Porous member

A porous and component technology, used in ceramic products, other household appliances, transportation and packaging, etc., can solve the problems of large dielectric loss, decreased yield of semiconductor products, unstable plasma, etc., to achieve uniform dispersion and restrain energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

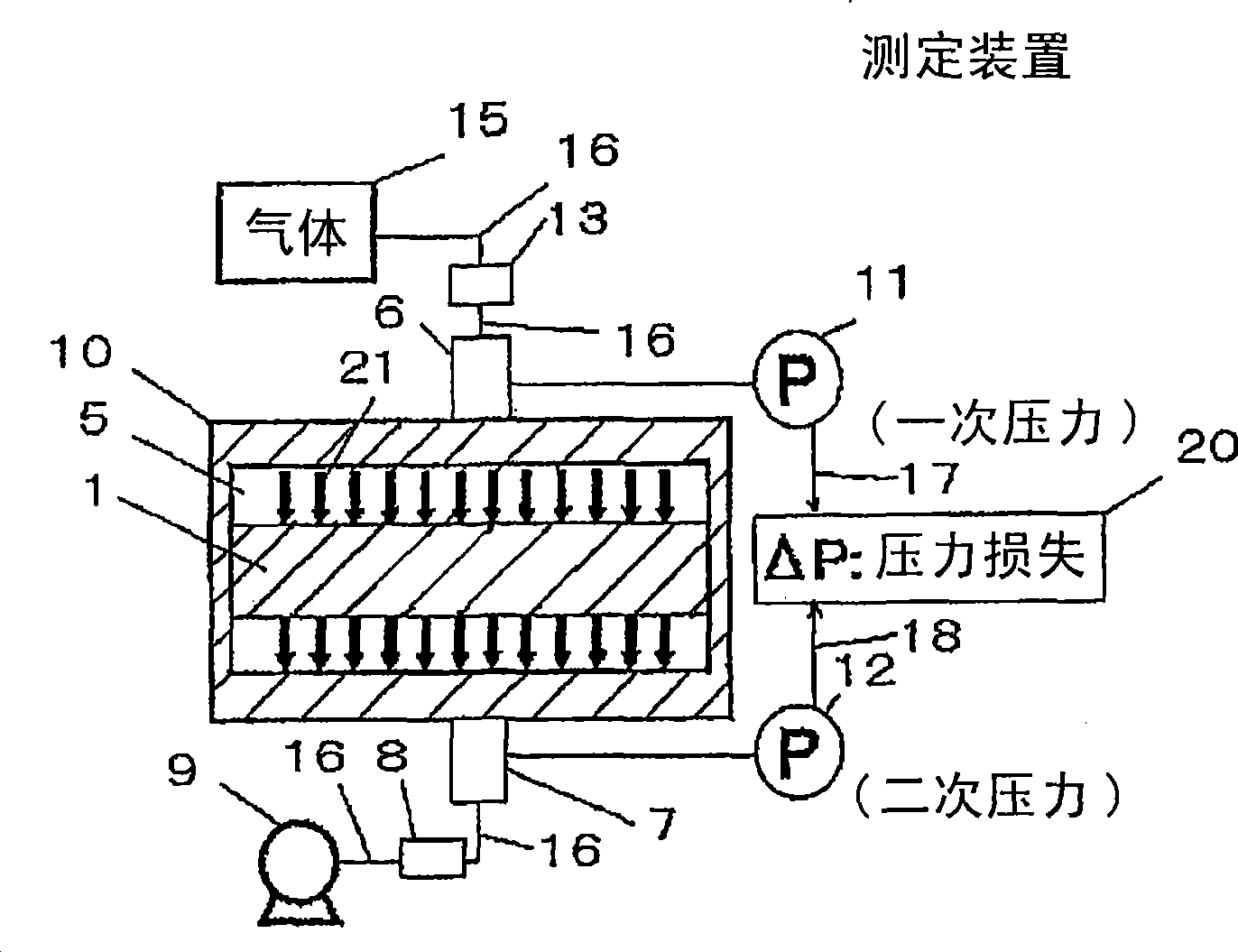

Method used

Image

Examples

Embodiment

[0068] Next, examples of the present invention will be given. In the following examples, although examples 1 to 4 are preferable, it goes without saying that the present invention is not limited to these examples.

