Oxygen torch sealing machine

A hydrogen-oxygen torch sealing machine, hydrogen-oxygen technology, applied in glass reshaping, glass manufacturing equipment, glass forming, etc., can solve problems such as non-concentration of heat, affecting sealing quality, waste of gas source, etc., and achieve sealing Stable quality, high degree of automation, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

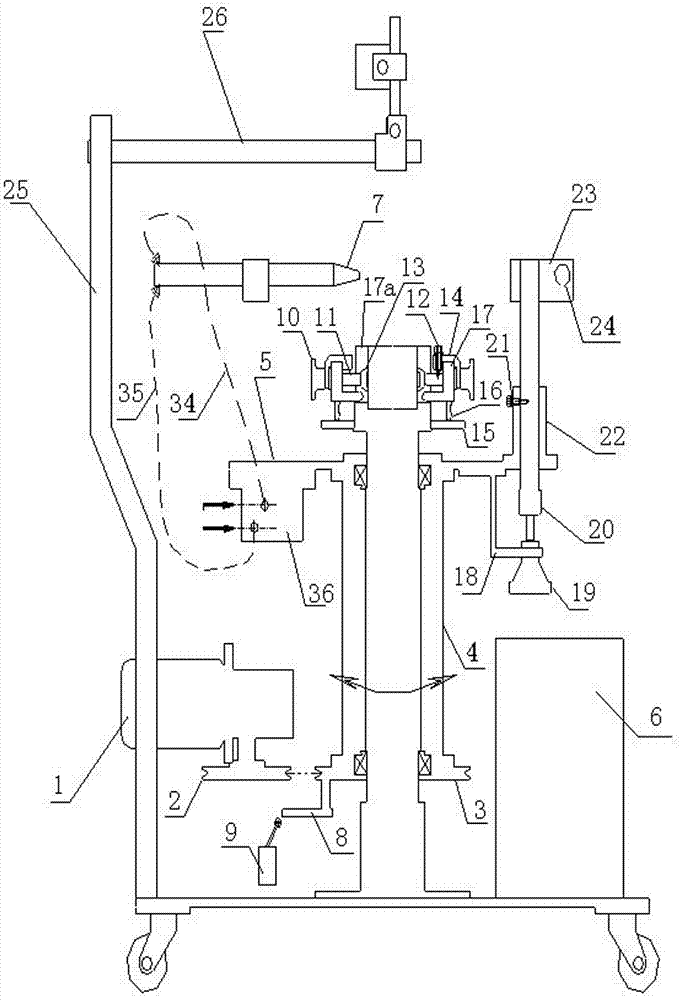

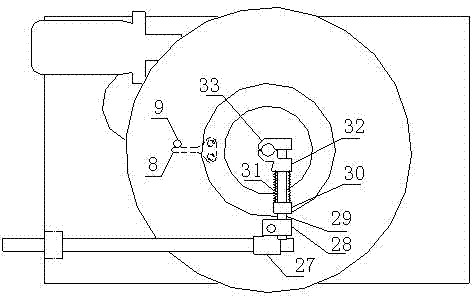

[0013] The sealing machine of the present invention is divided into a transmission device, a burner turntable rotating device, a turntable rotation angle control device, a clamping and positioning device for the lower end of the quartz glass tube, a position adjusting device for the burning gun, a clamping and positioning device for the upper end of the vacuum quartz glass tube, a gas supply device, Ignition device and gas concentration detection alarm device. The following is a more detailed structural introduction of the new sealing machine and a description of the functional data matching its structure with reference to the accompanying drawings.

[0014] (1) Transmission device: It consists of a reducer 1, a small pulley 2, a large pulley 3 and a rotating sleeve 4. The reducer 1 is installed on the fixed plate, and there is a mounting inner hole on the reducer 1. The small pulley 2 is connected with a through-core shaft through screws, and then the through-center shaft is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com