Control device for hot rolling line

A control device and technology for rolling materials, which are applied in rolling mill control devices, driving devices for metal rolling mills, metal rolling, etc., can solve the problem of increased time required for rolling, increased energy consumption, and inability to ensure output interval time. and other problems to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

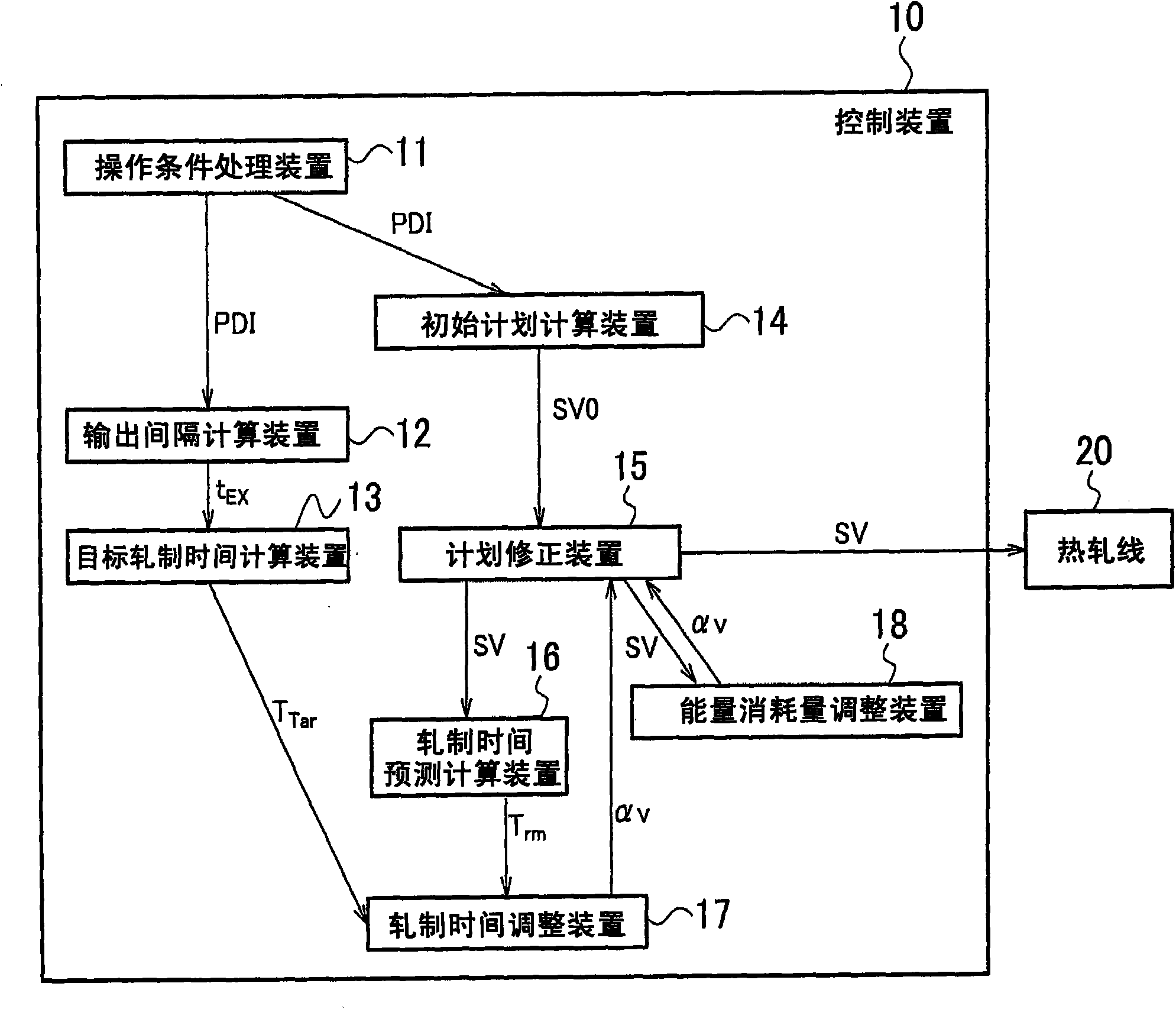

[0052] The control device 10 of the hot rolling line according to Embodiment 1 of the present invention is as follows: figure 1As shown, it is a control device for a hot rolling line 20, including an operating condition processing device 11, an output interval calculation device 12, a target rolling time calculation device 13, an initial plan calculation device 14, a plan correction device 15, and a rolling time forecast calculation device. device 16, rolling time adjustment device 17, and energy consumption adjustment device 18.

