Telescopic pipe suitable for floating platform testing

A floating platform and telescopic tube technology, applied in the field of petroleum exploration, can solve the problems of complex structure of telescopic tools and difficulty in bearing radial force, and achieve the effects of reducing the risk of unsealing, weakening radial force, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the drawings and embodiments.

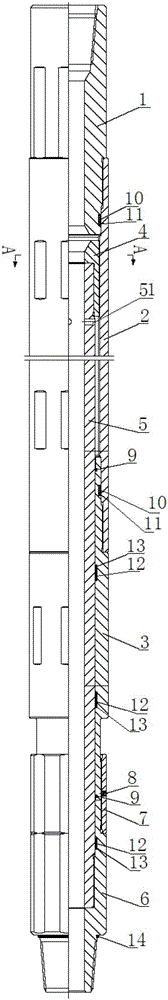

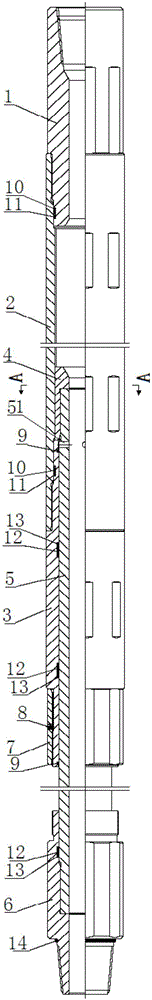

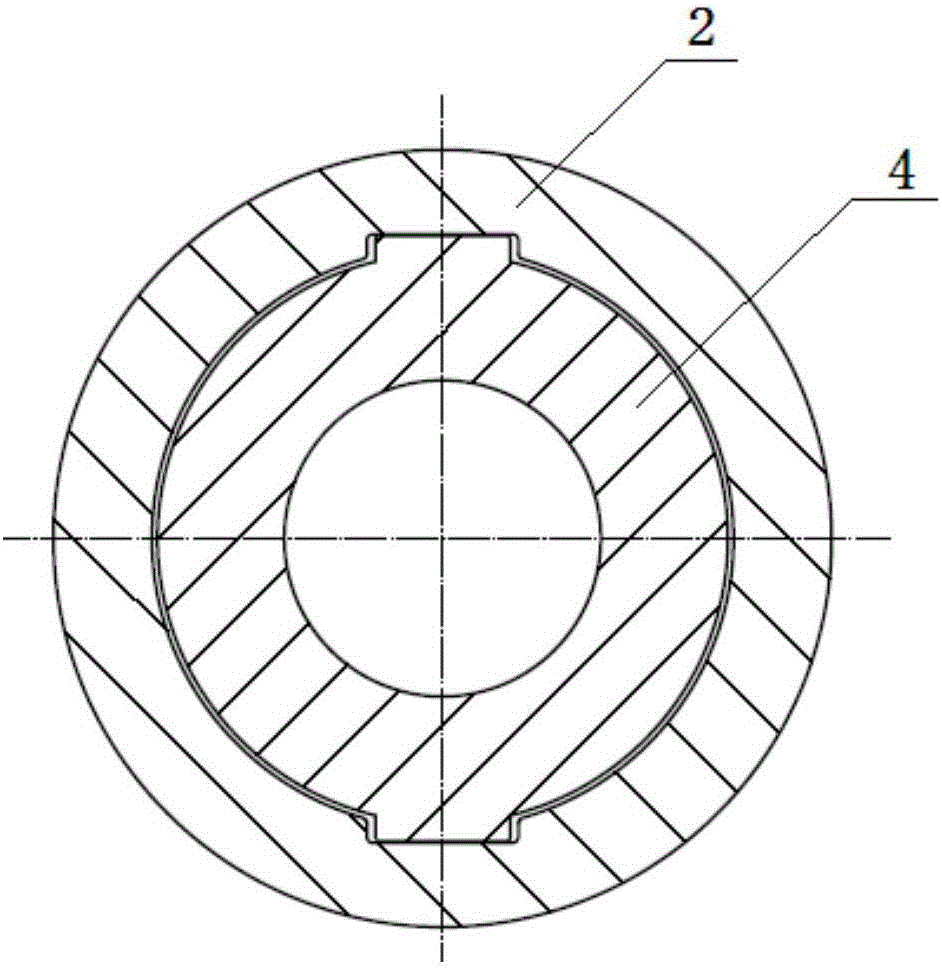

[0024] Such as Figure 1 ~ Figure 3 As shown, the present invention includes an outer cylinder string and a mandrel string located inside the outer cylinder string. The outer cylinder string includes an upper joint 1, a spline outer cylinder 2 and a sealing pup joint 3. Wherein, the upper and lower ends of the spline outer cylinder 2 are provided with internal threads. The lower end of the upper joint 1 is matedly connected with the upper end of the spline outer cylinder 2 through external threads. The upper end of the sealing pup joint 3 is matedly connected with the lower end of the spline outer cylinder 2 through external threads. The mandrel string includes spline stub 4, torsion mandrel 5 and lower joint 6. Wherein, the upper and lower ends of the torsion mandrel 5 are provided with external threads. The lower end of the spline stub 4 is matedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com