Trench integrated mine collecting and mining method of inclined ore body

A mining method and ore gathering technology, which are applied in surface mining, mining equipment, underground mining, etc., can solve the problems of low collection efficiency of caving ore, bottom structure construction, and high mining loss rate, so as to reduce the exposed area of the upper wall and reduce equipment. The effect of less loss and fewer work adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

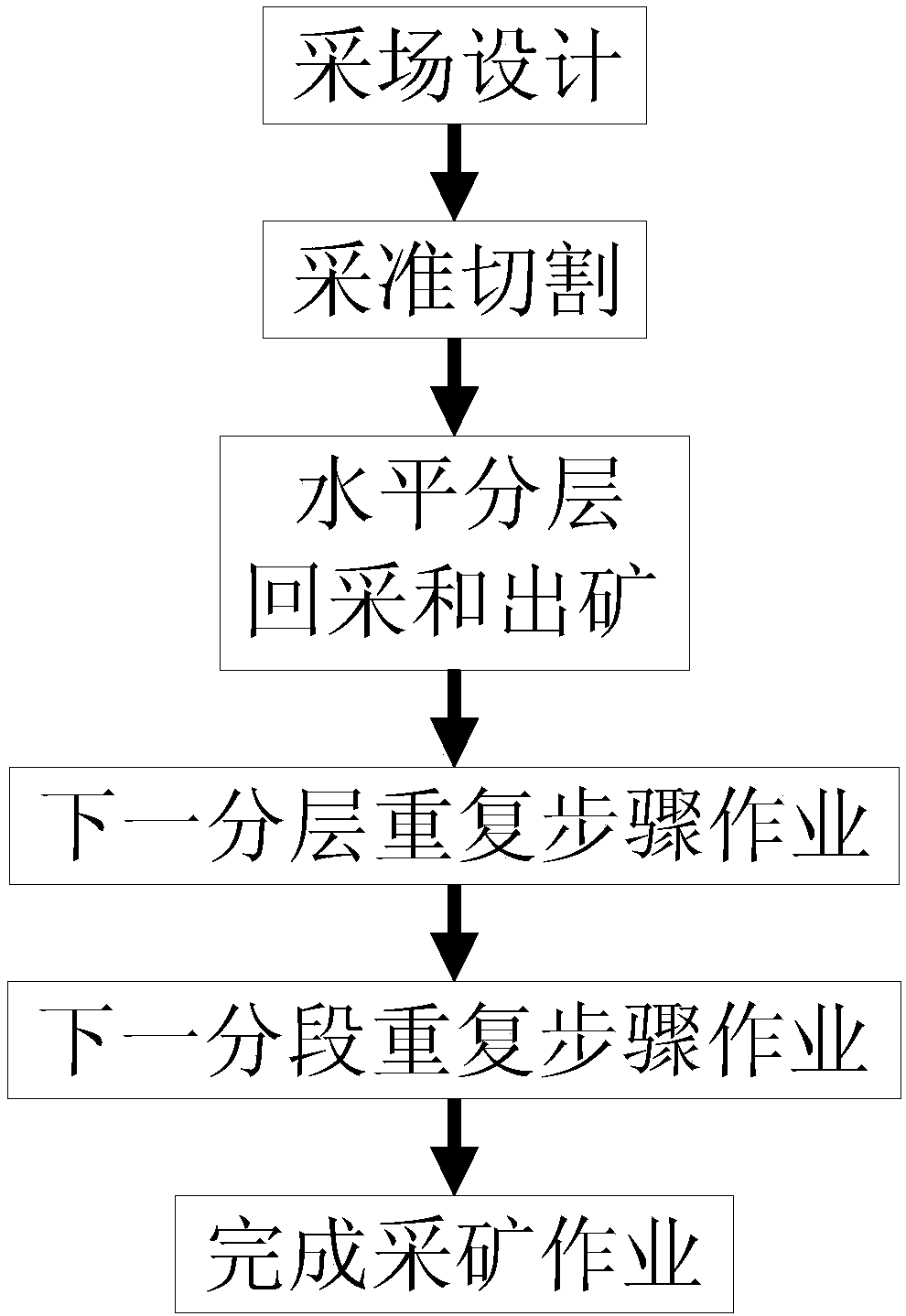

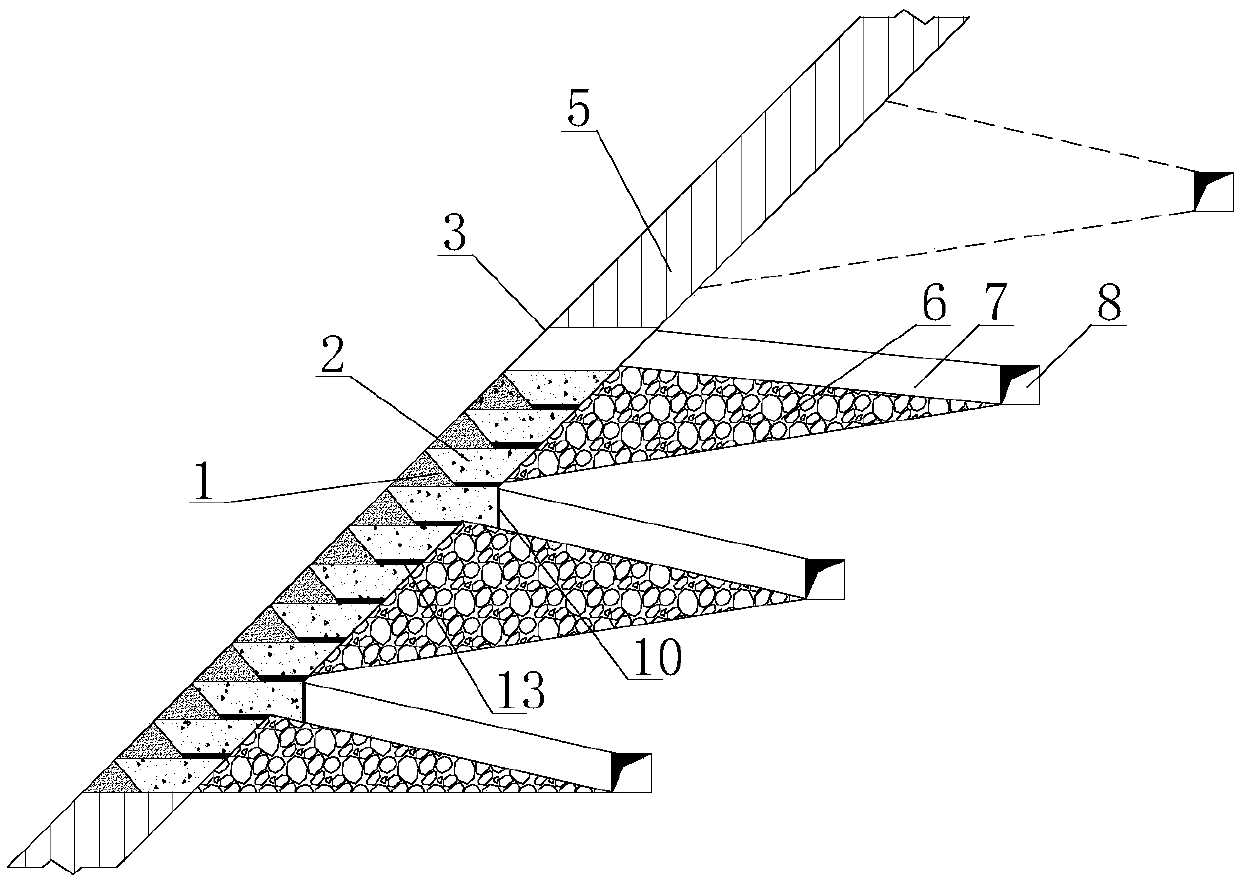

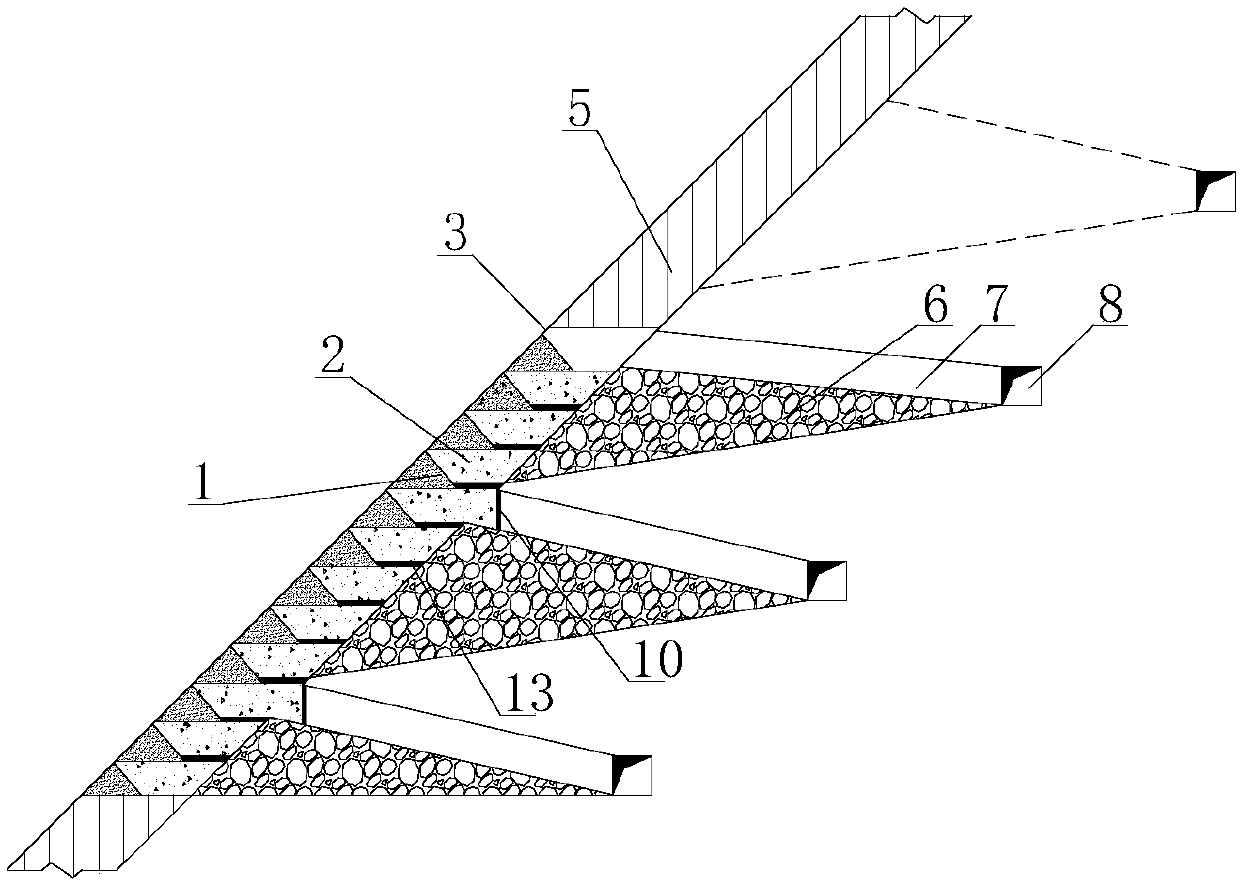

[0033] like figure 1Shown, the cutting ditch collecting ore mining method of the inclined ore body of the present embodiment comprises the following steps: a, divide the stage along the vertical direction of the ore body, divide the ore block along the stage strike, divide