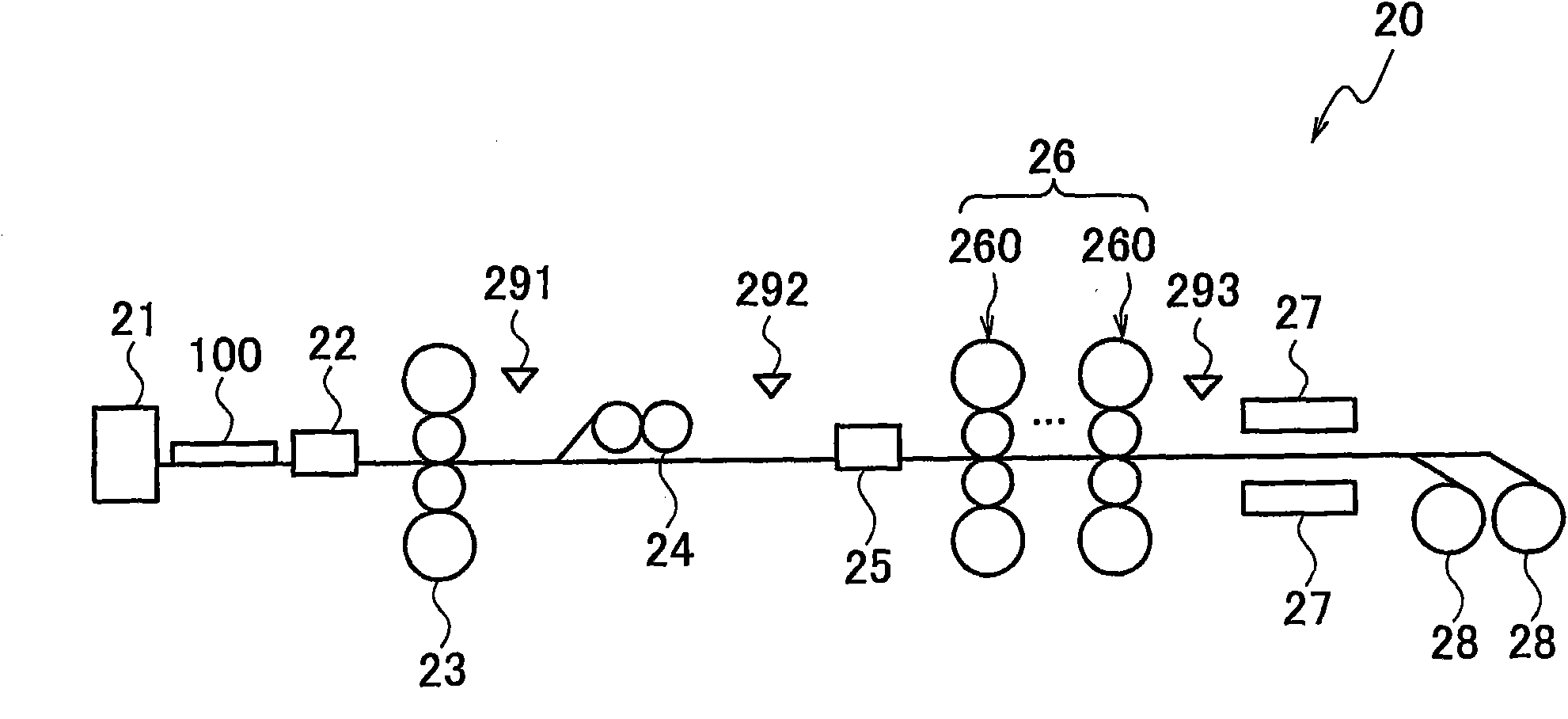

[0053] The hot rolling line 20 controlled by the control device 10 includes a heating furnace and a finishing mill including a plurality of rolling stands arranged continuously and cooling sprayers arranged between the plurality of rolling stands. Before describing the control device 10 in detail, refer to figure 2 The hot rolling line 20 will be described. figure 2 The hot rolling line 20 shown includes a furnace 21 , a roughing mill 23 , a fin...

Embodiment approach 2

[0176] Figure 10 shown for illustration in figure 1 The flow chart of the method of determining the output interval time in Embodiment 2 performed by the control device 10 of the hot rolling line 20 shown.

