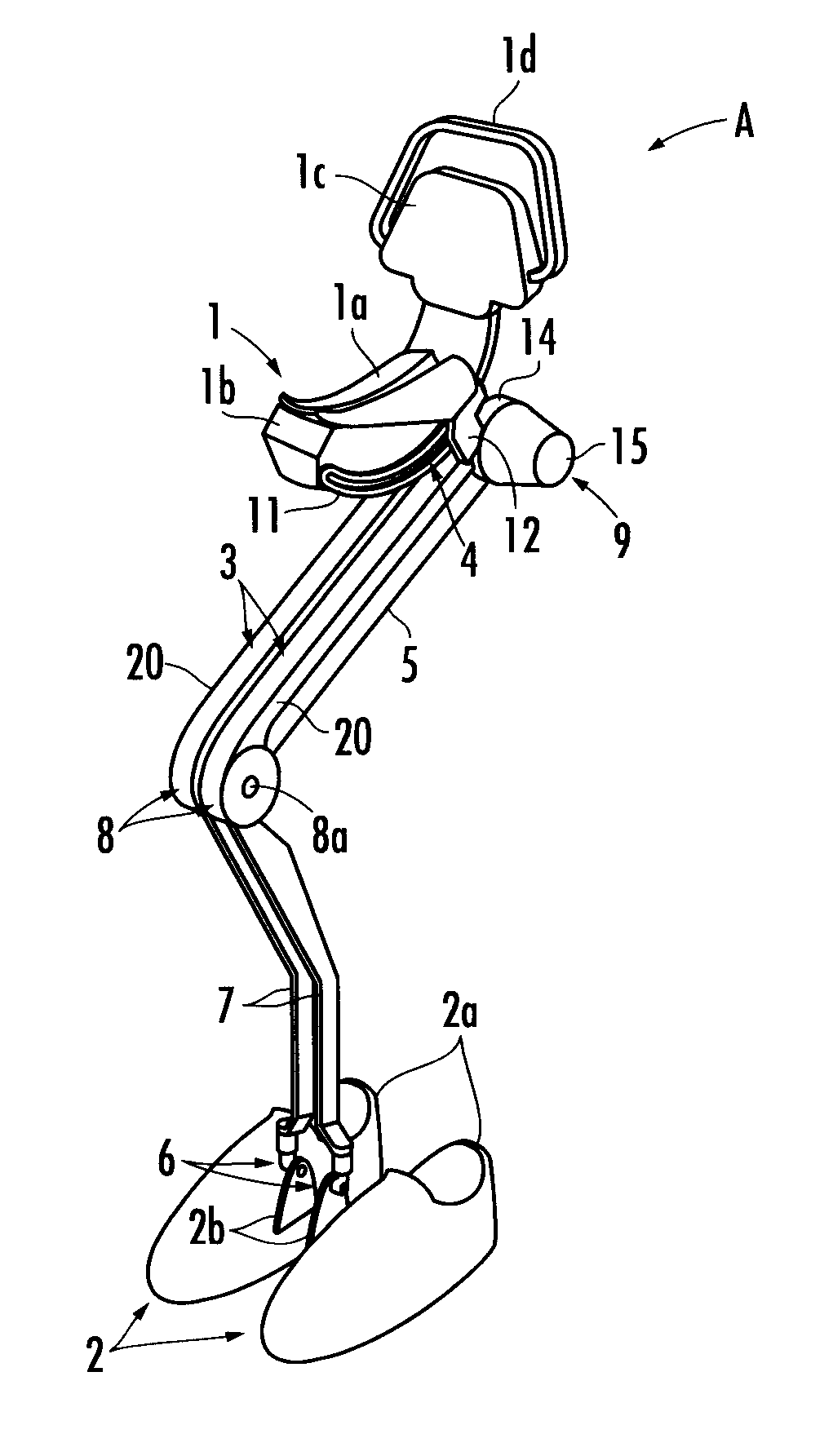

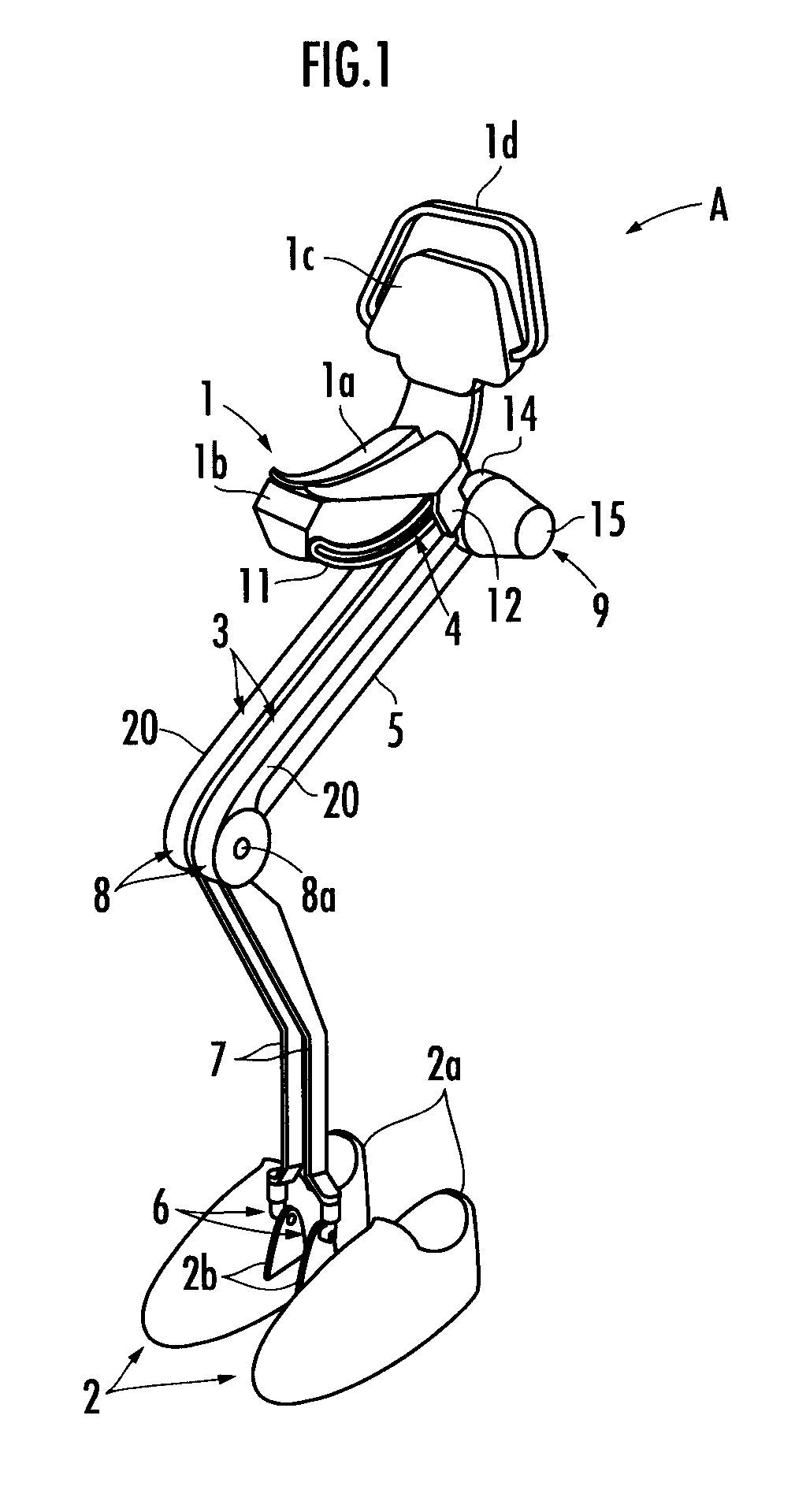

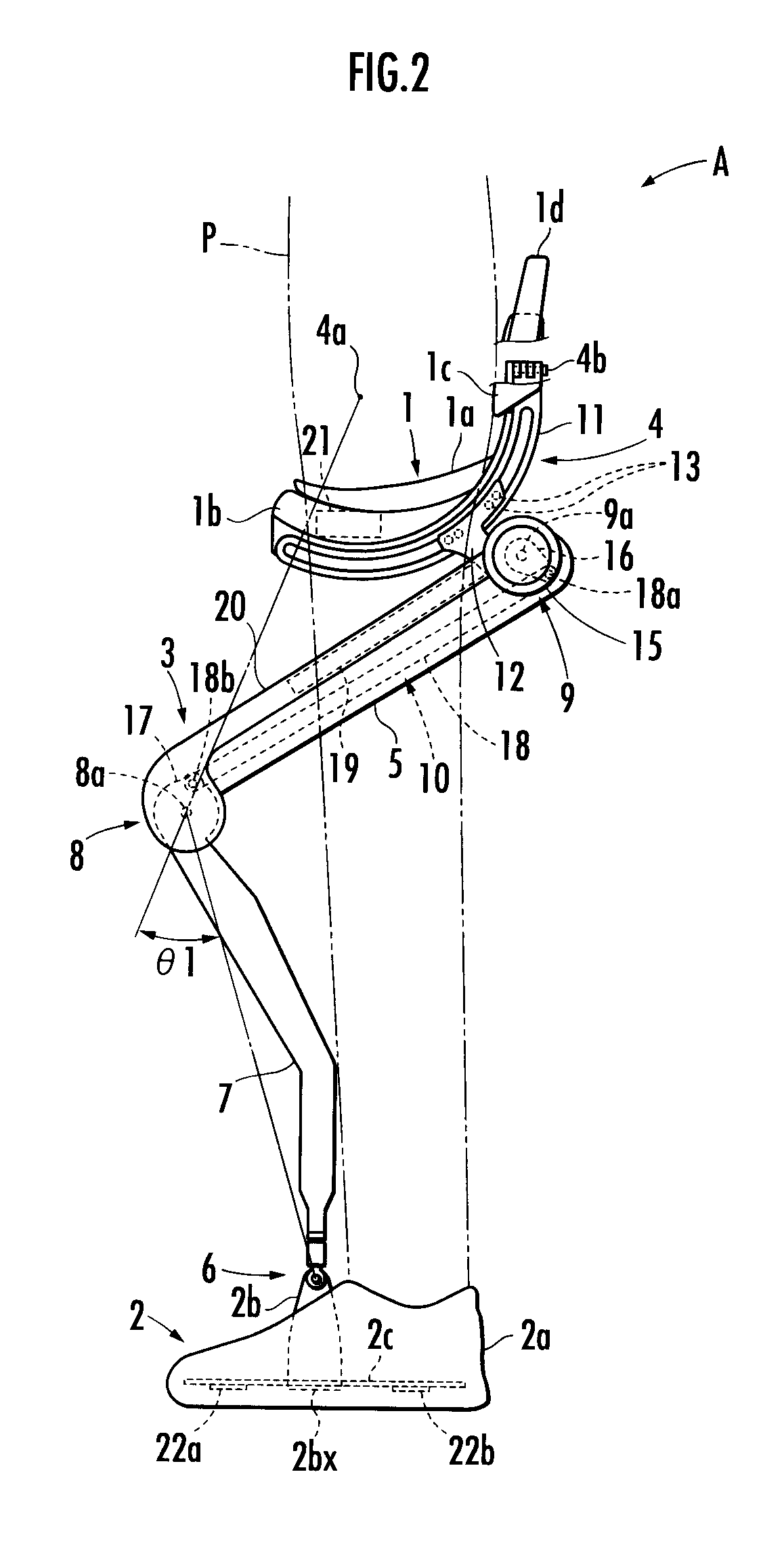

Motion assisting device

InactiveUS20100130894A1Curb energy consumptionBlock valueChiropractic devicesWalking aidsLower limitElectricity

A motion assisting device comprises a first index value measuring means 65 which measures a first index value indicating a remaining energy amount of an electrical storage device 19 and power regulation means 63 and 64 each of which regulates the motive power of an electric actuator 9 after the time point of measuring the first index value at least according to the first index value measured by the first index value measuring means 65. The power regulation means 63 and 64 regulate the motive power of the electric actuator 9 so that the remaining energy amount of the electrical storage device 19 is maintained at a predetermined lower limit or greater until the end time point of a desired operating time of the motion assisting device A.

Owner:HONDA MOTOR CO LTD

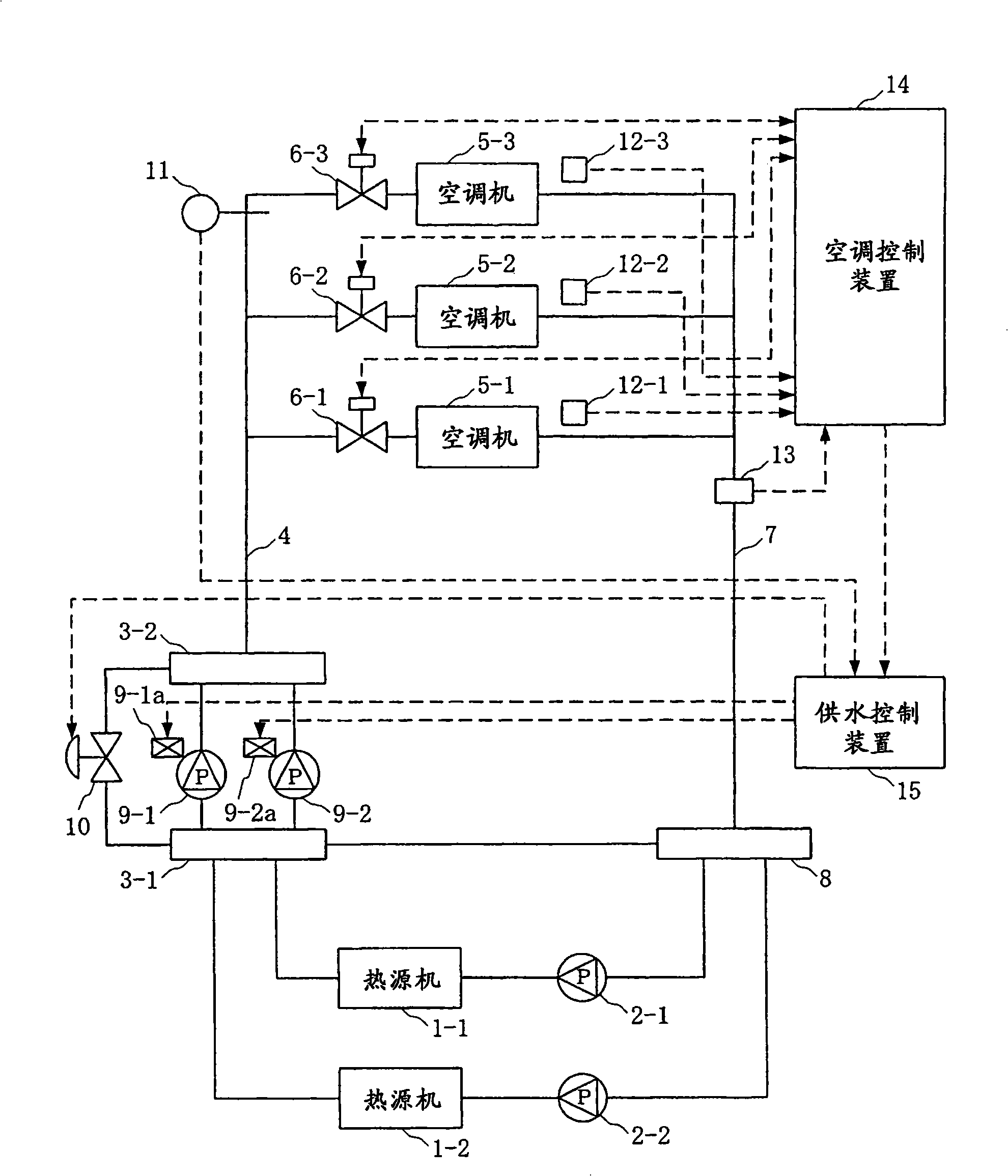

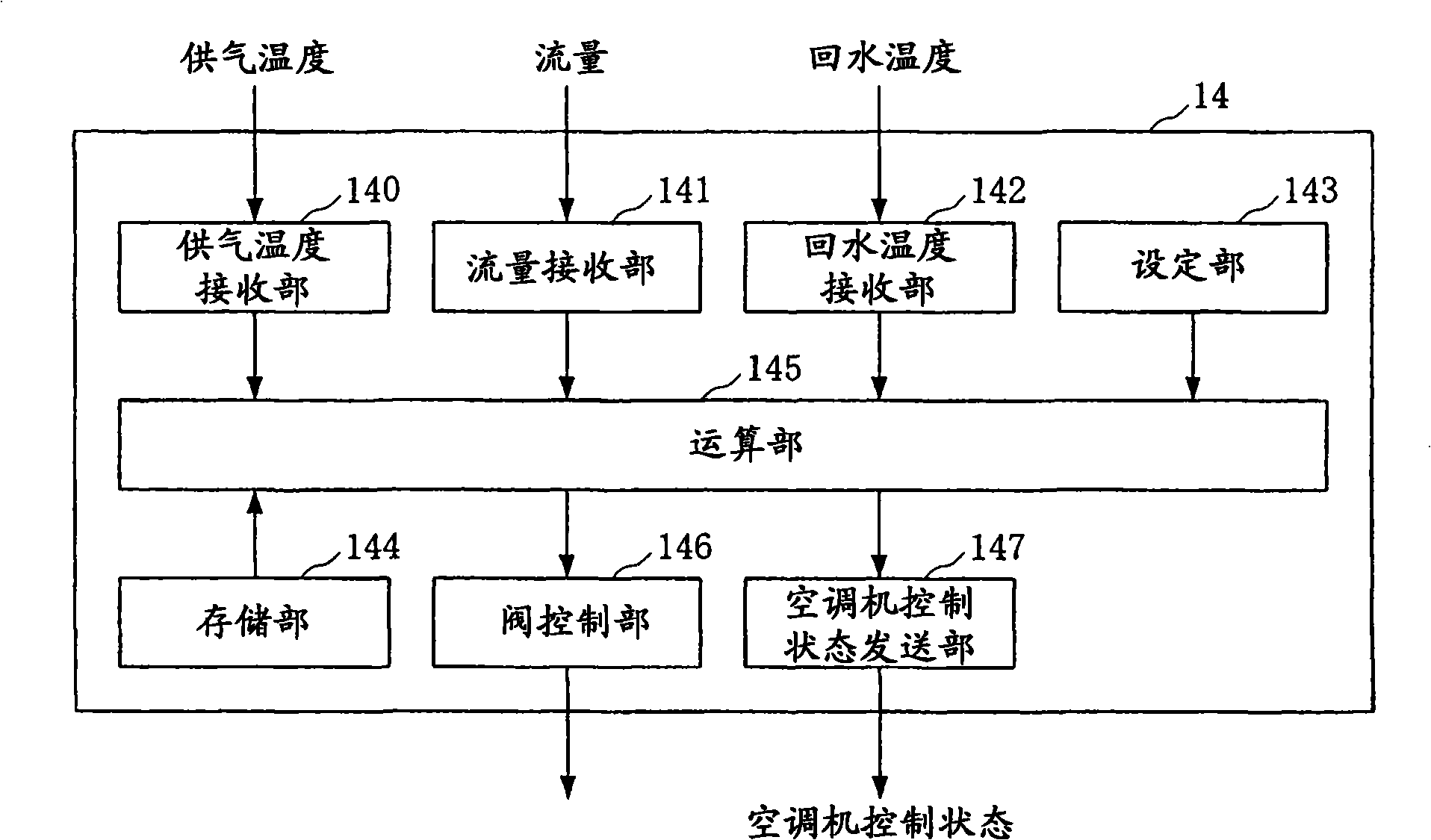

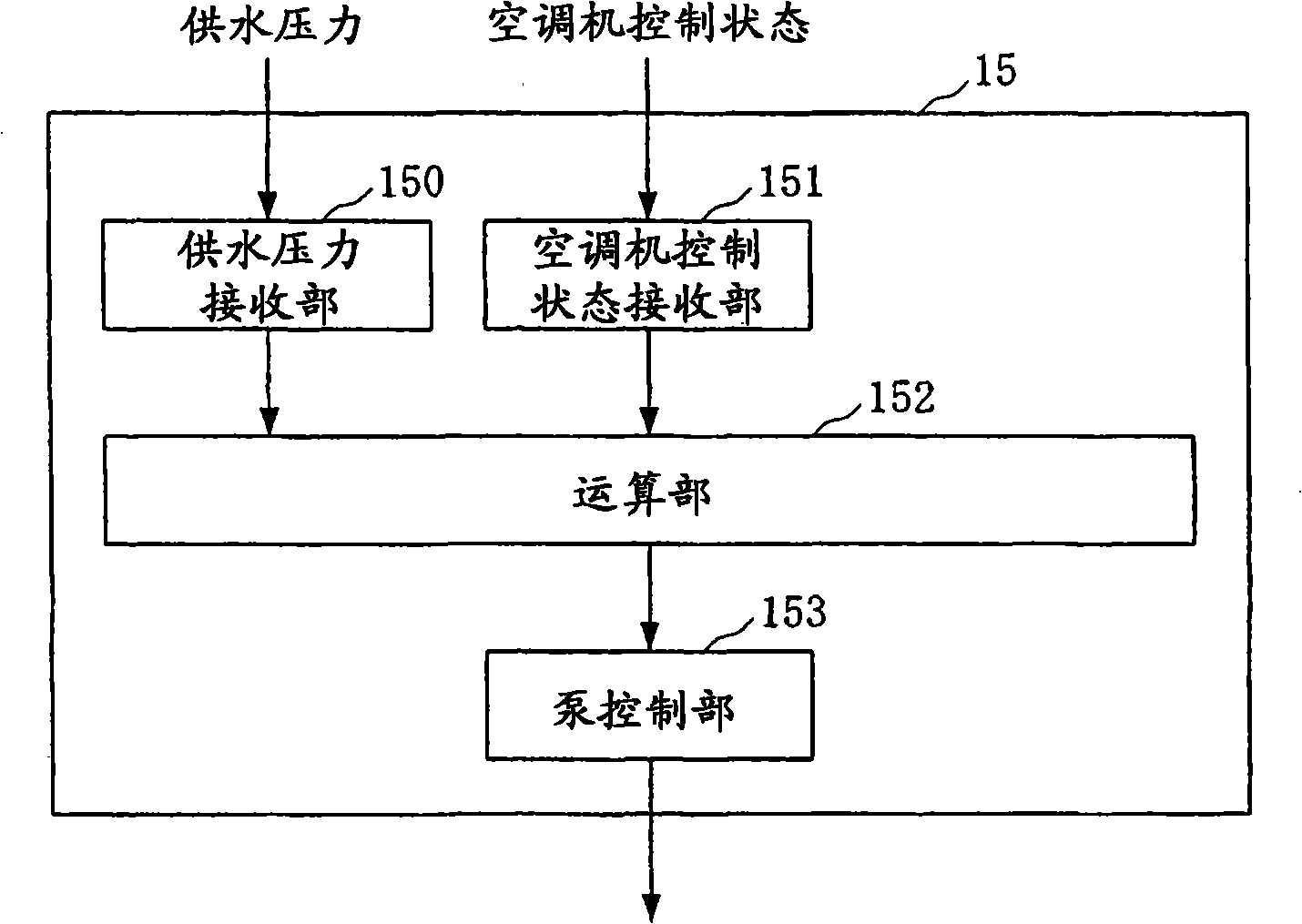

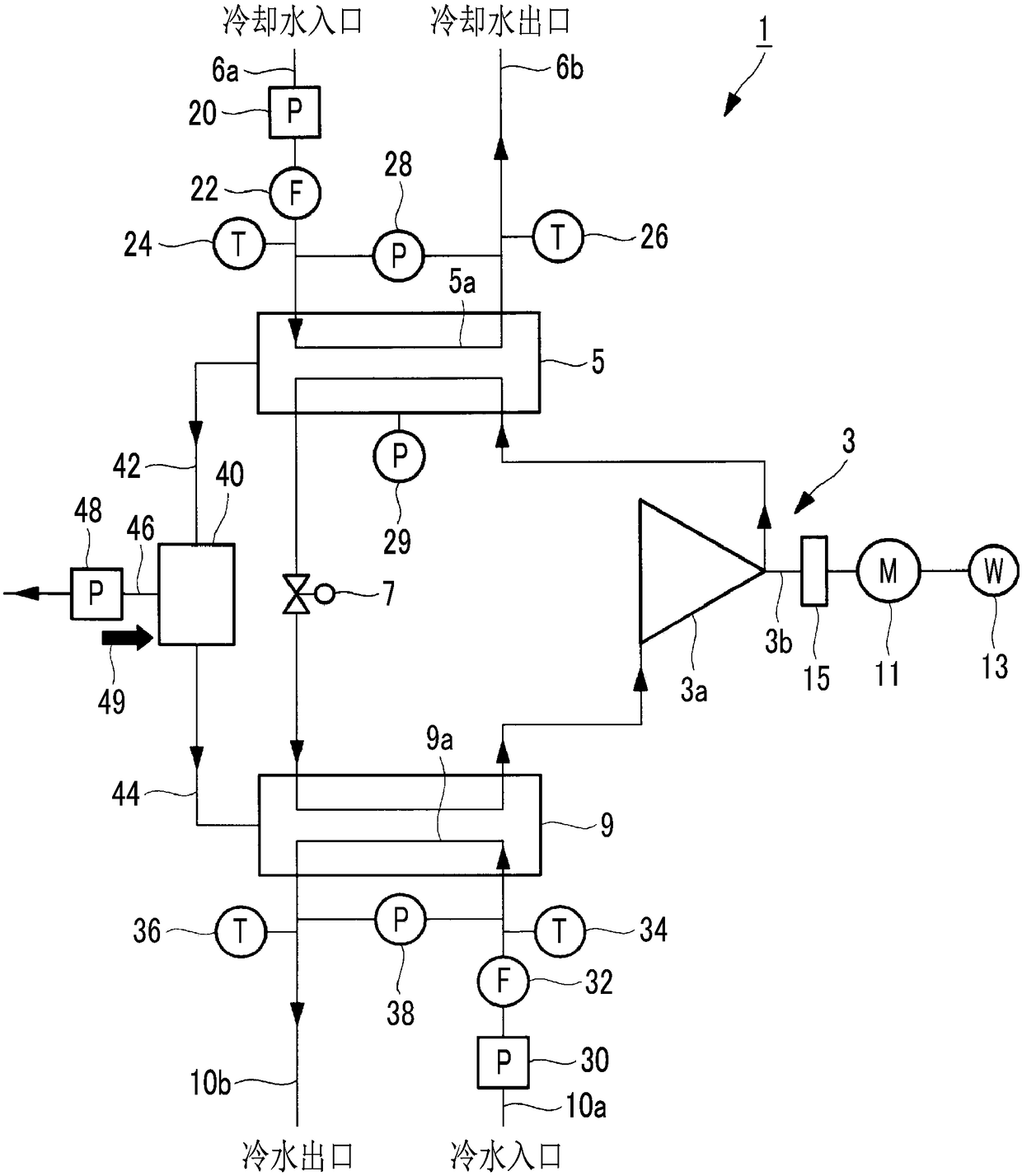

Air conditioner control system and method

InactiveCN101354170ACurb energy consumptionHigh energy consumptionMechanical apparatusSpace heating and ventilation safety systemsControl systemEngineering

The invention provides an air-conditioning control system for inhibiting energy consumption increment, which comprises pumps (9-1, 9-2) conveying cold water and hot water, air conditioners (5-1 to 5-3) receiving the supplied cold water and hot water, valves (6-1 to 6-3) controlling the flow of the cold water and hot water, a flow measuring mechanism arranged inside the valves (6-1 to 6-3), an air-conditioning control device (14) controlling the opening of the valves according to the partial difference of the air supply temperature sent from the air conditioners (5-1 to 5-3) and a set temperature and limiting the opening of the valves when the flow passing through the valves is over the maximum set flow to cause the flow passing through the valves to be maintained below the maximum set flow, and a control device (15) controlling water supply pressure according to the control state of the air conditioners (5-1 to 5-3) determined by the opening of the valves and the flow passing through the valves.

