Hydraulic actuator and hydraulic vibration test device

A vibration test and actuator technology, applied in fluid pressure actuation devices, vibration tests, fluid pressure actuation system components, etc., to achieve the effect of suppressing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

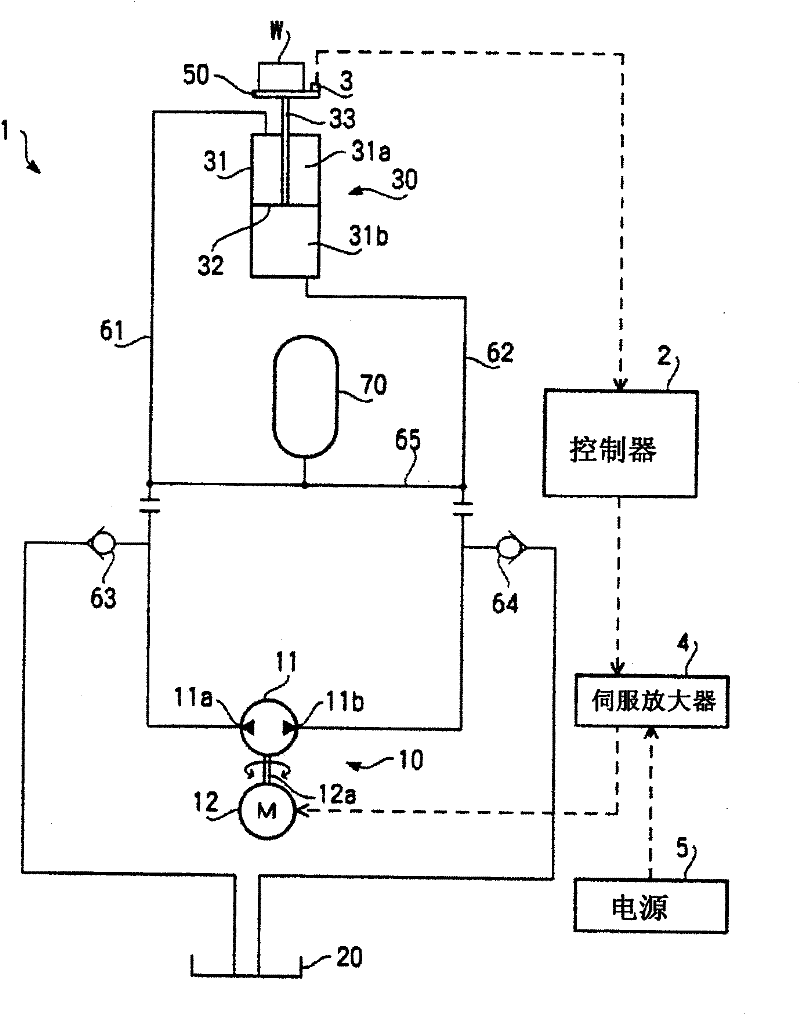

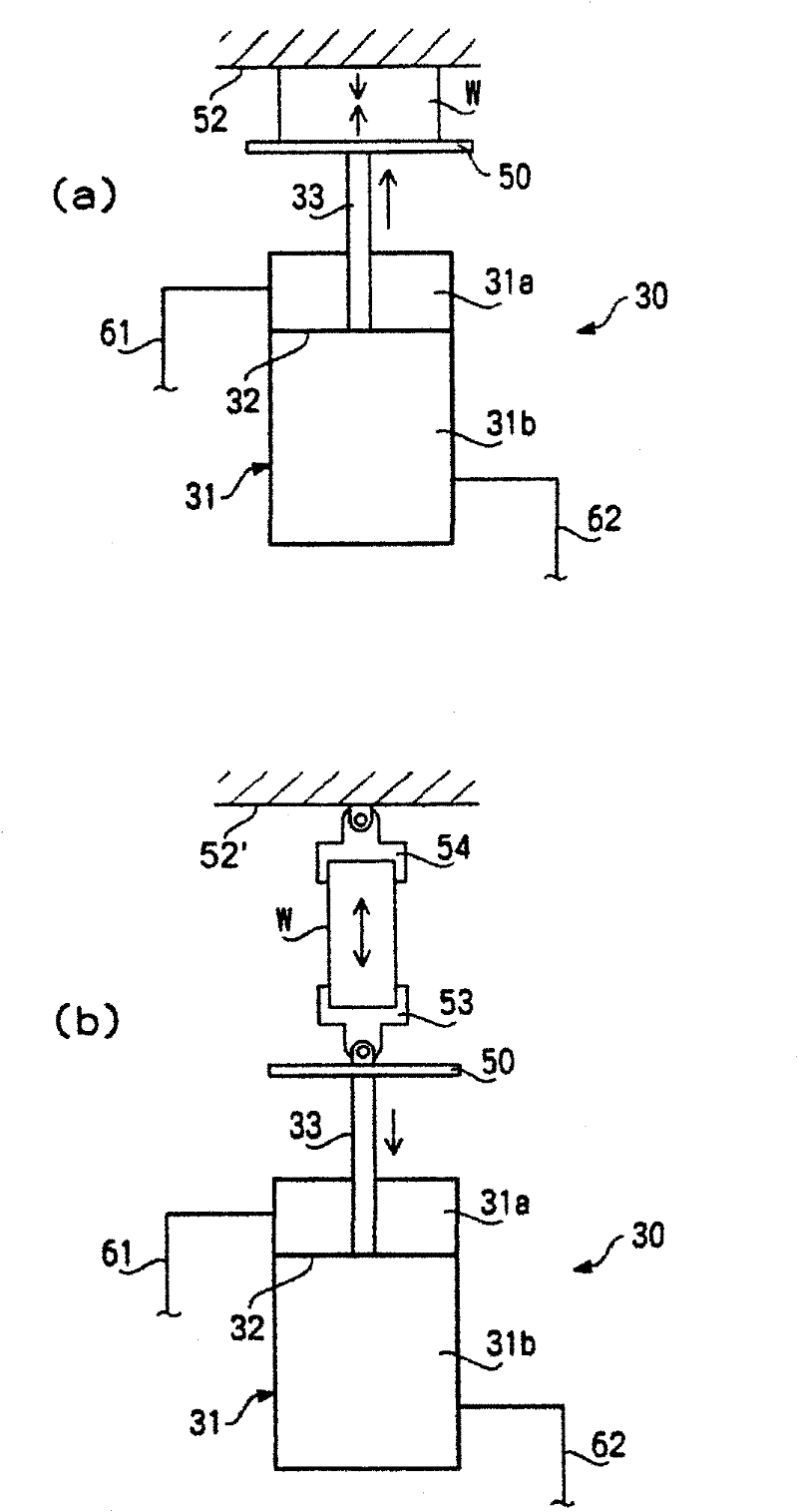

Method used

Image

Examples

Embodiment

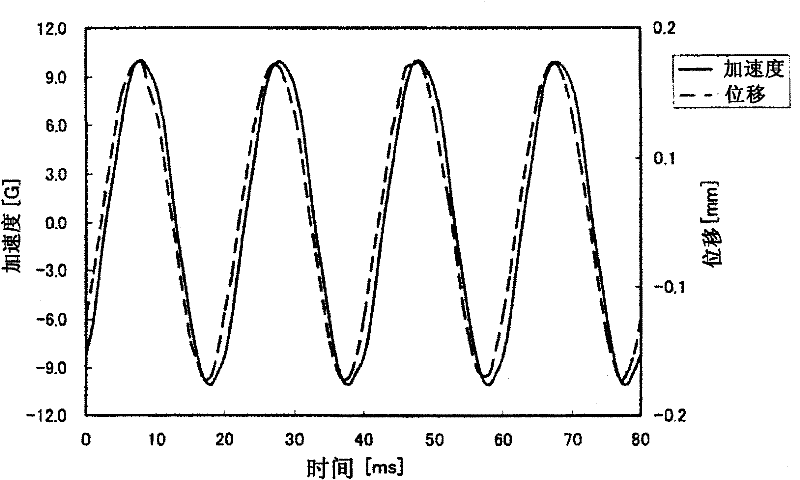

[0046] Next, the results of a vibration test performed using the vibration test device 1 of the present embodiment described above and the results of a vibration test performed using a vibration test device that does not include a pressure accumulator will be described. image 3 It is a graph of the acceleration and displacement of the vibrating table measured when the target waveform of a sine wave with a frequency of 50 Hz is supplied to the vibration test apparatus 1 (example) of this embodiment and the subject W is vibrated . also, Figure 4 It is a graph of acceleration and displacement of a vibrating table measured when a target waveform of a sine wave with a frequency of 50 Hz is supplied to a vibration test device (comparative example) not equipped with a pressure accumulator, and the subject W is vibrated ongoing. In addition, there is no structural difference between the vibration test device of the example and the vibration test device of the comparative example e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com