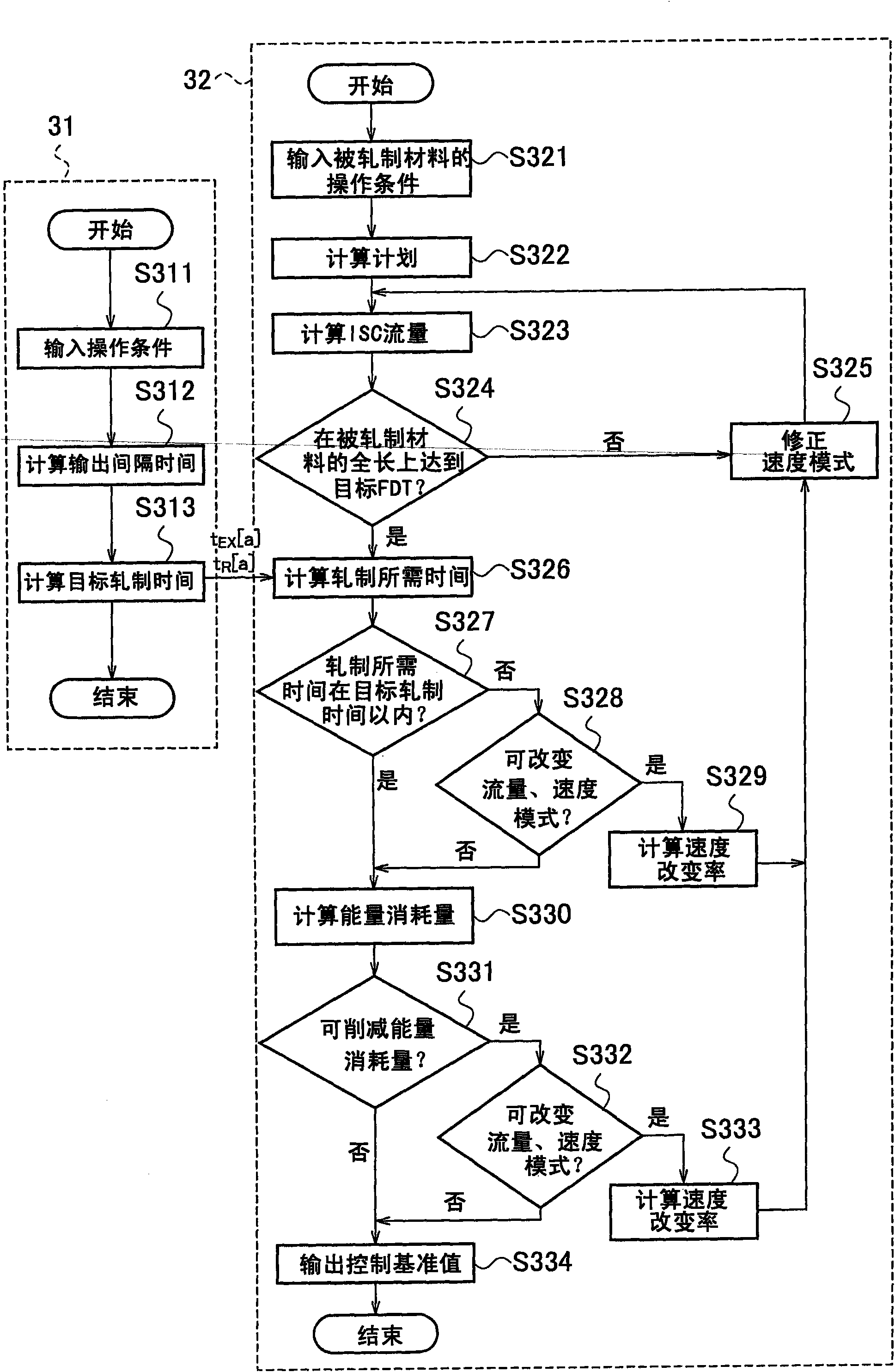

[0177]First, in step S1010, with reference to image 3 The method described in the flow chart 31 is the same, and the rolling operation period in which the total number of rolled materials 100 is P is calculated. Next, in steps S1020 to S1140, the following calculations are performed in the order of rolling for the rolled materials 100[1] to 100[P-1] in the rolling operation cycle.

[0178] In step S1030, the calculated output interval time t of the rolled material 100[a] EX [a] and the output interval time t of the rolled material 100[a+1] EX The combination of [a+1] is set as the first output interval time combination.

[0179] In step S1040, the energy consumption adjustment device 18 uses the output interval time t EX [a],t EX [a+1], refer to rolled material 10...

Embodiment approach 3

[0197] In addition to formula (1), the following formula (27) can also be used to calculate the output interval time t EX .

[0198] t EX = t Tgt / P+χ(dh)(dh[a]-dhAV)+χ(l)(l[a]-lAV)+

[0199] χ(FDTa)(FDTa[a]-FDTa AV )+χ(Rp(GC))(Rp(GC[a])-Rp(GC) AV )…(27)

[0200] In formula (27), dh is the reduction, l is the length of the rolled material, FDTa is the target FDT, and GC is the material type code. Values marked with letters AV for each item represent the average value of all the rolled material to be treated. The function Rp() calculates the number of rolling passes of the rough rolling mill 23 based on the material type code GC.

[0201] In addition, the function χ () is calculated according to the variation of the required rolling time t relative to the variation of each item x of formula (27):

[0202] χ(x)=dt / dx...(28)

[0203] That is, in the control device 10 according to Embodiment 3 of the present invention, the output interval calculation device 12 calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com