Owner:YAMATAKE HONEYWELL CO LTD

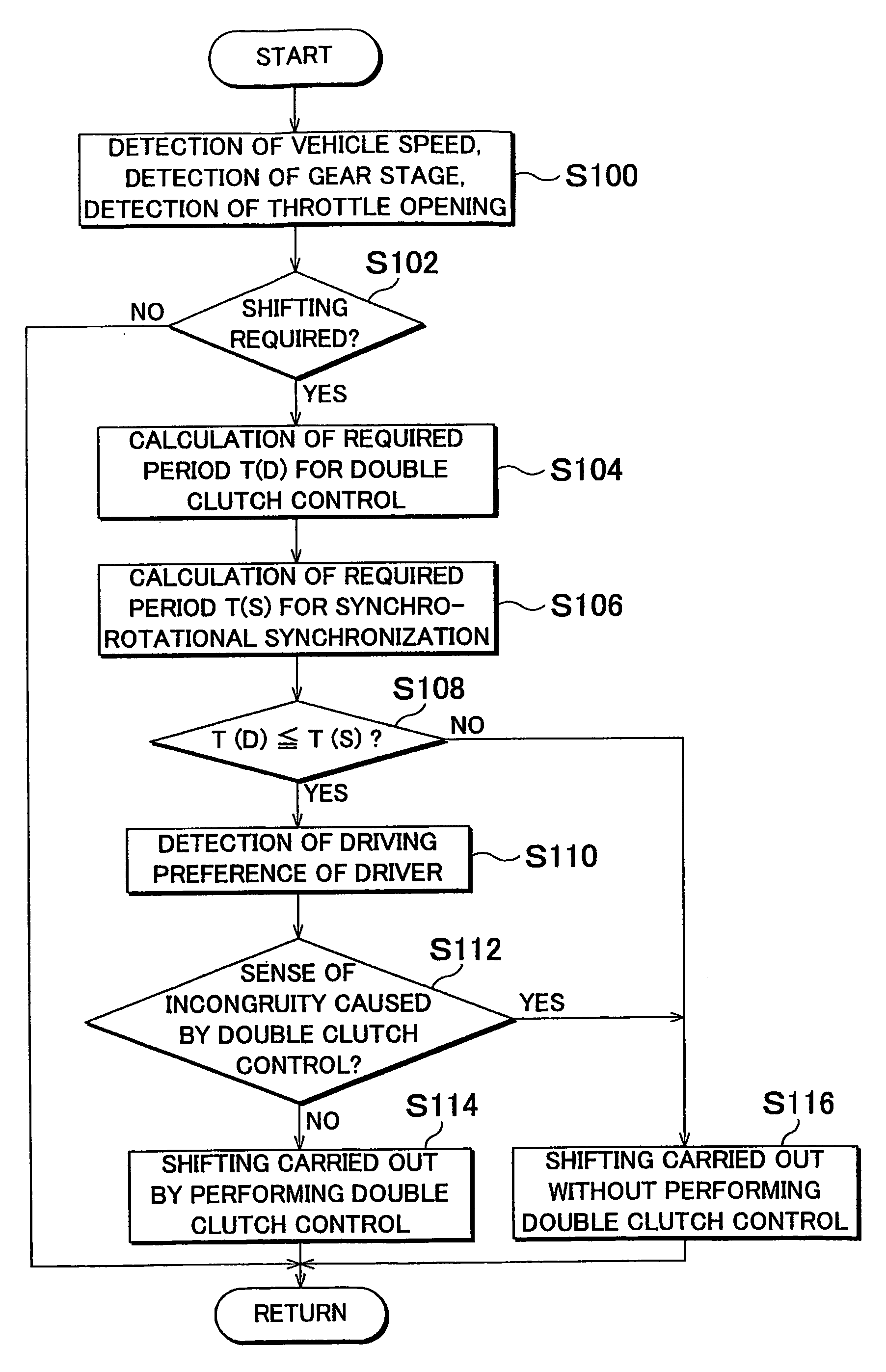

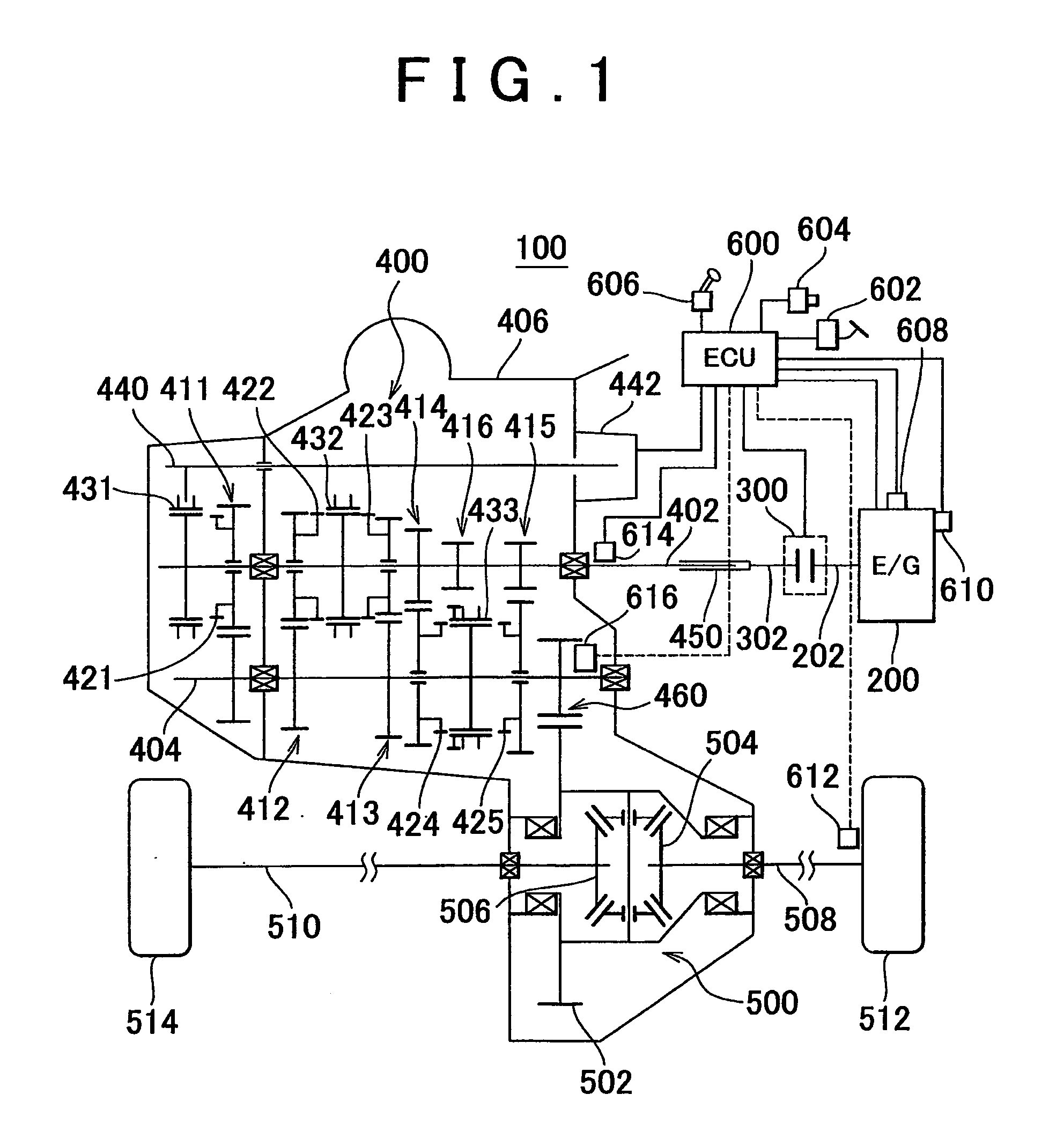

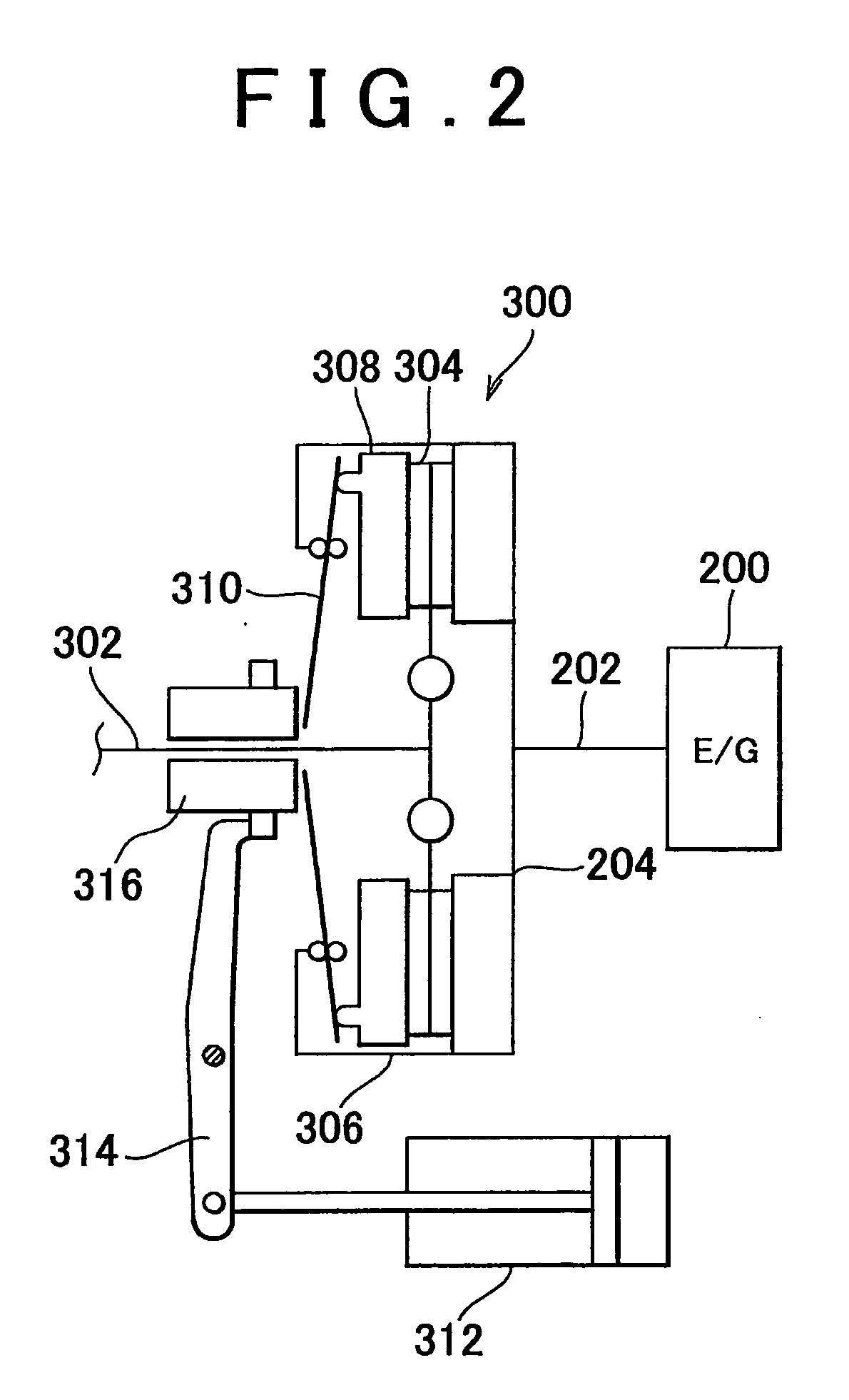

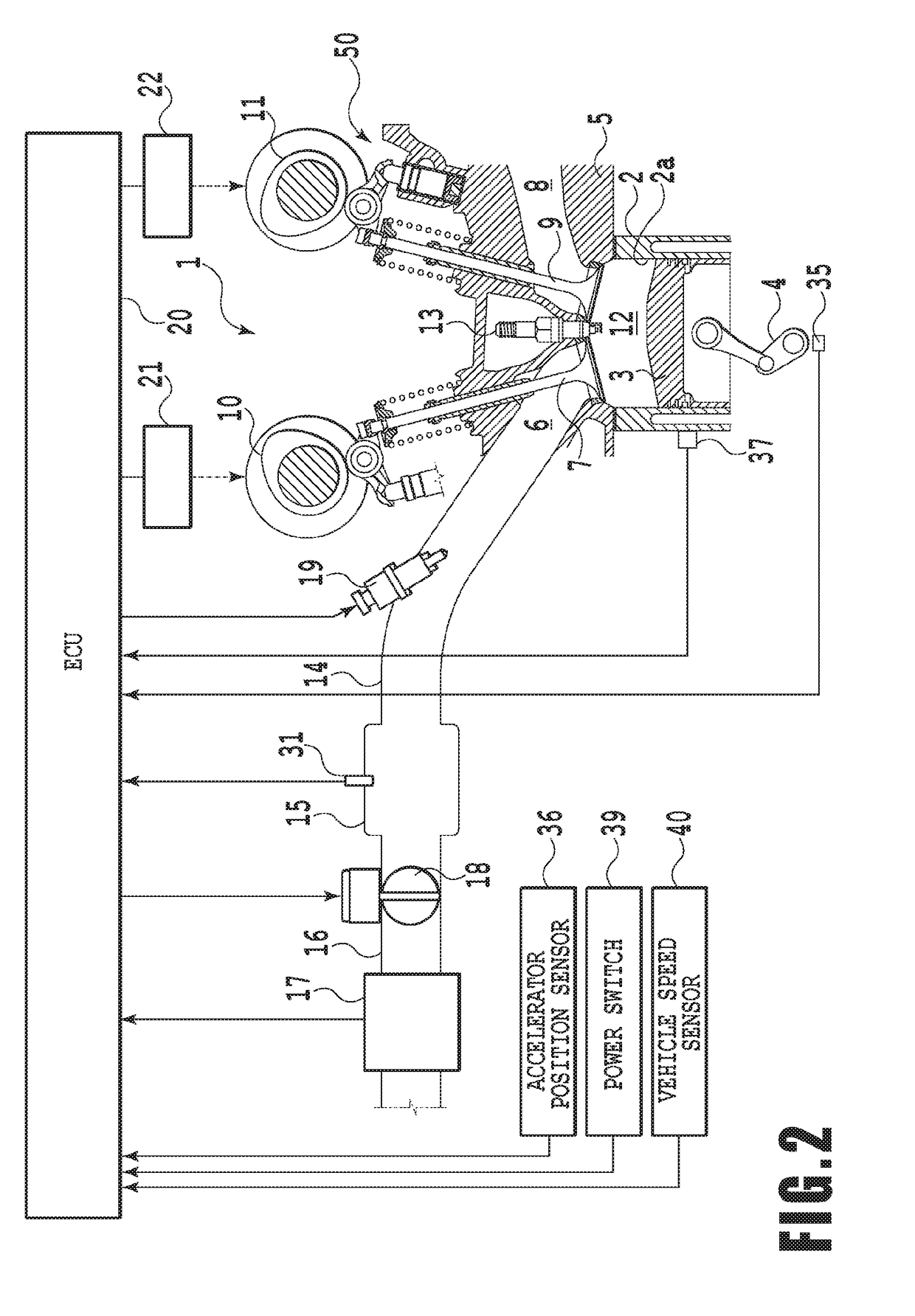

Shifting Apparatus and Shifting Control Method Thereof

InactiveUS20080248923A1Deterioration in fuel consumption can be suppressedCurb energy consumptionDigital data processing detailsGearing controlClutch controlDriver/operator

An ECU executes a program including a step of detecting a running speed of a vehicle and a current gear stage of the vehicle, a step of determining whether or not shifting is required, a step of calculating a required period T(D) for performing double clutch control if shifting is required, a step of calculating a required period T(S) for synchro-rotational synchronization, a step of determining whether or not the required period T(D) for double clutch control is equal to or shorter than the required period T(S) for synchro-rotational synchronization, and a step of carrying out shifting by performing double clutch control if the required period T(D) for double clutch control is equal to or shorter than the required period T(S) for synchro-rotational synchronization. A sense of incongruity felt by a driver during shifting is thereby suppressed.

Owner:TOYOTA JIDOSHA KK

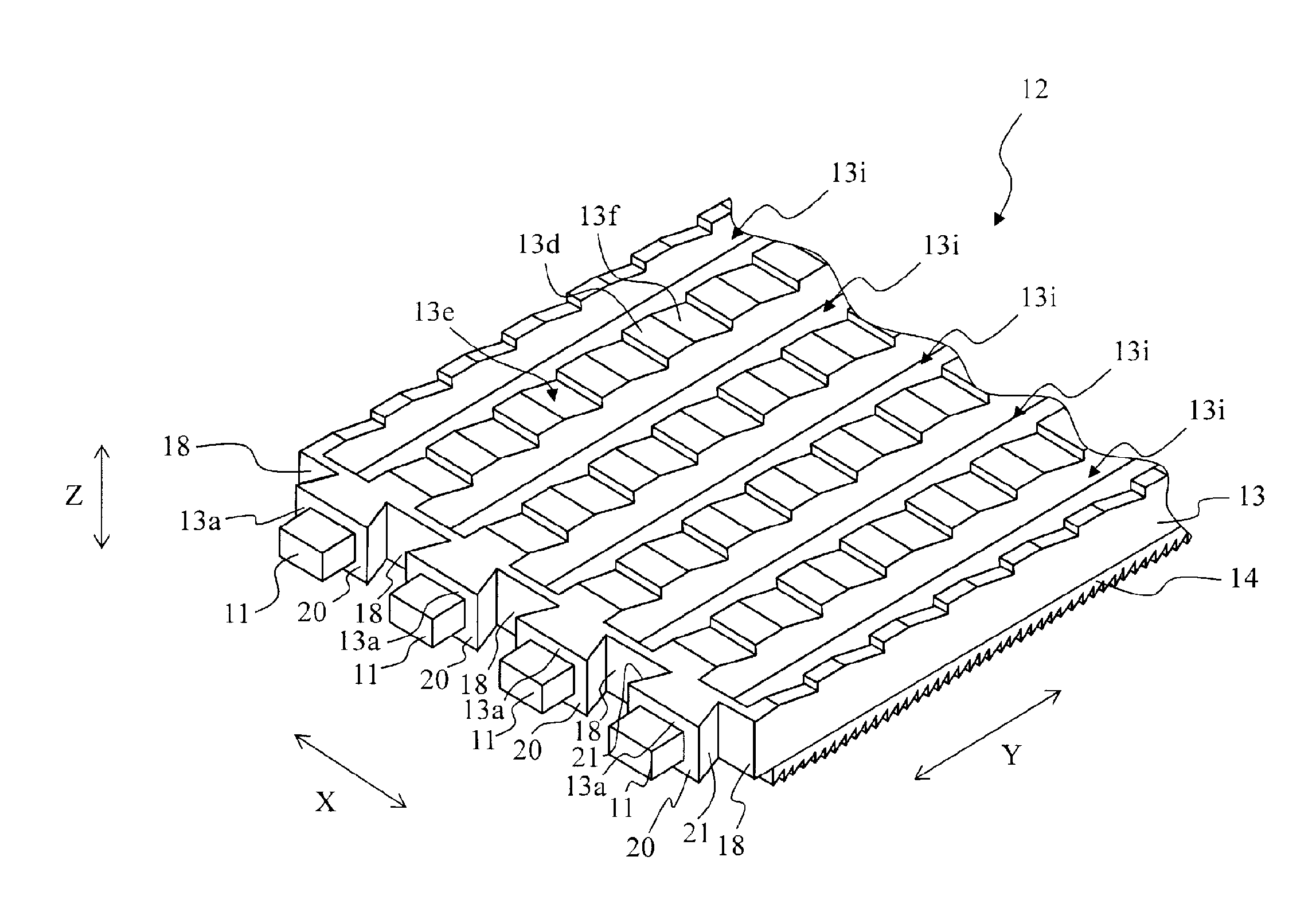

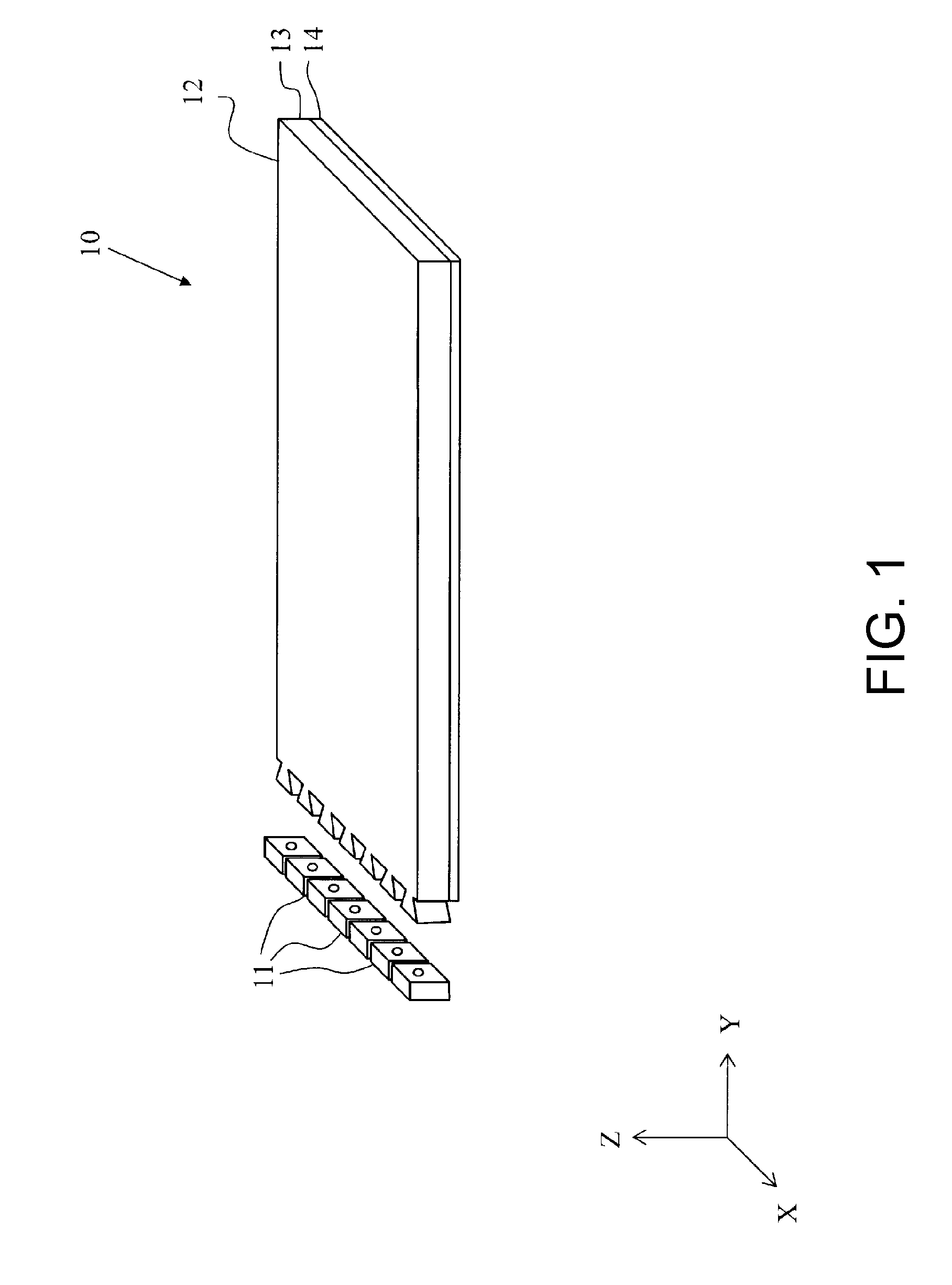

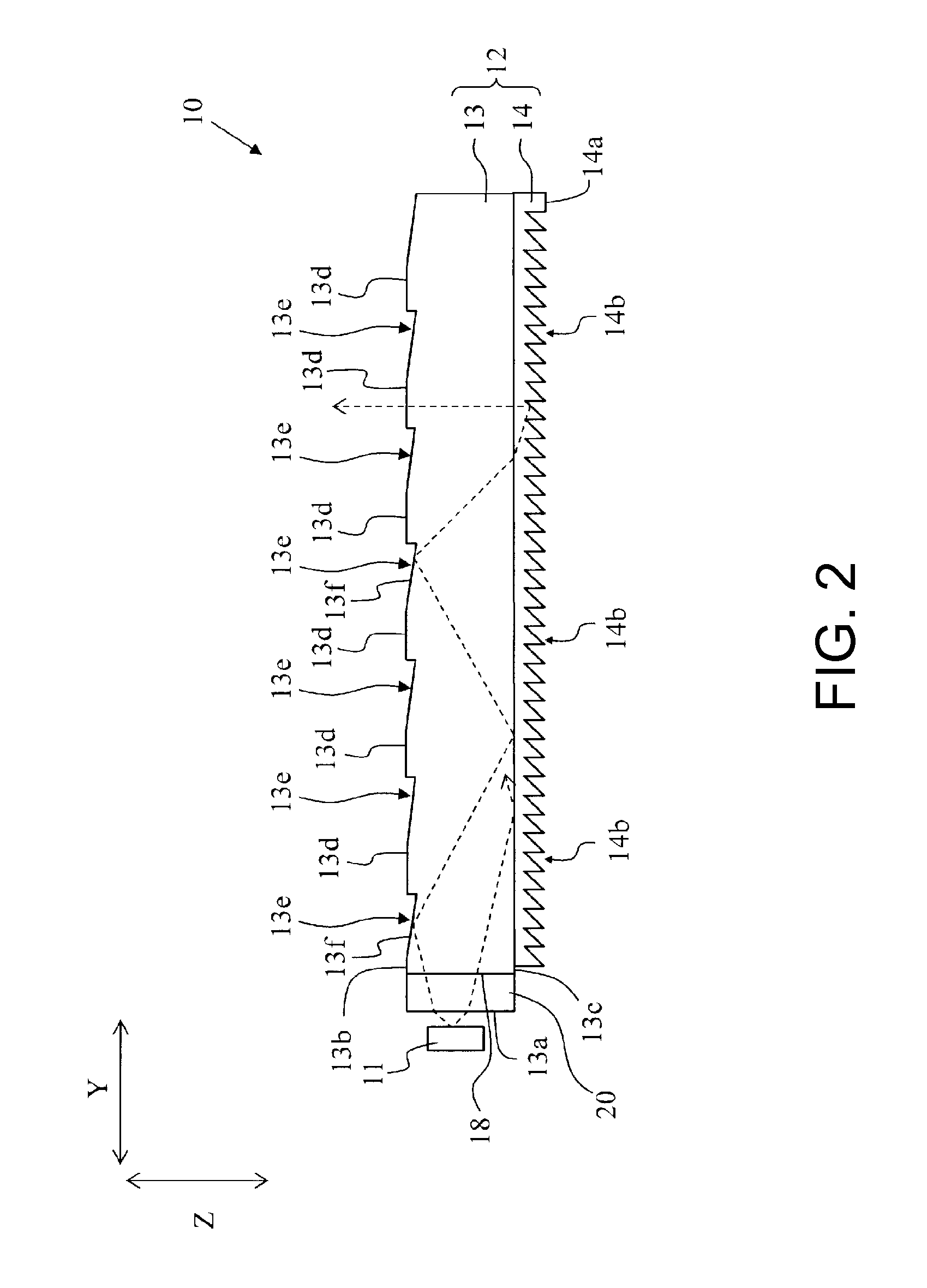

Illumination device, and display device

InactiveUS20150131317A1Simple configurationCurb energy consumptionMechanical apparatusPlanar/plate-like light guidesLight guideDisplay device

The present invention aims at providing an illumination device and a display device that can suppress uneven brightness while improving light use efficiency and brightness. The illumination device includes a plurality of light sources arranged next to each other, a light guide member that guides light from the light sources, and protrusions that protrude towards the respective light sources from an end face of the light guide member. The protrusions each have side faces formed such that light emitted so as to spread in the arrangement direction of the light sources exits the light guide member and then re-enters from the end face thereof.

Owner:SHARP KK

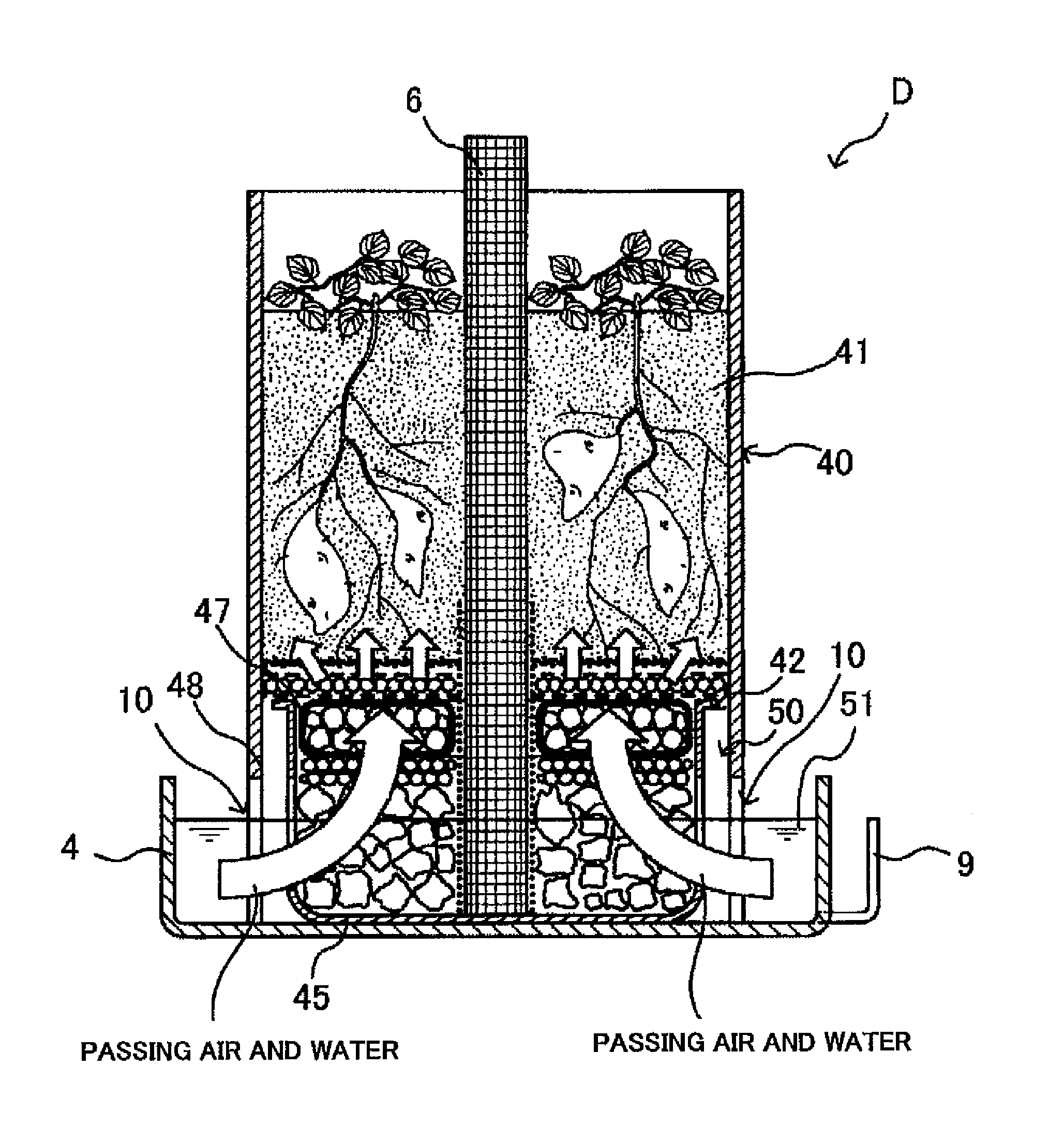

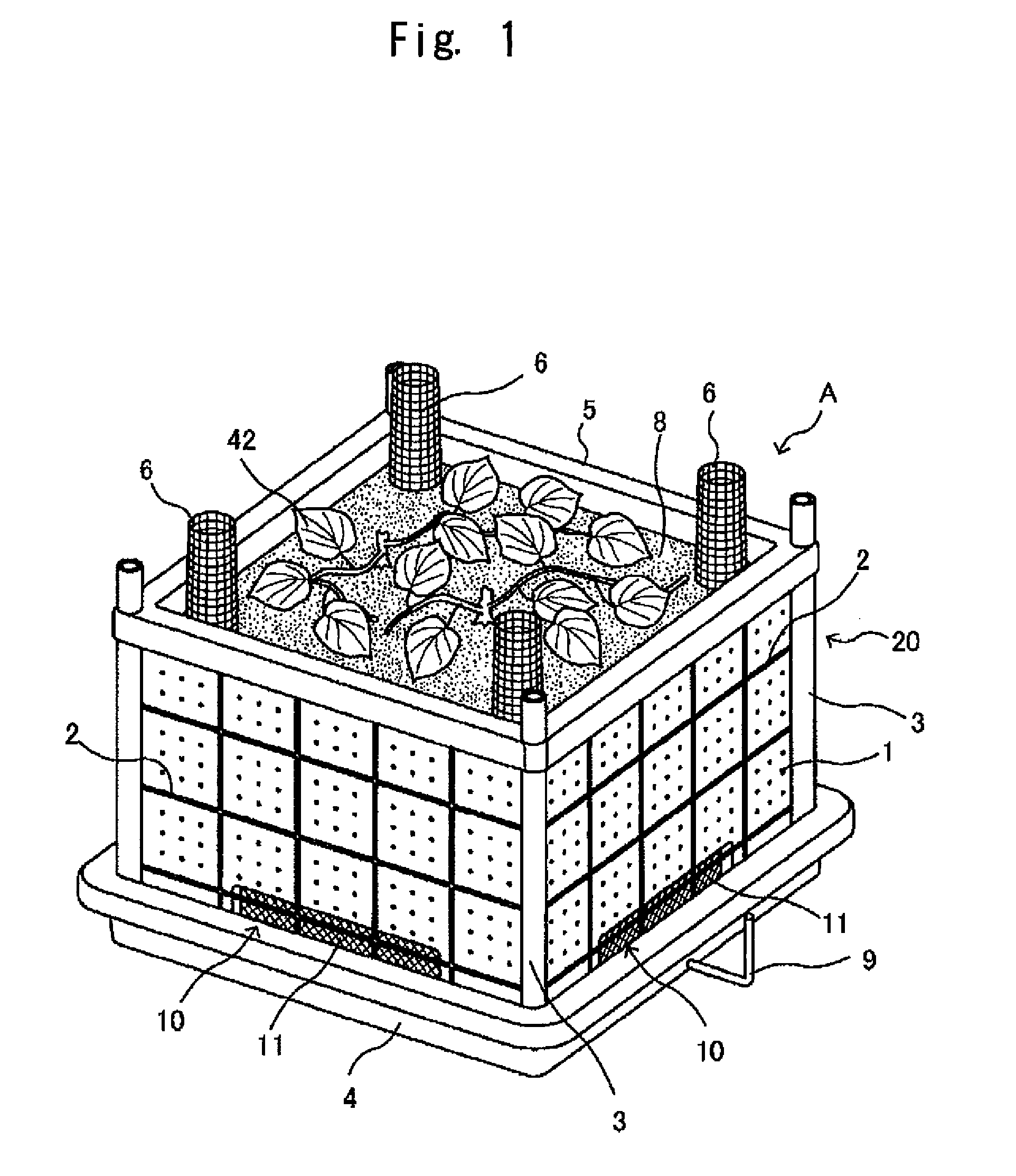

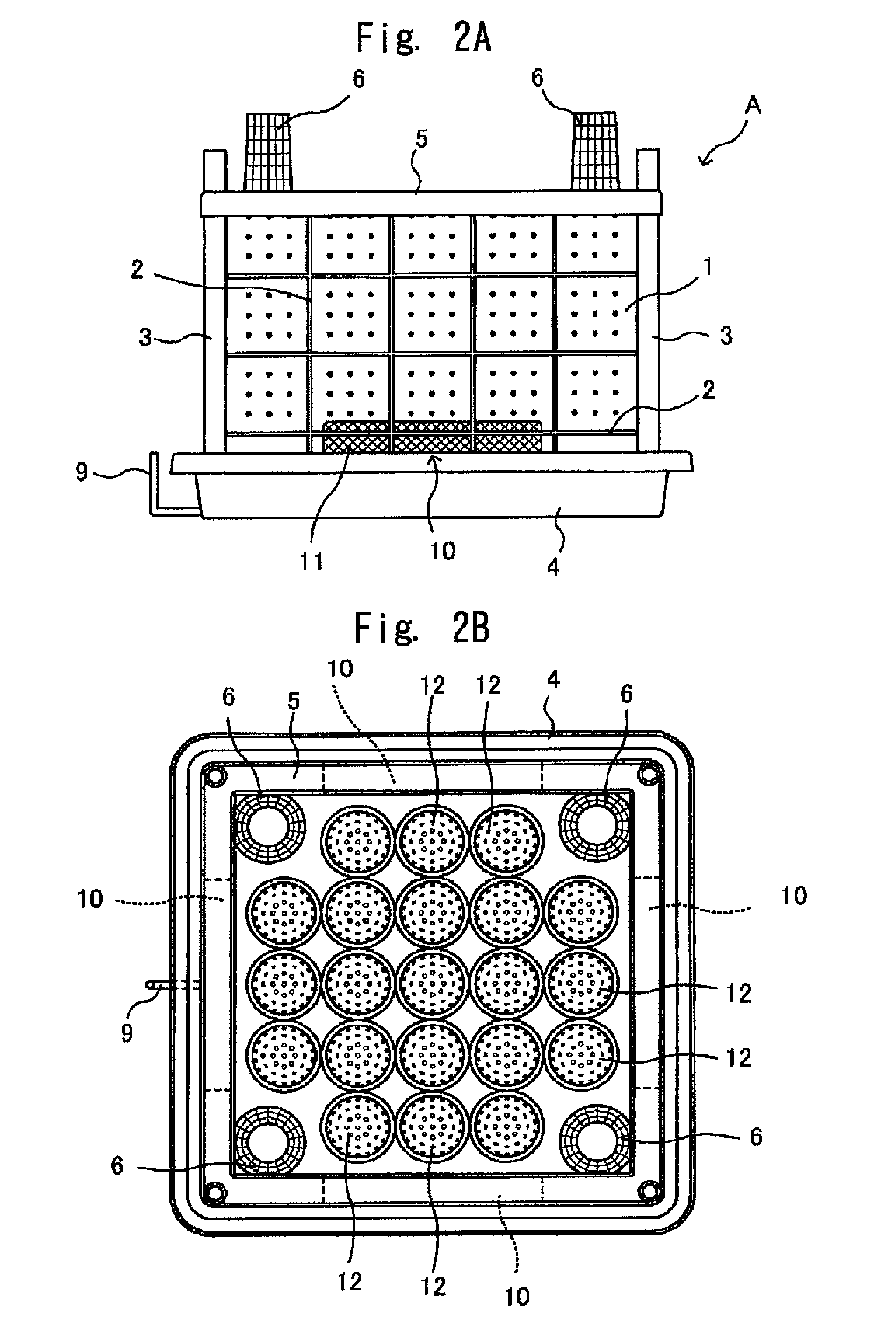

Device for fixing biomass-based solar heat and carbon dioxide gas, and house equipped with same fixing device

