Pumping-improvement centralizer of pumping rod

A sucker rod and centralizer technology, used in drill pipes, drilling equipment, earthwork drilling and other directions, can solve the problems of reducing the efficiency of the oil production pump and the unsatisfactory effect of the plunger, so as to improve the pumping efficiency, prevent friction, reduce the The effect of the pressure difference up and down the plunger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

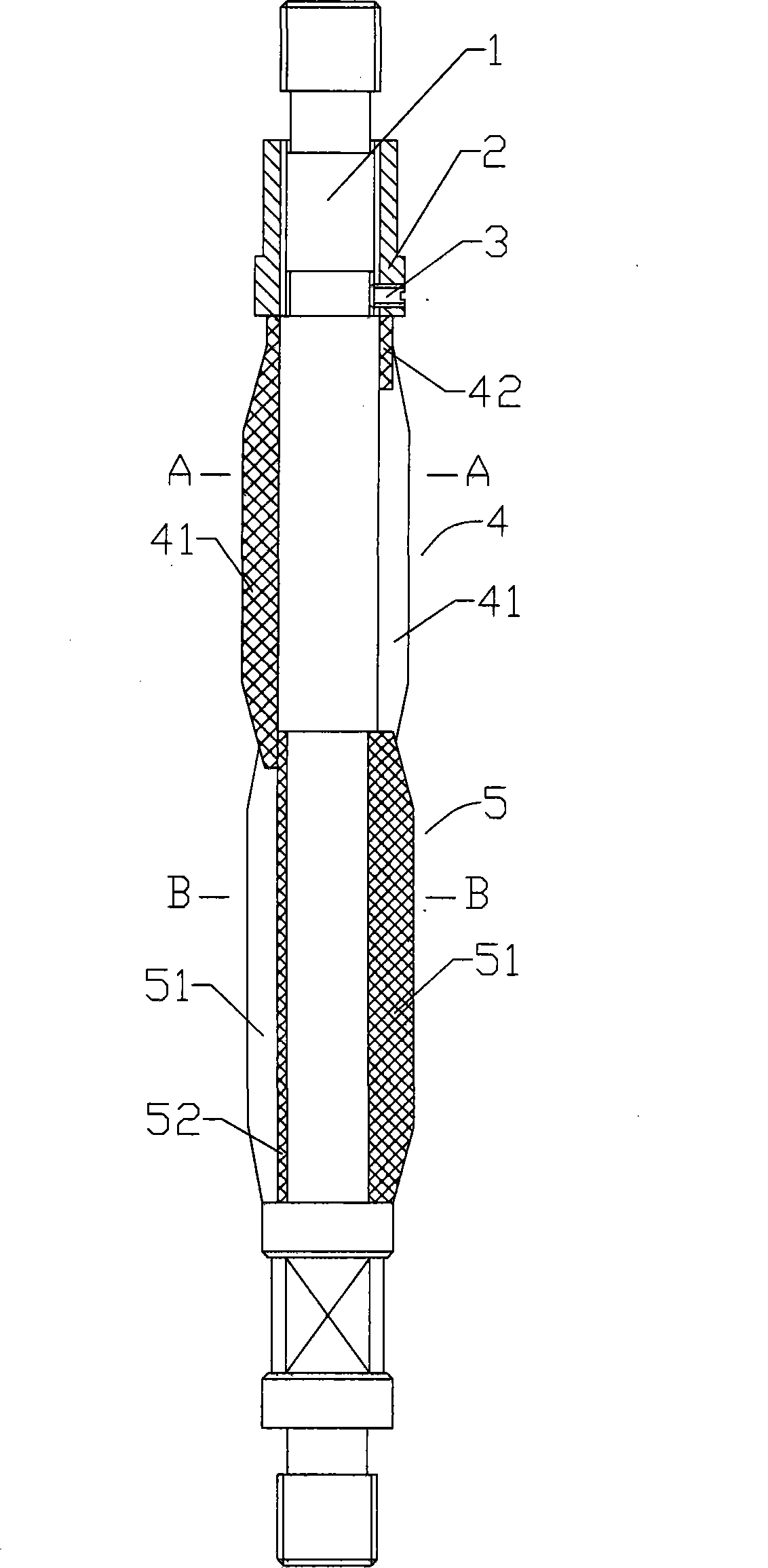

[0021] as attached figure 1 As shown, the sucker rod pumping aid centralizer includes a center rod 1, joints are arranged at both ends of the center rod 1, and a first centralizer 4 and a second centralizer 5 are arranged on the central rod 1.

