Water treatment method and water treatment device

A water treatment device and water treatment technology, applied in biological treatment devices, biological treatment adjustment methods, water treatment parameter control, etc., can solve the problems of increased import costs and inability to increase sludge concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

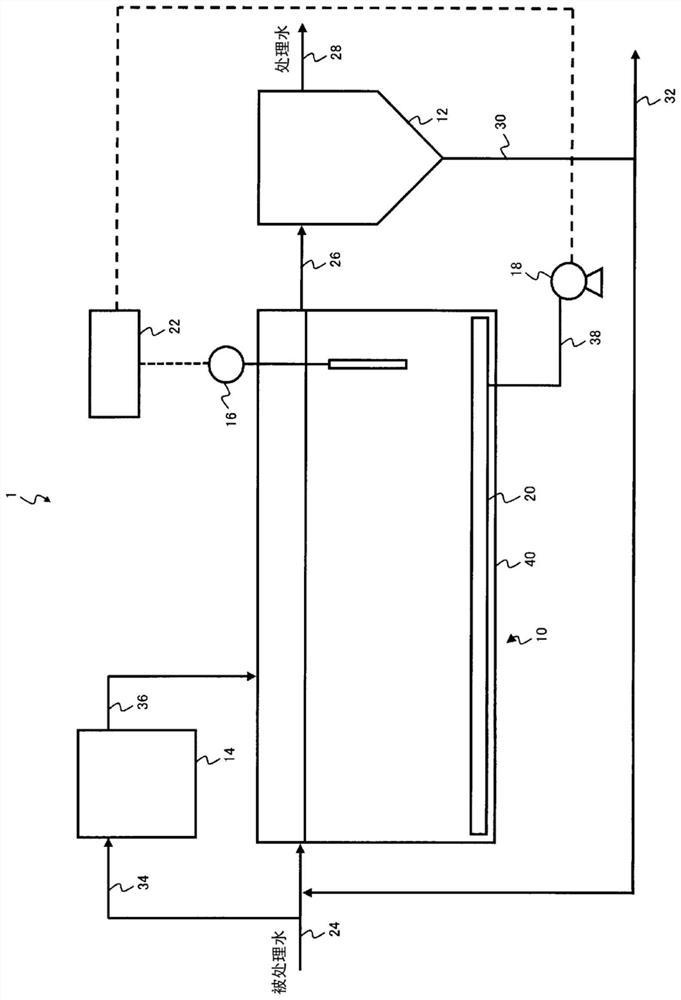

[0051] The water treatment device 1 is a water treatment device that treats treated water containing organic matter and nitrogen components. It has: a biological treatment device 10, which has at least an aerobic tank 40 and a blower 18, wherein the blower 18 is used to In the oxygen-containing gas supply unit for supplying oxygen-containing gas to the aerobic tank 40, the above-mentioned biological treatment device 10 is used to biologically treat the incoming water to be treated in an aerobic manner through the sludge containing particles; the solid-liquid separation device 12 , which is to carry out solid-liquid separation of the biological treatment liquid in the aerobic tank 40, and separate it into a solid-liquid separation unit for treating water and concentrated sludge; Thickened sludge is sent back to the sludge return unit at the front stage of the biological treatment device 10; the ammoniacal nitrogen concentration measuring device 16 is used to measure the ammoniac...

Embodiment approach 2

[0072] figure 1 In the water treatment device 1 , the water to be treated containing organic matter, nitrogen components, and phosphorus is supplied to the aerobic tank 40 of the biological treatment device 10 through the water to be treated pipe 24 . The aerobic tank 40 is a continuous reaction tank for treating organic matter and phosphorus with a pseudo-AO method (pseudo-anaerobic-aerobic activated sludge method) as the target, and the blower 18 supplies air and the like through the aeration device 20. Oxygen gas is used to aerate and maintain an aerobic state while stirring the tank, but stop or weaken aeration at the front end (inflow portion) of the tank to maintain an anaerobic state. On the other hand, part of the water to be treated is supplied to the granule formation tank 14 through the water to be treated pipe 34, and granules containing polyphosphoric acid accumulation bacteria are formed in the granule formation tank 14 (particle formation process), and the forme...