InactiveUS8950111B2Improve cultivation technologyIncrease productionBioreactor/fermenter combinationsBiological substance pretreatmentsProduction rateWater flow

There are provided a device for fixing biomass-based solar heat and carbon dioxide gas with a similarity to containerized culture having high crop productivity, which is capable of fixing carbon dioxide gas highly efficiently, while being compact and easily managed, and a house equipped with the fixing device having an energy circulation system. The fixing device for biomass-based solar heat and carbon dioxide gas is configured to include an air intake unit which takes air into a box, a mesh-like air and water flow-through unit laid in the bottom of the box that is configured to be open to the atmosphere, a water reservoir tray on which the box is mounted, and cultivation soil which is held inside the box. Further, in the house relating to the present invention, the fixing device for biomass-based solar heat and carbon dioxide gas is arranged in an area that gets a lot of sunshine.

Owner:PLUS KAKEN INNOVATE LABO

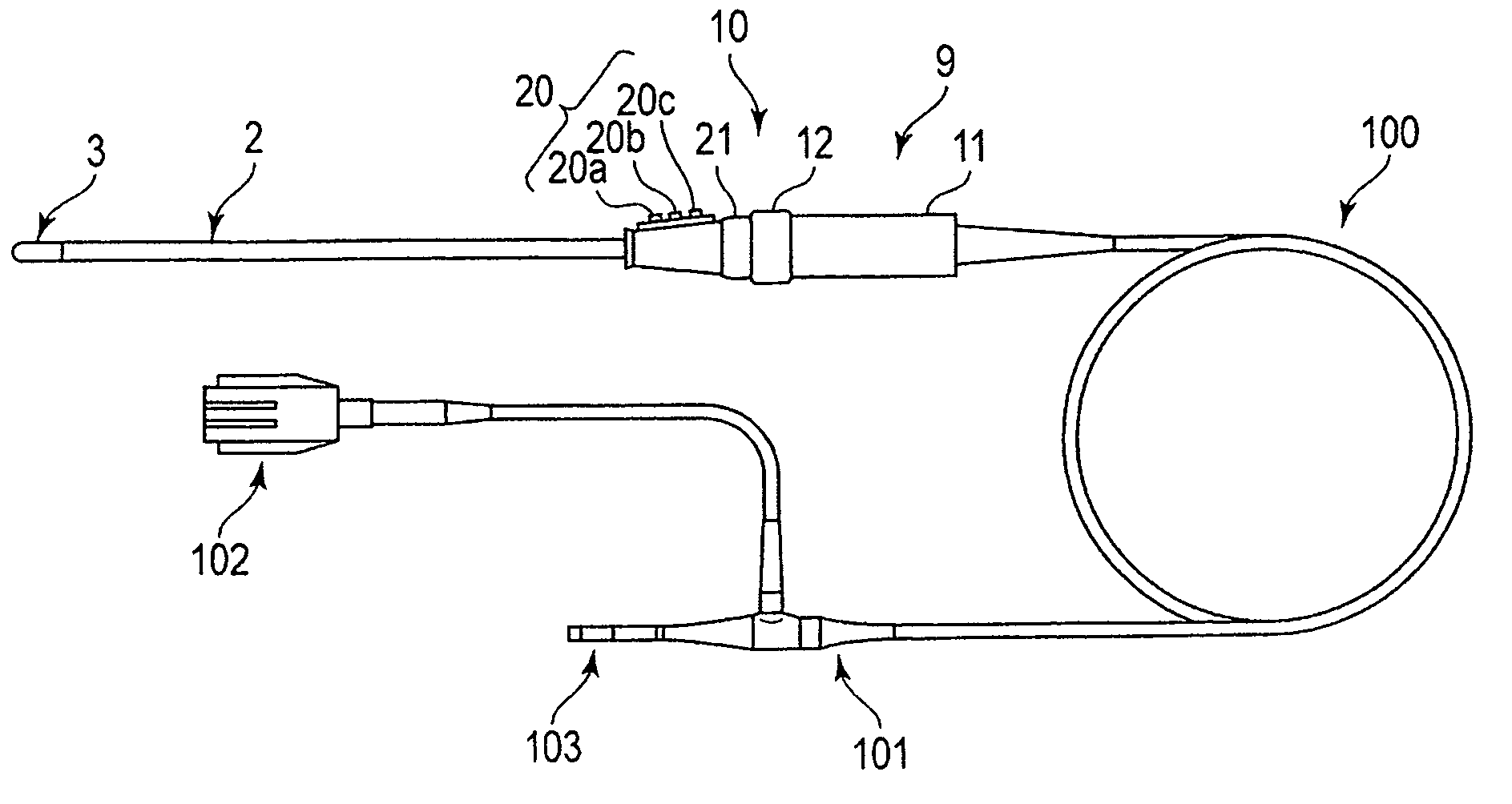

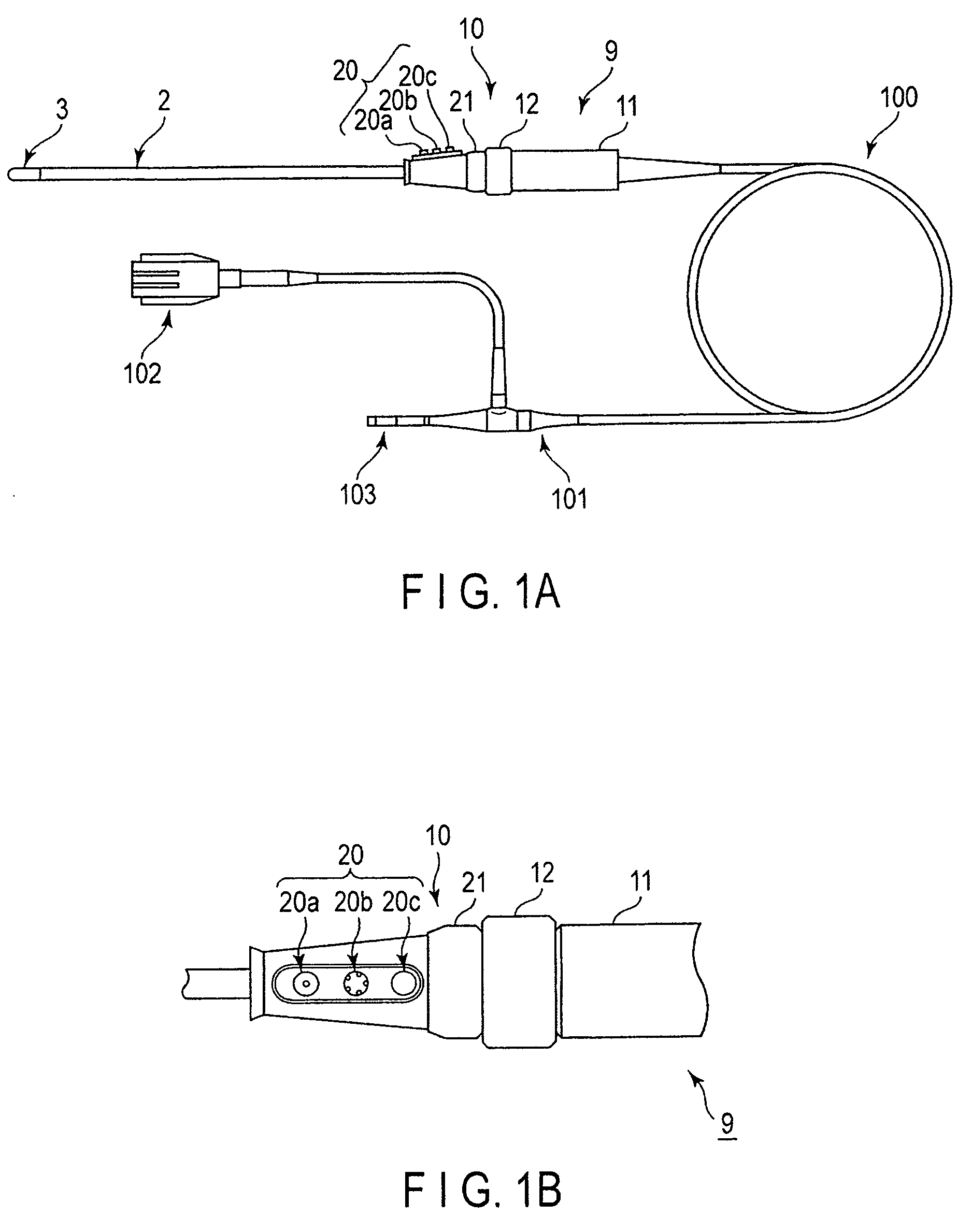

Medical device which acquires the picture for observation

ActiveUS20130258081A1Curb energy consumptionDownsizing of an insertion unitSurgeryEndoscopesLight switchField of view

In a medical device, a field-of-view switching mechanism which moves a field of view imaged by an observation section, and an illumination-light switching mechanism including an illumination section having an illumination range of illumination light whose entire field of view is covered by movement, are configured integrally with each other. The illumination light is illuminated to the current field of view by moving the illumination range of the illumination light, in synchronism with pivoting of an observation and in compliance with the field of view.

Owner:OLYMPUS CORP

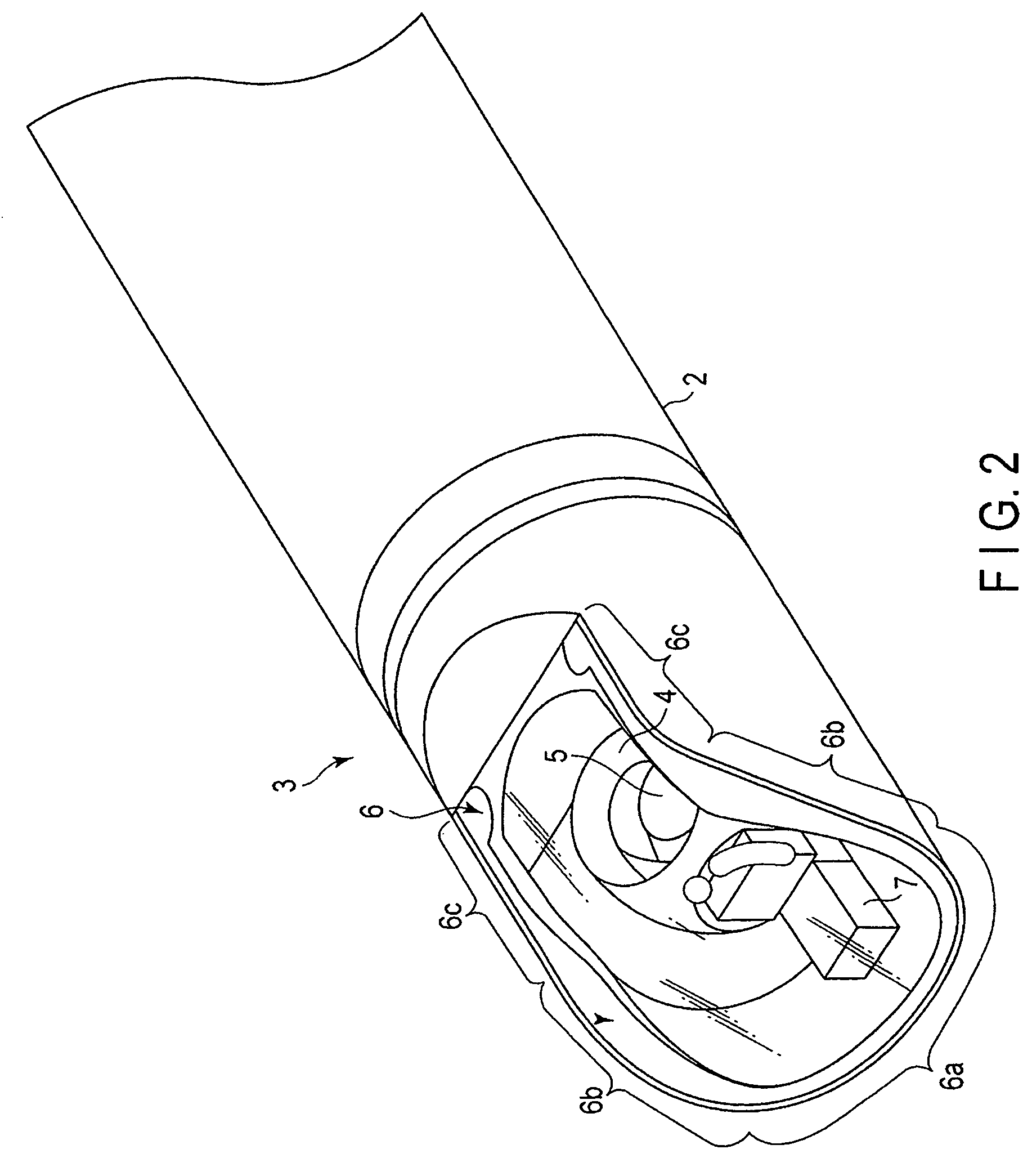

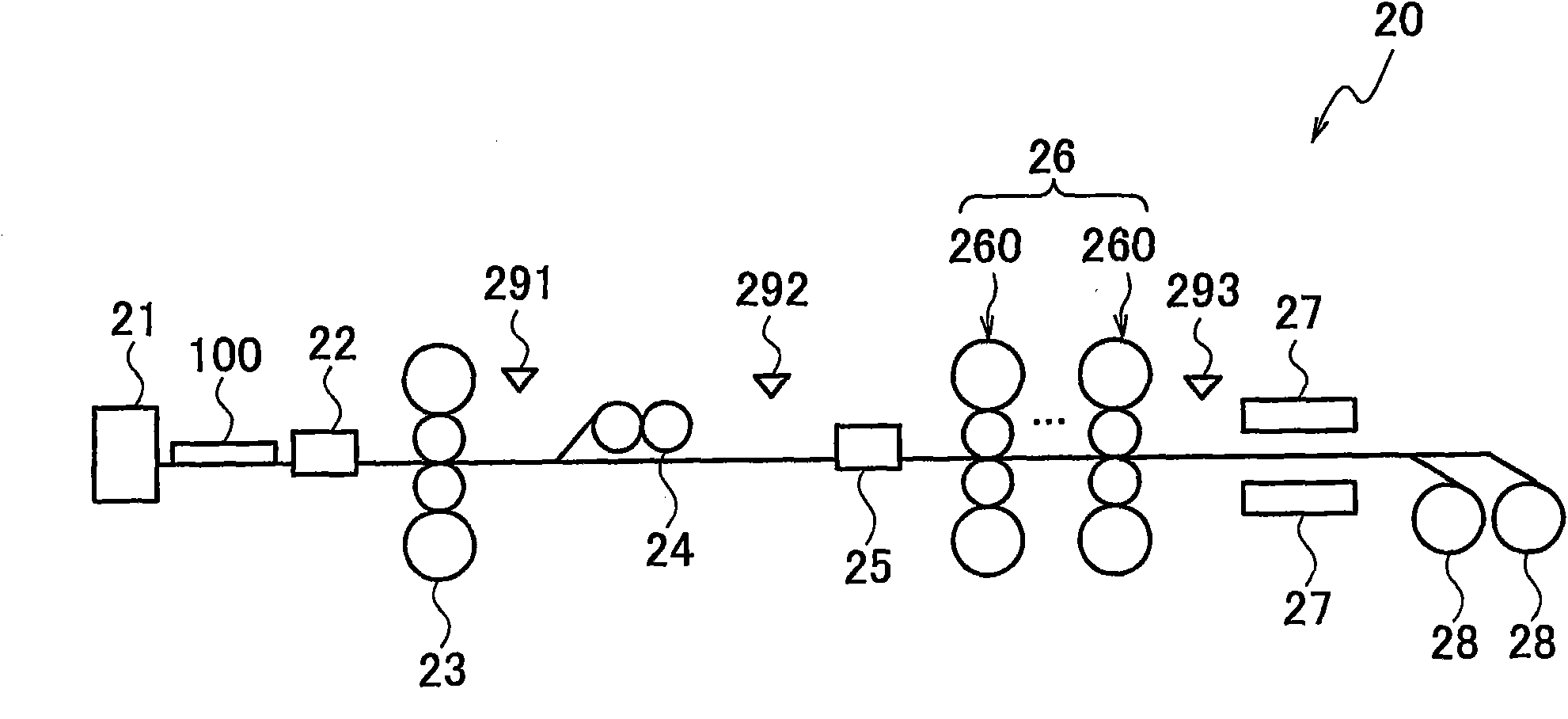

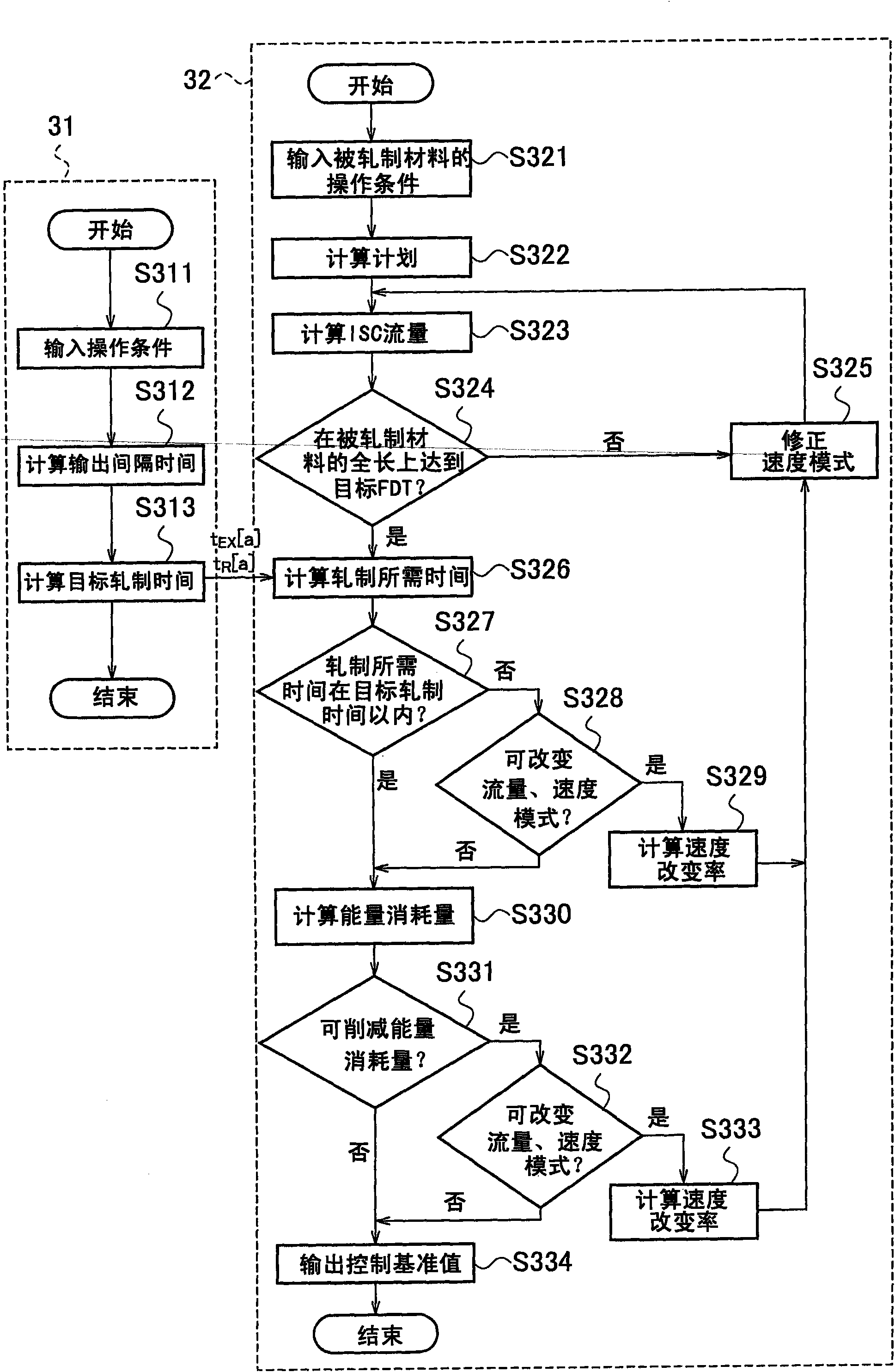

Control device for hot rolling line

ActiveCN102641893ACurb energy consumptionCurb consumptionTemperature control deviceWork cooling devicesTraffic volumeSynchronism

A rolling line material prediction and material control apparatus for controlling the material with high accuracy by having a function of simulating the variation course of a process and complementing information to improve the prediction accuracy of a material model. The apparatus has a rolling record information collecting function of collecting rolling record information obtained from a sensor for measuring the state of a hot rolling line and the state of a rolled steel sheet and from the controller for controlling the hot rolling line, process information supplement function for predicting process intermediate information representing the intermediate state of the rolling line not collectable as rolling record information on the basis of the rolling record information, fixed information such as the machine dimensions,; and target information such as on the thickness and width of the rolled steel sheet, material prediction function for predicting the material of the rolled steel sheet in synchronism with the progress of the rolling record information and the process intermediate information on the basis of the rolling record information and the process intermediate information, and material control function of making a control so that the predicted material agrees with the target one.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

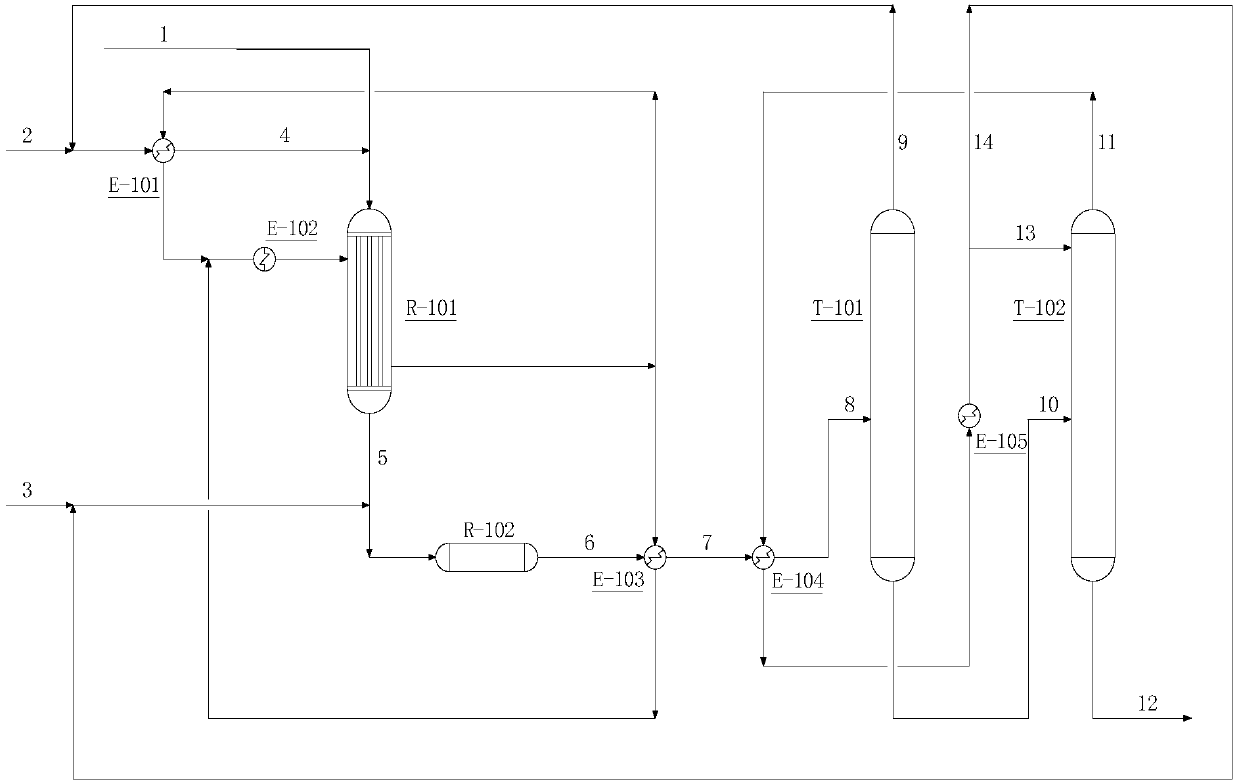

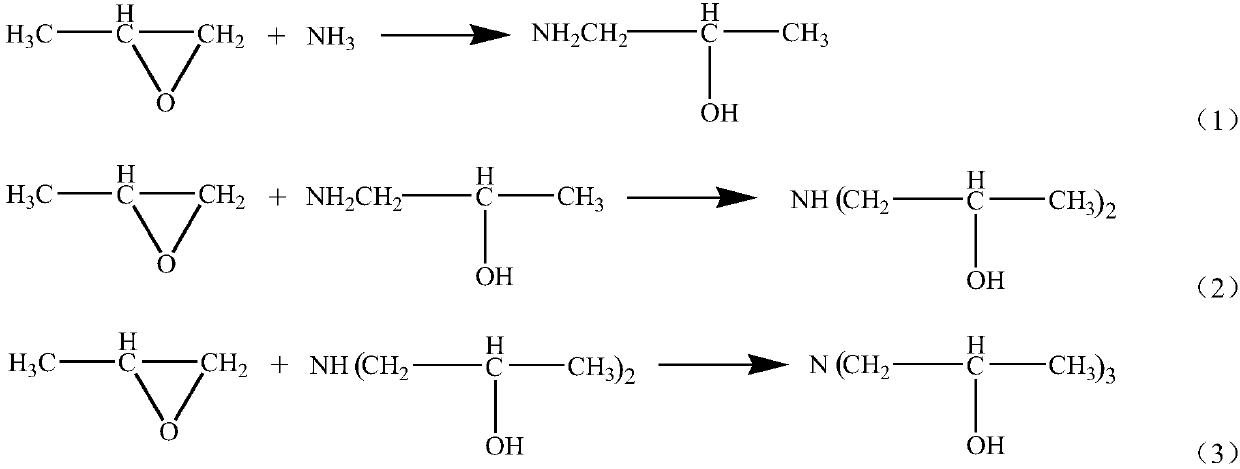

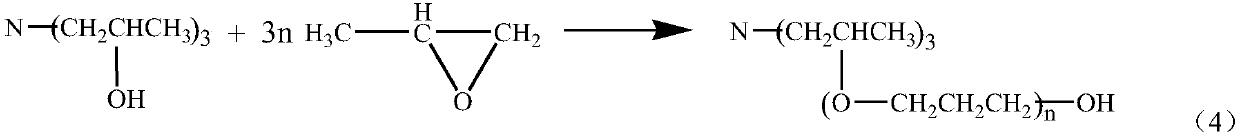

Isopropanolamine production method

ActiveCN109748804AReduce concentrationReduce the chance of spawningOrganic compound preparationChemical industryHigh concentrationFixed bed

The invention relates to an isopropanolamine production method and mainly solves problems of high device investment, large floor space, high dewatering energy consumption, large quantity of byproductsand the like in use of a long tube reactor with water serving as a catalyst in the prior art. The isopropanolamine production method is characterized in that a tubular fixed-bed reactor and a heat insulating tube reactor are adopted to guarantee complete conversion of epoxypropane; anhydrous liquid ammonia and epoxypropane are used as reaction raw materials in the tubular fixed-bed reactor, and high-concentration ammonium hydroxide and epoxypropane are used as raw materials in the heat insulating tube reactor; in the tubular fixed-bed reactor, by circulating hot water heat removal, heat removal hot water is used for preheating raw materials and pressure-reduced reaction products to realize reaction heat recovery, the reaction products sequentially passes through an ammonia recovery towerand a dewatering tower to recover ammonia and water, and overhead gas of the dewatering tower is used for preheating pressure-reduced reaction raw materials to reduce energy consumption. The method islow in byproduct quantity, equipment investment and device energy consumption can be reduced, and the method can be applied to industrial production of isopropanolamine.

