Apparatus for melting metal by electron beams and process for producing high-melting metal ingot using this apparatus

A technology for electron beam melting and high-melting point metals, which is applied to furnace components, furnace types, lighting and heating equipment, etc., can solve the problems of low operating rate, achieve the effect of increasing operating rate, shortening maintenance operations, and avoiding shortening the life of the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

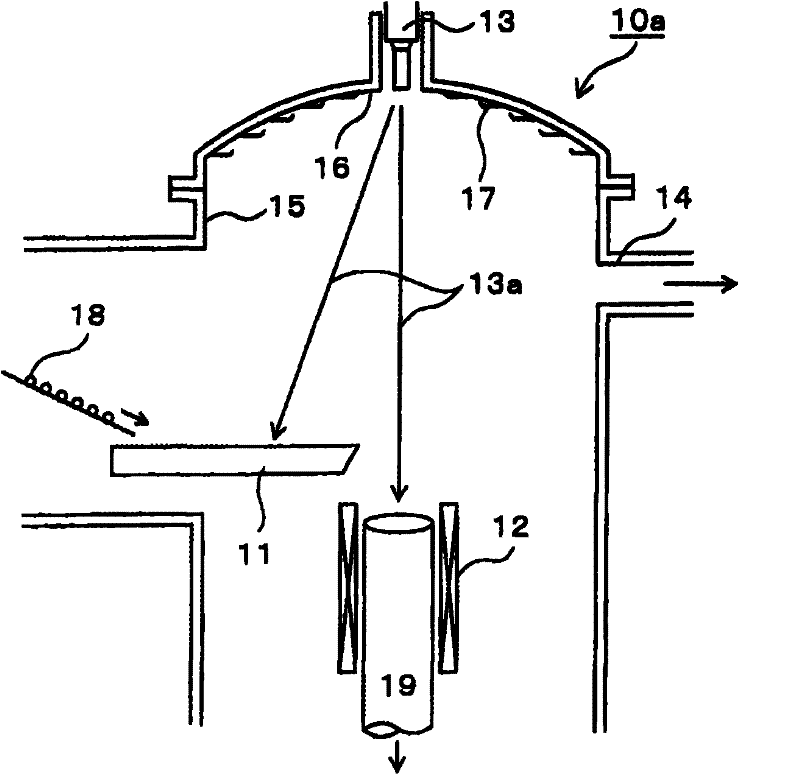

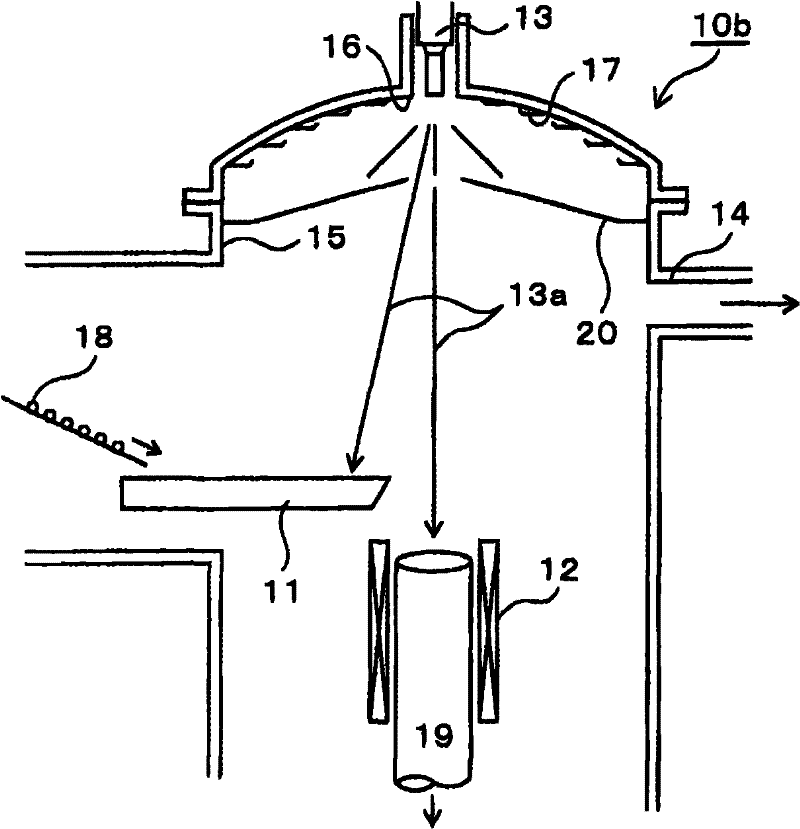

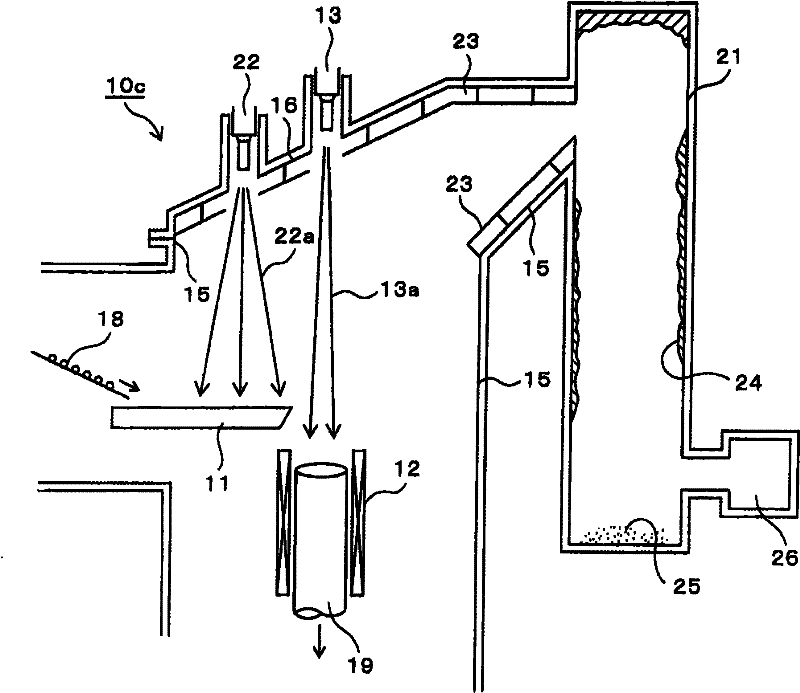

[0096] adopt respectively Figure 1 to Figure 3 The device of the shown structure is used to melt 1000 kg of titanium sponge with electron beams to obtain titanium ingots. This operation was repeated five times with each device, and LDI in the produced titanium ingots was investigated, but LDI was not detected in any of the titanium ingots. LDI is obtained by forging and rolling the produced ingot into a thin plate and observing it by X-ray fluoroscopy.

Embodiment 2

[0100] use Figure 4 The shown electron beam melting device 10d of the present invention having a top furnace lining, a side furnace lining and a bottom furnace lining and a power of 2000KW melts 15 titanium ingots of 10t / piece. Wait for the temperature in the furnace to drop to room temperature, disassemble the furnace body, and then remove the top furnace lining, side furnace lining and bottom furnace lining in sequence. Then, the inside of the furnace is cleaned, and then each furnace lining that has been maintained is attached to the inner surface of the melting device 10d to assemble the melting device 10d, thereby completing preparations for the next melting process. The time required for this process is 3 days.

[0101] The furnace lining removed from the melting device is ground, washed and dried outside the furnace to be used for the next assembly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com