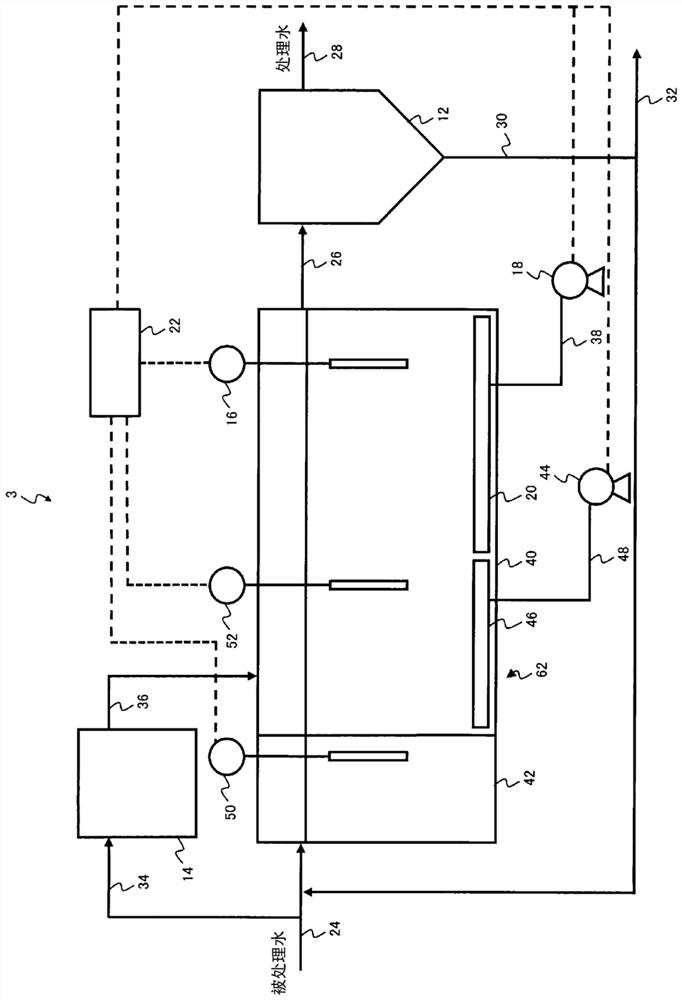

Embodiment approach 3

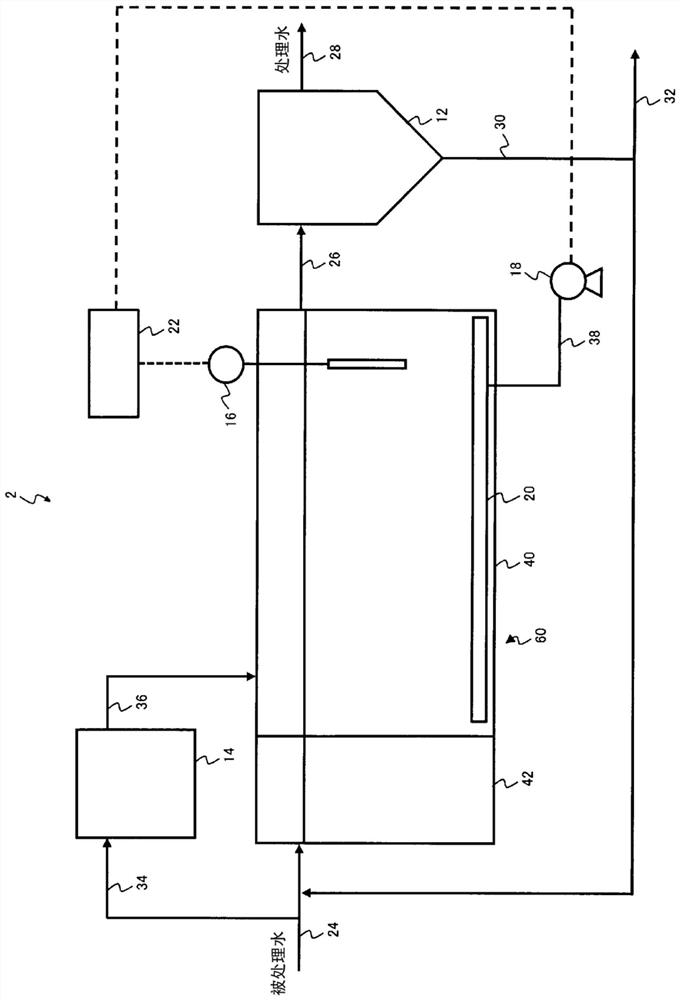

[0079] figure 2 In , the schematic structure of another example of the water treatment apparatus concerning embodiment of this invention is shown. figure 2 The water treatment device 2 has: biological treatment device 60, which has anaerobic tank 42, aerobic tank 40 and blower 18; solid-liquid separation device 12; sludge returns to piping 30; ammoniacal nitrogen concentration measuring device 16; and control device 22. The water treatment device 1 may have a particle formation tank 14 provided outside the biological treatment device 60 .

[0080] figure 2 In the water treatment device 2, the water to be treated pipe 24 is connected to the water to be treated inlet of the anaerobic tank 42 of the biological treatment device 60. The outlet of the aerobic tank 40 and the inlet of the solid-liquid separator 12 are connected by a biological treatment liquid pipe 26 . A treated water pipe 28 is connected to the treated water outlet of the solid-liquid separator 12 . The slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com