Owner:CHINA PETROLEUM & CHEM CORP +1

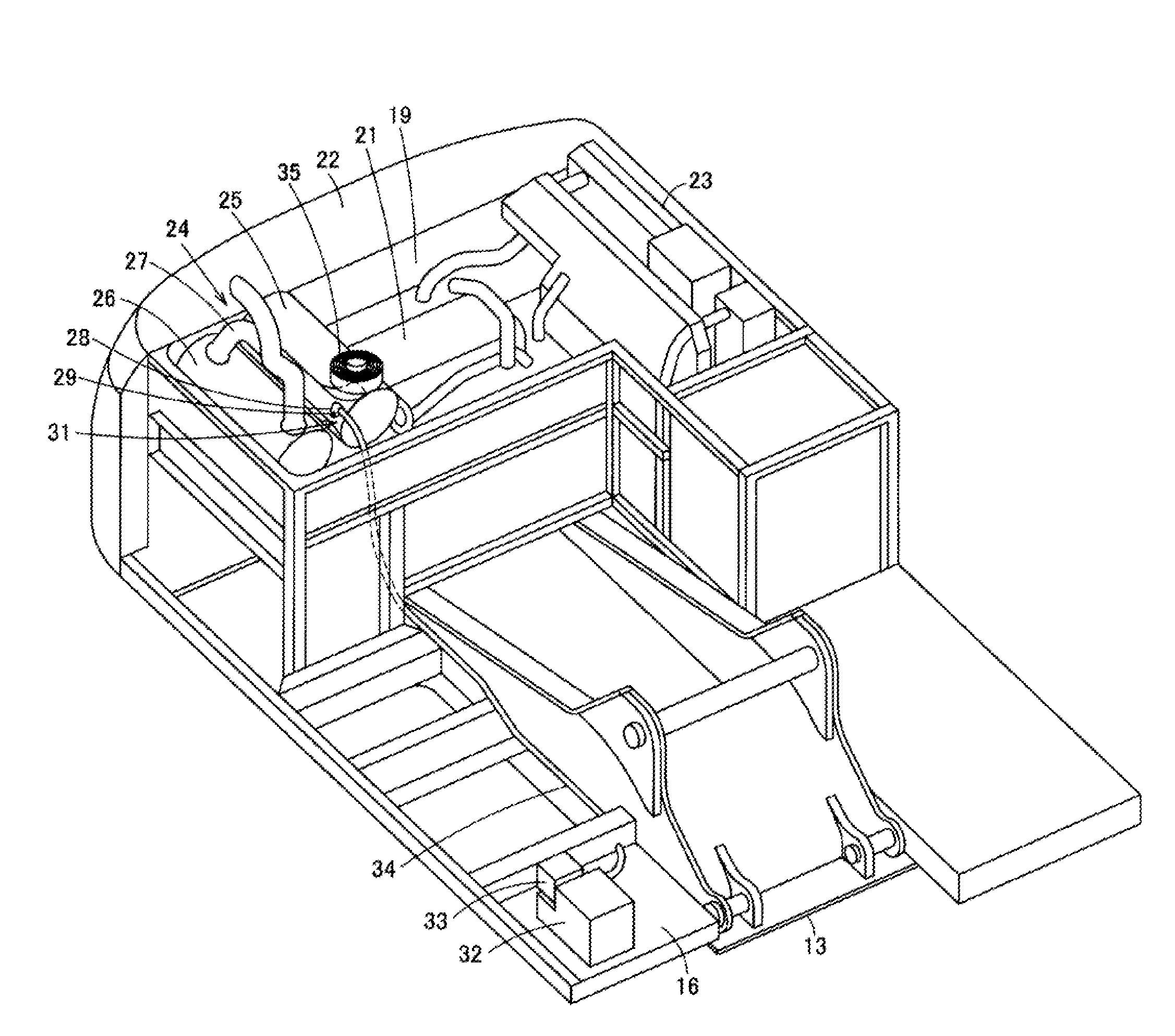

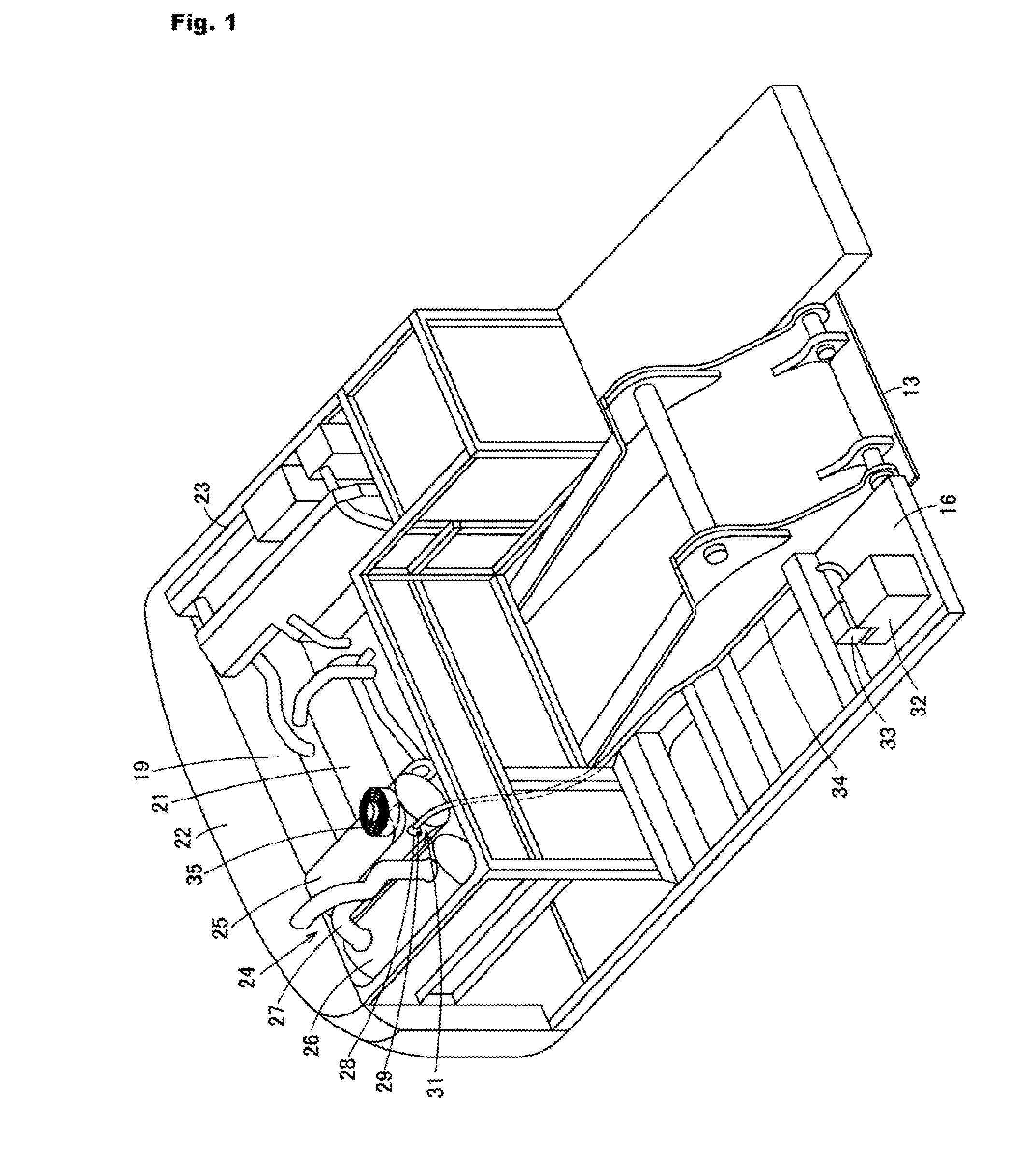

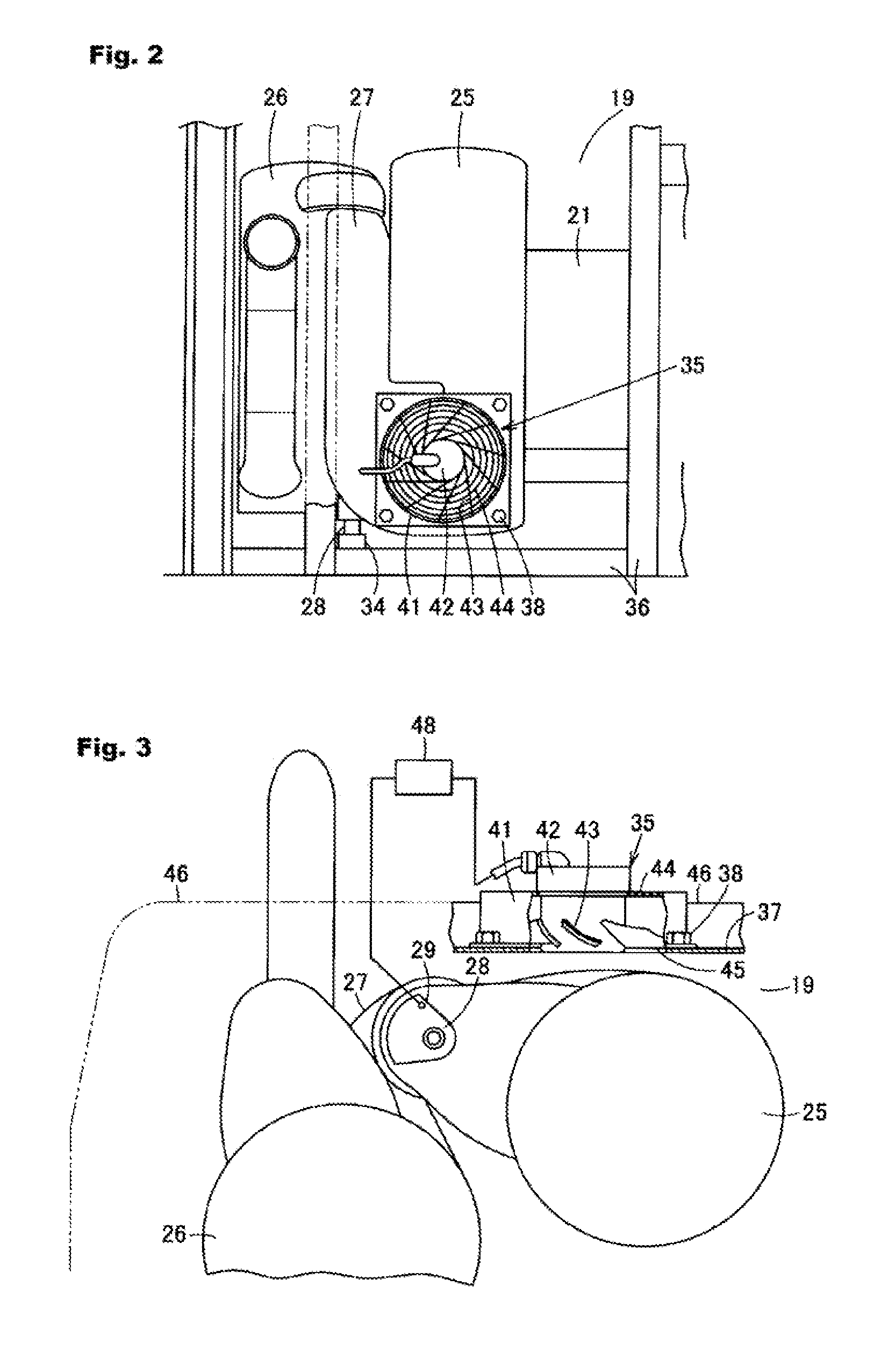

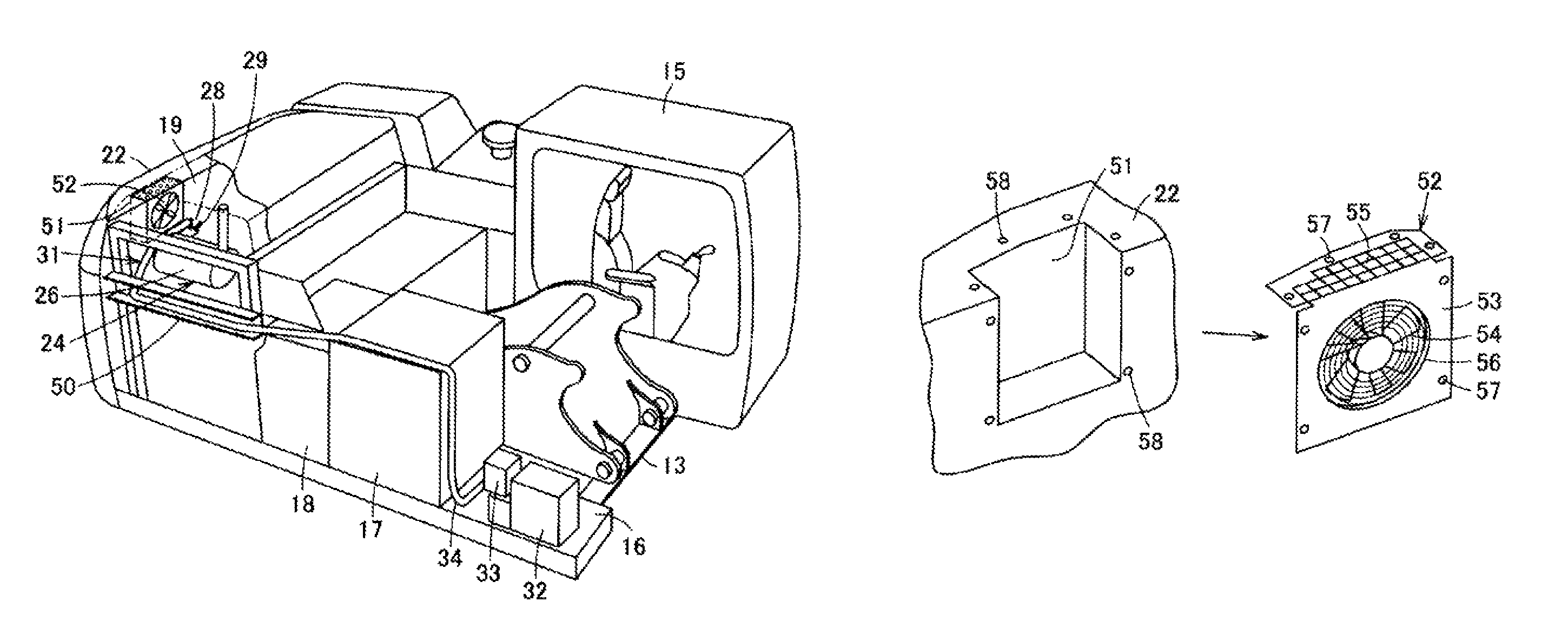

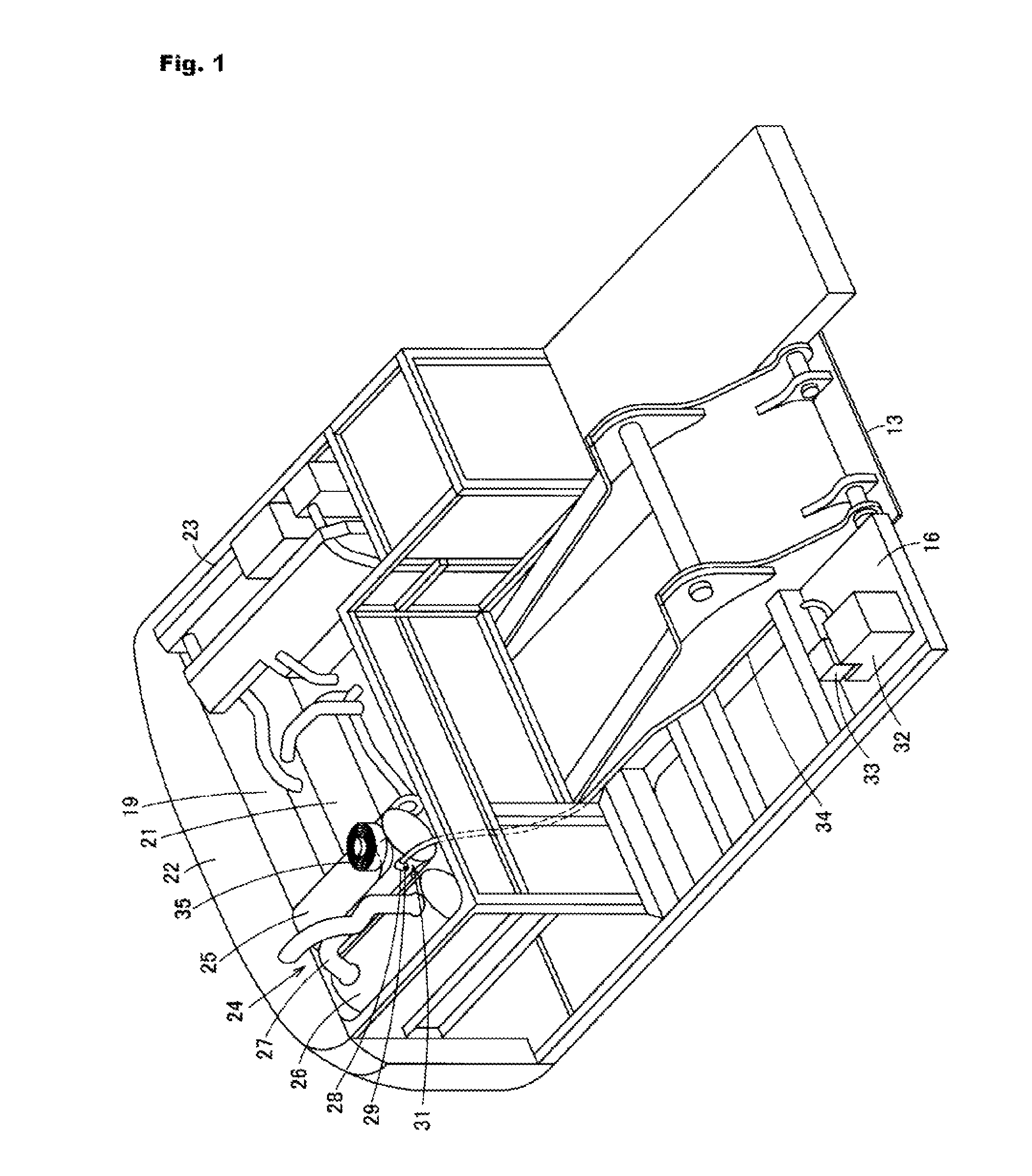

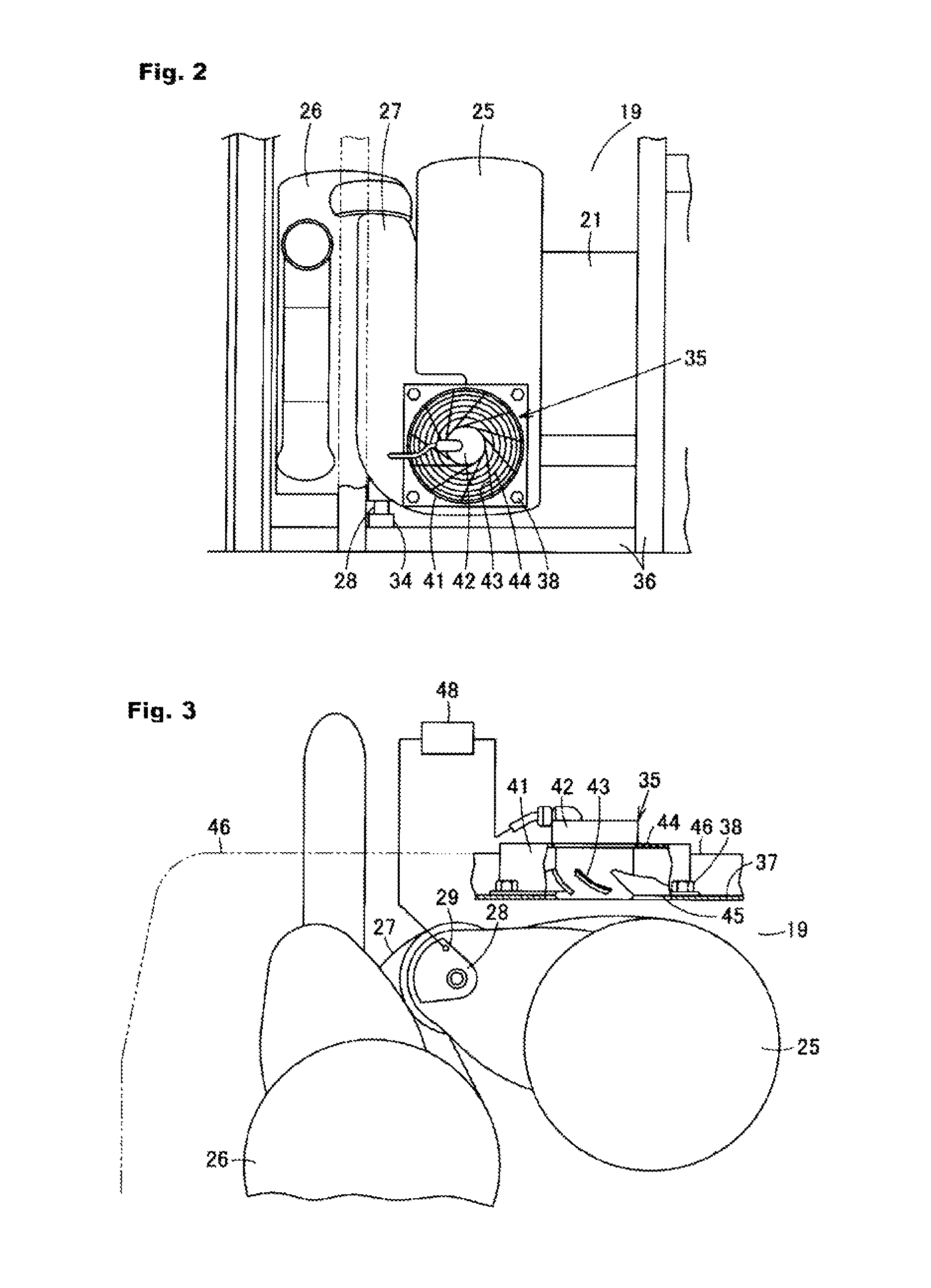

Machine body and machinery

InactiveUS20150184361A1Curb energy consumptionIncrease temperatureInternal combustion piston enginesExhaust apparatusNitrogen oxidesEngineering

Provided is a machine body capable of preventing thermal decomposition of a liquid reducing agent in a reducing agent injector. The machine body includes an exhaust gas treatment device that reduces nitrogen oxides in exhaust gas of an engine provided within a machine room, and a reducing agent supplier that supplies the liquid reducing agent to the exhaust gas treatment device. The exhaust gas treatment device includes a reducing agent injector that injects the liquid reducing agent supplied from the reducing agent supplier, and a cooling fan that is installed in the vicinity of the reducing agent injector so as to face the reducing agent injector. The cooling fan performs cooling by blowing cooling wind of external air, which is taken in from the outside of the engine room, against the reducing agent injector and its upstream side.

Owner:CATEPILLAR SARL

Method and apparatus for treating exhaust gas

ActiveUS8420034B2Reduce the amount requiredCurb energy consumptionGas treatmentMagnesium halidesAmmoniaMetal

Owner:MITSUBISHI HEAVY IND LTD

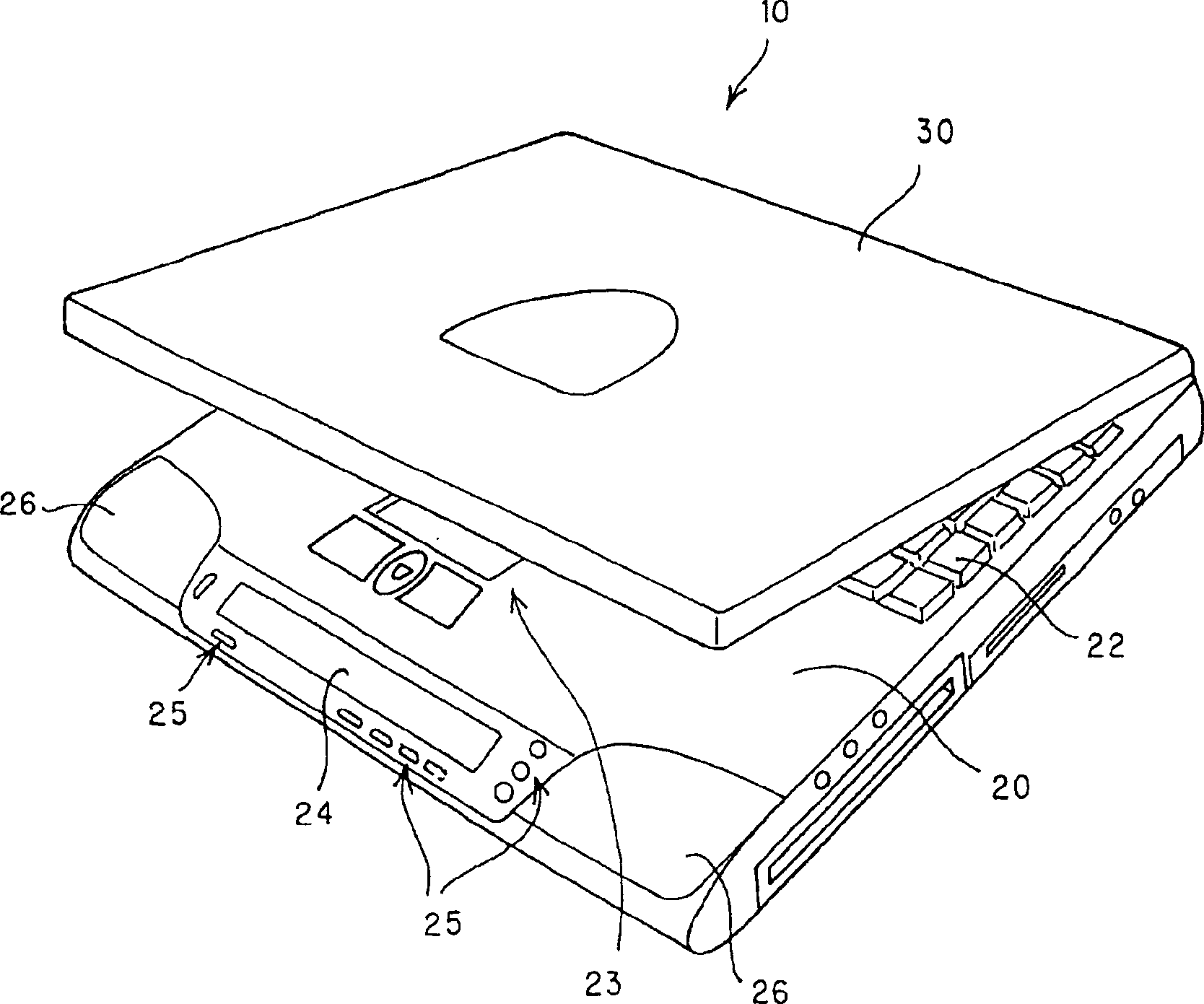

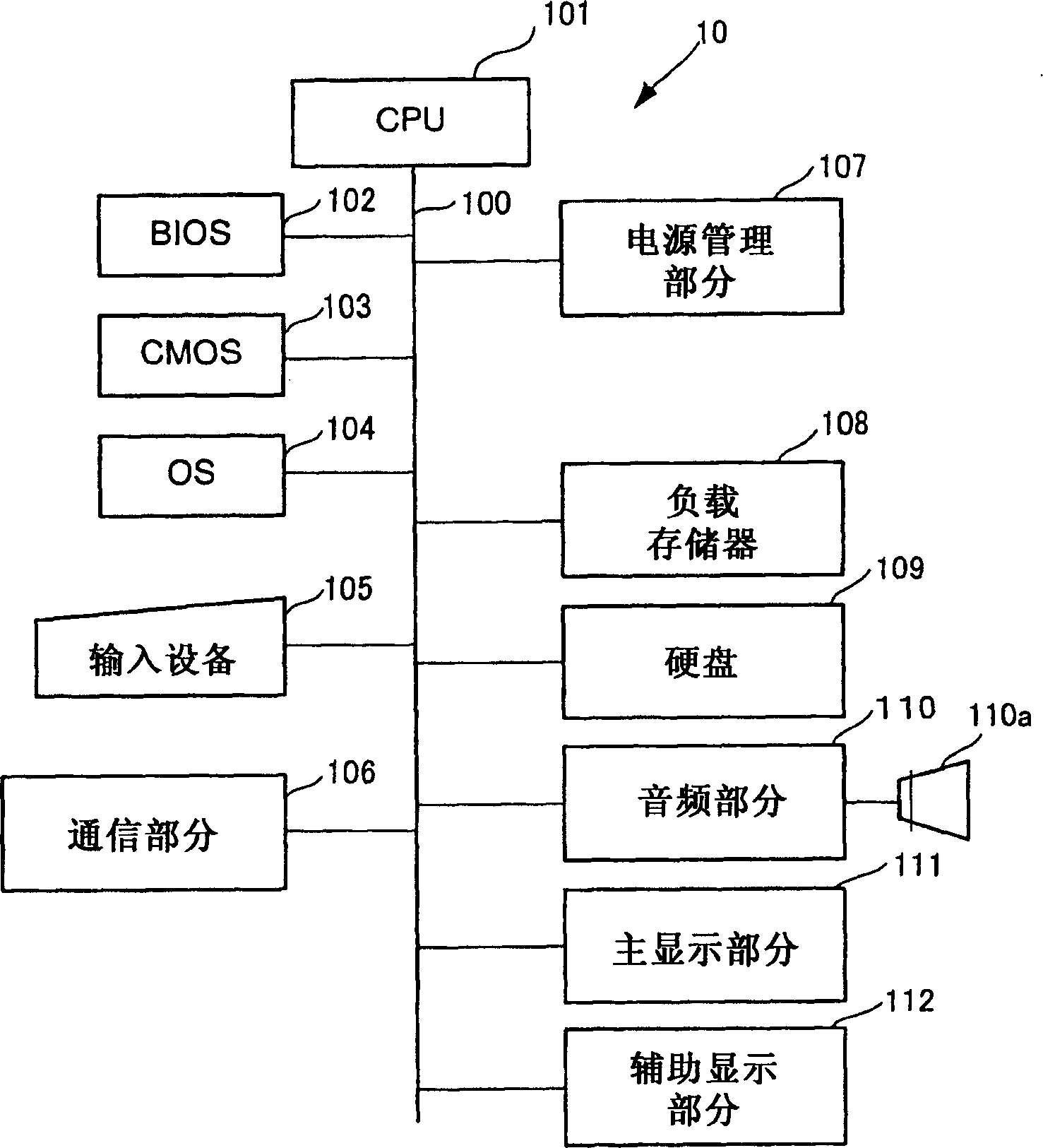

Information processing device and information processing programme storage medium

InactiveCN1455309AImprove convenienceAvoid consumptionEnergy efficient ICTPower supply for data processingComputer hardwareInformation processing

The present invention relates to an information processing apparatus such as a personal computer and an information processing program that is executed there, and the process is immediately executed while the power consumption is suppressed. A program that is operable even when the operating system is in its state of sleep is prepared. By supplying a power source to only the necessary components, aprescribedprocess is executed with that program while the operating system is kept in its state of sleep.

