Angle-adjustable clamping mechanism

A clamping mechanism and angle technology, which is applied to workpiece clamping devices, workbenches, manufacturing tools, etc., can solve the problems that the angle of the clamping mechanism cannot be adjusted, cannot effectively intercept abnormal glass, and reduce glass output. Straight angle, strong practicability, smooth and clean surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

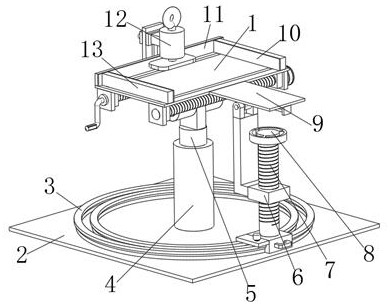

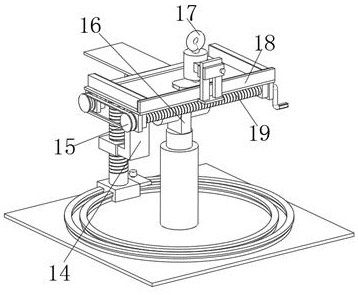

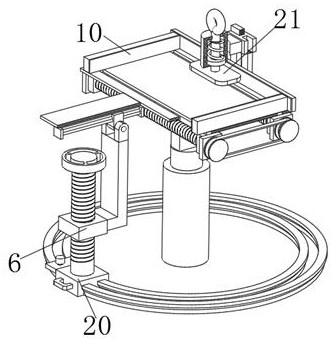

[0041] Example: Reference Figure 1-8 The shown clamping mechanism with adjustable angle includes a placement board 1, a base 2 located at the bottom of the placement board 1, and an adjustment board is fixedly connected to the side wall of the placement board 1, and the adjustment board can be any A metal plate, which is welded to the side wall of the placement plate 1 for fixing.

[0042] A U-shaped bar 32 is fixedly connected to the top of the adjusting plate, and the U-shaped bar 32 can be any metal bar in the prior art, which is fixed by welding with the top of the adjusting plate.

[0043] On the two sidewalls of the U-shaped bar 32 that are close to each other, an I-shaped block 31 is slidably connected, and the side walls of the I-shaped block 31 are fixedly connected with a fixed block 30, and the fixed block 30 can be any metal in the prior art. block, which is welded with the side wall of the I-shaped block 31 for fixing.

[0044] The side wall of the fixed block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com