Solar wafer position calibrating device and detection machine station with the same

A calibration device, solar energy technology, applied in the monitoring of photovoltaic systems, single semiconductor device testing, optical testing flaws/defects, etc., can solve the problems of reducing output efficiency, fragmentation, increasing downtime cleaning time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with accompanying drawings.

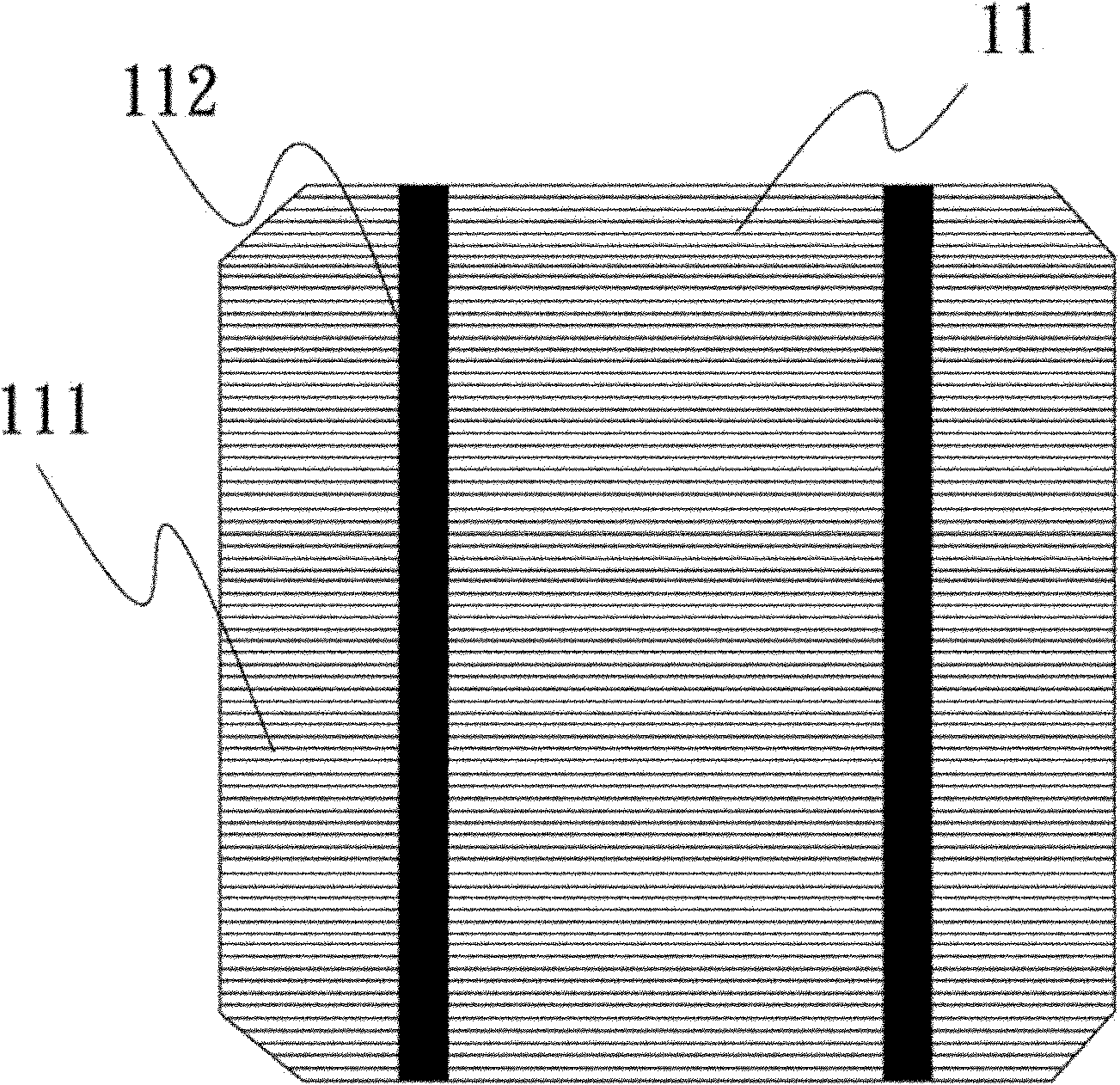

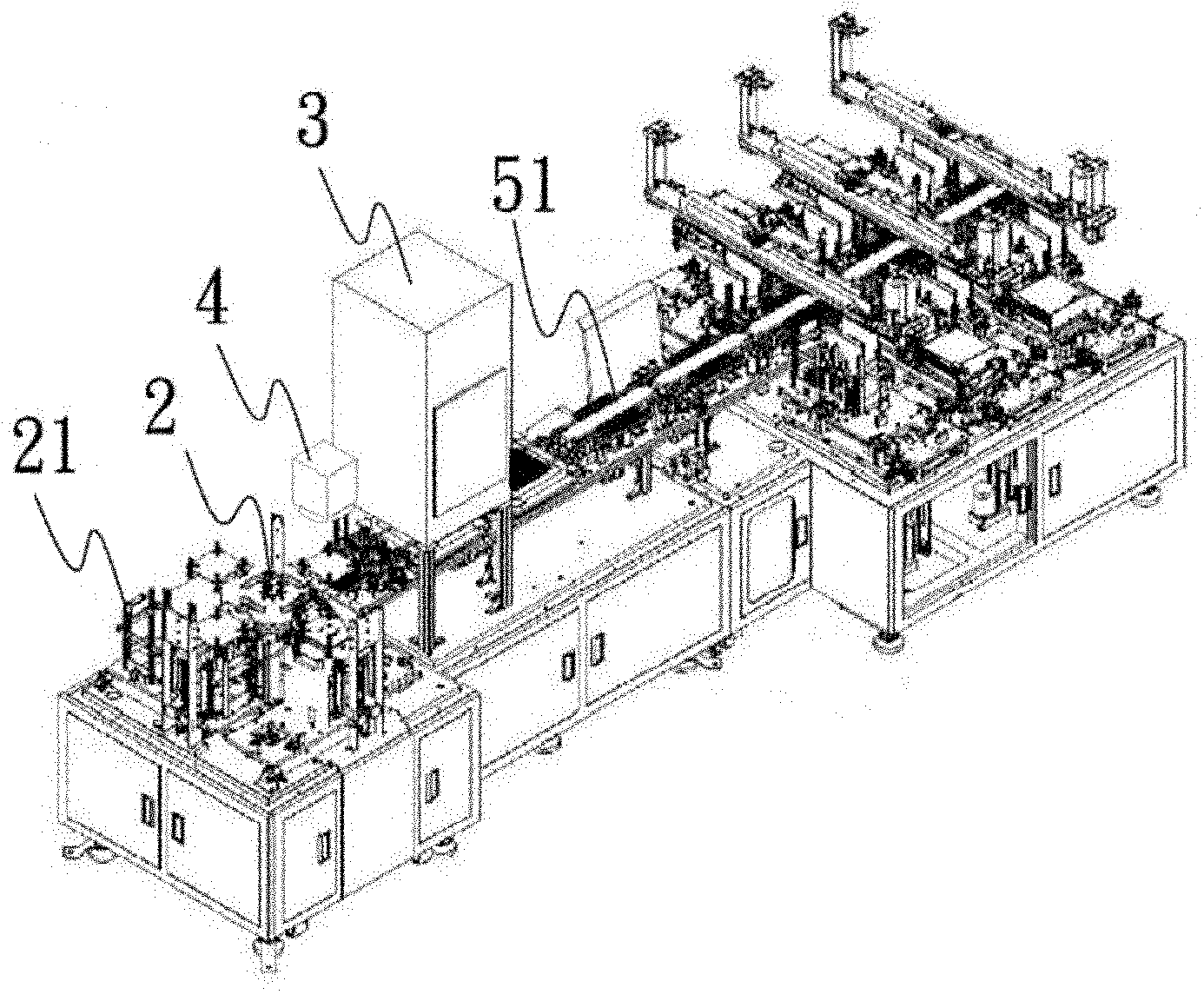

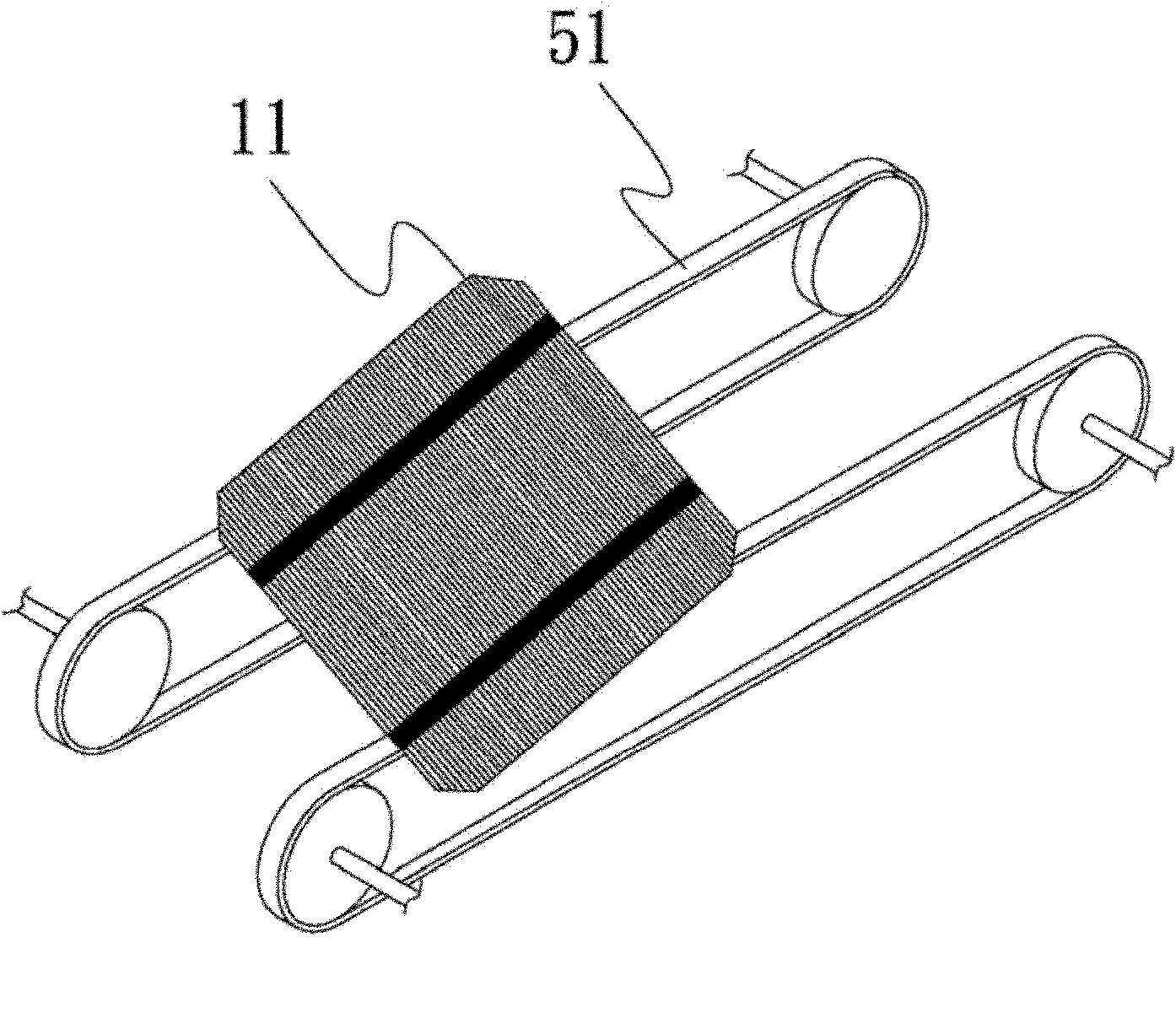

[0043] And the solar wafer to be tested of this example is identical with known, therefore continue to use figure 1 The solar wafer under test shown also has a light-receiving surface 111, and a conductive bus bar 112 for outputting electric energy is formed on the light-receiving surface 111. The detection machine of this example is as Figure 5 and Figure 6 As shown, it includes a base 6', and a series of automatic operation feeding device 2', transfer device 5', optical detection device 4', light detection device 3', position calibration device 7', and classification device 8'. For the sake of illustration, in this example, the position where the feeding device 2' is placed into the magazine 21' is called a plurality of placement positions, and the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com