Karst treatment and track grouting construction method

A technology for tracking grouting and construction methods, used in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problem of cave expansion, long processing time for pilot holes and pre-buried sleeve valve pipes, and the inability of drilling rigs to work. problems such as compacting the soil layer, to achieve the effect of saving processing time and reducing the further expansion of karst caves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

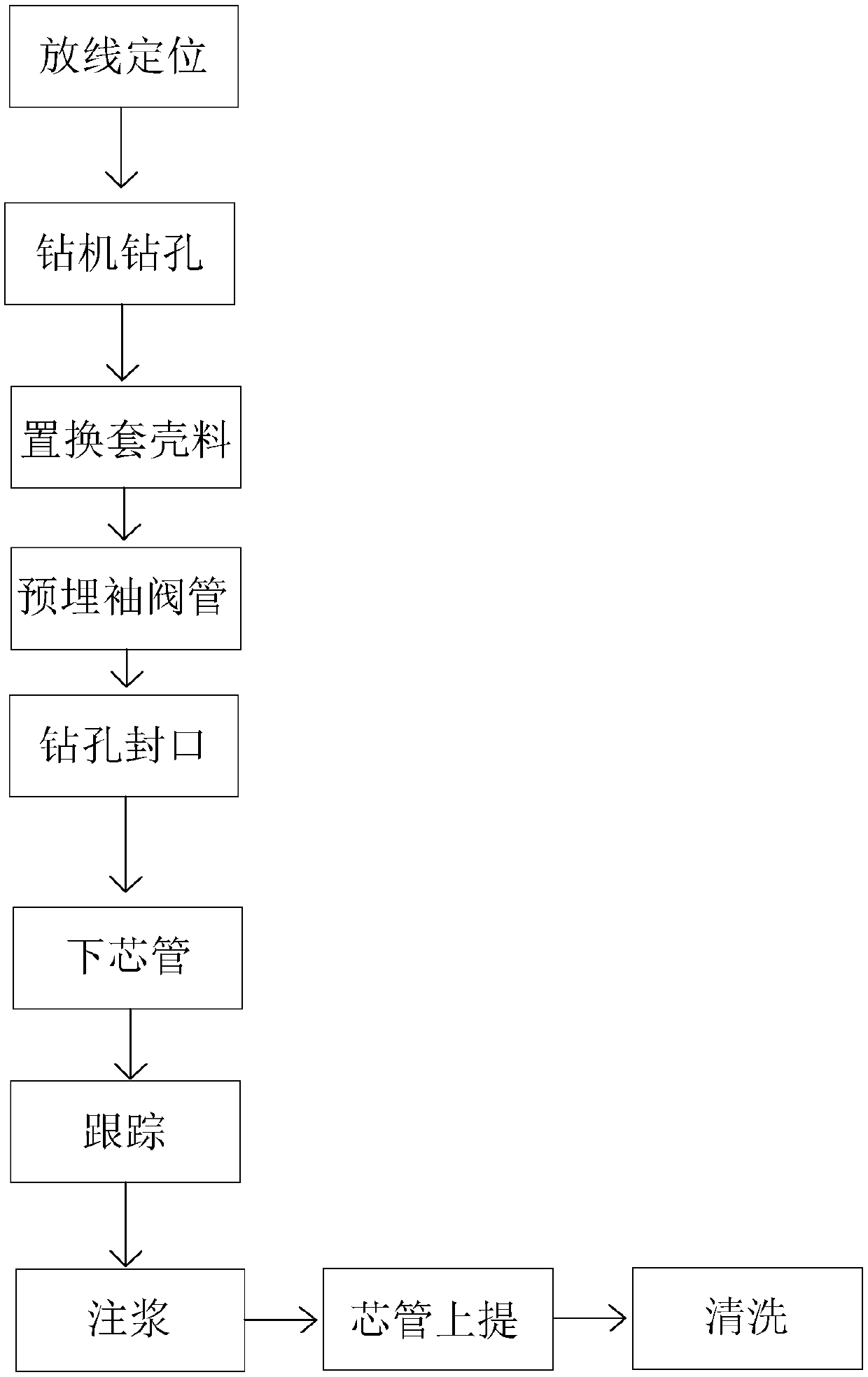

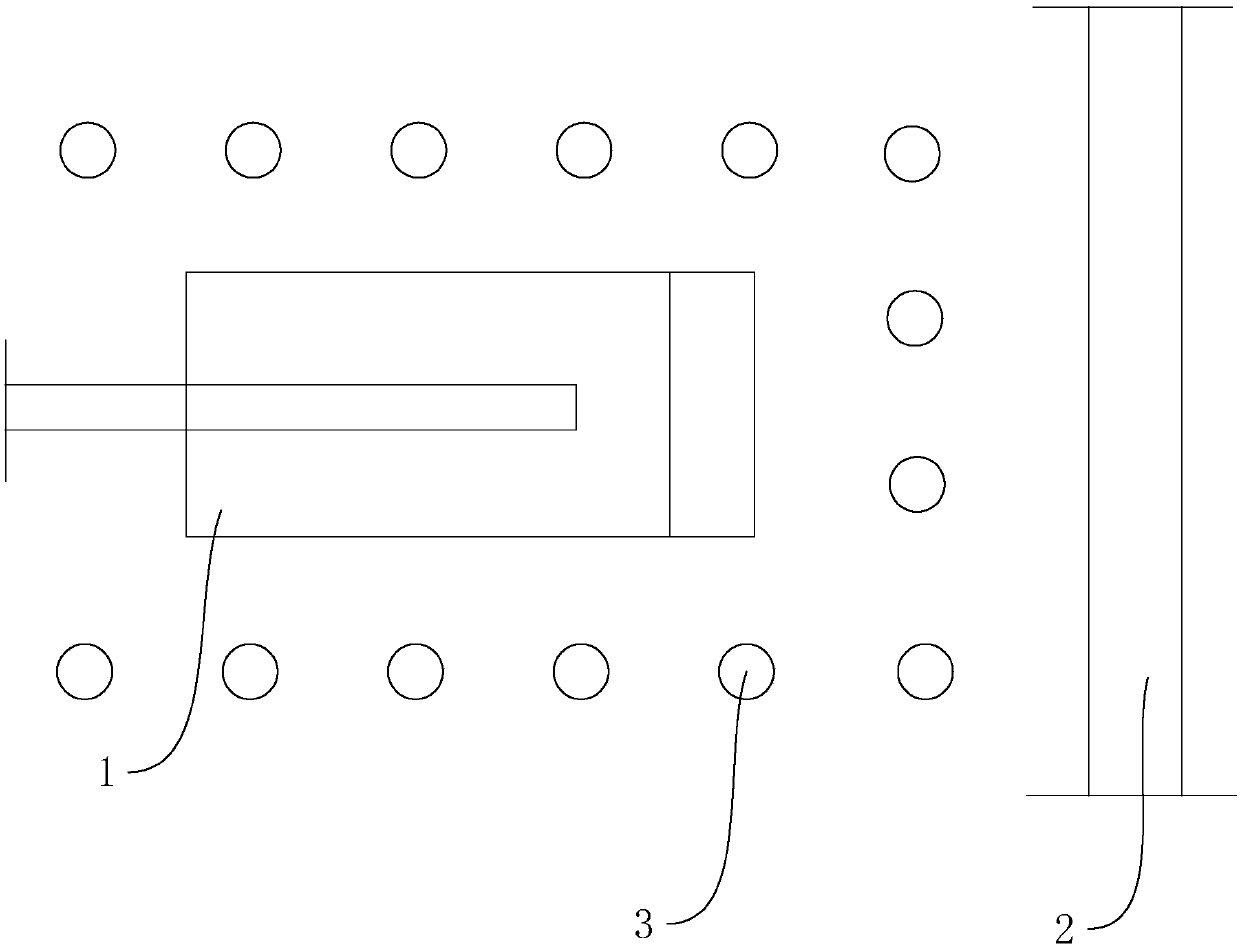

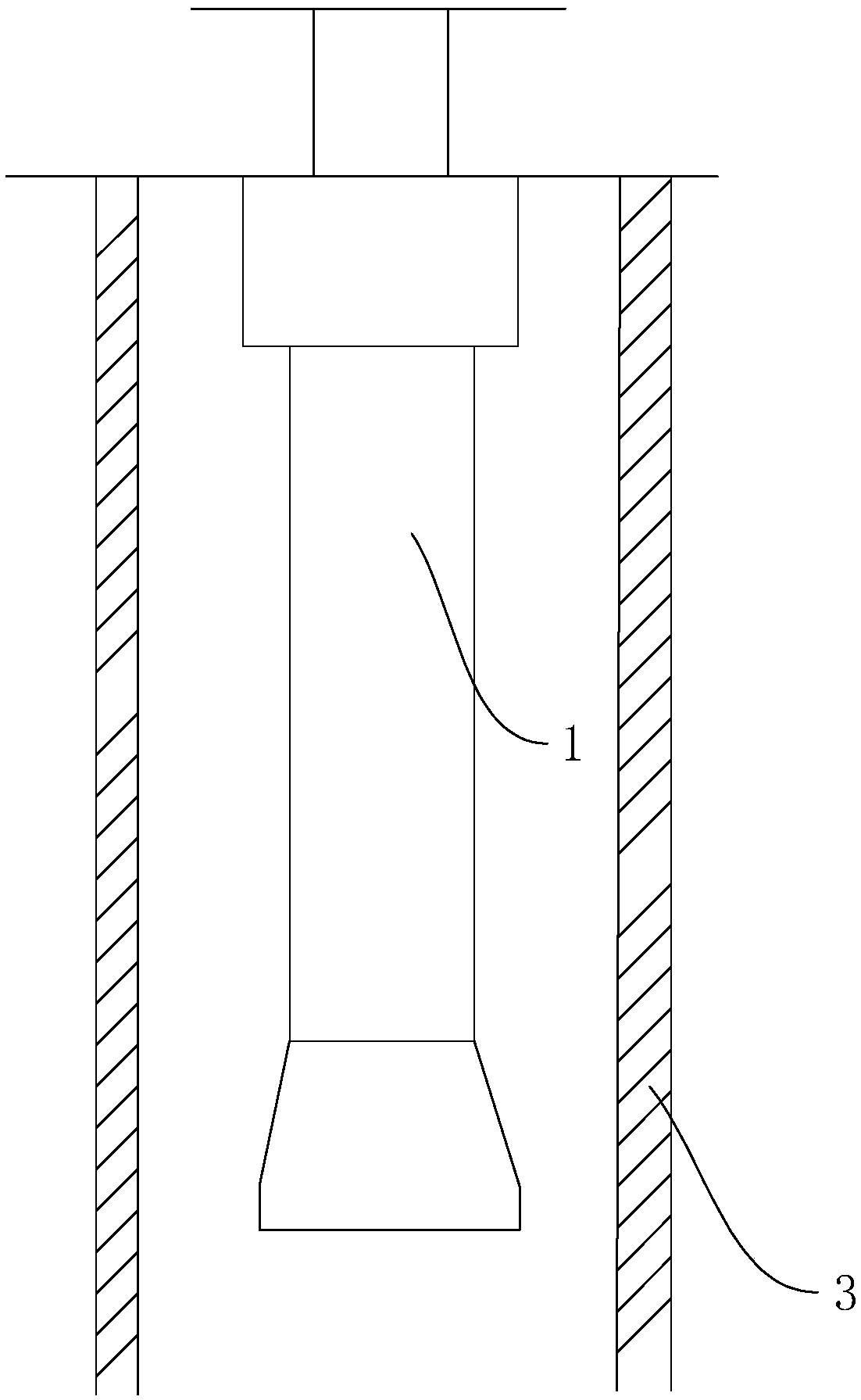

[0046] refer to figure 1 and figure 2, is a kind of karst cave treatment and tracking grouting construction method disclosed by the present invention, comprising the following steps:

[0047] 1) Setting-out positioning: the pile foundation cap 1 is a rectangular parallelepiped, and the two nearest coordinate points between the pile foundation cap 1 and the continuous wall 2 are measured by a total station, and measured by a pull wire and a tape measure , at the distance between the two coordinate points of the house pile foundation cap 11m, and the position of the diaphragm wall 21.5m, the drilling hole positions are determined. The hole positions are marked with the pile foundation cap 1 of the enclosure, and the distance between adjacent drill holes is 1m;

[0048] 2) Drilling with drilling rig: make the bottom of the drilling rig smooth and stable, use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com