the segment along the height of the ore block, and divide the segment in the segment Re-divided into layers; b, mining and cutting engineering construction; c, mining and mining layer by layer from bottom to top; d, layered filling and trench construction; e, repeat steps c and d, start the next layer operation; f, complete the mining operation. This method is suitable for the mining of thin to medium-thick ore bodies with inclined moderate stability and above. The trench ore-collecting mining method of the inclined ore body of the present invention, the constructed trench slope 11, the ore collection road 13 and the ore body footwall slope 12 jointly form a trench ore collection system, and after the upper...

Embodiment 2

[0044] In this embodiment, only the trench is constructed at the lowest part of the stope, and the ore bodies in the upper part of the trench gather in the trench after collapse. The mining is expanded from the bottom cutting roadway to the upper and lower walls, and then the mining is carried out upwards to a certain height to meet the height requirement for the construction of the trench. Generally, the mining height is ≥ 2m, and then the trench is constructed. The trench is constructed by the bag filling method, and the layered stacking construction technology is adopted, and the slope angle of the trench is ≥ the natural repose angle of the ore. The trench slope 11 , the reserved ore-collecting road 13 , and the footwall slope 12 of the ore body form the trench; after the trench construction is completed, follow-up operations can begin.

[0045] During implementation, a cutting and ditch mining method for inclined ore bodies is provided, which can realize safe and efficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com