Owner:FUJITSU LTD

Method for drying konjac slices with heat pump

InactiveCN104642965AGood lookingReduced activityFood preparationFruits/vegetable preservation by dehydrationBiotechnologyBrowning

The invention relates to a method for drying konjac slices with a heat pump. The method comprises the following steps: firstly, selecting fresh konjac free of damages and diseases, removing the peel of the fresh konjac and cutting the fresh konjac into konjac slices which are 3-7mm thick; mixing color retention agents L-cysteine, citric acid and ascorbic acid with water to prepare a color protecting solution, putting the processed konjac slices into the color protecting solution for performing color protecting for 3 minutes, taking out and draining the konjac slices, tiling the konjac slices on a material plate, and putting the material plate into a heat pump dryer to dry for 7-10 hours, wherein the moisture content of the dried konjac is 12%; finally, sealing and storing the dried konjac slices. According to the method disclosed by the invention, the drying energy consumption is reduced, and the drying efficiency is improved. Moreover, the color protecting agents are used for pre-processing, low-temperature drying is performed through the heat pump, the brown stains of the konjac in a drying process can be effectively avoided, and glucomannan is protected to be not easily subjected to sugar coking, so that the dried konjac has the advantages of being white in color, good in appearance, free of sulfur, low in cost and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

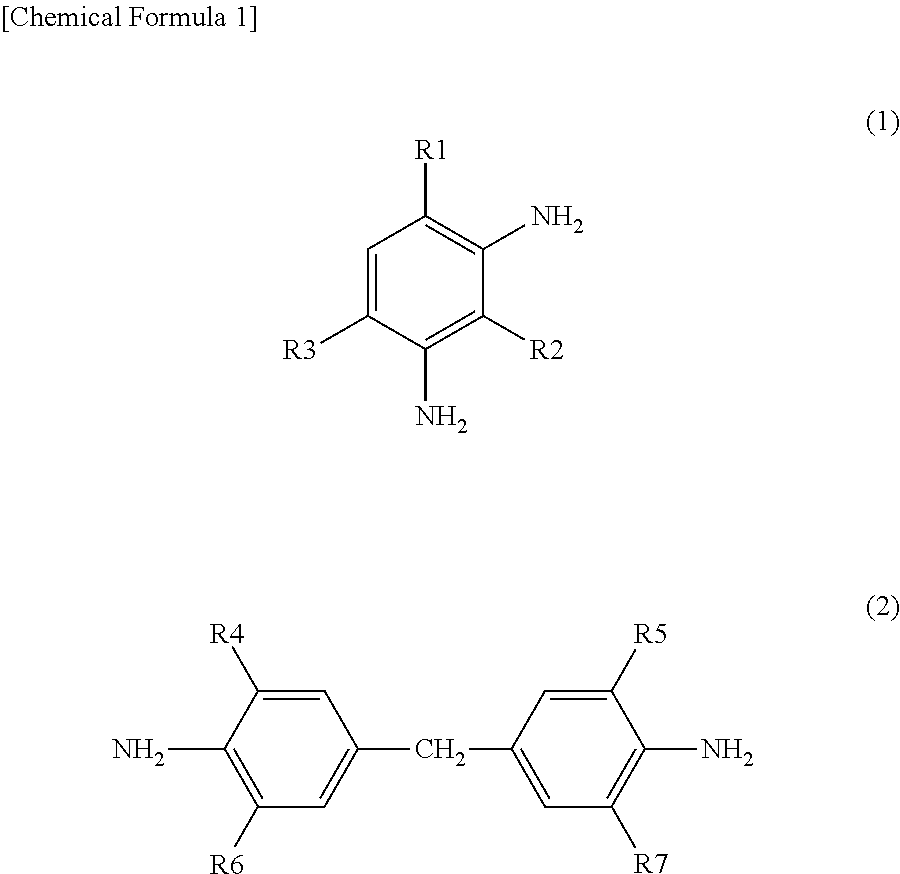

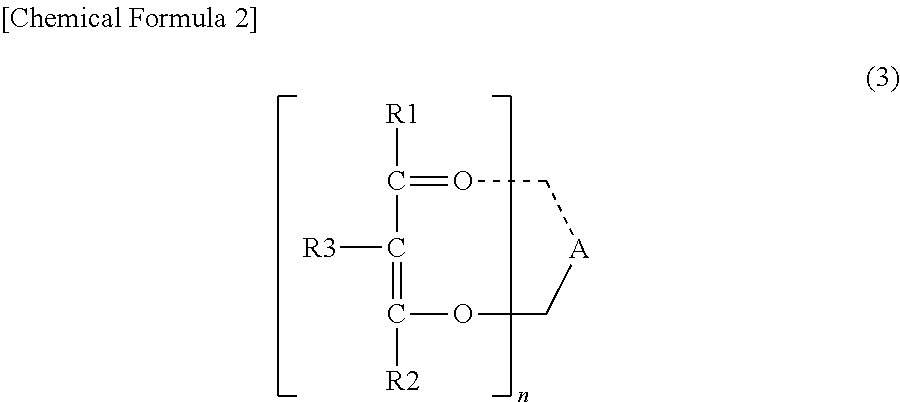

Epoxy resin composition

InactiveUS20120308831A1Stable stateSimple compositionSemiconductor/solid-state device detailsSynthetic resin layered productsEpoxyRoom temperature

A low temperature curable epoxy resin composition which comprises: an epoxy component that contains an epoxy compound having per molecule at least two epoxy groups and that is liquid at 25° C.; an aromatic amine based curing agent that contains an aromatic amine compound having per molecule at least two amino groups directly bonded to the aromatic ring and that is liquid at 25° C.; and Mg(II) acetylacetonate as a cure accelerator. The composition, which contains a novel cure accelerator using a metal complex, exhibits high stability at room temperature while lowering a cure temperature or shortening a cure time.

Owner:NAGASE CHEMTEX CORPORATION

Machine body and machinery

InactiveUS9187877B2Direct coolingCurb energy consumptionInternal combustion piston enginesExhaust apparatusNitrogen oxidesEngineering

Owner:CATEPILLAR SARL

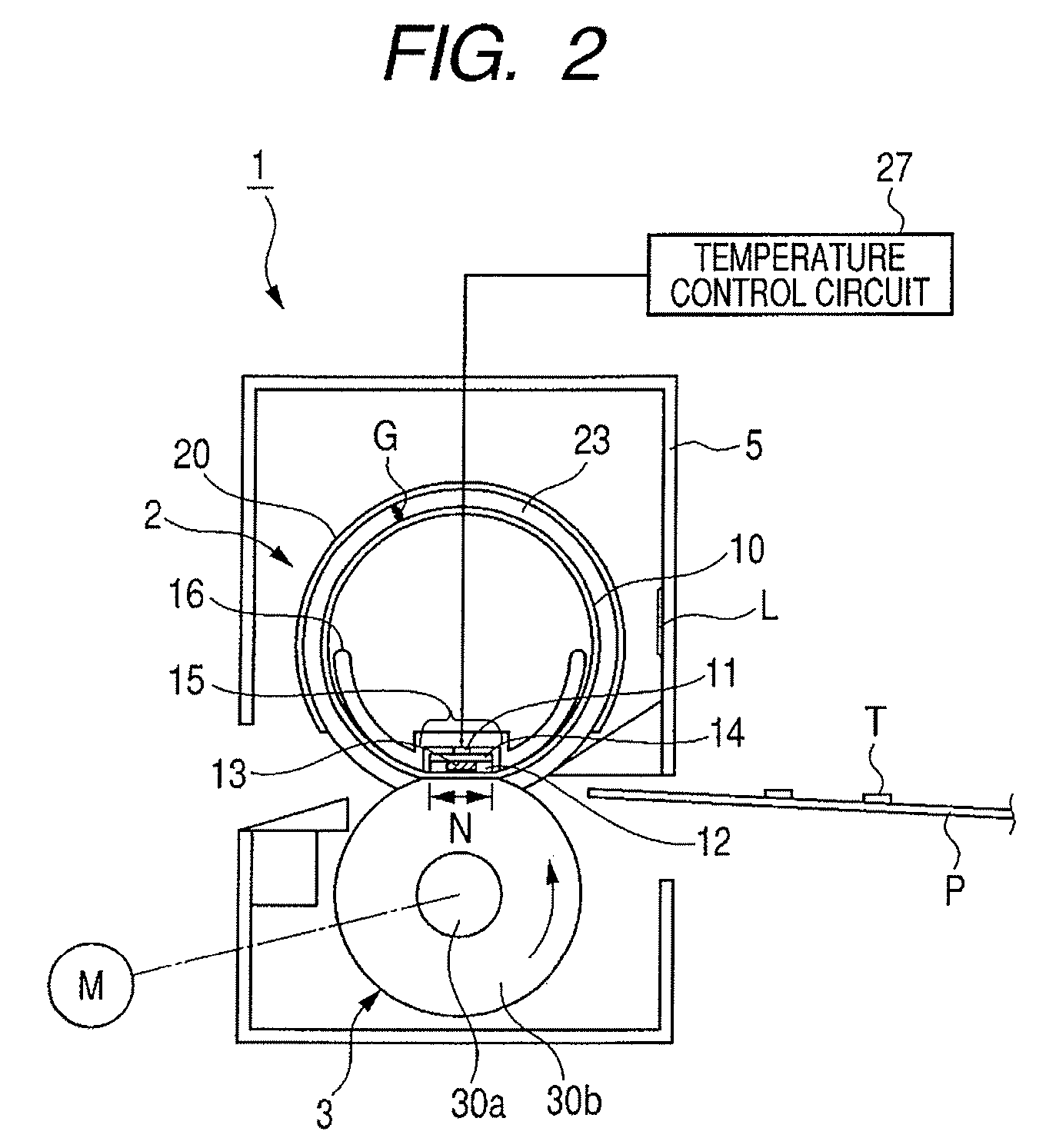

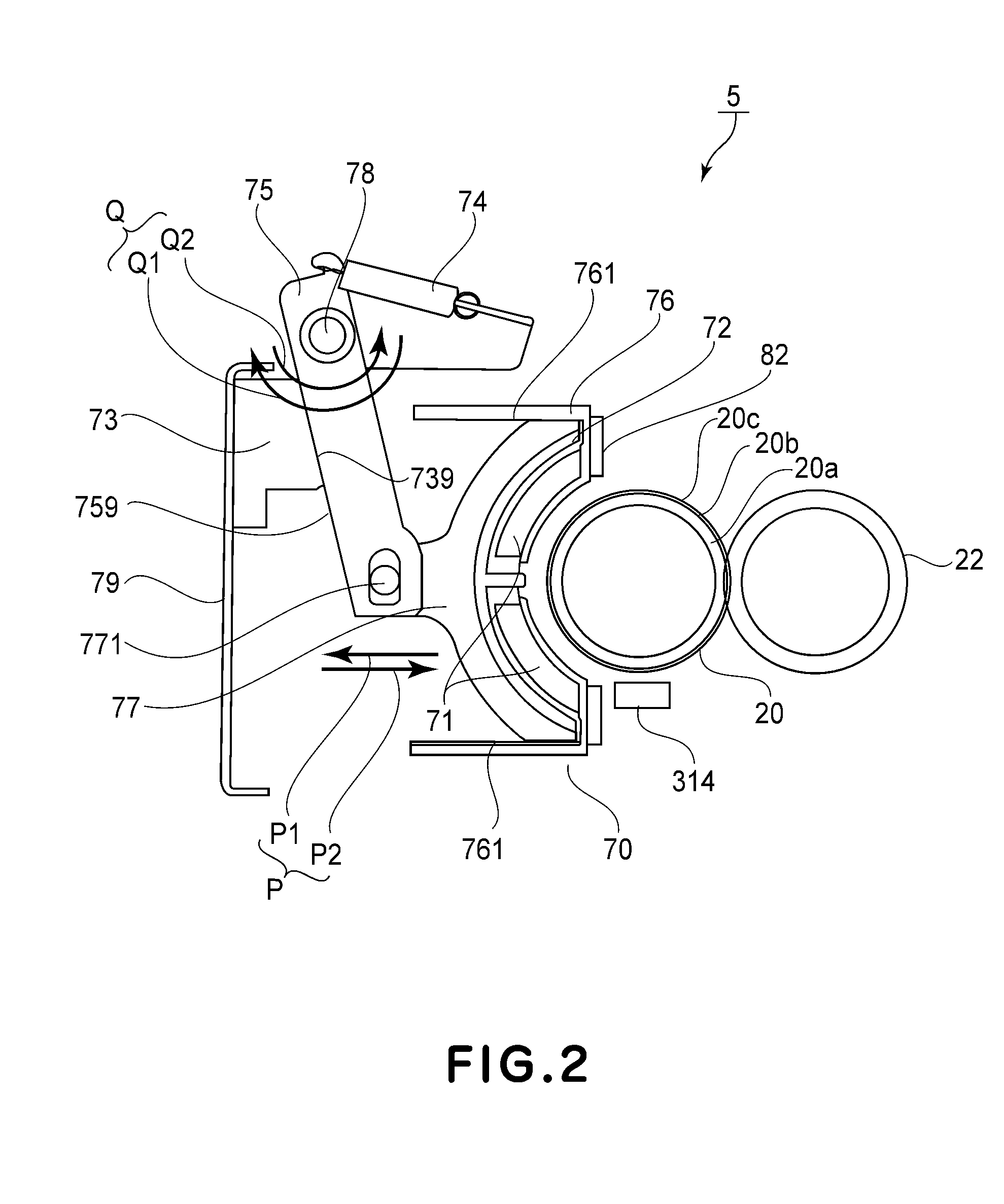

Image heating apparatus with frame accommodating apparatus components

InactiveUS7778582B2Curb energy consumptionElectrographic process apparatusEngineeringEnergy consumption

Owner:CANON KK

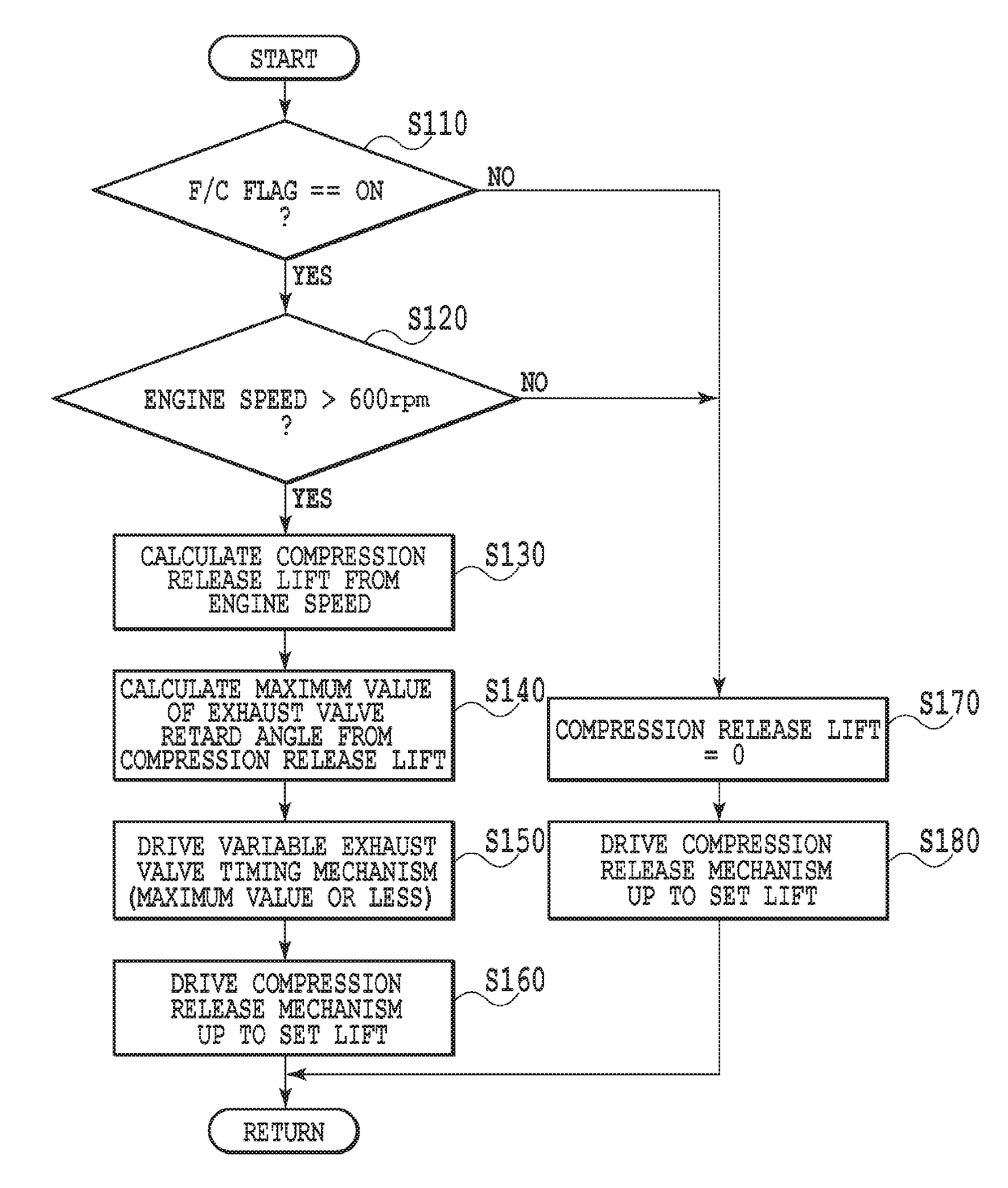

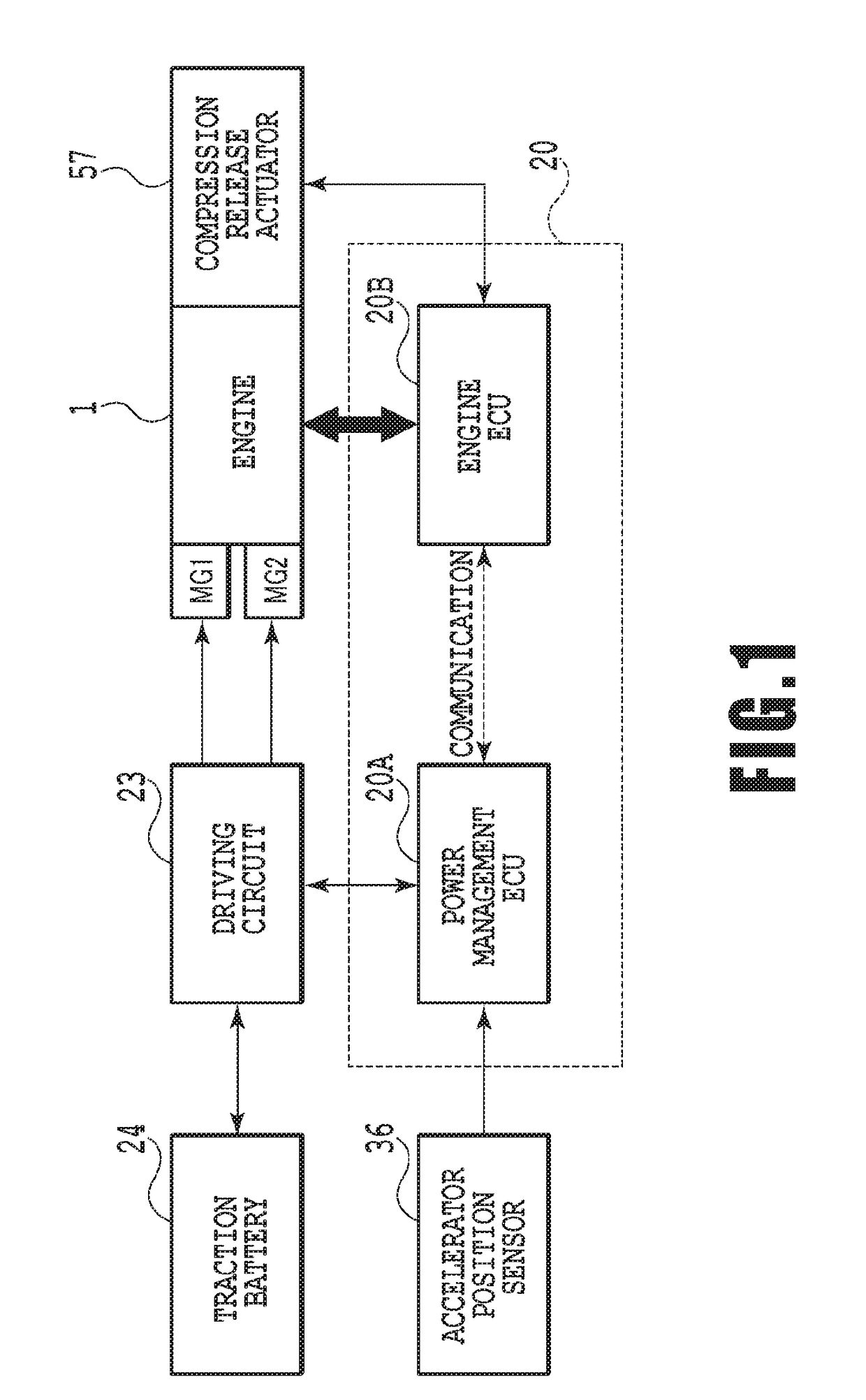

Apparatus for controlling internal combustion engine

ActiveUS20170292460A1High degree of opennessImprove utilizationElectrical controlOutput powerCombustion chamberInternal combustion engine

An apparatus for controlling an internal combustion engine is provided. An engine includes a compression release mechanism and a fuel injection valve. The compression release mechanism variably controls the opening degree of a valve member, and thereby connects the combustion chamber of the engine with at least one of the intake passage and the exhaust passage in order to release in-cylinder pressure during at least the compression stroke. A controller controls the fuel injection valve to execute coasting with the fuel cut off in which the fuel is cut off under a predetermined condition, and while executing coasting with the fuel cut off, controls the compression release mechanism to increase the opening degree of the valve member of the compression release mechanism as the speed of the engine is higher.

Owner:TOYOTA JIDOSHA KK

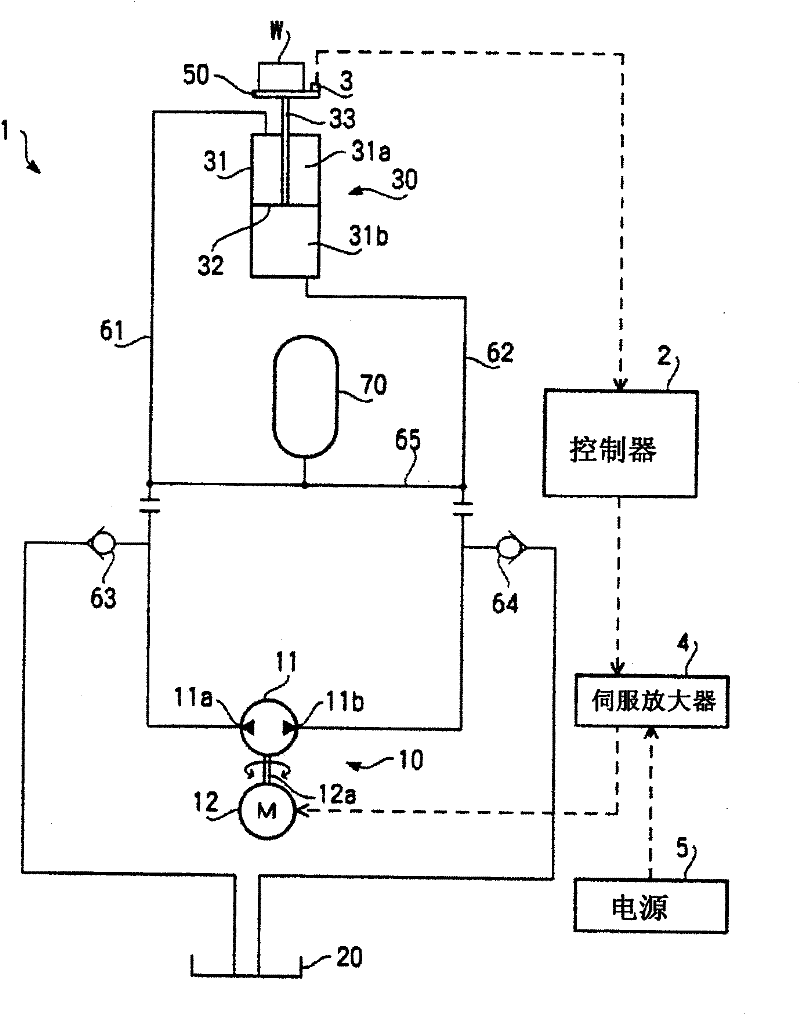

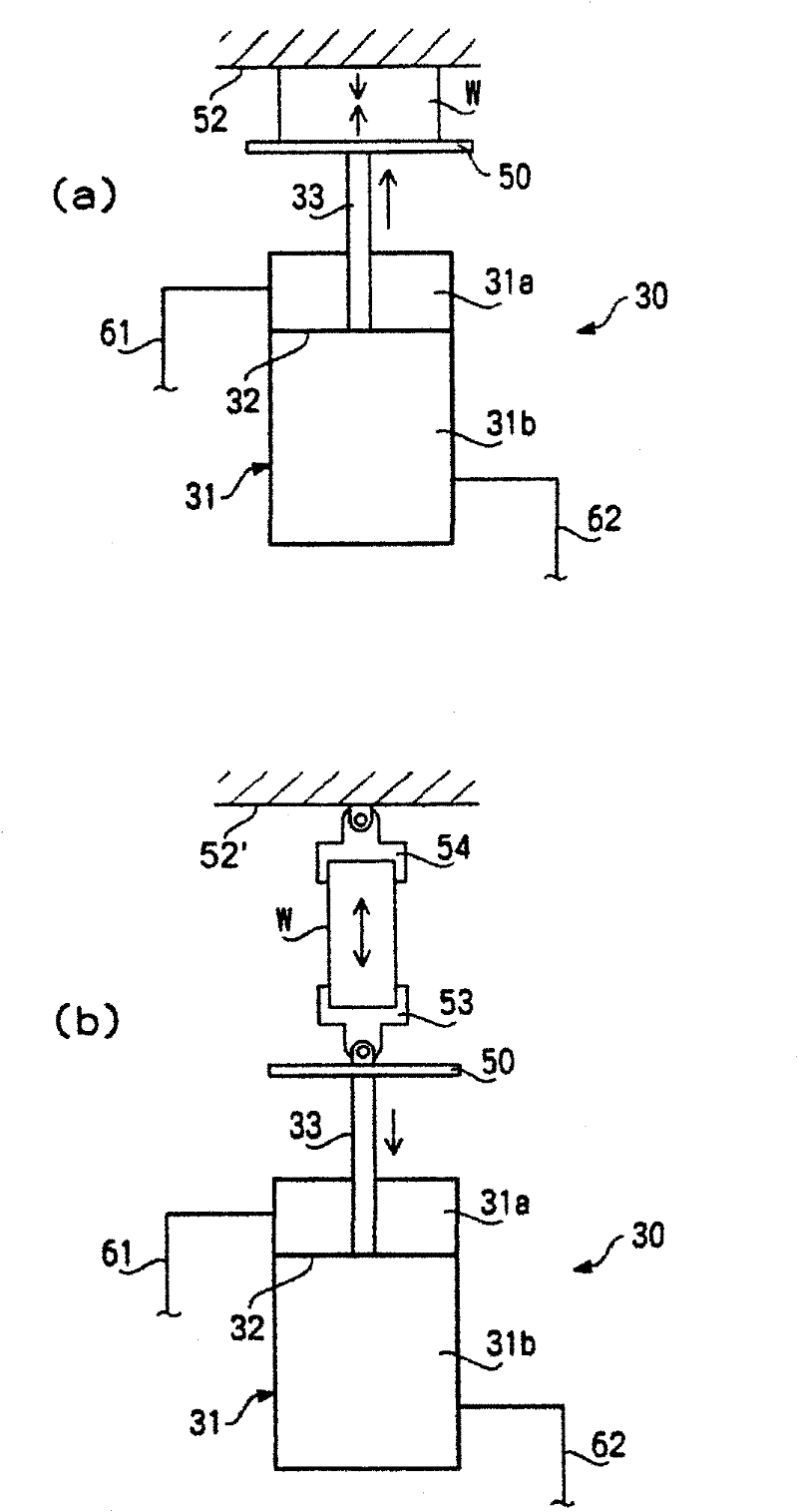

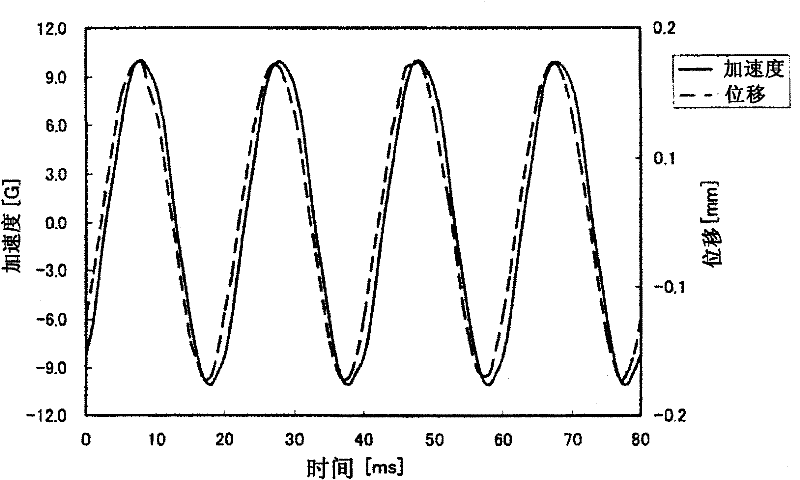

Hydraulic actuator and hydraulic vibration test device

ActiveCN102216750ACurb energy consumptionHigh outputServomotorsMaterial strength using repeated/pulsating forcesPipingOil pressure

A hydraulic actuator provided with a hydraulic pump and a hydraulic cylinder unit. The hydraulic pump has a first suction and discharge opening and a second suction and discharge opening and can be reversely operated. The hydraulic cylinder unit is provided with a piston, a sleeve having an inner space partitioned by the piston into a first pressure chamber and a second pressure chamber, and a piston rod connected to the piston and having a front end projecting to the outside of the sleeve. The hydraulic actuator is provided with first piping for interconnecting the first pressure chamber and the first suction and discharge opening, and also with second piping for interconnecting the second pressure chamber and the second suction and discharge opening. When the hydraulic piston is reversely operated, hydraulic pressure is alternately applied to the first and second pressure chambers to vertically move the piston. The hydraulic actuator is further provided with a bypass pipe for interconnecting the first and second piping and also with an accumulator provided in the middle of the bypass pipe and applying back pressure to the first and second pressure chambers. A vibration test device equipped with the hydraulic actuator is also provided.

