Engine with low pumping loss and method for reducing engine pumping loss

A pumping loss and engine technology, which is applied in the field of engines with reduced pumping loss and low pumping loss, and can solve the problems of engine pumping loss, loss of engine energy, and low engine performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

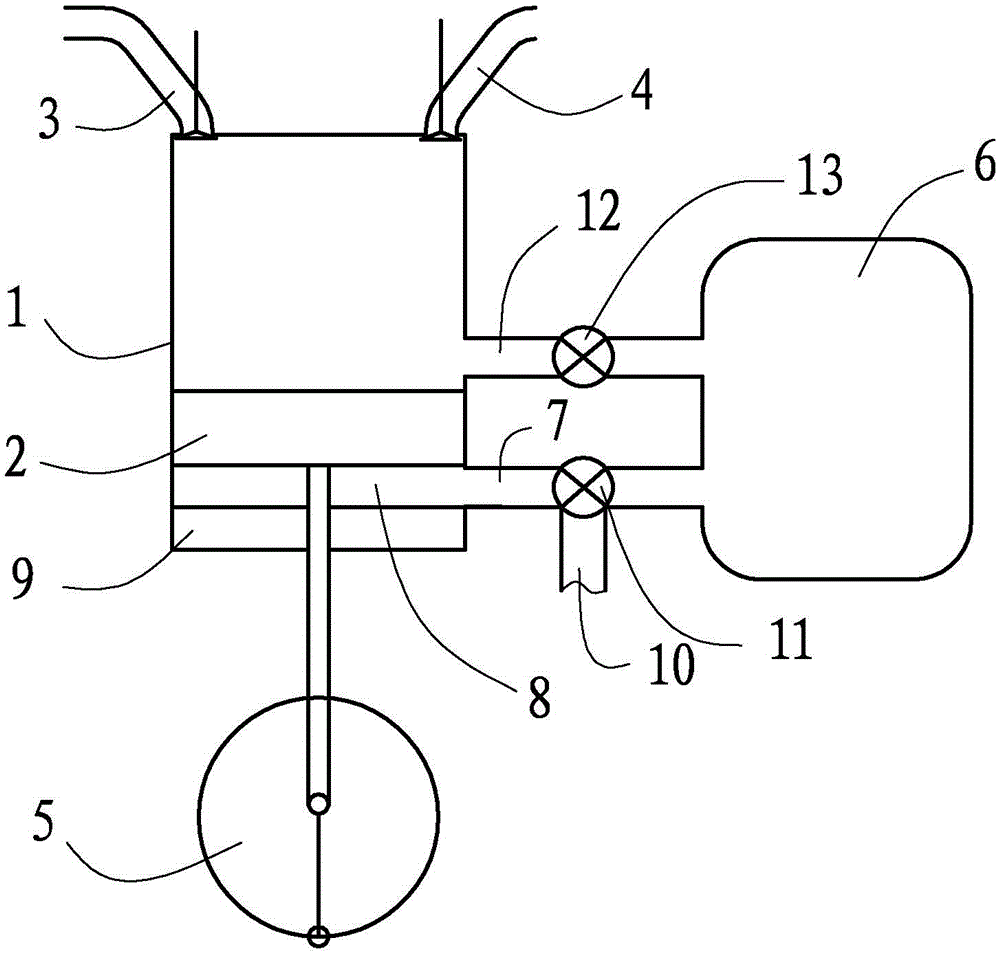

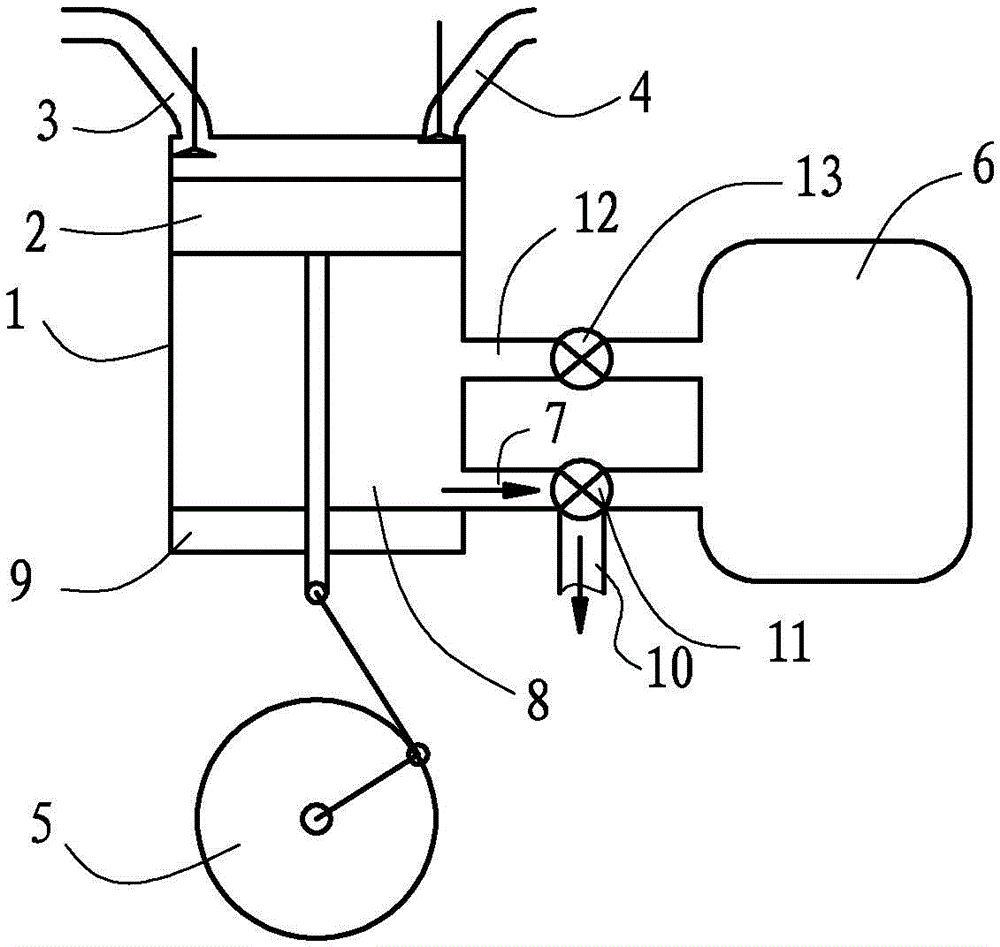

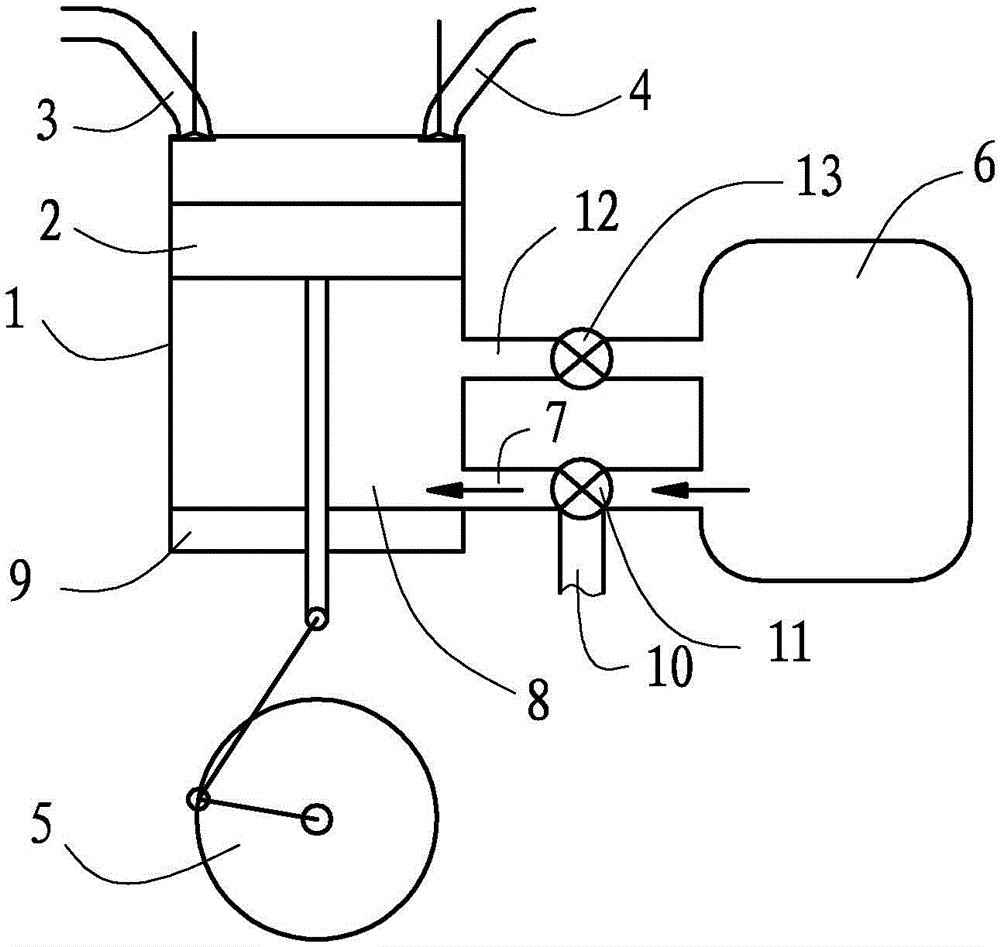

[0026] The engine of the low pumping loss that present embodiment relates to, by figure 1 As shown, it has a cylinder body 1, a piston 2 arranged in the cylinder body 1, an air inlet pipe 3 and an air outlet pipe 4 communicating with the inside of the cylinder body 1 are arranged on the top of the cylinder body 1, and the piston 2 is driven by the crankshaft mechanism 5. Next, move up and down in the cylinder block 1 to complete the intake, compression, work and exhaust strokes of the engine.

[0027] A gas storage device 6 is arranged outside the cylinder body 1, and the gas storage device 6 can adopt a device such as a gas storage tank to store gas in a sealed manner. A first pipeline 7 is connected between them, and the connection position between the first pipeline 7 and the cylinder body 1 is set at the lower section of the cylinder body 1, that is, close to the bottom dead center of the piston 2 in the cylinder body 1, so that when the piston 2 is located in the non- At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com