Automatic catwalk and method

A catwalk and sliding connection technology, which is applied in the direction of earthwork drilling, drilling equipment, instruments, etc., can solve the problems of low work efficiency, error-prone, time-consuming and labor-intensive, etc., to improve accuracy, improve safety, and ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

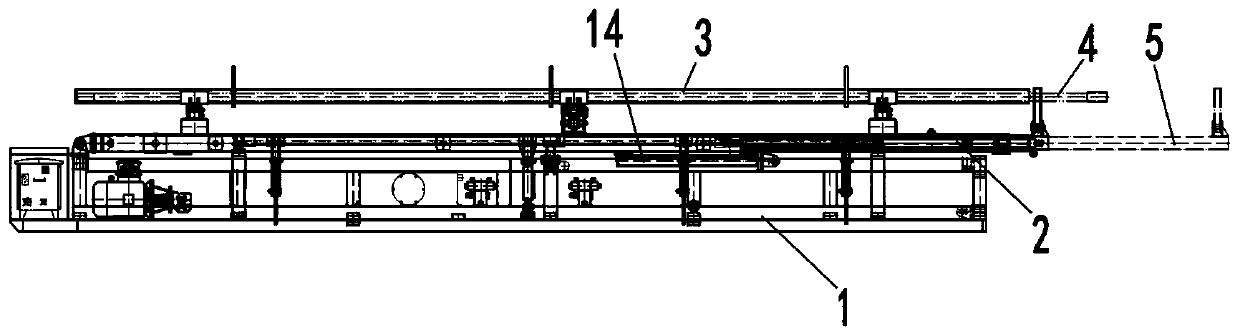

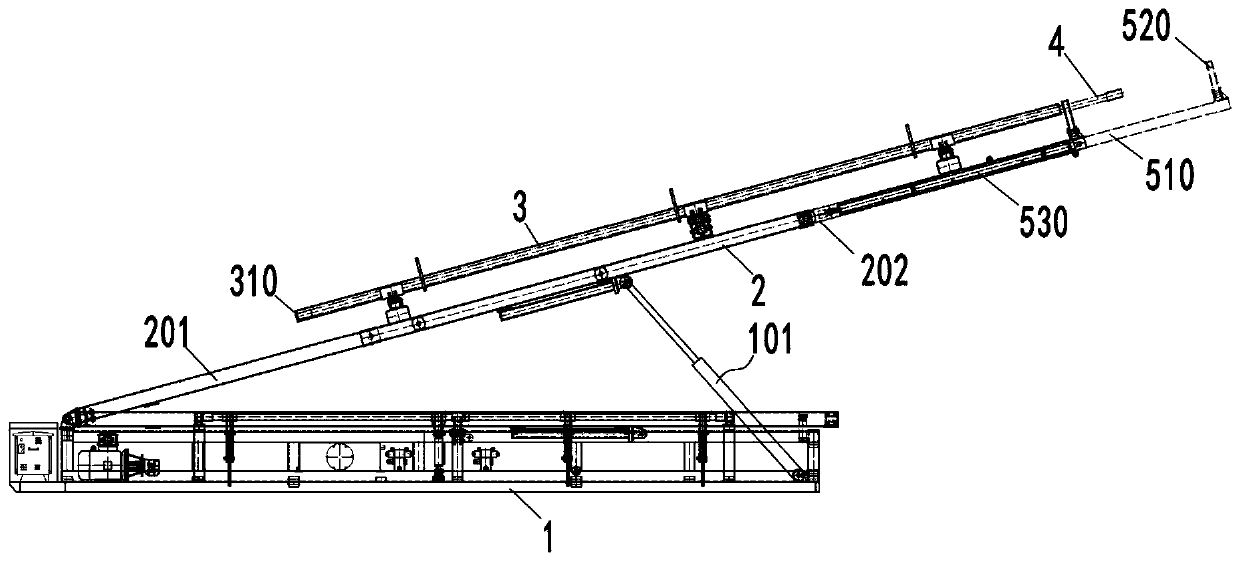

[0054] figure 1 It is a structural schematic diagram of an automated catwalk in an embodiment of the present invention, wherein the automated catwalk is in a falling state. figure 2 It is a structural schematic diagram of an automated catwalk in an embodiment of the present invention, wherein the automated catwalk is in a lifting state.