Owner:KOKUSAI KEISOKUKI KK

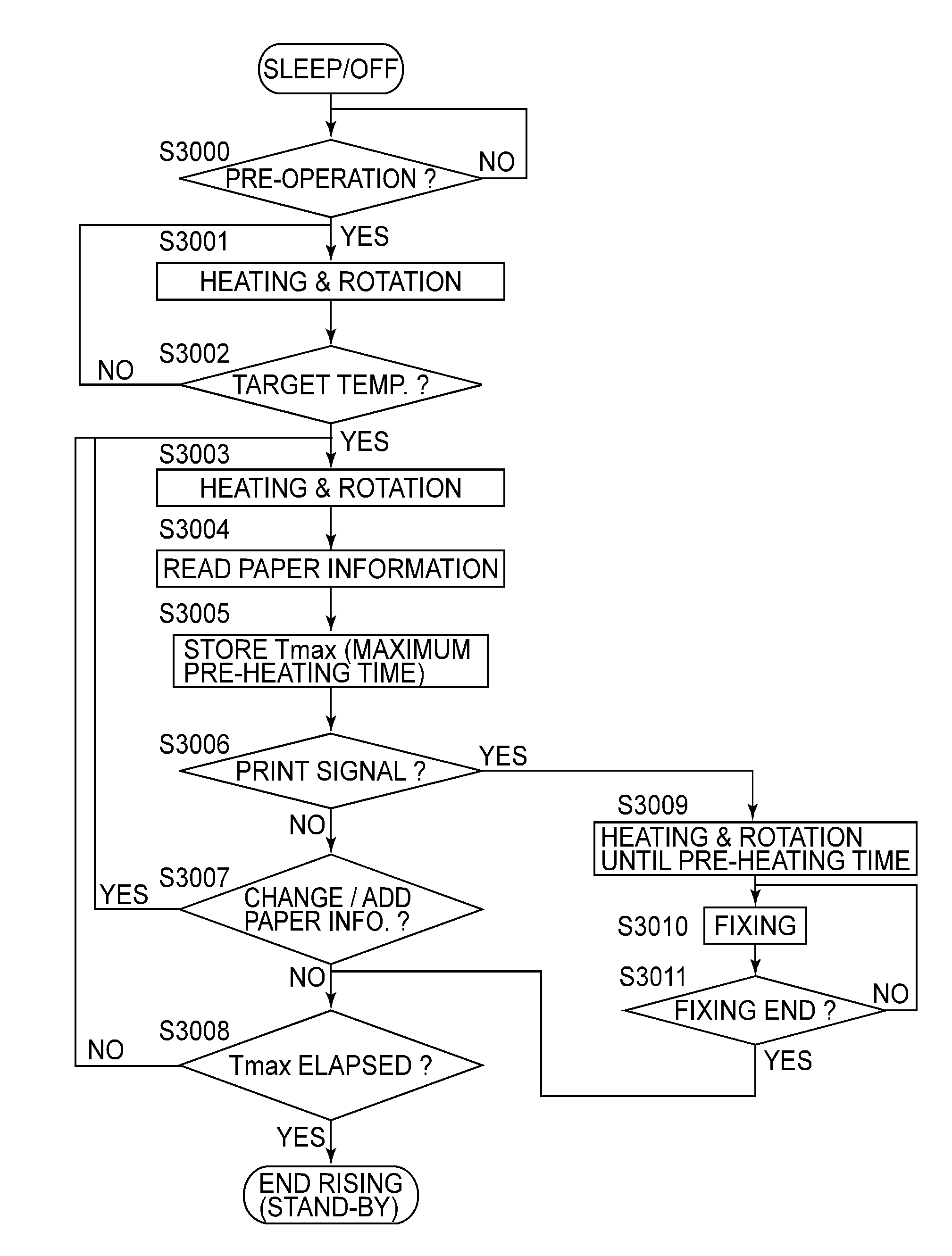

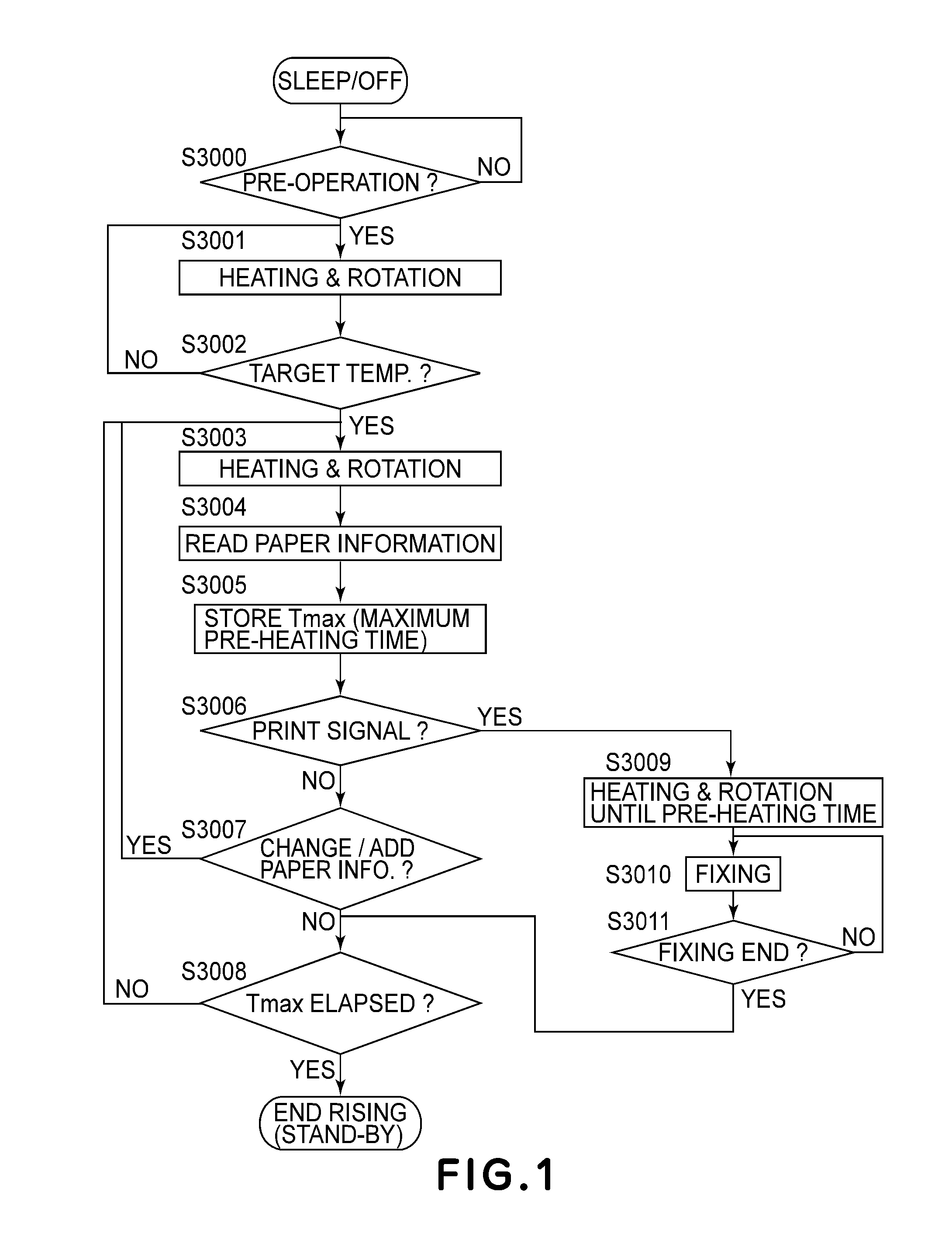

Image forming apparatus

ActiveUS20150043930A1Reducing operator timeShorten the timeVisual presentationElectrographic process apparatusImage formationImage storage

An image forming apparatus includes: a recording material accommodating portion configured to accommodate a recording material; an image forming portion configured to form a toner image on the recording material fed from the recording material accommodating portion; a fixing portion configured to heat-fix the toner image formed on the recording material by the image forming portion; a storing portion configured to store information corresponding to a type of the recording material accommodated in the recording material accommodating portion; a detecting portion configured to detect that a predetermined operation is performed by an operator before the image forming apparatus receives an image formation instruction; and an executing portion configured to execute a start-up process, when the detecting portion detects the predetermined operation performed by the operator, over a time depending on the information stored in the storing portion.

Owner:CANON KK

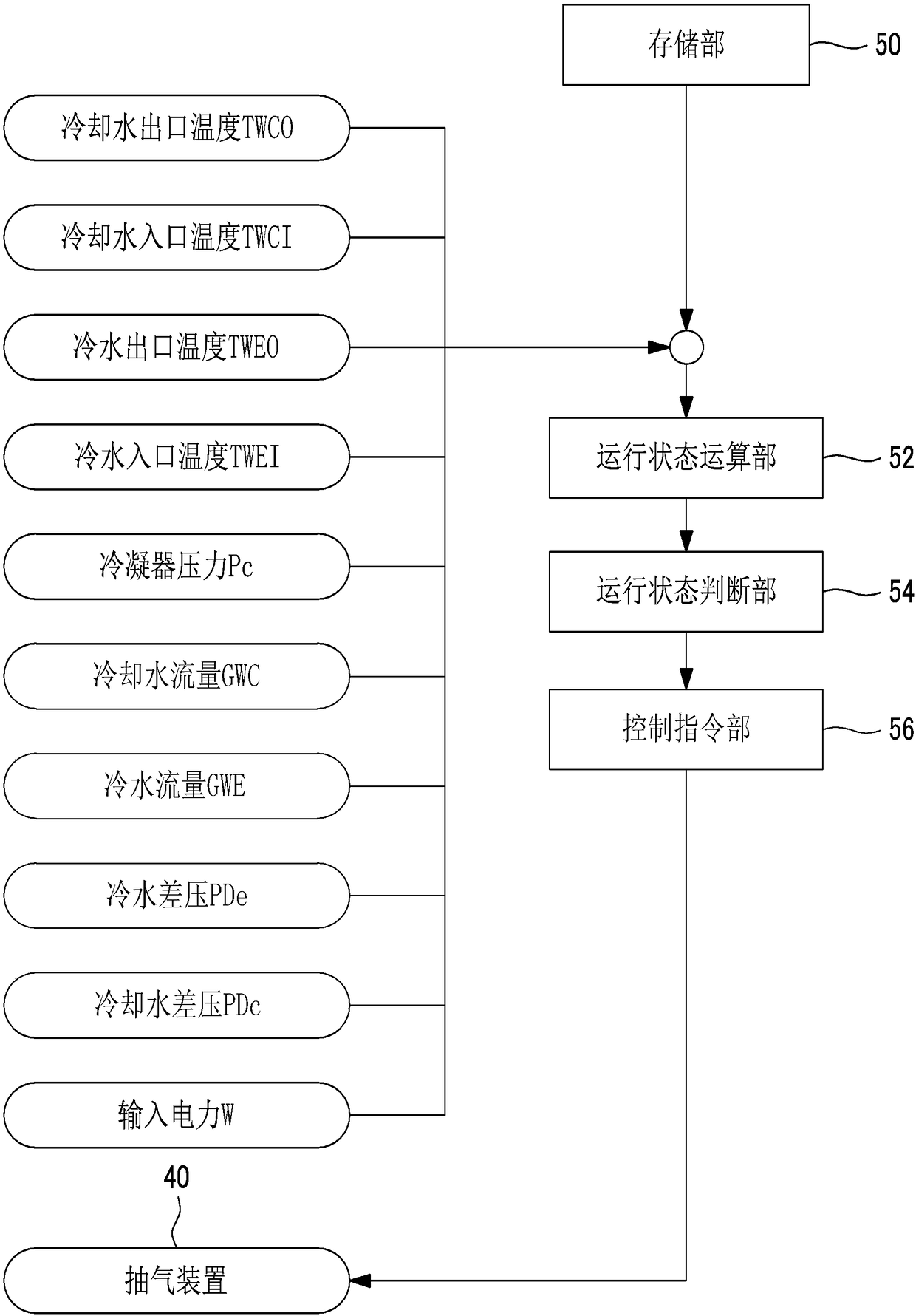

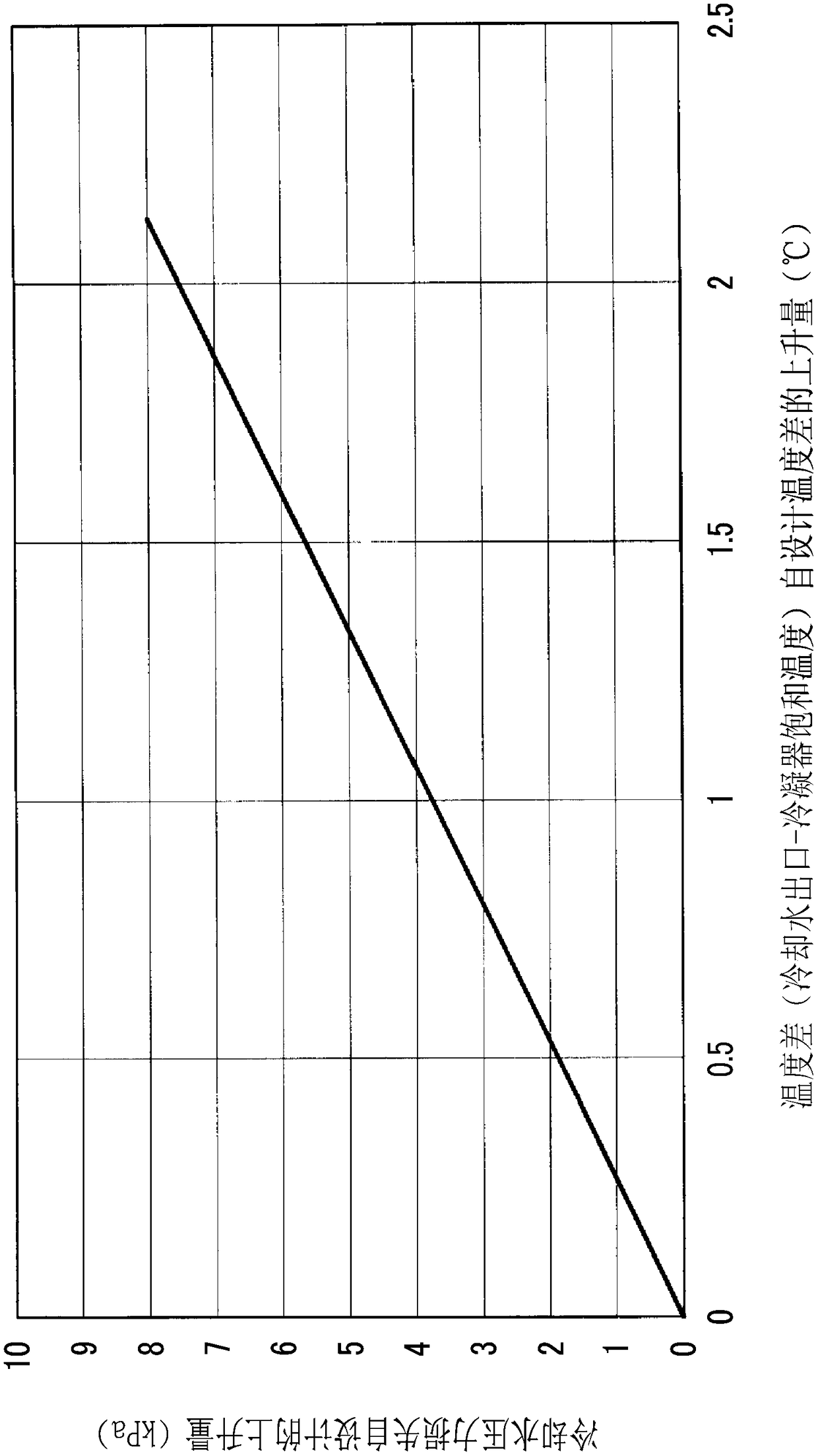

Vapor compression-type refrigerator and method for controlling same

ActiveCN108474601ACurb energy consumptionMechanical apparatusEvaporators/condensersEngineeringTemperature difference

The present invention provides a vapor compression-type refrigerator provided with an extraction device (40) including: a cooling unit for cooling gas that has been extracted from a condenser (5) andcondensing condensed gas; and an exhaust pump (48) for discharging, to the exterior, uncondensed gas that has been isolated without having been condensed by the cooling unit. A current temperature difference, which is the difference between the current saturation temperature in the condenser (5) and the current outlet temperature of a cooling water heat transfer tube (5a), and a planned temperature difference, which is a planned value, are computed. Using information on an in-tube fouling temperature difference elevation, which is a difference between the saturation temperature in the condenser (5) and the outlet temperature of the cooling water heat transfer tube (5a) and which is predetermined assuming in-tube fouling of the cooling water heat transfer tube (5a), the temperature difference elevation due to the current in-tube fouling is computed. The extraction device (40) is operated if the elevation of the current temperature difference from the planned temperature difference is greater by a predetermined value or more than the temperature difference elevation due to the current in-tube fouling.

Owner:MITSUBISHI HEAVY IND THERMAL SYST

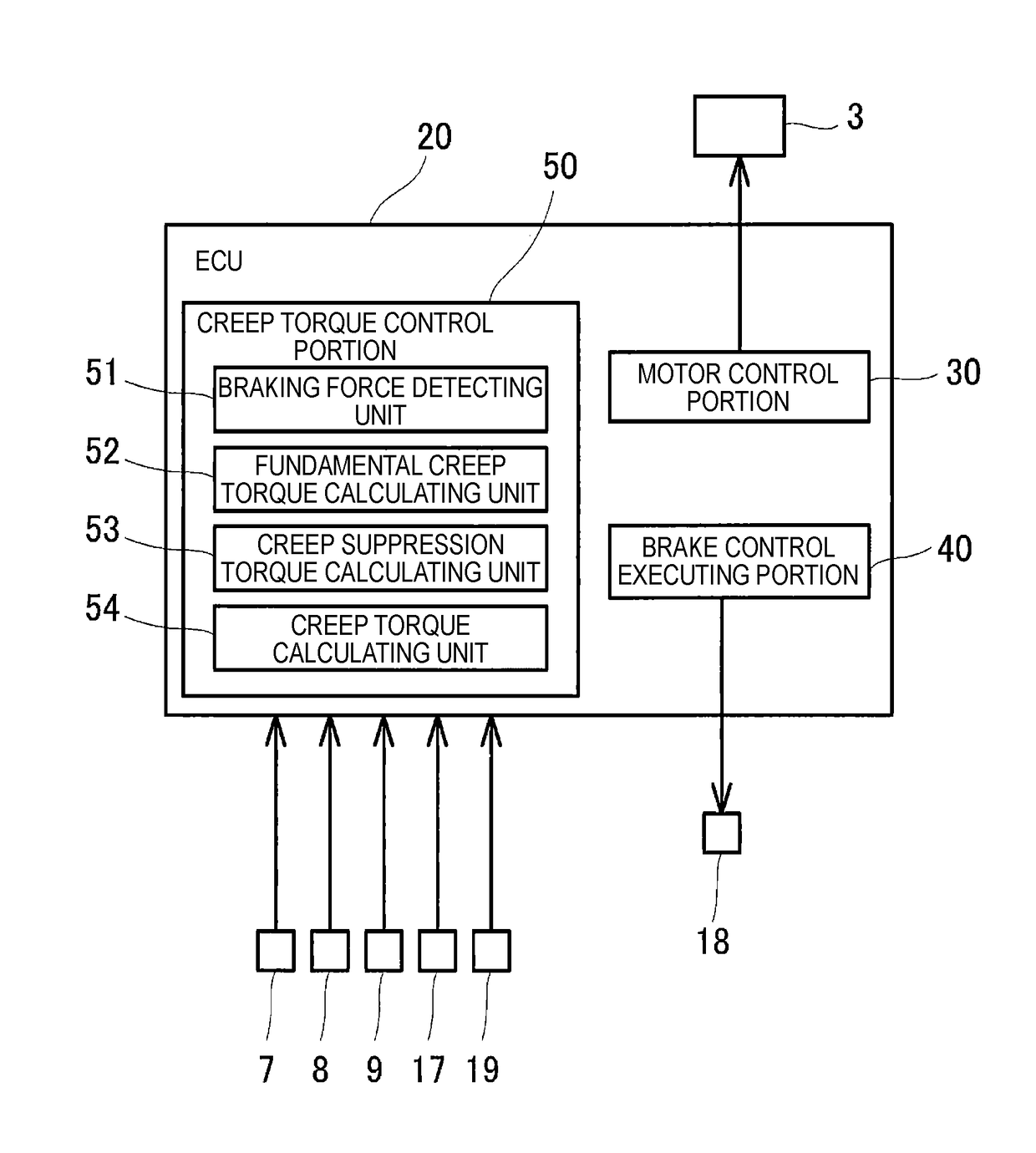

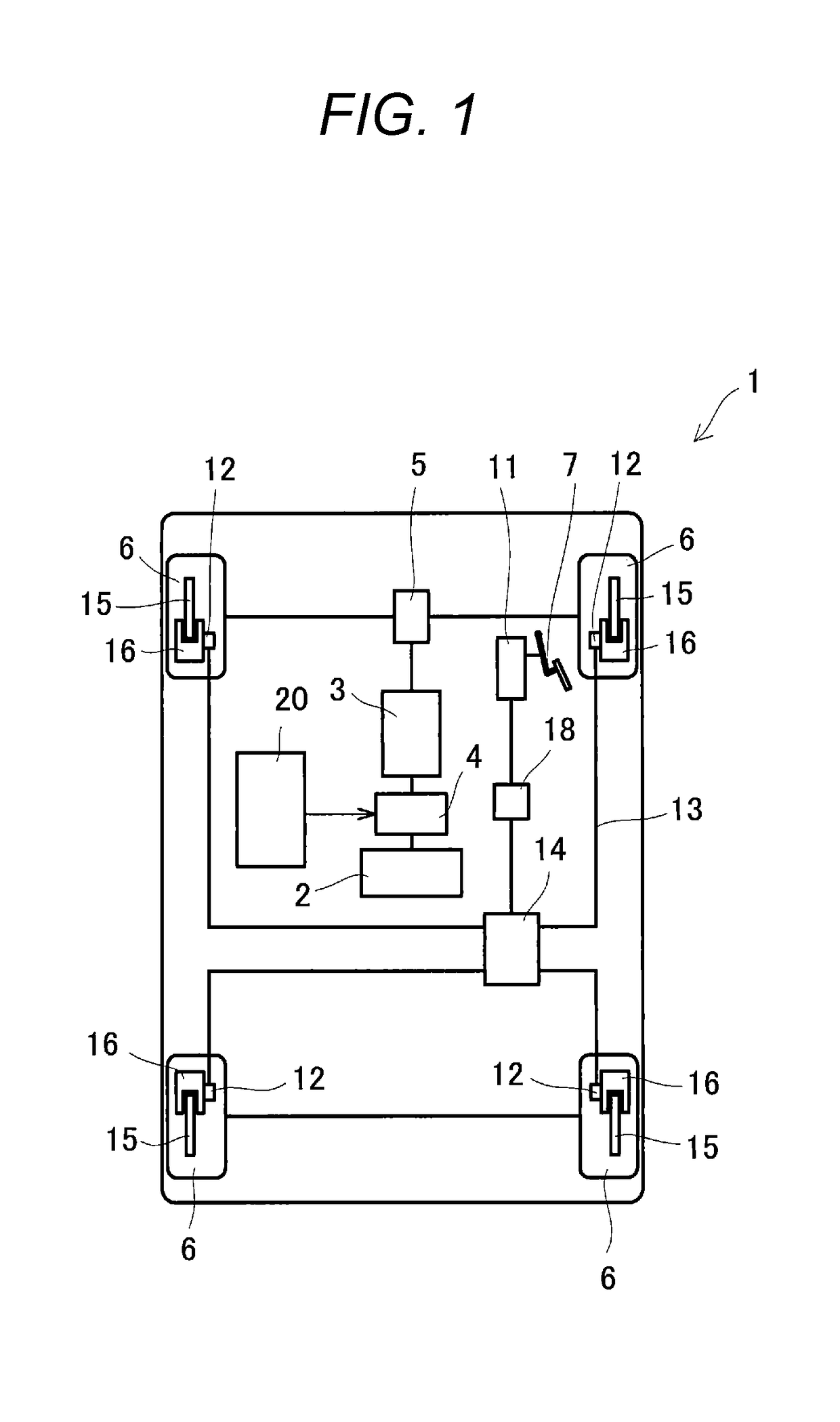

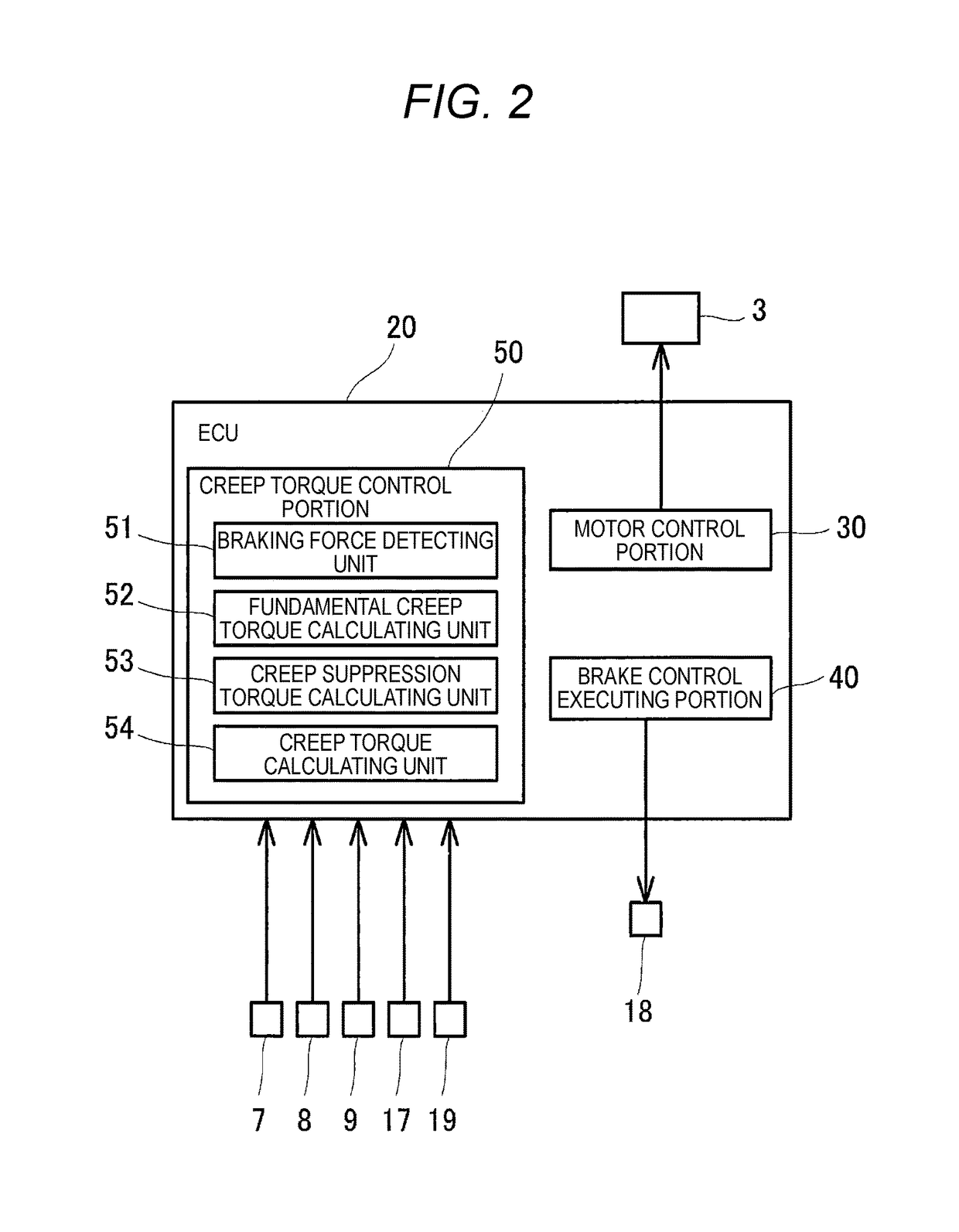

Control device for controlling electric vehicle

ActiveUS9862370B2Suppress energyCurb energy consumptionSpeed controllerDigital data processing detailsEngineeringElectric vehicle

A control device for controlling an electric vehicle includes a driving source that rotates wheels, a braking device that applies braking force to the wheels, a creep torque control portion that controls magnitude of creep torque to be applied to the wheels, wherein the creep torque control portion includes a braking force detecting unit that detects the braking force applied by the braking device, a fundamental creep torque calculating unit that calculates fundamental creep torque corresponding to vehicle speed, a creep suppression torque calculating unit that calculates creep suppression torque smaller than the fundamental creep torque based on a result of the detection of the braking force detecting unit and a creep torque calculating unit that calculate the creep torque by subtracting the creep suppression torque from the fundamental creep torque.

