Tool for press fitting of motor rotor bearing

A technology for motor rotors and bearings, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of rotor skew, low efficiency, affecting the normal press-fitting of bearings, etc., and achieve high press-fitting accuracy, high efficiency, and positioning accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

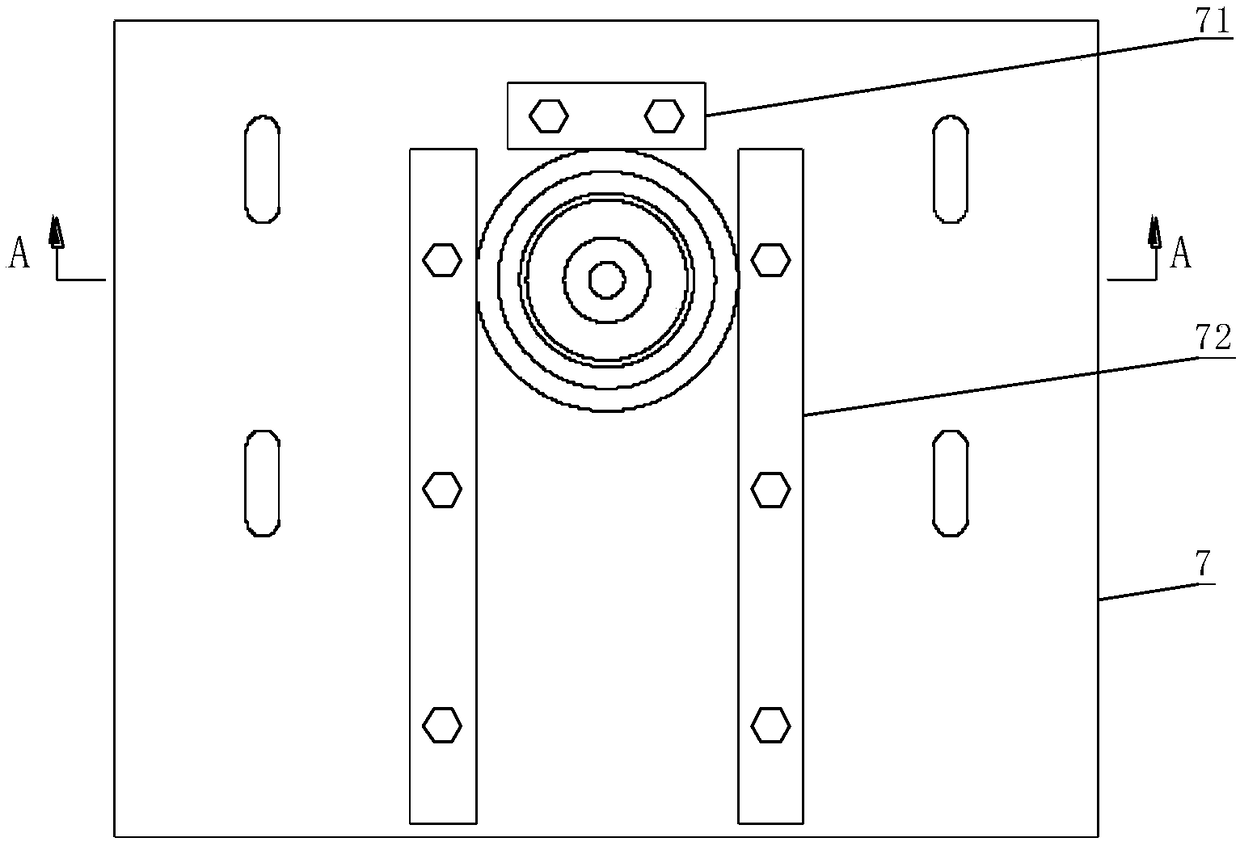

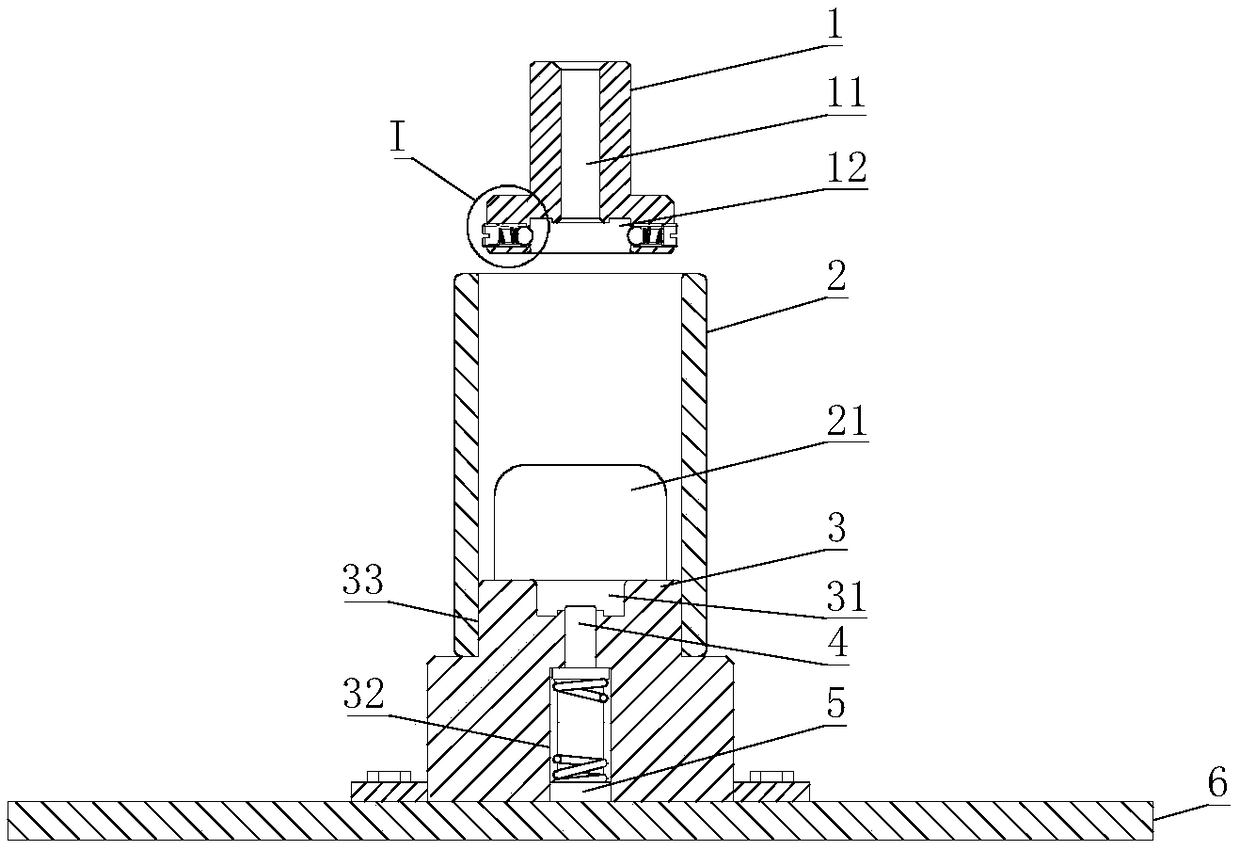

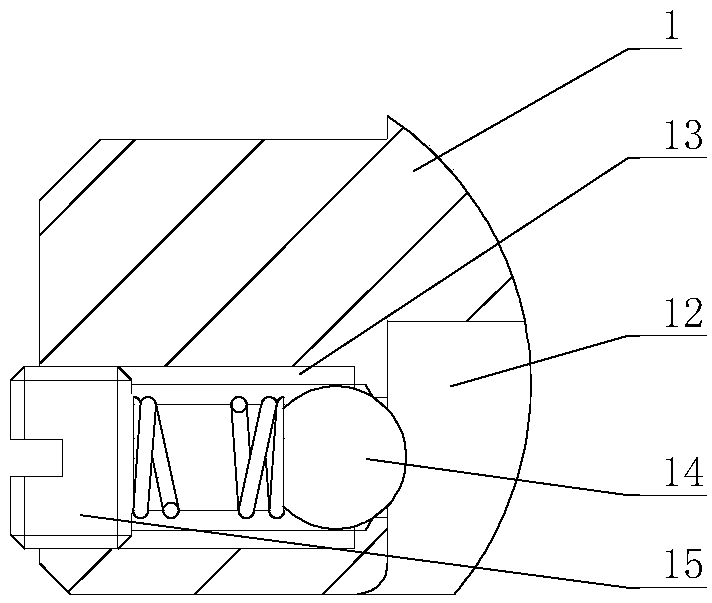

[0019] Such as Figure 1 to Figure 3 As shown, a tooling for press-fitting motor rotor bearings according to the present invention includes a pressure head 1, a positioning part 2 and a base 3, and a boss 33 is processed on the base 3, and the inside of the boss 33 is coaxially processed There is a groove B31, and the shape and size of the boss 33 is consistent with the inner cavity of the positioning part 2. One end of the positioning part 2 is sleeved on the boss 33, and the indenter 1 is provided with a groove A12, and the concave A through hole 11 is coaxially provided in the groove A12, and the indenter 1 is placed outside the positioning part 2. The inner cavity of the positioning part 2 can be circular or square. When in use, the inner diameter of the through hole 11 is consistent with the outer diameter of the bearing inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com