[0055] Such as figure 1 and figure 2 As shown, an automated catwalk includes: a frame 1, a lifting bracket 2, an accommodating slot 3 and a length measuring mechanism 5.

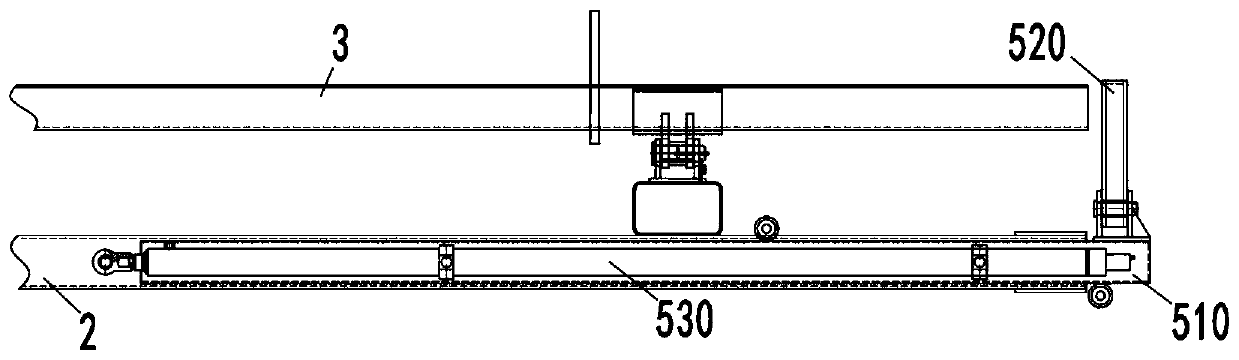

[0056]Wherein, the lifting bracket 2 is connected with the frame 1; the receiving slot 3 is slidably connected with the lifting bracket 2. Specifically, the lifting support 2 includes a first frame body 201, a second frame body 202 and a telescopic hydraulic cylinder 14, the first frame body 201 is pivotally connected with the frame 1, and the second frame body 202 and the first frame body 201 are slidable connected, and the extension direction of the second frame bod...

no. 2 approach

[0087] During the implementation of the technical solution of the present invention, the inventor found that when the first baffle 310 and the second baffle 520 clamp the pipe 4, the middle part of the pipe 4 will bend, which will affect the accuracy of the measurement, and may even It will cause a safety accident.

[0088] In order to solve the above technical problems, the technical solution of the present invention further includes a safety righting mechanism 6 . Figure 6 It is a schematic structural diagram of the safety righting mechanism 6 in an automated catwalk according to an embodiment of the present invention, wherein the safety righting mechanism 6 is in an open state. Figure 7 The safety righting mechanism 6 in the closed state.

[0089] Such as Figure 6 and Figure 7 As shown, the safety righting mechanism 6 includes a righting arm 601 and a righting hydraulic cylinder 603 . One end of the righting liquid cylinder 603 is pivotally connected to the first en...

no. 3 approach

[0091] Such as Figure 9 As shown, a method for measuring the length of a pipe using an automated catwalk mainly includes the following steps:

[0092]S200, clamping the pipe 4 in the length direction of the pipe 4;

[0093] S400, acquiring displacement information of the piston rod of the length measuring cylinder 530;

[0094] S600. Calculate the length of the pipe 4 according to the displacement information.

[0095] Further, as Figure 10 As shown, before the step S200 of clamping the pipe in the length direction of the pipe 4, it also includes:

[0096] S100 , make the second baffle 520 face the first baffle 310 .

[0097] Specifically, the first baffle 310 is fixed at one end of the receiving slot 3 , and the second baffle 520 can rotate or move to a position opposite to the first baffle 310 , so as to clamp the pipe 4 .

[0098] Further, before the step of clamping the pipe 4 in the length direction of the pipe 4 includes:

[0099] Righting the pipe so that the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com