Owner:MITSUBISHI MOTORS CORP

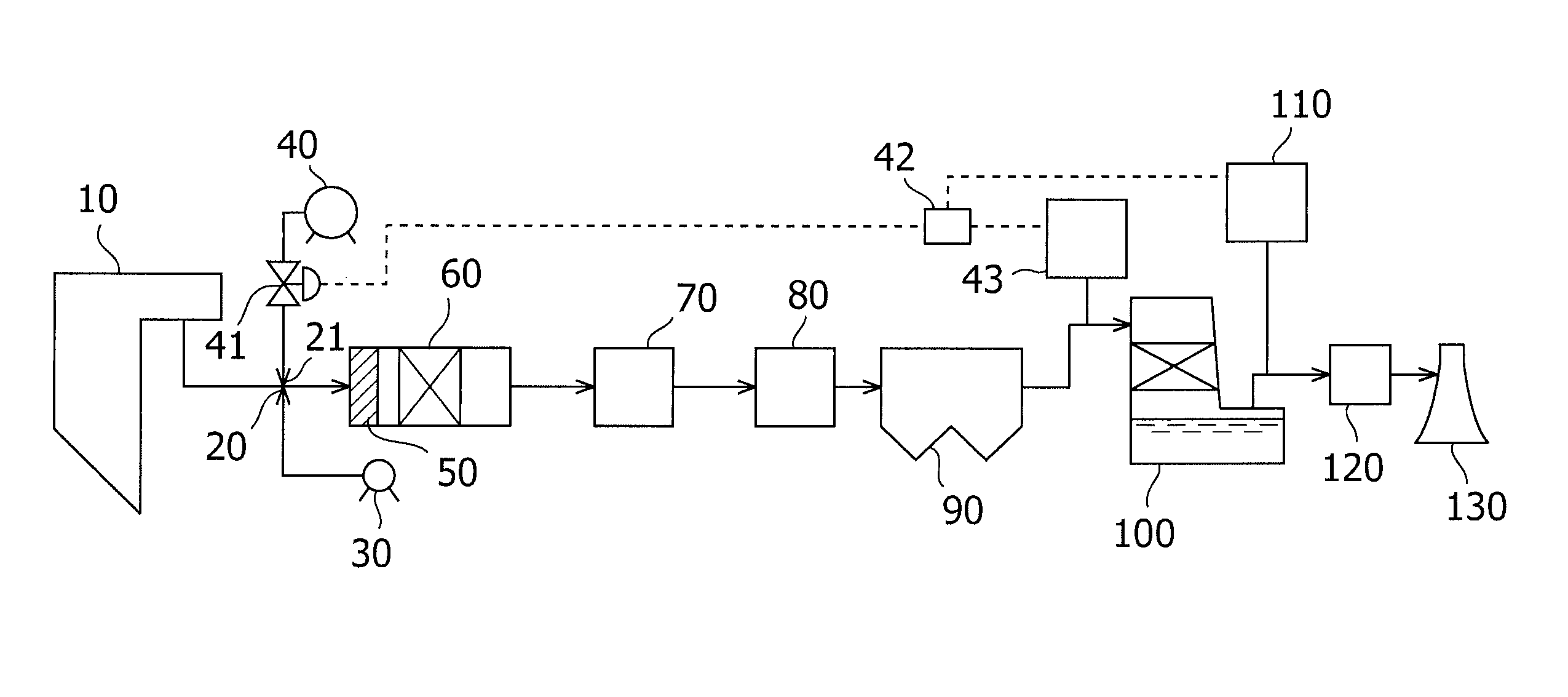

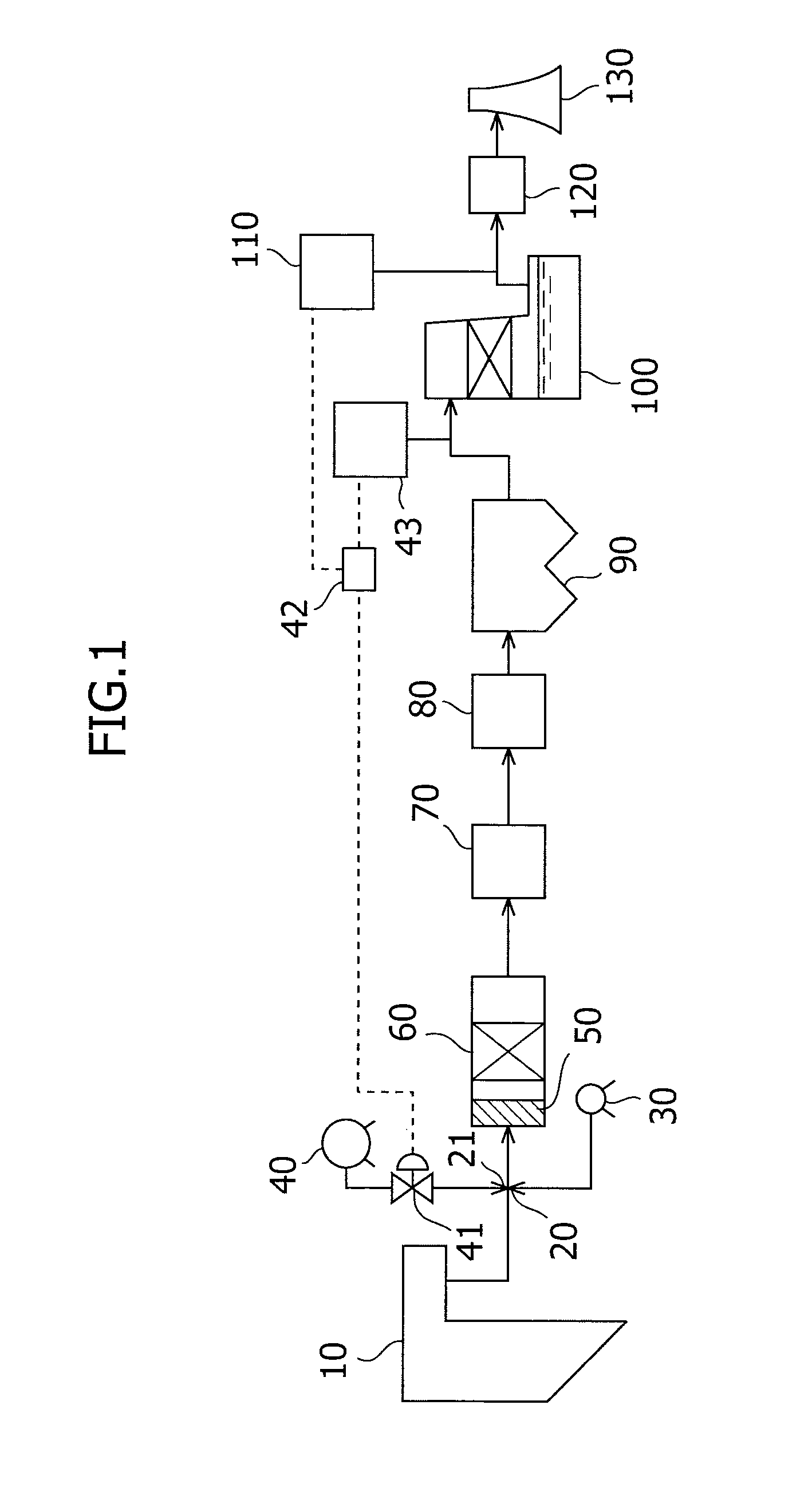

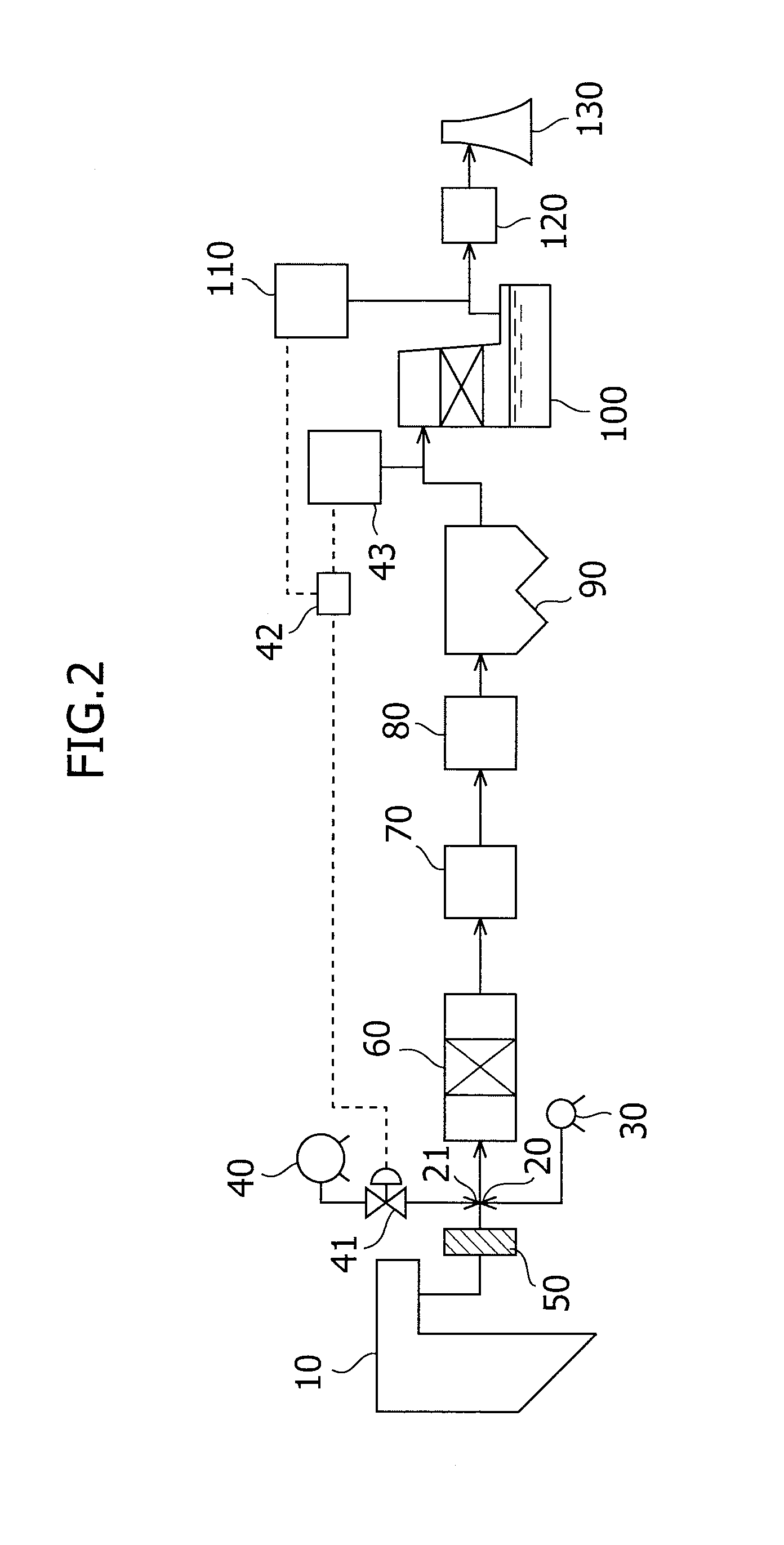

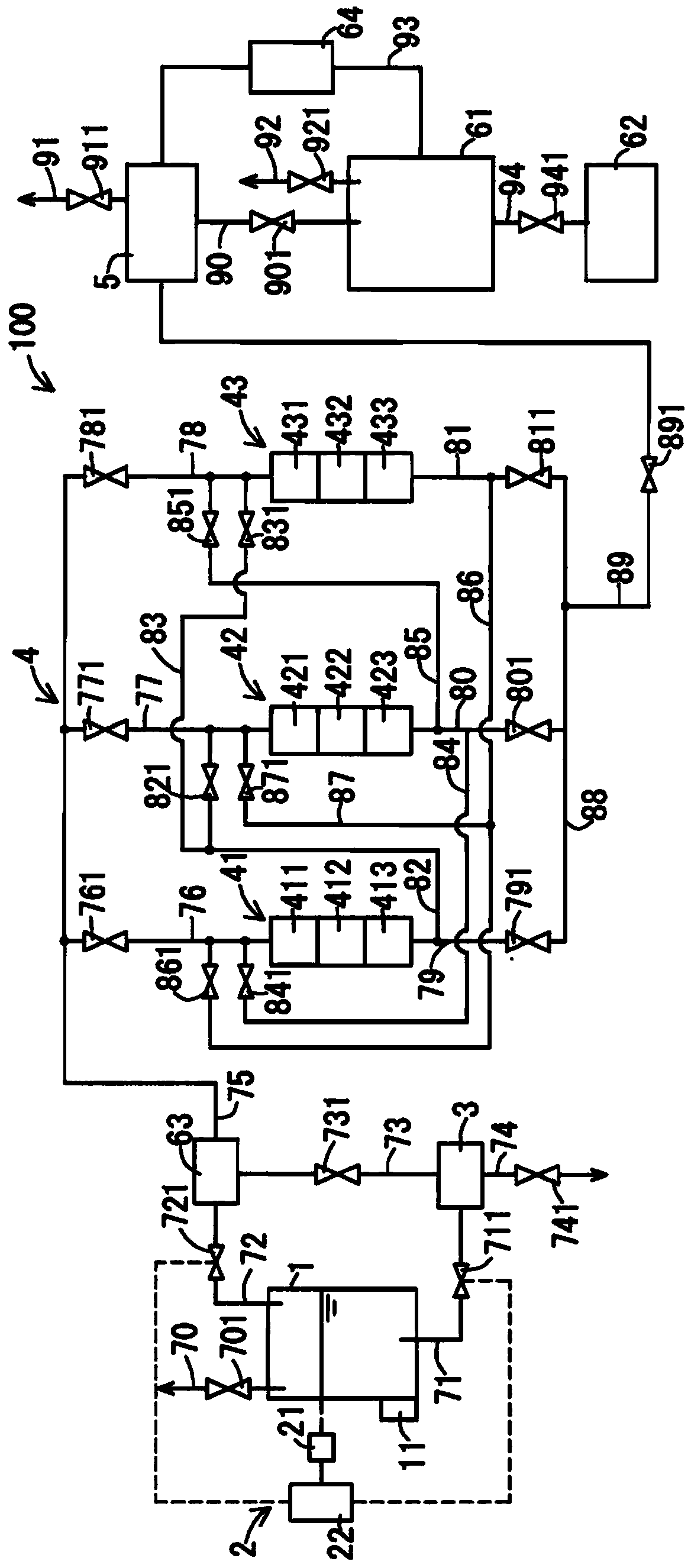

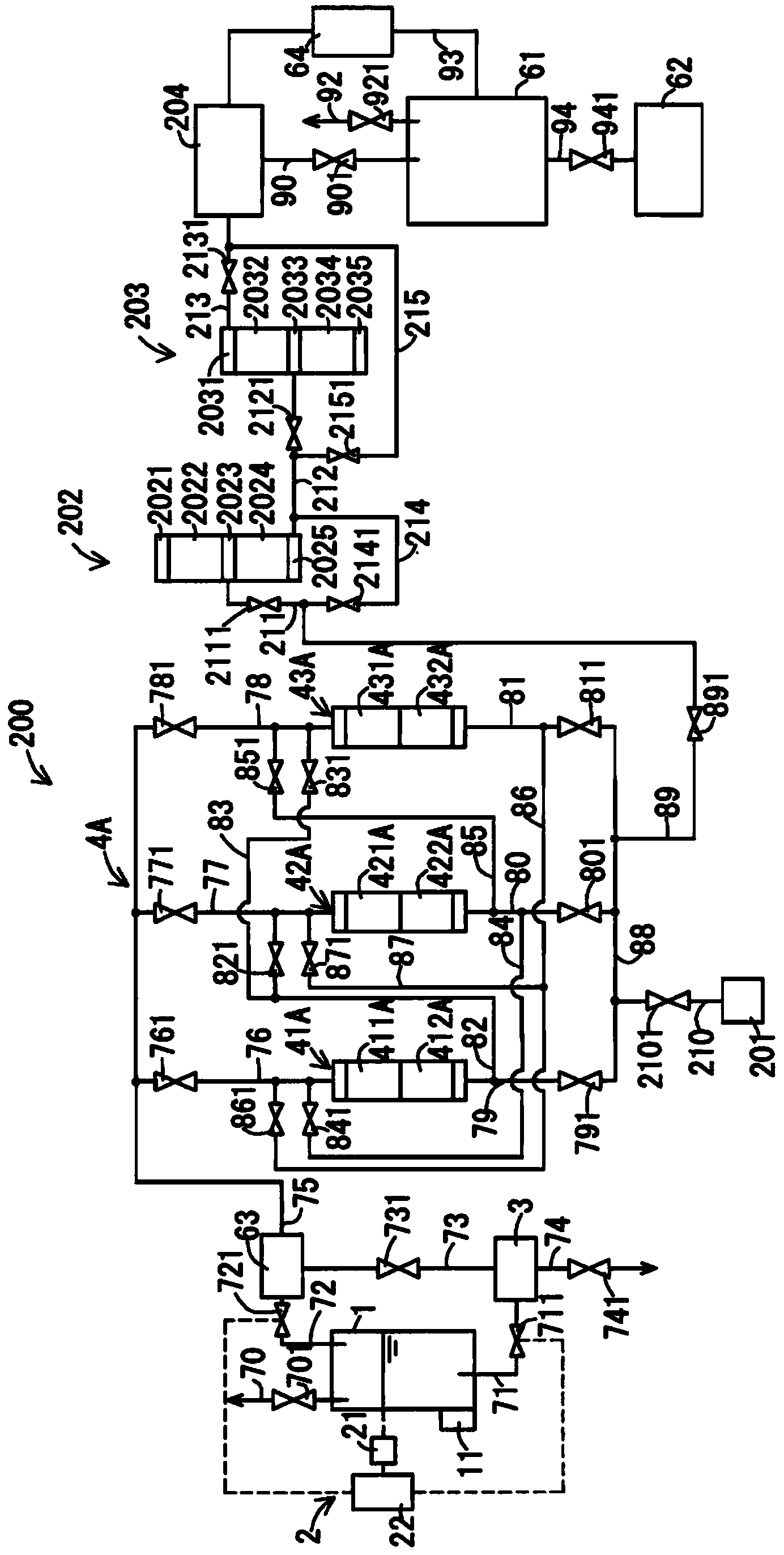

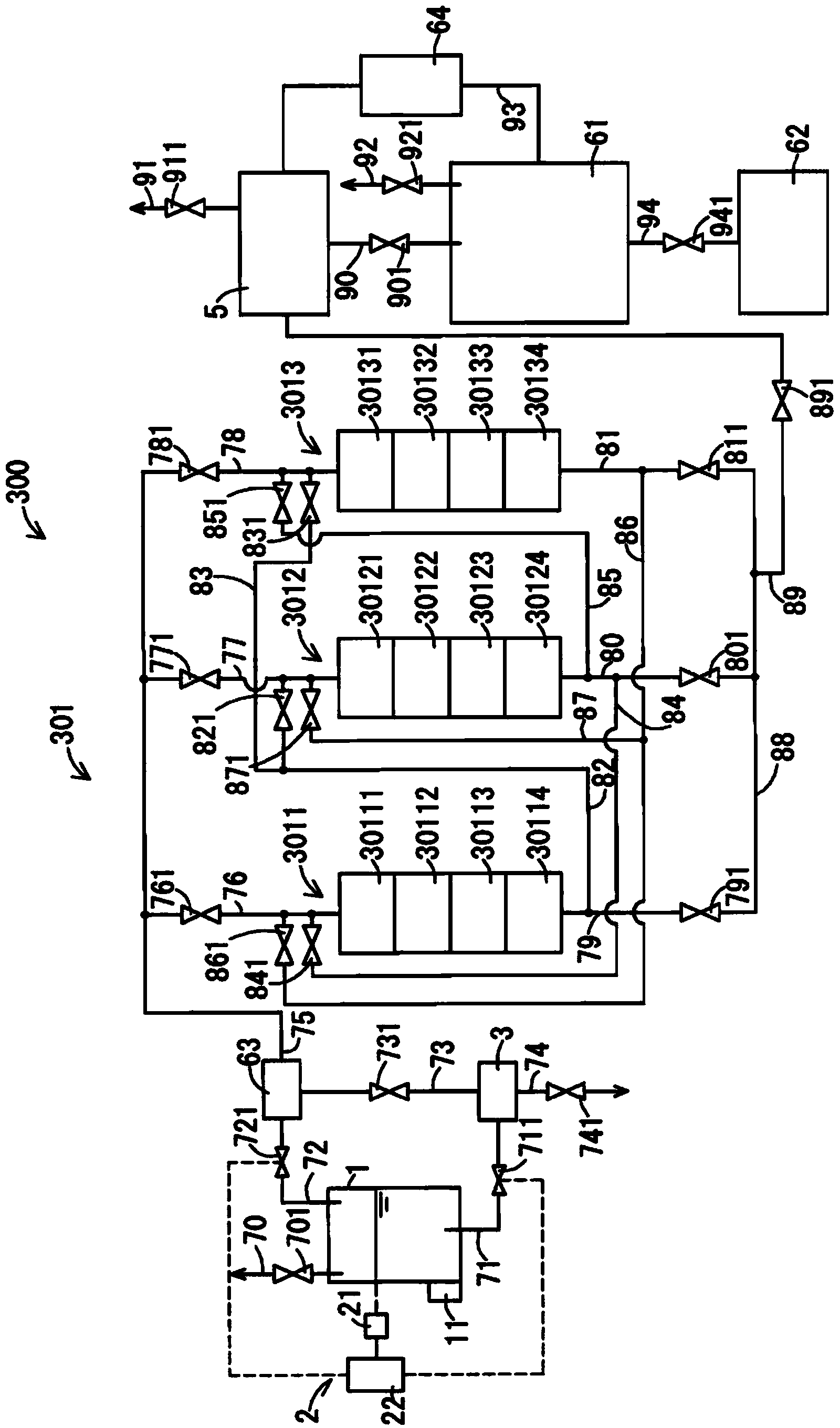

Ammonia purification system

InactiveCN103619756ACurb energy consumptionConcentration deviation preventionGas treatmentChemical industryChemistrySorbent

Provided is an ammonia purification system which can prevent large variations in purity of the final refined ammonia. In this ammonia purification system (100), a control unit (2) controls a raw material storage tank (1) such that if, in the raw material storage tank (1), the volume ratio of the liquid phase to the total volume of the internal space is greater than or equal to a preset threshold value, then crude ammonia is delivered from the liquid phase, and if said volume ratio is less than said threshold value, then the crude ammonia is delivered from the gas phase. Further, an adsorption unit (4) delivers either the gaseous crude ammonia taken from the gas phase of the raw material storage tank (1), or the gaseous ammonia obtained by adsorbing with an adsorbent and removing impurities contained in the gaseous ammonia delivered from a vaporizer (3).

Owner:SUMITOMO SEIKA CHEM CO LTD

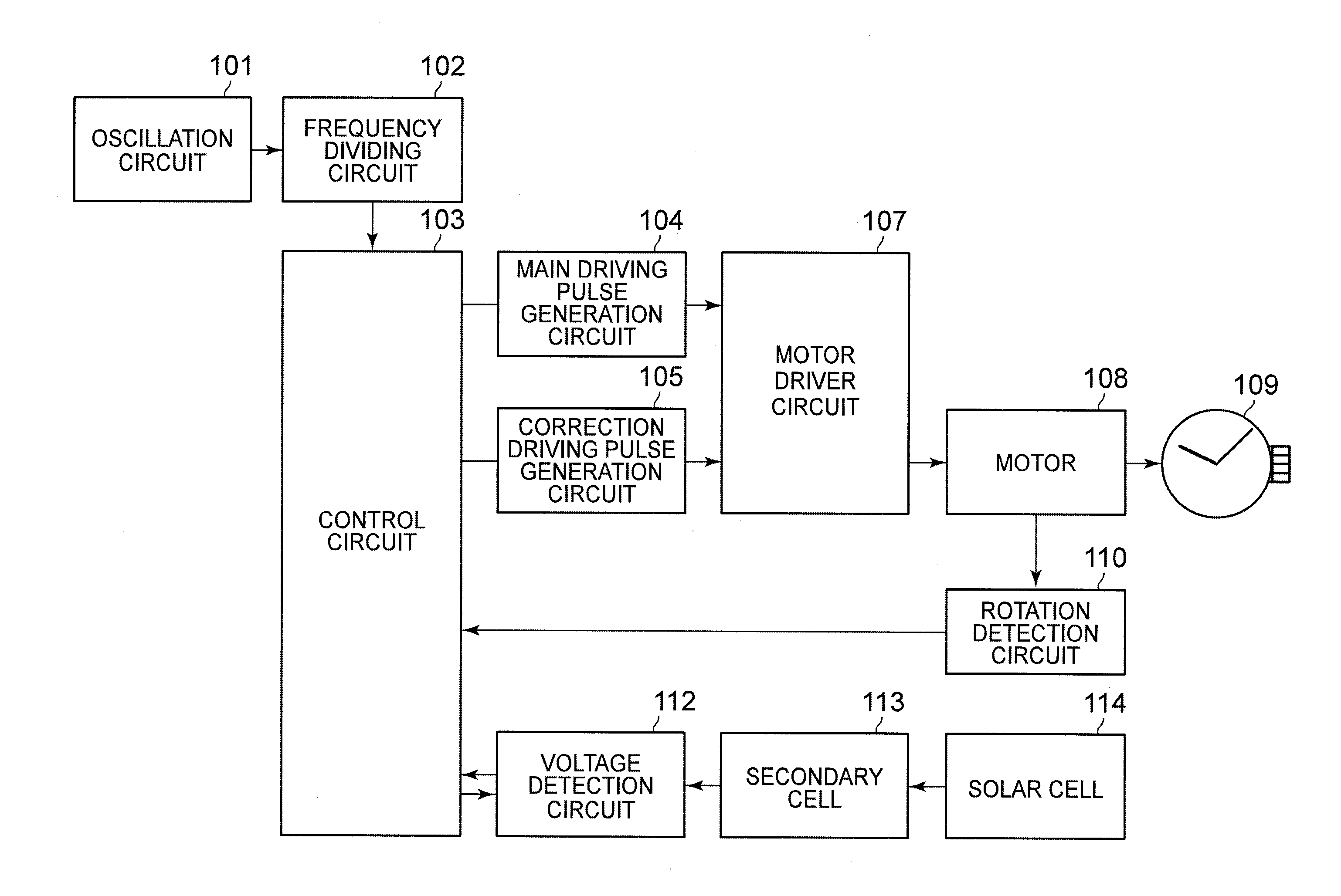

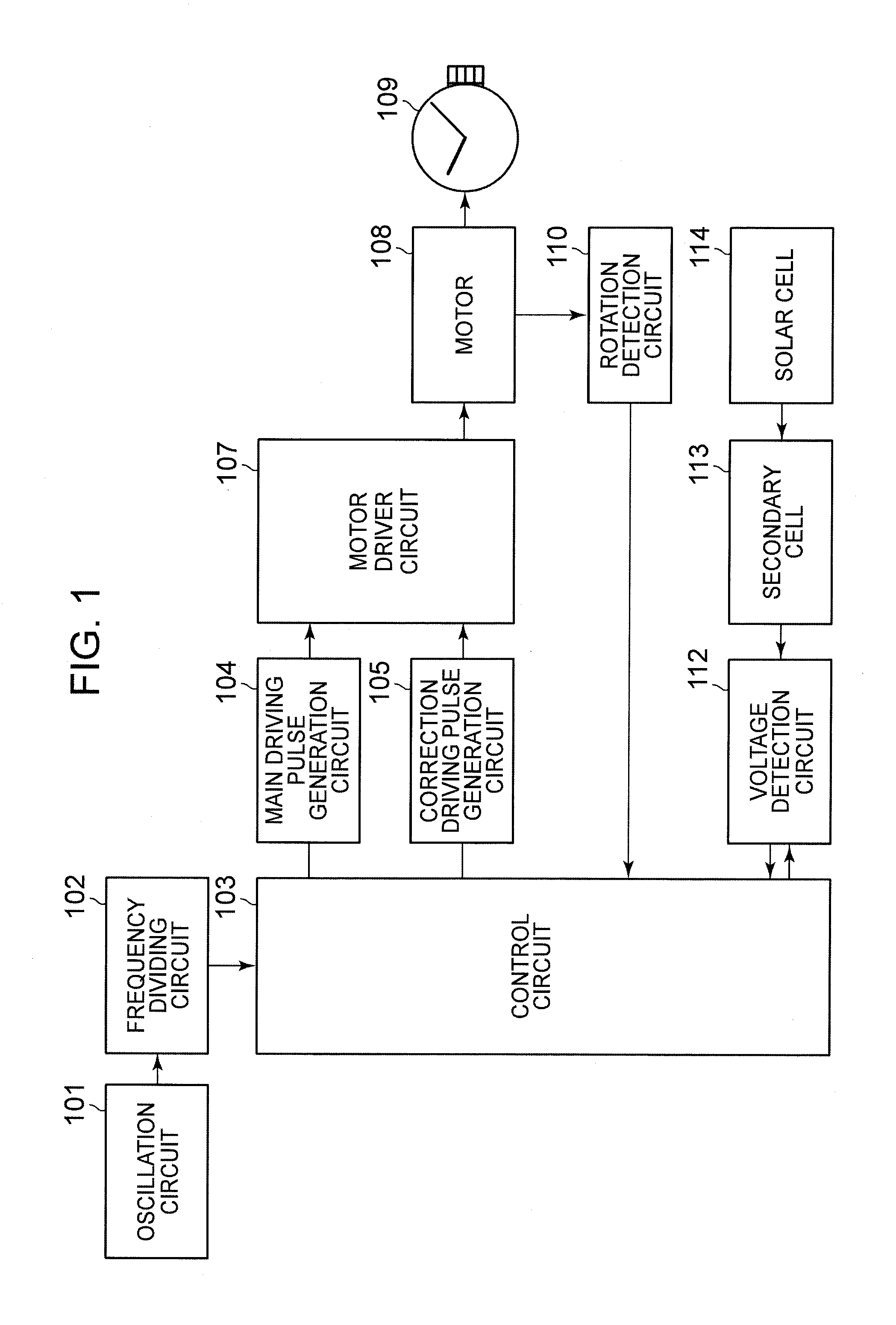

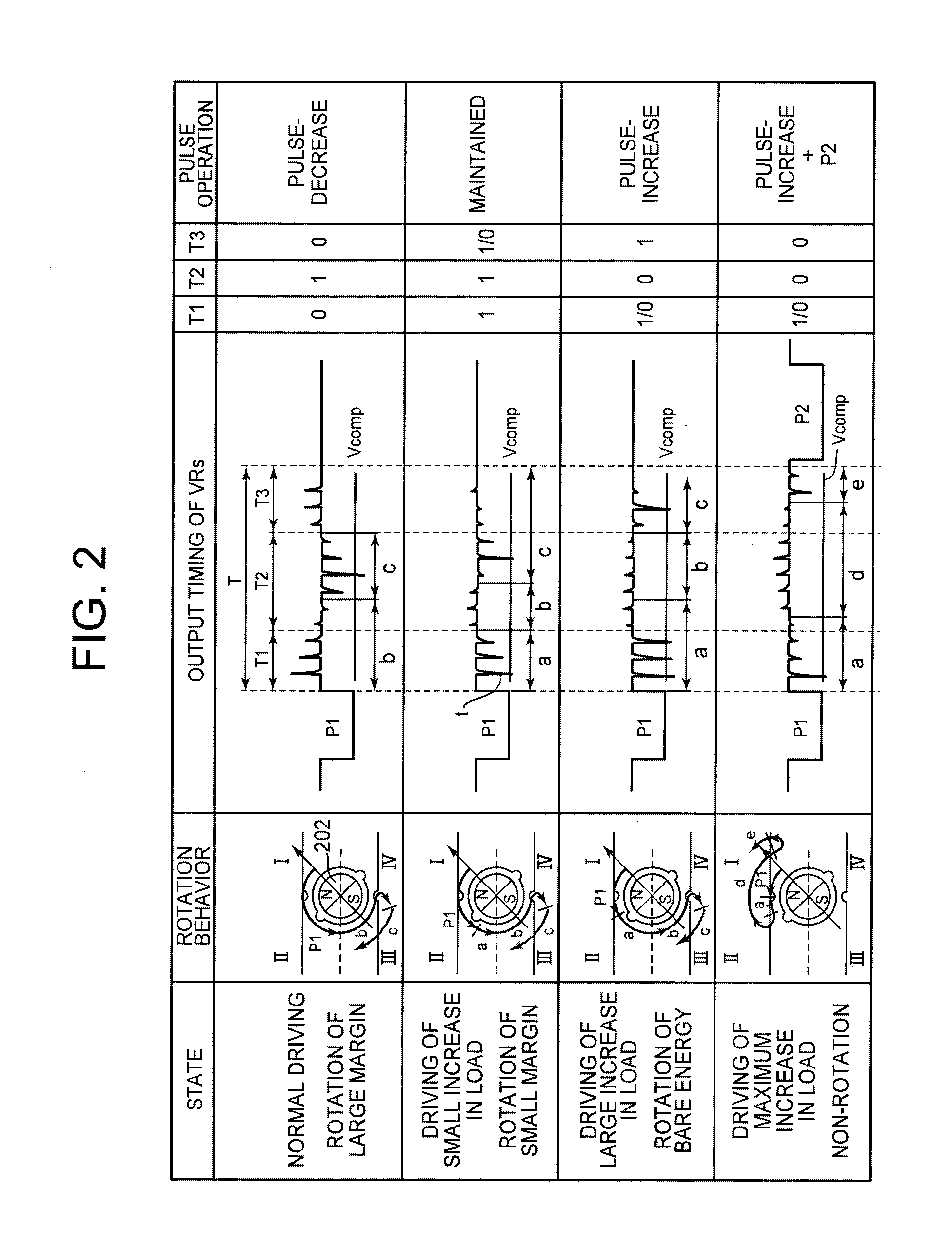

Stepping motor control circuit and analog electronic timepiece

InactiveUS20120306428A1Energy consumption can be suppressedPrevent non-rotationComputer controlSimulator controlMotor controlControl circuit

A control unit is provided which drives a stepping motor in a first mode in which a driving pulse is selected between one kind of main driving pulse and a correction driving pulse with energy greater than the one kind of main driving pulse in accordance with a rotation state of the stepping motor and the stepping motor is driven or a second mode in which the driving pulse is selected among plural kinds of main driving pulses and a correction driving pulse with energy greater than the plural kinds of main driving pulses in accordance with the rotation state of the stepping motor and the stepping motor is driven. The control unit switches a mode between the first and second modes depending on whether the voltage of a secondary cell serving as a power supply exceeds a switch voltage and drives the stepping motor.