[0069] The material particle type / purity / particle size of the raw materials used to produce the porous member of the present invention, the type of bonding material / the compounding ratio of material particles are shown in Table 1 below. The types of material particles are alumina, quartz, and yttrium oxide, the purity is more than 99%, and the particle size is 1-300 μm. Quartz with a purity of more than 99% or alkali-free glass with a low alkali content is used as the bonding material.

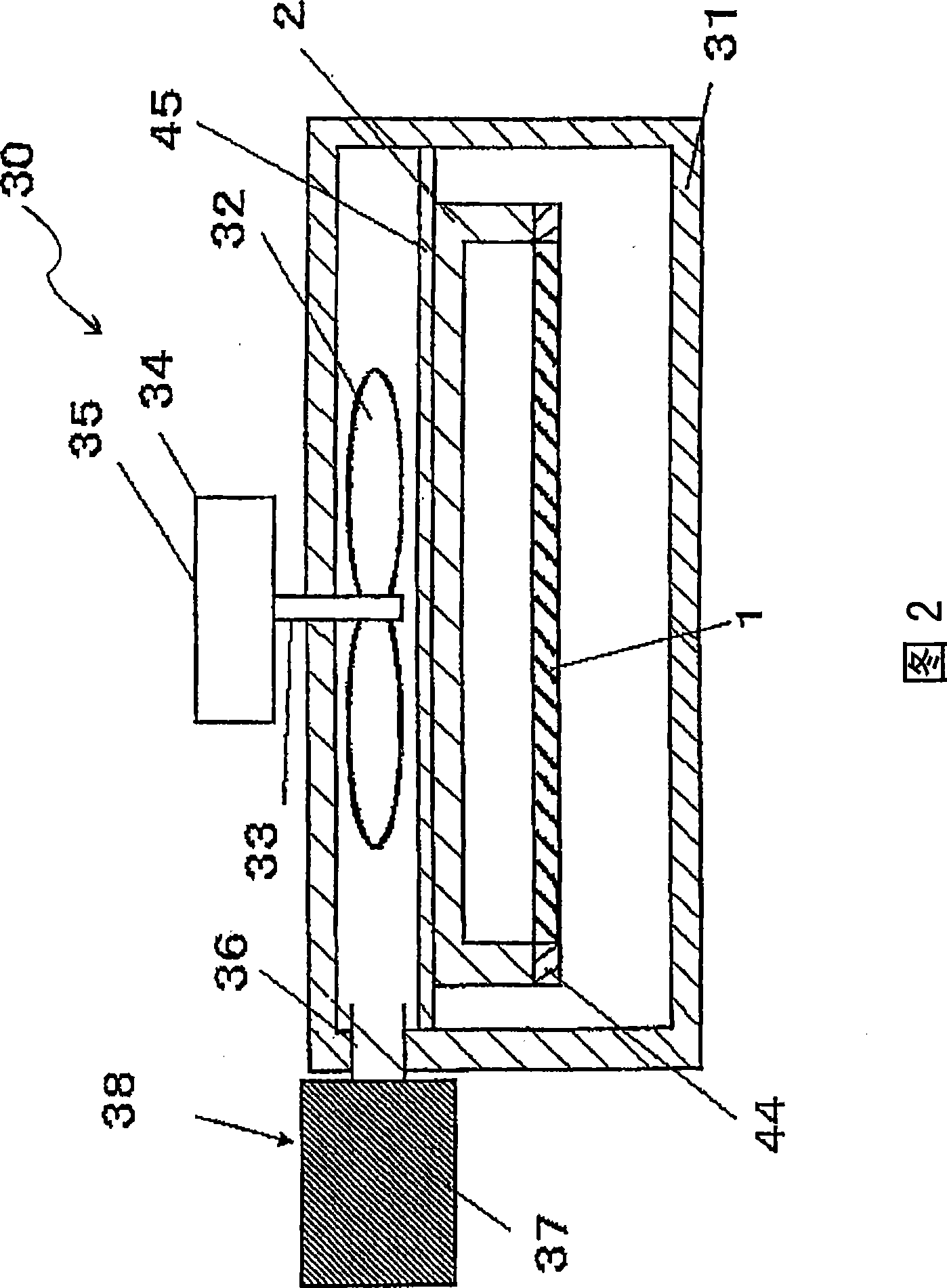

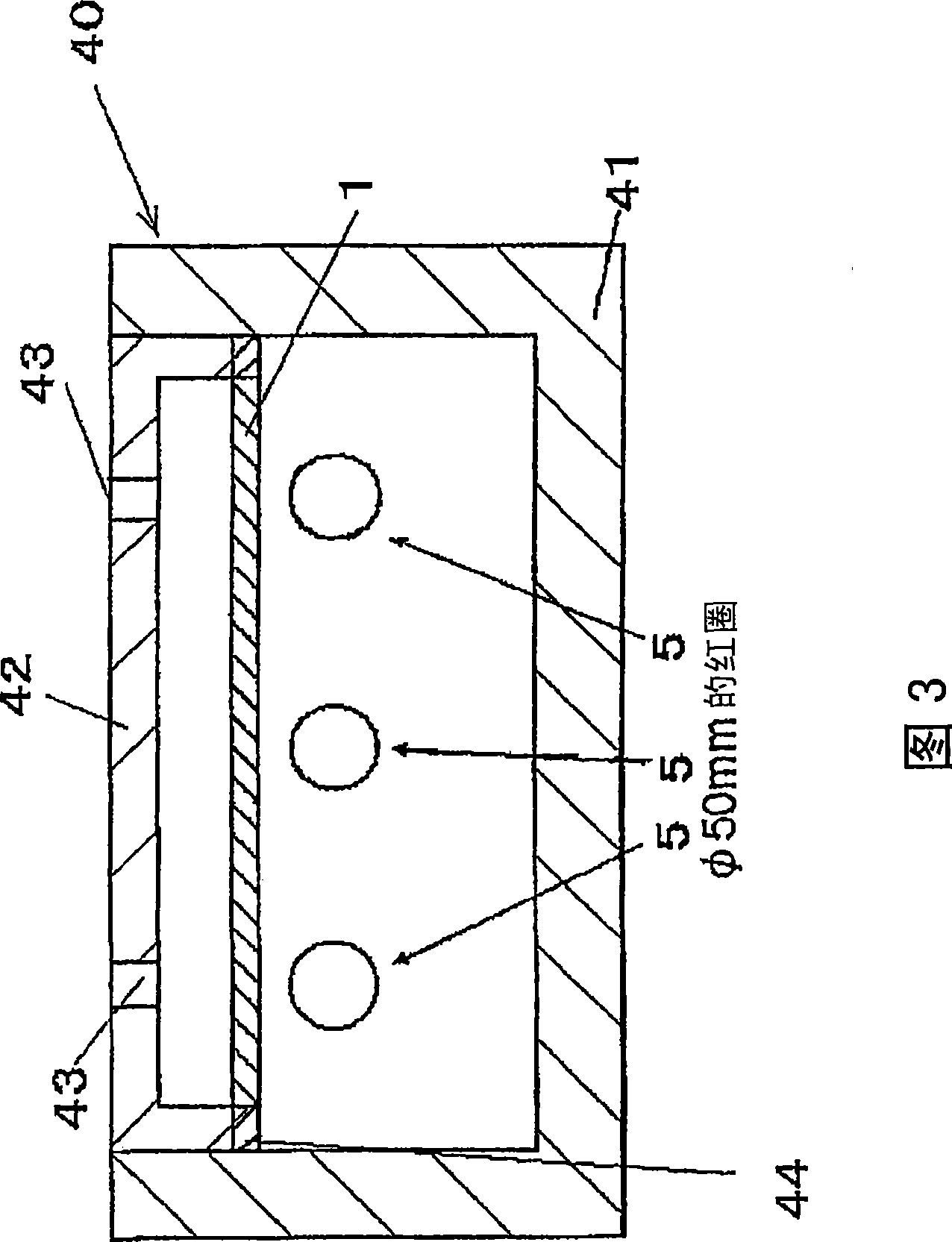

[0070] The material particles and the bonding material are weighed in a predetermined ratio, and a mixed slurry of the material particles and the bonding material is prepared by a ball mill using resin balls in ion-exchanged water. This was poured into a mold of □200×t50 mm made ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com