Vapor compression-type refrigerator and method for controlling same

A compression refrigeration and compression technology, applied in refrigerators, compressors, compressors with reversible cycles, etc., can solve problems such as the performance decline of cooling and heating equipment with condensing performance, and achieve the effect of restraining energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

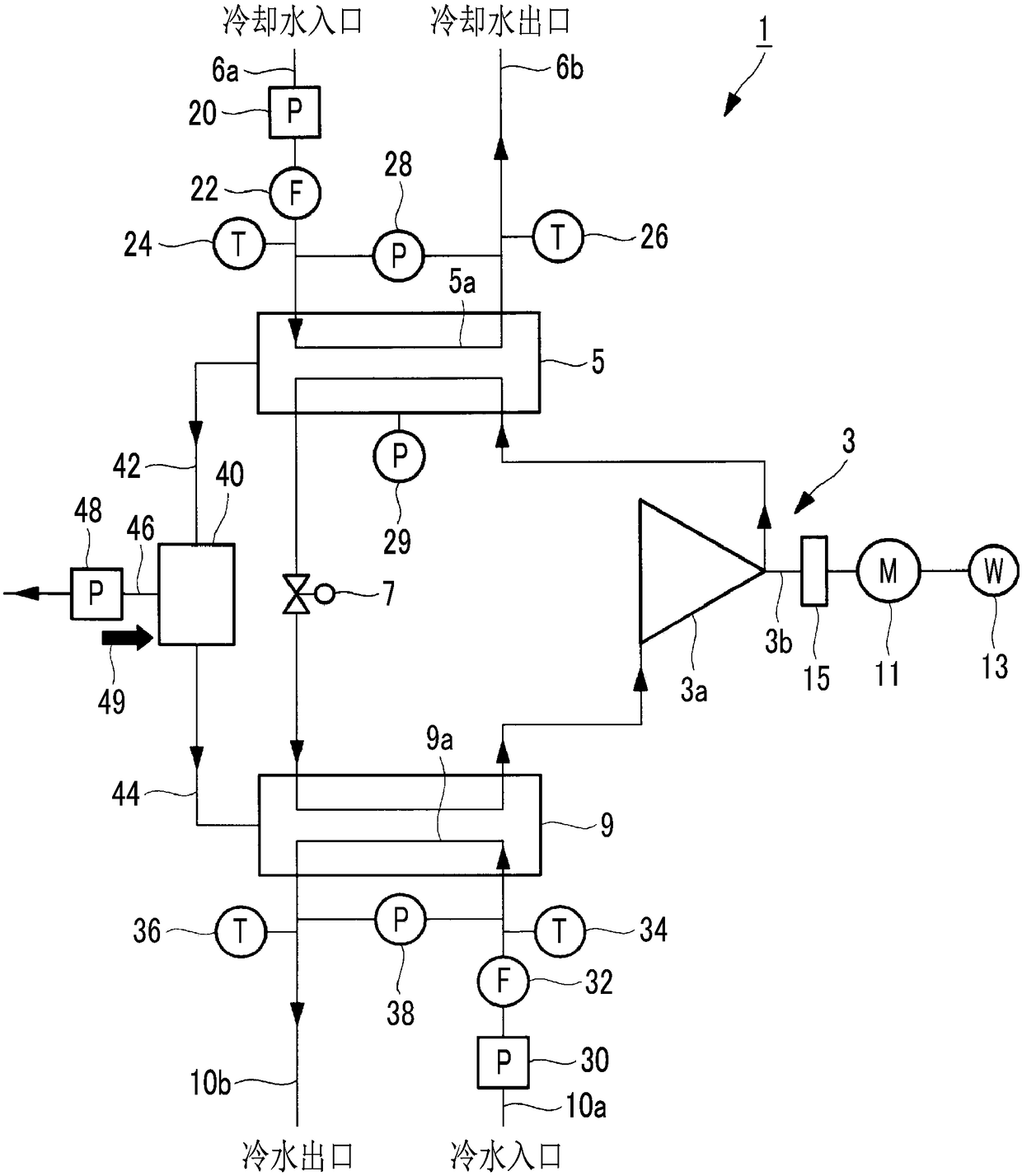

[0088] In the present embodiment, the cooling water flow rate GWC is measured by the cooling water flow rate sensor 22, but even without the cooling water flow rate sensor 22, the cooling water flow rate GWC can be estimated as follows.

[0089] Using the cooling water flow rate sensor 32, the cooling water flow rate GWC is obtained from the heat balance of the entire turbo refrigerator 1 by the following equation.

[0090] GWC=(W+Qact) / ((TWCO-TWCI)×Cpcw×ρcw)…(3)

[0091] Here, W is the input electric power [kW] of the electric motor 11 measured by the power meter 13 . TWCO is the cooling water outlet temperature measured by the cooling water outlet temperature sensor 26 , and TWCI is the cooling water inlet temperature measured by the cooling water inlet temperature sensor 24 . Cpcw is the specific heat of cooling water [kWh / kg℃], ρ cw is the specific gravity of cooling water [kg / m 3 ].

[0092] Qact in the formula (3) is the actual measurement value [kW] of the cooling ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com