[0022] The second centralizing body 5 is fixedly connected with the center pole 1 , the first centralizing body 4 can slide on the central pole 1 , and the first centralizing body 4 is located on the top of the second centralizing body 5 .

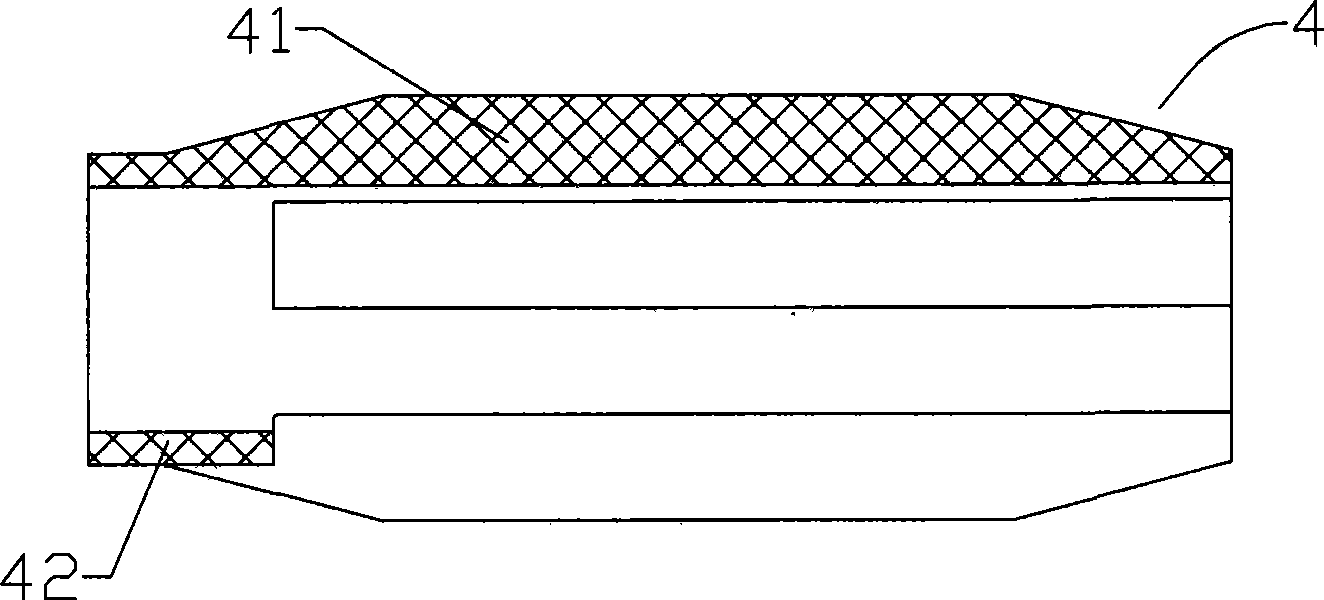

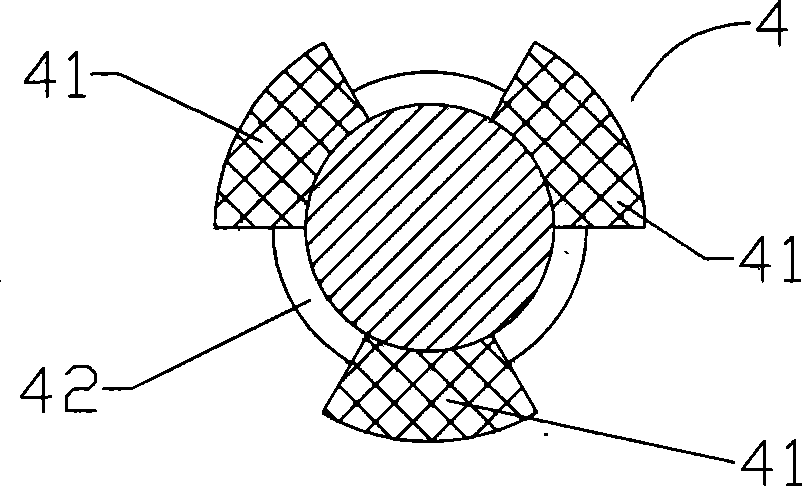

[0023] as attached figure 2 , attached image 3 As shown, the first centralizing body 4 includes three first centralizing claws 41 , and a first sleeve 42 is arranged on the upper end of the first centralizing claws 41 .

[0024] as attached Figure 4 As shown, the second centralizing body 5 includes a second sleeve 52 on which three second centralizing claws 51 are arranged.

[0025] The three first righting claws 41 overlap with the three second righting claws 51 alternately, and the transve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com