Automatic assembly line of electronic organ and assembly technology thereof

An automatic assembly and electronic organ technology, which is applied in the direction of assembly machines, manufacturing tools, metal processing equipment, etc., can solve problems such as skew, sound control spring installation is not in place, and there is no automatic production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

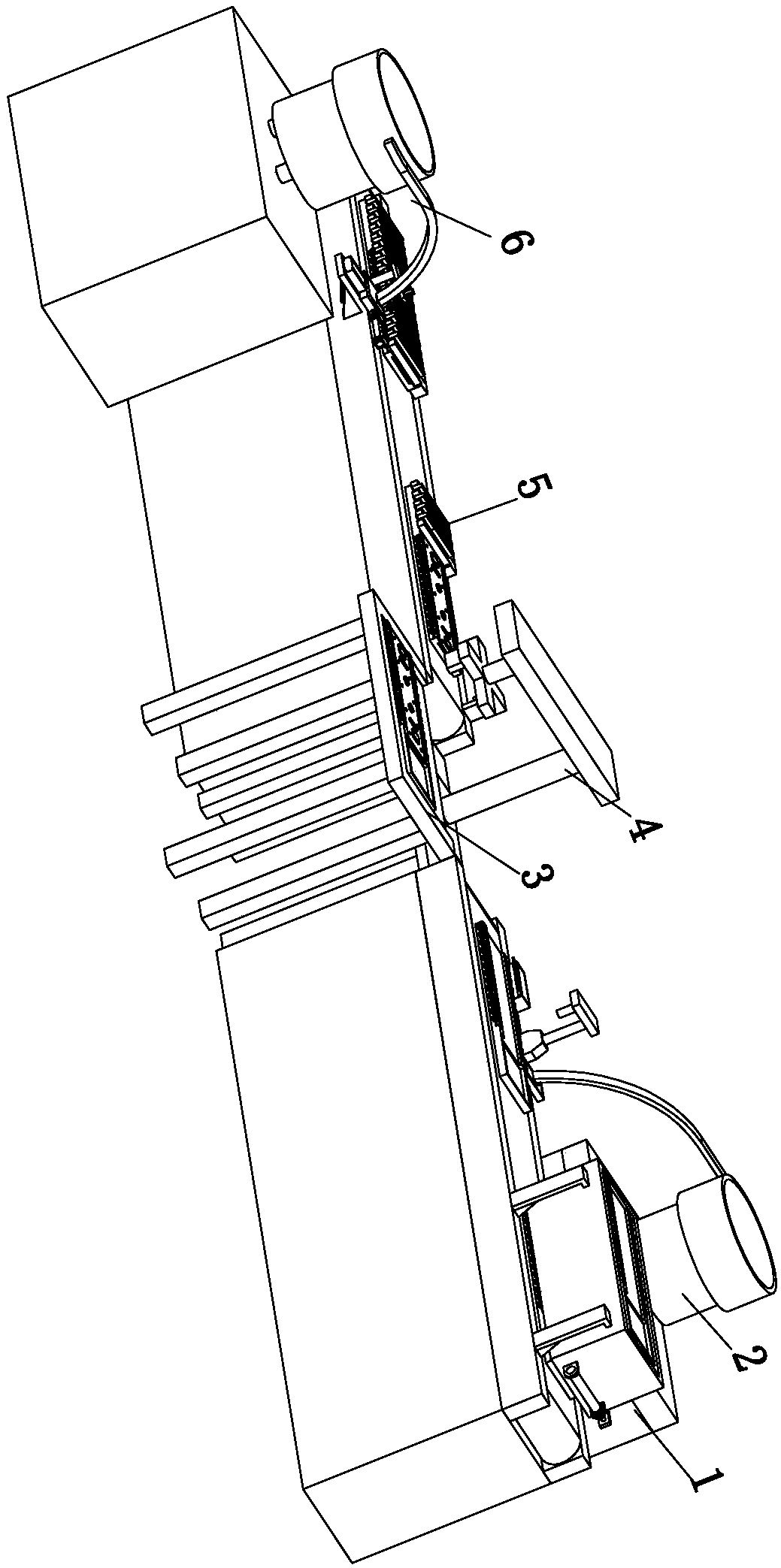

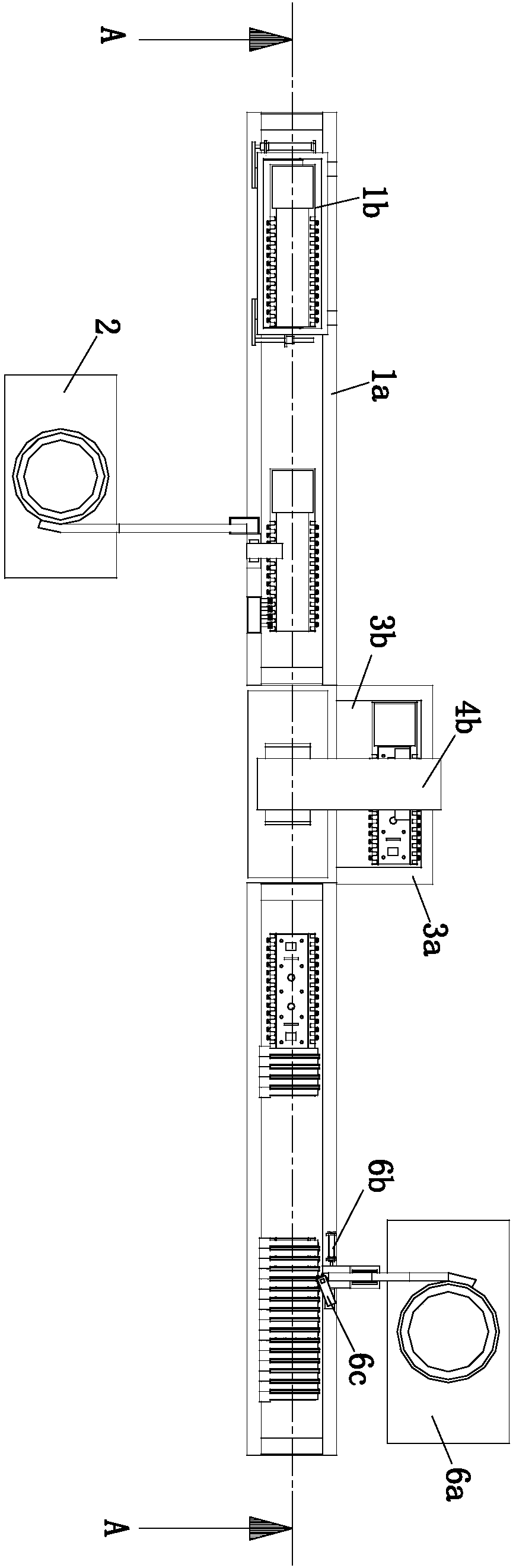

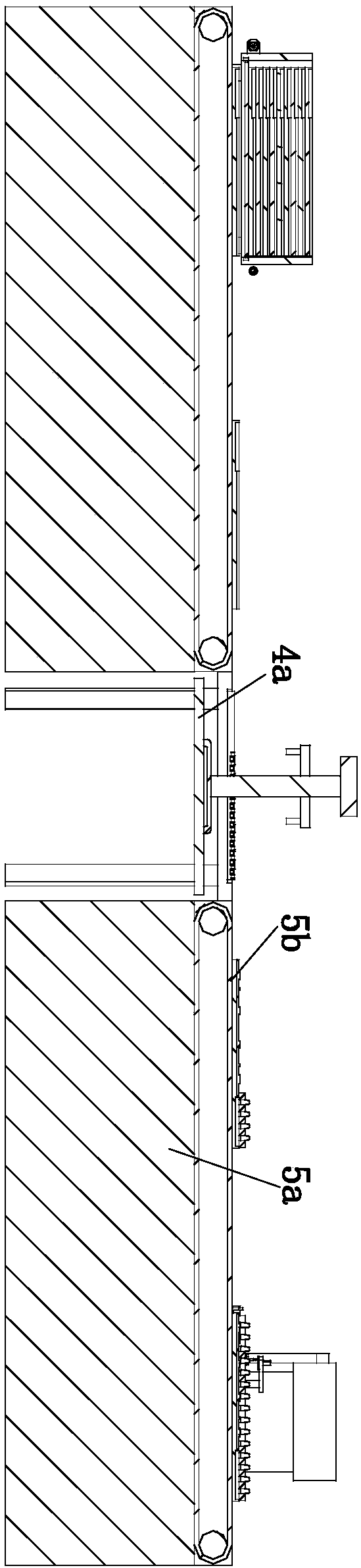

[0045] refer to Figure 1 to Figure 16 The electronic piano automatic assembly machine shown in the figure includes the base automatic feeding mechanism 1, the automatic assembly of the silicone sleeve mechanism 2, the base and PCB board installation mechanism 3, the mechanical clamping mechanism 4, and the key assembly mechanism in sequence according to the installation sequence of the electronic piano 5 and a sound-controlled spring automatic feeding assembly mechanism 6, the base automatic feeding mechanism 1 includes a base transfer table 1a and a base feeding part 1b installed on the top of the base feeding transfer table, and an automatic assembly silicone sleeve mechanism 2 Including the first workbench 2a installed on the side of the base transfer table 1a, the sound-activated spring positioning silicone sleeve vibration plate 2b installed on the top of the first workbench 2a, and the sound-activated spring positioning silicone sleeve vibration plate 2b installed at the...

Embodiment 2

[0066] The assembly process of the electronic organ automatic assembly line described in embodiment 1, comprises the following steps:

[0067] Step 1. Firstly, the base 7 is loaded through the base automatic feeding mechanism 1;

[0068] Step 2. After the base 7 is loaded onto the base transfer table 1a, a number of sound-activated spring positioning silicone sleeves 8 are transported to the 7-base 7 through the automatic assembly of the audio-activated spring positioning silicone sleeve mechanism 2, and then the assembly operation is completed , the automatic oil brushing part 2d automatically brushes oil on both sides of the sound control spring positioning silicone sleeve 8;

[0069] Step 3, using the mechanical clamping mechanism 4 to clamp the base 7 assembled with the sound control spring positioning silicone sleeve 8 to the positioning installation platform 3a;

[0070] Step 4. The base and the circuit board installation mechanism 3 install the circuit board to be inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com