Owner:SEIKO INSTR INC

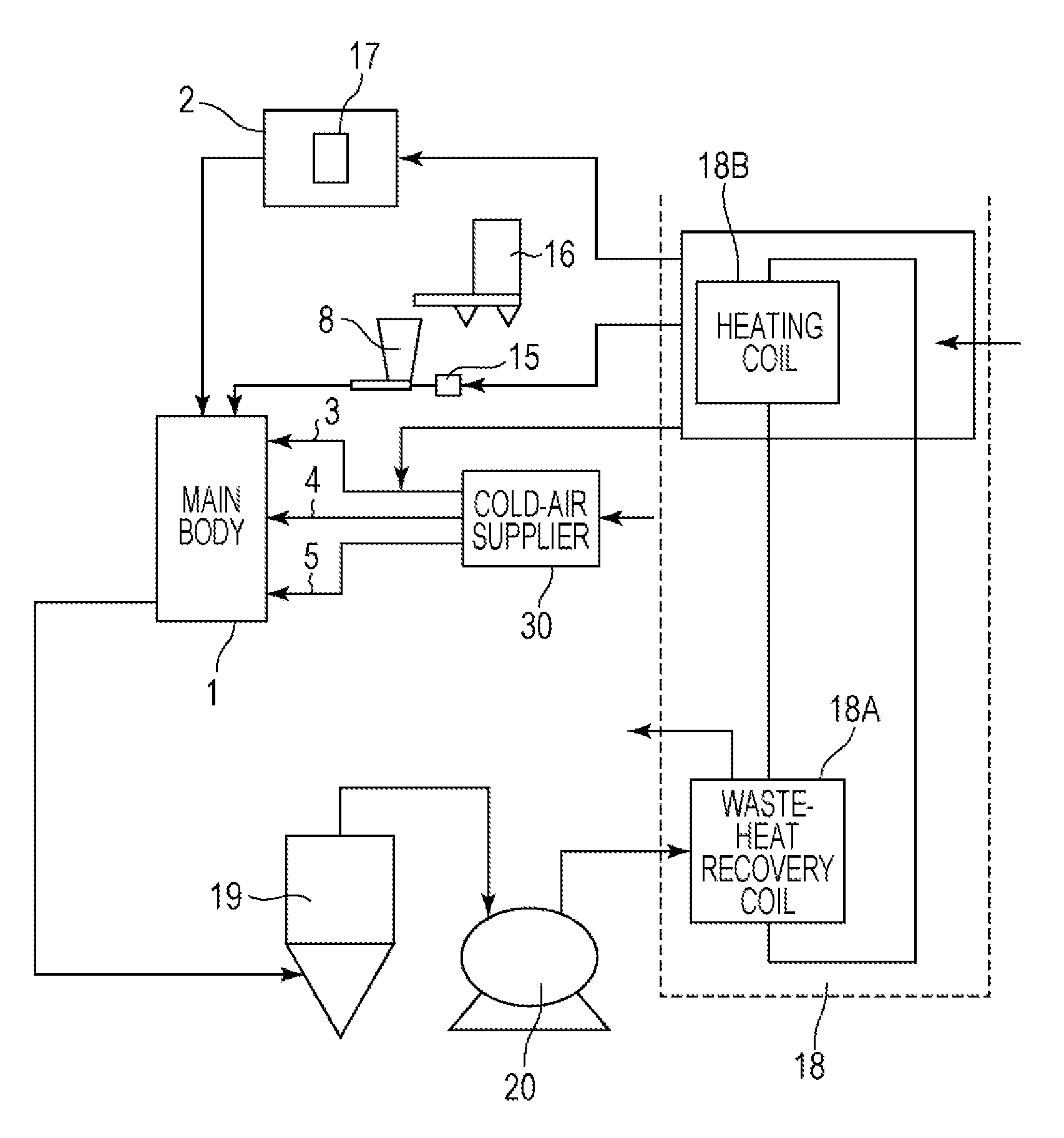

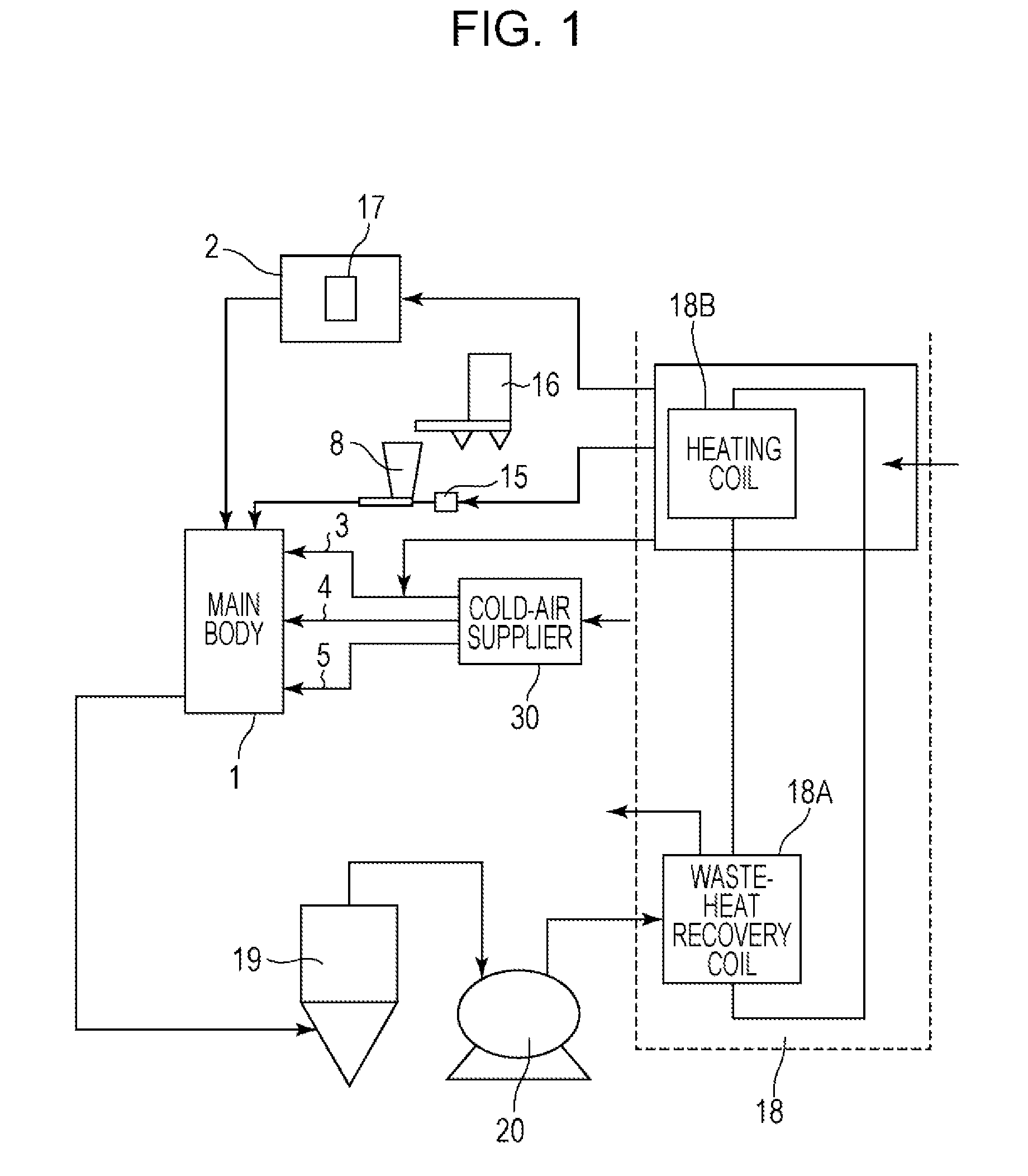

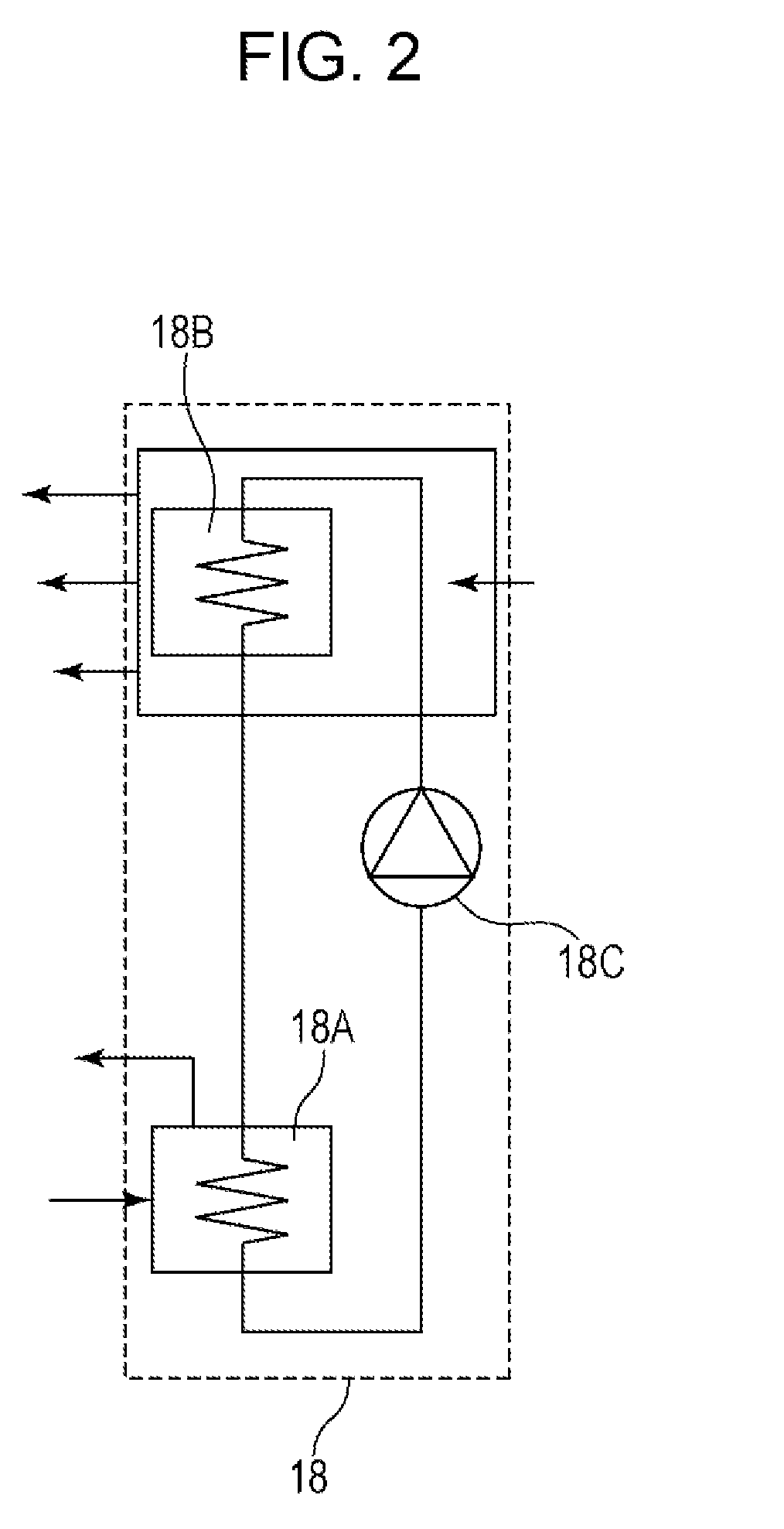

Apparatus for heat-treating toner and method for producing toner

ActiveUS20120231382A1Heat treatmentReduce environmental loadDevelopersEngineeringProcess engineering

An apparatus for heat-treating a toner includes a raw-material supply unit configured to supply a toner treatment space with a raw-material toner, a hot-air supply unit configured to heat-treat the raw-material toner in the toner treatment space, a suction and ejection unit configured to eject hot air used for the heat treatment of the raw-material toner, and a waste-heat recovery and supply unit configured to recover heat from the hot air ejected by the suction and ejection unit and supply the hot-air supply unit with the recovered heat.

Owner:CANON KK

Ozone generating apparatus

ActiveUS20090283399A1High ozone concentrationImprove efficiencyElectrical apparatusElectrical discharge ozone preparationDielectricSurface resistivity

Owner:MITSUBISHI ELECTRIC CORP

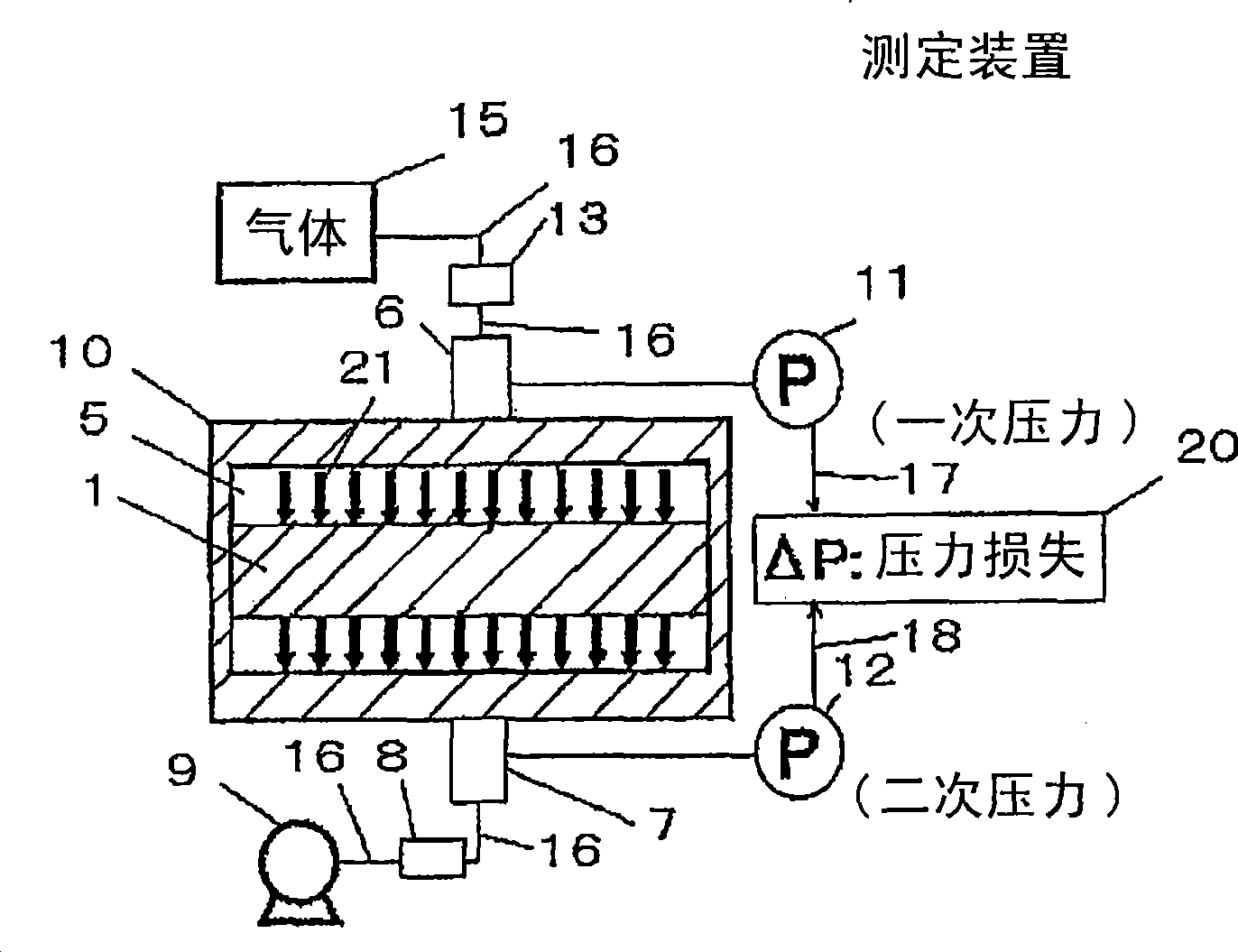

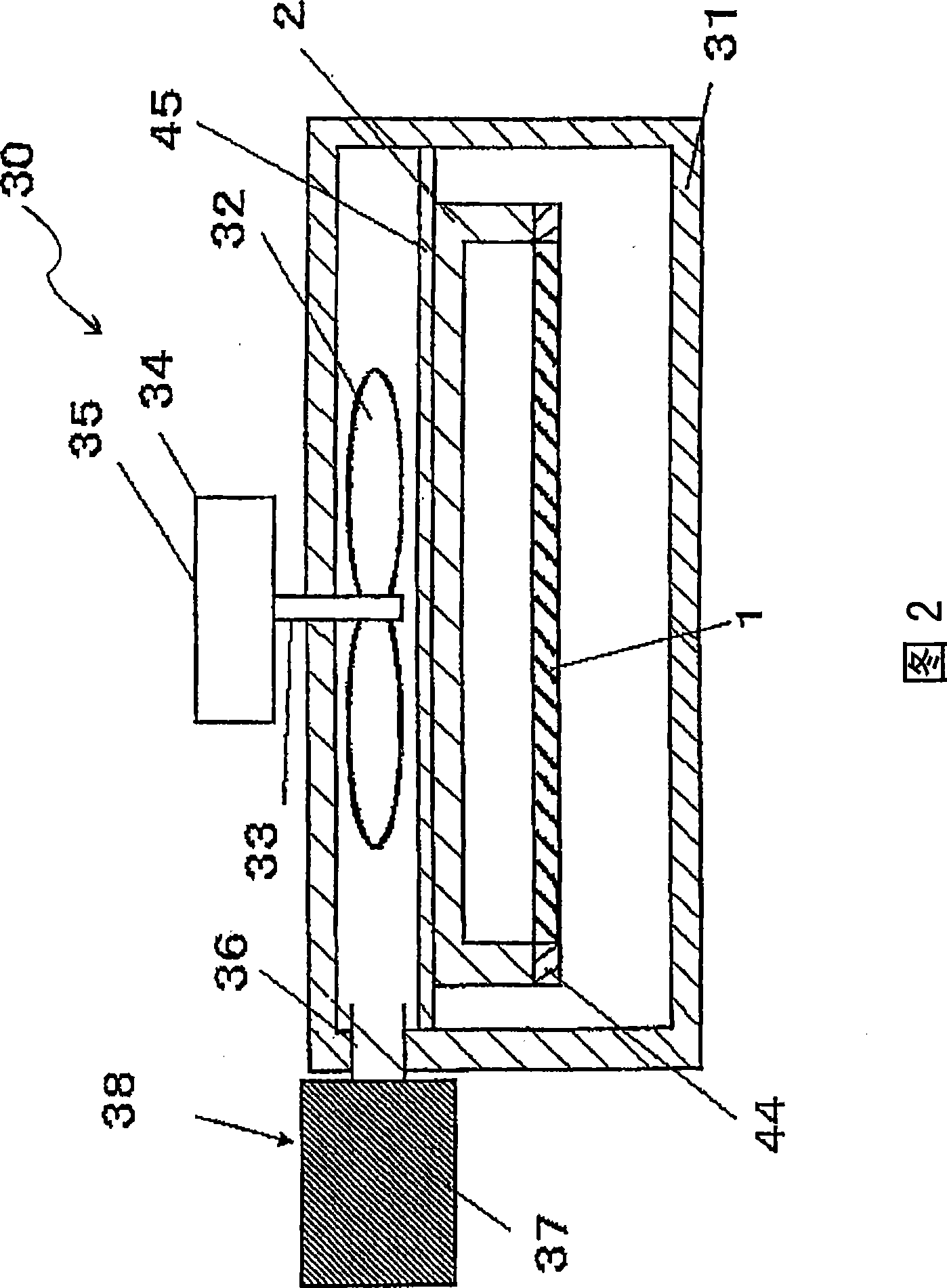

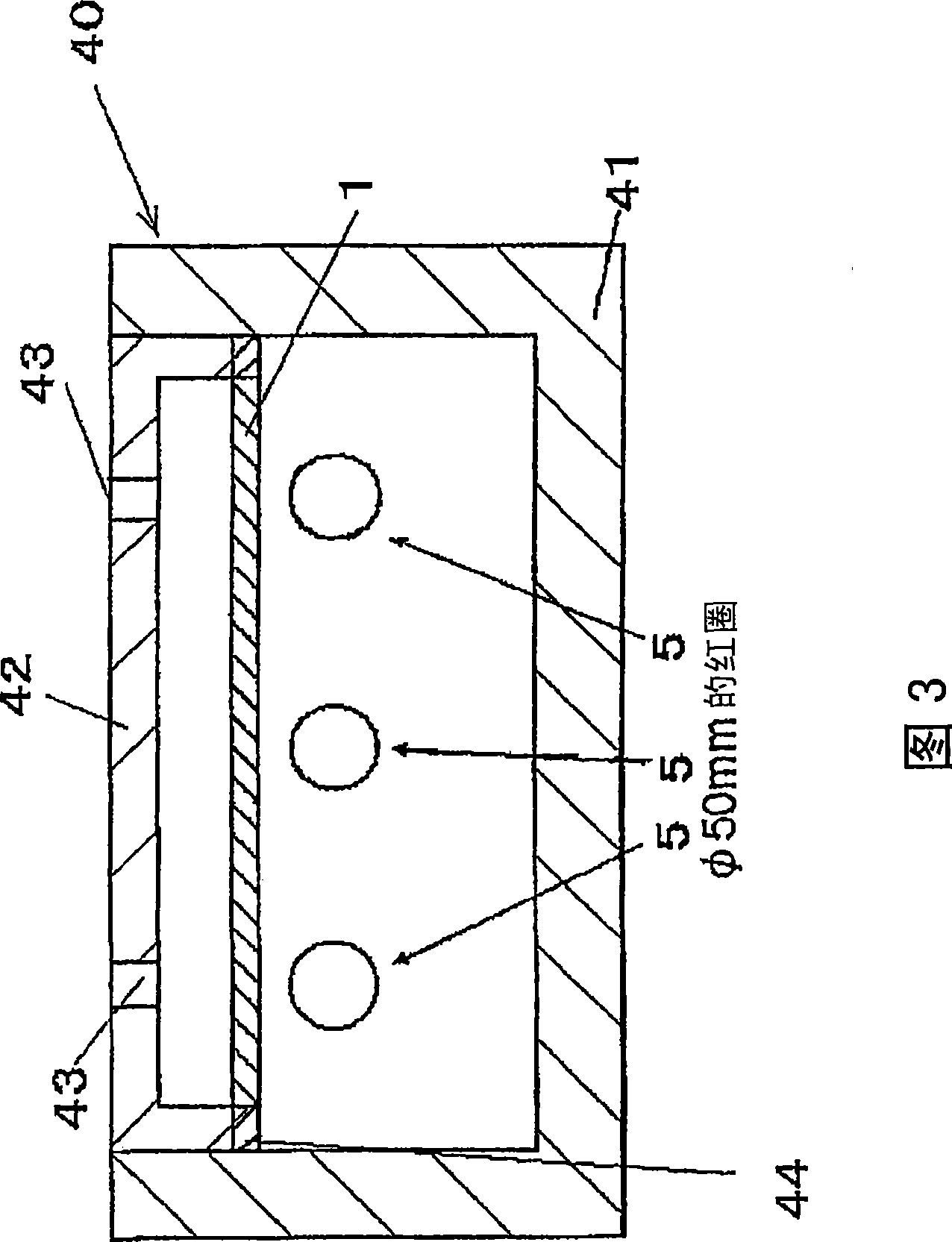

Porous member

ActiveCN101421203ACurb energy consumptionEvenly dispersedThin material handlingCeramicwareCeramic sinteringDielectric loss

This invention provides a porous member that, when used in a field requiring a high level of cleanness, can suppress energy loss in a microwave band and can evenly disperse gas. The porous member is formed of a porous ceramic and has a dielectric loss tangent at a microwave band of not more than 1x10<-3>. A ceramic member comprising a ceramic sinter comprising this porous member in a part thereof is also provided.

Owner:TOHOKU UNIV +1

Refrigeration apparatus

ActiveUS8806876B2Lower energy requirementsReduce energy consumptionCompressorTemperatue controlPhase stateEngineering

An air conditioner (10) composed of a refrigerating apparatus includes a controller (90). A heating control section (91) of the controller (90) feeds electric current in an open phase state to an electric motor (62) of a compressor (30) to heat the compressor (30) in operation stop of the air conditioner (10). The heating control section (91) monitors the detection value of an outdoor air temperature sensor (72) during the operation stop of the air conditioner (10) and keeps on stopping feeding the electric current to the electric motor (62) during the time when the detection value decreases.

Owner:DAIKIN IND LTD

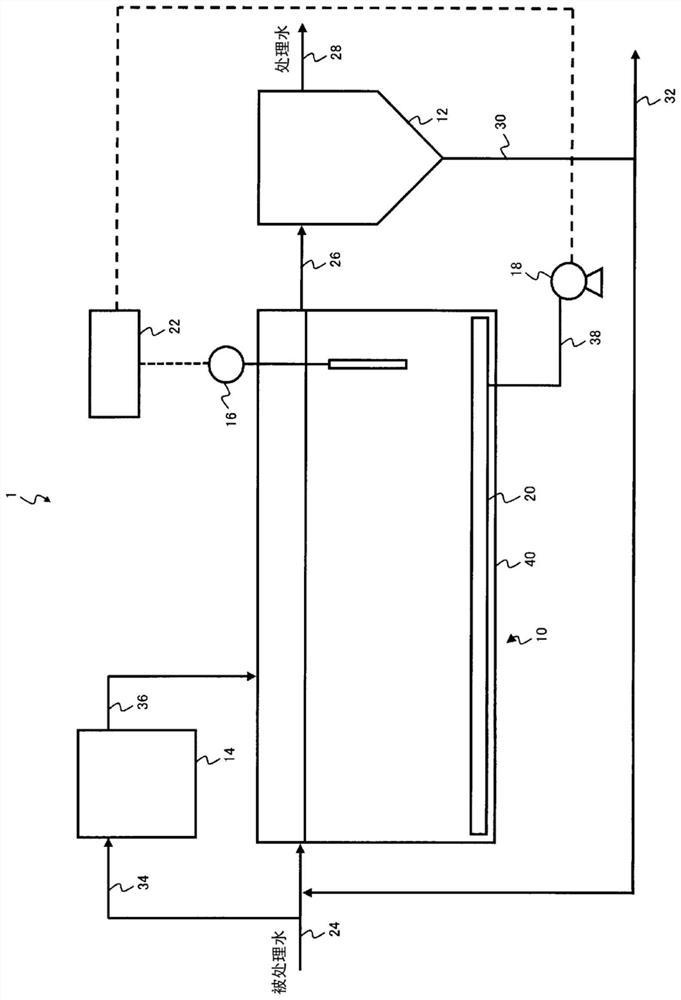

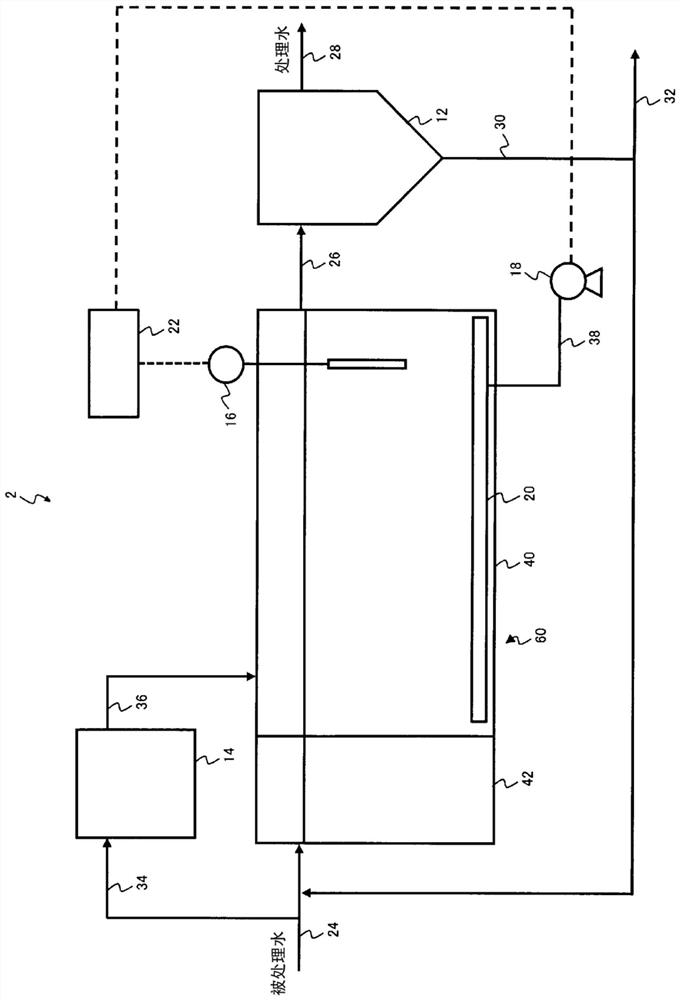

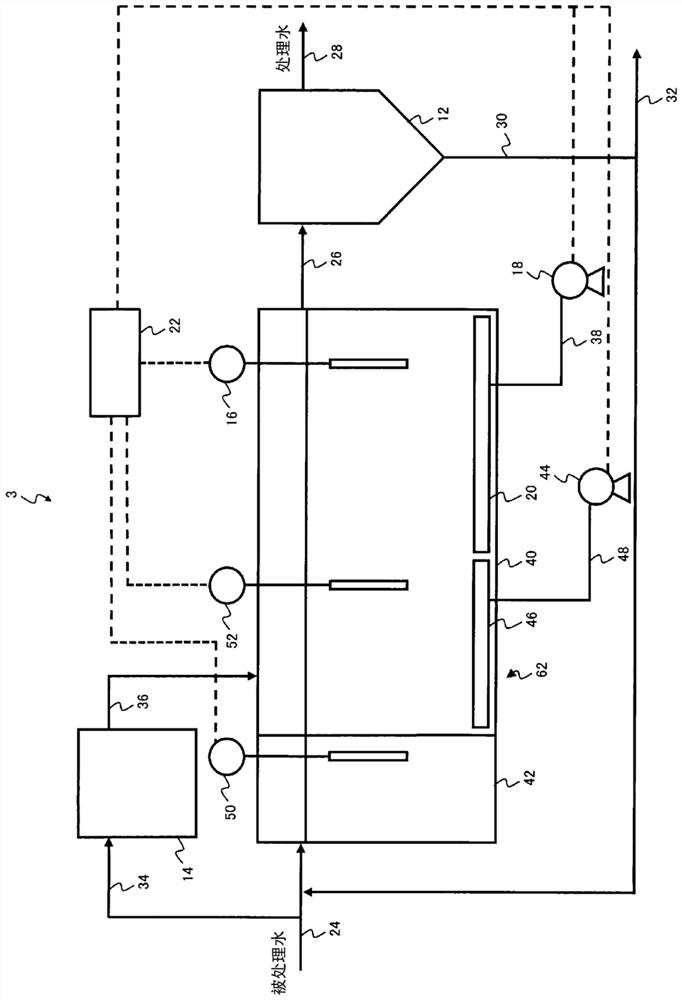

Water treatment method and water treatment device

PendingCN111670168AHigh removal rateCurb energy consumptionWater treatment parameter controlBiological treatment regulationSludgeTreatments water

Provided are a water treatment method and a water treatment device that can be introduced in a standard tank with an effective water depth of 5 m or less during treatment of water to be treated that contains organic matter and a nitrogen component, and that allow improvement in efficiency of removing nitrogen from the water to be treated and suppressing energy consumption for aeration while maintaining a high MLSS. The water treatment method is for treating water to be treated that contains organic matter and a nitrogen component, and includes, in a biological treatment device (10) comprisingat least an aerobic tank (40): a biological treatment step for biologically treating inflowing water to be treated aerobically by using sludge that contains granules; a solid-liquid separation step for separating the biological treatment solution in the aerobic tank (40) into treated water and concentrated sludge using a solid-liquid separation device (12); and a sludge return step for returning the concentrated sludge obtained in the solid-liquid separation step to a stage before the biological treatment device (10). The concentration of ammonia nitrogen remaining due to the nitrification reaction in the aerobic tank (40) is measured with an ammonia nitrogen concentration measurement device (16), and the amount of gas containing oxygen dispersed to the aerobic tank (40) is controlled witha blower (18) so that the measured ammonia nitrogen concentration is within a prescribed range.

Owner:ORGANO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com